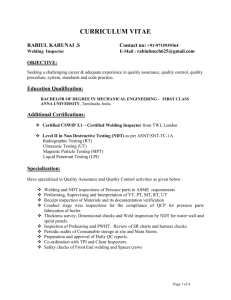

CV-KUSWANI-2

advertisement

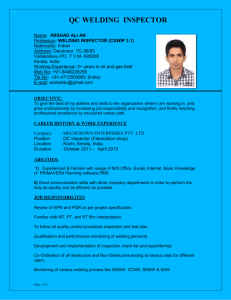

CURRICULUM VITAE , PROFILE: HIGHLY MOTIVATED PROJECT/CONTRUCTION QC MNGR, QA/QC ENGINEER & QA/QC INSPECTOR,WELDING SPECIALIST WITH 18 YEARS’ EXTENSIVE EXPERIENCE ON MULTI MILLION DOLLAR PROJECTS ( ON/OFFSHORE) IN THE OIL GAS, PETROCHEMICAL, MAINING, WHO HAS: PROJECT MANAGEMENT EXPERTISE (EPC,CLIENTREP, JOIN VENTURE PROJETS) CONTRUCTABILITY REVIEW CAPABILITIES(CRITICAL BEFORE BID SUBMISSION COST CONTROL AND EXECUTION OF THE WORKS) FABRICATION, INSTALLATION AND PIPELIN SKILLS AND MAINTENANCE ORGANISATIONAL SKILLS, ADMINISTRATIVE PROFICIENCY THE ABILITY TO COMMUNICATE EFFECTIVELY AT ALL LEVELS. A FLEXIBLE, YET POSITIVE APPROACH TO PROBLEM SOLVING. Name Place, Date of Birth Height/ Weight Sex Status Citizenship Passport : : : : : : : KUSWANI SAYUTI AHMAD Serang, March 14th, 1967 176 cm/ 87 Kg Male Married Indonesia A9578621(Valid Till 20 Jan 2020) Address Phone Mobile Email Languages/spoken Bachelor Degree : : : : : : Jl.Raya Taktakan No. 46 RT. 04/05 Lontar Baru – Serang Banten (0254) 213427 +62 818-797-421 kuswani_st@yahoo.com Indonesian and English University Technology of Sultan Ageng Tirtayasa Cilegon – Banten Department of Metallurgy Engineer Degree (S1) Certificate Computer Skill : Ms Office 2007, Word, Excel, Internet task PROFESSIONAL COURSE AND QUALIFICATION CERTIFIED Welding Inspection CSWIP 3.1 as Welding Inspector Lev 2 (Passed Certificate Number is 58810 expire date 10 July 2016 ) Conducted by The Welding Institute TWI UK Indonesia Welding Inspector Oil & Gas B4T Comply To American Standards ( 480 hours total training for 3 months ) (Passed Certificate Number is 0699.41.0776 ) Conducted by Ministry of Industries and Trade, Institute For Research and Development of Materials and Technical Product Industries Indonesia. API 510 Pressure Vessel Inspector Covering The Relevant Of(API 510, API RP 571, 572, 576, 577, ASME SEC VIII, ASME SEC IX, ASME SEC V NDE) Completed Certificate Number is 1178/C/TR-API510/01-JAKARTA-03/2014) Conducted by Oil Institute Jakarta Indonesia and American Petroleum Institute. Management Quality Control and Materials B4T ( 240 hours total training for 1 month ) (Passed Certificate Number is 1098025 ) Conducted by Ministry of Industries and Trade, Institute for Research and Development of Materials and Technical Product Industries Indonesia. Quality Management Systems Auditor/Lead Auditor ISO 9001:2008 (Certificate : NCI – P 1703) IRCA Certified Conducted by Neville Clarke International International Welding Specialist ( 360 hours training 6G Position SMAW, GTAW & OAW Materials CS, SS, DUPLEX, CUNI, BRAZING for 2 month ) Passed 09-09-1994 Certificate No T-1699 Conducted by PT. Gema Sem Brown Anyer Indonesia European Welding Specialist EN 3834 Welding, Jointing and Cutting Passed 2005/06/02 (Certificate No is D-SLV-70736-1171-050602-0600122EWF) Conduct by DVS-PersZert EWF Authorised National Body Germany 1 of 9 Pipe Line Inspector DNV Offshore Standard OS-F101, Submarine Pipeline Systems, 2000 (Passed Certificate Number is (159/1PP/DNV-MIGAS/2007 ) Conducted by DNV& Directorate General of Oil and Gas Energy and Mineral Resources Department of Republic Indonesia. NDT Inspection ASNT Radiographic Film Evaluation & Interpretation Level 2 (2 times renewal) (Passed Certificate Number is SNS/RI/120927 Expire date May 11,2017 ) Conducted by ASNT NDT Corporate Partner Level 3 (ID 145394) ASNT Ultra Sonic Test Plate & Pipe Level 2 (2 times renewal) (Passed Certificate Number is SNS/UT/120926 Expire date: May 04,2017 ) Conducted by ASNT NDT Corporate Partner Level 3 (ID 145394) ASNT Magnetic Particle MT Test 2 (times renewal) (Passed Certificate Number SNS/MT/120942 Expire date May 19,2017 ) Conducted by ASNT NDT Corporate Partner Lev 3 ( ID 145394) ASNT Dye Penetrant PT Test Level 2 (times renewal) (Passed Certificate Number SNS/PT/120956 Expire date May 27,2017) Conducted by ASNT NDT Corporate Partner Lev 3 (ID 145394) Industries and Trade,Institute For Research & Development Of Materials Tech Product Ind ASNT PHASED ARRAY Ultrasonic’s & Data Viewing Level 2 (Passed Certificate ) Conducted by UT Quality ASNT Level 3 ONGC Project PTG Cilegon Indonesia Coating & Painting Inspection Coating Inspector NACE Level 2 (Passed Certificate Number 50/AD/04/2009 ) Conducted by NACE Level 3 -174 Bethesda Multi Mandiri Cilegon Indonesia Corrosion Inspector (Passed Certificate Number 0701.31.043 )Conducted by Ministry of Industries and Trade, Institute for Research and Development of Materials and Technical Product Industries Indonesia Health, Safety and Environment SEA SURVIVAL Guidelines IMO/STC.OPITO and OGP (Passed Certificate Number SS. 19576/IKS/11. British Safety Council member ship Nu S0387962 ) Conducted by Industrialindo Konsultrain Services Jakarta Indonesia. H2S SAFETY AWARENESS LEV 2 TRAINING (Passed Certificate Number 0314H2S-132) Conducted by Exxon Mobil Cepu & PT.Pandu Utama Jakarta Indonesia. First Aid Training Lev 2 Conducted by Exxon Mobil & PT. Pandu Utama Jakarta Indonesia Expertise QA/QC Welding Inspector Supervisor QA/QC Engineer/Coord/Mngr NDT Inspector-UT,MT,PT. Welding Superintendent/Supervisor : : : : Welding Instructor&Welding specialist : (6G & 6GR) Long of Duration 7 Years 4 Years 2 Years 3 Years 4 Years Course & Seminar Attended : 2 of 9 01 ~28 May 2012 : Renewal NDT ASNT Level 2 RI,UT,MT,PT.Conducted By ASNT NDT Corporate Partner Lev 3 (ID 145394) Jakarta Tangerang Indonesia 15 December 2011 : 11~18 January 2005 : 07~ 13 August 2010 : 16 ~ 22 November 2009 : 16 March to 24 June 1999 : 01 to 13 April 2009 : 23 to May 2000 : 29 Sep to 10 Oct 1998 : January 16 – 30 – 2007 : February 06 – 08 – 2007 : Sea Survival Course BRITISH SAFETY COUNCIL Membership No.0387952 certificate No .SS.19576/IKS/II Basic Safety Training (BST) Course For Offshore Conduct By STIP JAKARTA Certificate No. 6200406747010105 Phased Array Ultrasonic’s and data Viwing Level II Conducted From UT Quality Inc & PT. Gunanusa Utama Fabricator at Grenyang Cilegon Indonesia International Welding Inspector CSWIP Lev II ( 3, 1 ) Conducted From TWI The Welding Institute .South East Asia Office In Duta Merlin Jakarta Indonesia.( certificate ) Welding Inspector Course for Industrial Application Conducted From Ministry of Industry and Trade ( B4T. Bandung & Oil Gas ) ( certificate ) Coating Inspector Nace Level.I and Level.II By Bethesda Multi Mandiri ( certificate ) Weld Tech Indonesia 2000 Seminar Attended For Industrial Application Conducted By lws, Ministry of Industry and Trade ,Itenas, Depnaker.( certificate ) Quality Control Management & Material Course for Industrial Application Conducted ( certificate ) From Ministry of Industry and Trade, (B4T. Bandung). The Re – Certification Radiographic Film Interpretation and Evaluation Lev. II in Accordance to ASNT – TC – 1A 1996 Edition Conducted From Ministry of Industry and Trade B4T Bandung The Re – Certification for NDT. Ultra Sonic Testing Lev II Weld Plate 7 Pipe in Accordance to SNT – TC. 1A – 2001 Edition conducted From Ministry of Industry and Trade B4T Bandung Seminar UNDER WATER WELDING at Hotel Horison Bandung Human Sources, Welder’s Qualification – Welding process, DVS.148 – DVS.1149 DIN EN ISO 15618-1 for Construction Activity OffShore Conducted by B4T Bandung. The Re-Certification for NDT.Ultra Sonic Testing Lev II Weld Plate & Pipe in Accordance to SNT – TC. 1A – 2001 Edition Conducted From Ministry of Industry and Trade B4T Bandung The RE – Certification for NDT- Magnetic Particle & Liquid Penetrant test Level II in Accordance to Asnt-TC I A 1996 Edition Conducted From Ministry of Industry and TradeB4T Bandung Radio Graphic Film Evaluation and Interpretation Level II In Accordance to ASNT – TC – 1A 1996 Edition Conducted From Ministry of Industry and Trade B4T Bandung Pipeline Surveyors inspectors Course for Offshore Conducted by Detnorks ke Veritas (DNV) Norway and Migas at Bogor, Indonesia Instructor NDT Level II & Ultrasonic Test Asnt Level II Plate & Pipe for Industrial Application Conducted By DITJEN ILMEA & B4T Bandung 1. Welding & Casting Process, Welding & Casting Defect 2. Personal Qualification & Certification, Training for Trainer System 3. General Ultrasonic Testing System, Specific Ultrasonic Testing System, Practical Ultrasonic Testing System December 08 – 12 – 2005 : March 07 – 10 – 2005 : March 02 – 04 – 2004 : April 29 – 13 May 2003 : February 17 – 21 – 2003 : 20 Augustus to 19 Sept : 2001 3 of 9 4. Practical Training for Trainer system Corrosion Inspector Course for Industrial Application Conducted BY Ministry of industry and trade B4T Bandung 1. Material Science and Metallurgy 2. Basic Corrosion & from of Corrosion system 3. Corrosion Control & Prevention System a. Chemical Treatment System, Mat’l Selection System b. Cathode Protection System, Protective Coating System 4. Corrosion Monitoring Inspection & testing System, Practical Function supervise Employer Course for Industrial 1. Guide 2. Function Supervisor 3. Action Supervisor 4. Supervision 10 to July 2001 : 03 May to 21 July 1997 : 16 Oct to 28 Oct 1995 : Quality Control Supervisor ISO 9000 & 9001 Course for Industrial Application Conducted From Ministry of Industry and Trade (B4T Bandung) SPECIALIZATION : Supervision and Inspection - Pressure Vessels – Pressure Piping Process - Pipe mill – Pipe Lines – Boiler-Spherical Tank - Storage Thanks – Steel Structural Plat Form-Jackets-Top Sides - Conveyor – Jetty – Pontoon - Welding – Metallurgy-Nde- Painting - Welder Performance Qualification test-Pqr THE METHODS CONSISTOF - MT – PT Inspection Test - Radiographic Inspection - Ultra Sonic Test of Structural Weld of Plate Pipes - Surface and Sub-Surface Inspection. Familiar With The Welding Process Qualification and Certification From Dept of Oil & Gas - SMAW All Position ( 6 GR ) - GTAW All Position - GMAW & FCAW 1G, 2G, 3G, 4G, 5G only - SAW 1 G only - PAW 1 G only - OAW 1 G, 2G, 3G only Hold on Certificates Of ASME IX From Department of Oil & Gas Welding Training Result Tested GTAW SS 6G-316L-304-308L from Gunanusa Utama GTAW (Project Total Indonesia Tunu Phase II) GTAW/SMAW CS 6G SMAW/ AWS 6G From Menaker SMAW/ AWS 6G CS,SS,DS,SDS,INCOLOY GTAW 6G C7 1500 ER CUNI FM 67 GTAW & 6GR From MIGAS MANUAL BRAZING 67 from Gema Sembrown(Project Conoco Blida II) Experience using Electrode product : 4 of 9 Electrodes Essab OK 70.18, Lincoln/Zetweld LH 90.70 18/70.10 A1/60.10, KOBESTEEL E6010-7010, EASS316L/Soft Weld (Cost lron), E Aluminium XHD2 1002 1003, LB.52.18 & PVC Pipe Welding, B17, TGS. 50 & TGS 308 NC 3804-3161, KOBE STEEL & LB 52U MIG ALUMUNIUM, ER 2209 & 25.104L (Duplex SS) Familiar With The Codes & Standard : AWS, D1.1,D1.2 – AWS A5,3 A5,3M API 650-API510,576,572,577-ASMEVIII,V, IX-ANSI, B31, 3, API1104 – DNV – BS, ANSI/AWWA C207-94, AUSTRALIAN STD. 1554, 1-AUST STD. 885, DNV. DETNORSKE VERITAS 1864.ISO9000&9001 ETC. PROFESIONAL WORK EXPERIENCES : I Have the Experiences of QA/QC Manager, Engineer, Coordinator ,QA/QC Supervisor, Welding Inspector and Welding Superintendent/ Welding Instructor, Welder Specialist Since 20 May 2015 to 25 Oct 2015 with McConnell Dowell Indonesia as QA/QC Superintendent Duties and Responsible for all direction, definition and Coordination in order to ensure that Quality Control Activities are completed in accordance with the Project Specifications, Budget and schedule. Ensure that Construction execution Procedures and Inspection Test Plans are developed Based on Client / Owner Specifications, Codes and Standards. Ensure all activities are performed and controlled in compliance with the requirements of the relevant Construction Execution Procedure and Inspection and Test Plan. Ensure that all Personnel are trained roles and Responsibilities and are component to perform the duties allocated to them. Prepared and Review WPS / PQR and Welder, Welding Operator Qualification Procedure. Prepare and Review Inspection Test Plan, Prepare and Review Procedure Specification, Prepare Weekly Report to PM Ho. Since 16 December 2013 to 15 May 2015 with ExxonMobil / Mobil Cepu Ltd (Contract by Wide & Pin Company) epc1 Project Oil & LNG Production Processing Facilities Plant as PMC QA/QC Inspector Monitor and Ensure Fabrication and Installation activities For Piping and Welding Proces CS,SS,DSS,SDSS,INCOLOY. Witness NDT / Review NDT Report as required • Co-ordinate with other disciplines for interface activities, for Piping and structural • Monitor the structural welding activities inclusive of fit up / dimensional control inspections • Monitor the contractor uses only qualified welders and follows the approved welding procedures • Final inspection, generate punch lists and follow up of the same for close out • Verify Contractor, Subcontractor Quality management systems, plans, procedures, and processes are in place. Implement Cepu project Construction Surveillance Program. • Inspect / assist in monitoring structural/piping painting activities • Witness bolt torque tightening of structural components • Monitor quality, issue non-conformance reports when quality deficiencies are noted and set in motion the corrective actions jointly with contractor. Maintain the NCR data base for structural portion. • Prepare weekly or monthly quality reports to be submitted to Site Construction Assurance Coordinator. Since 24 June 2013 to 31 October with Leighton Offshore Asia Project Oil & Gas Pipeline 27 Km dia 12’’ MOL Pertamina from XA Platform To Plant Balongan Cirebon Indonesia as QA/QC Engineer Duties- Prepared ITP’s Offshore & Onshore Pipeline Installation , ITP WPQT & WQT , WPS & PQR , General Welding Specification,NDT Procedure, Monitoring and supervise fabrication/manufacturing activities (Flexible & Riser Pipe), monitoring contractor performance, 5 of 9 assuring the application of all the relevant HSEQ and QA procedures, and providing technical support as required. • Timeliness and accuracy of fabrication/manufacturing control information including: cost control information, executed works compliance to project technical specifications, work progress certification • Monitoring fabrication/manufacturing activities controlling that their execution is in line with project plans and highlighting any possible deviations suggesting possible solutions • Verifying manufacturing works compliance with project specifications, company procedures • Preparation of daily fabrication/manufacturing reports and submit to Company Office • Contractors daily progress report review and acceptance • Managing supervision team verifying that all the fabrication and manufacturing activities are performed according to specifications • Coordinate with Construction & Installation Engineer (Flexible) and Pipeline engineering • Managing and coordinate Company Inspectors Since 02 June 2012 to 08 May 2013 with Abu Dhabi Gas Industries Ltd GASCO Project Habshan Sulphur Granulation Plant (HSGP) Abu Dhabi UAE Contract by Intertek- Moody International UAE as PMC Representative 3rd Party QA/QC Engineer and Sr.QA/QC Welding Inspector Duties - Undertake familiarization with project & discipline specific inspection documents Project specifications, ITP’s, method statement, manuals, and procedure to ensure contract requirements are met. -Attend & witness RFI’s, surveillance inspection at plant piping and to control welding & post weld activities including witness of WQT & PQR, Dimensional Control -Visited Inspection to Vendor Ferro fab & FAM Danem in FZE Jebel Ali Dubai for ensuring and Reviewed of documents -Review radio graphic films, PWHT reports PMI reports & Hardness test reports -Prepare issue Observation or NCR and follow up the deficiency reports for material & activities that do not meet the specific project requirements -Witnesses key hold points during construction on an as-required basis -Participate Tri-Party walk down to identified multi-discipline punch item -Inspection of various system as per P&ID for discipline completion & Mechanical completion before plane RFSU -Actively participate in SAFETY & QUALITY audit of EPC contractor to strictly enforce Company policies rule & regulations Since Dec 2011 Until 25 MaY 2012 With TOTAL E&P OIL & GAS South Mahakam Offshore Contract by PT.MAFHINDO UTAMA Behalf of Representative Department Oil and gas Indonesia as 3rd Party (Certifying Authority Representative) Project Pipeline Dia 24’’X 80 Km Offshore South Mahakam East Kalimantan Main stupa, East Mandu, West Stupa Duties All Review Documents and Monitoring Of Pipeline Project, Jackets and Top Sides Since March 2011 Until Nov 2011 with PT.FASTTRACK INDONESIA PMC Project Managment Consultant and Engineering For LNG Storage Project and Gas Compressor Plant Duties: As QA/QC Manager –Ensure the Quality of the site fabrication ,Installation and Traceability is consistent with FTI Oil and Gas policy requirements and are in accordance with the applicable codes, standards, FTI and Client Specifications. –Review fabrication contractor and subcontractors’ procedures, ITP’s, quality documents and ensure compliance with the requirements of relevant specifications and project procedures. –Ensure effective co-ordination between fabrication contractor and Jakarta MCS team to ensure consistent delivery of Quality requirements. –Prepare Quality documentation as required in liaison with the MCS team based in Office Jakarta. –Initiate periodic review of Quality documents to reflect currency and implement changes where required. –Monitor Quality related activities as required by ITP and project procedures, Manage 3 rd party Inspection and certification. –Implement, monitor and supervise quality control , welding and NDE functions to ensure smooth operation of the project. –Overall management of field QA/QC Personnel inclusive of fabrication contractor personnel.-Plan and implement Quality audit schedules and be the Lead Auditor for all subcontractor Audits.-Manage the project non-conforming product and site query system in 6 of 9 liaison oversee and review material submittals and method statements submitted by the fabrication contractor to ensure the quality requirements set in the project is met. –Develop effective reporting and measurement of project quality performance including implementation of root cause analysis and corrective action as required to correct quality deficiencies. –Perform QA Implementation and contract review prior to commencement of project scope of work.-Expedite the resolution of site technical Queries with engineering team to reduce Site delays and improve understanding between the site and engineering teams. –Action as Deputy Site Construction Manager when Site Construction Manager is Offsite. Since December 18-2009 Up to 20 dec 2010 With Oil Natural Gas Coorporation India ONGC Contract by Afcons-Gunanusa Joint venture Company Project Offshore Platform. (ONGC) ICPR PROJET as Senior QA/QC Structural Inspector Representative Duties: Monitoring, inspecting, reporting, review NDE, check fit up, visual, Check Dimensional before and after welding for fabrication process platform, Bridge, Jackets and Topside Modules Since March 16 2009 up to 18 dec 2009 With Bureau Veritas Indonesia as Representative III Party Inspection(TPI) Duties :iReviewed documents and endorsement. Mill certificate and welding consumable certificate, WPS /PQR, mechanical test report, radiography test report, ultrasonic test report and MTPT report, Witnessed welding procedure qualification test, witness and monitoring welder performance qualification test. For ONGC ICPR Project Platform, Jackets and Topsides Modules Since December 03th 2007 Up To February 28 / 2009 with HESS Oil and Gas Indonesia Contract By Indospec Asia as PMC Representative Sr. QA/QC welding Inspector. Project Onshore and OffshoreTreating Facilities LNG Storage, Condensate Tanks & LPG Recovery Plant ,Platform, Jackets, Topsides Modules Pangkah Liquid Development Project East Java . Duties:Monitoring,Inspecting and Reporting For Piping & Pipeline Process ,Reviewed WPS,Consumable,Monitoring PQR & WQT Welders Qualification Test Reviewed Film Radio Graphyc For Piping Duplex ss Pipeline, sphere tank, crud oil tank, Inspecting and Reporting To QA/QC Coordinator Since August 08th 2005 to November 30th 2007 with PT. PENSPEN JO PETROTECH INDONESIA UTAMA PMC (PMC team for Perusahaan Gas Negara). Position as : QA / QC Engineer Representative Project Offshore & Onshore LNG Plant and Pipe Line Transmission & Distribution Sumatra Island to West Java Island for Liquid Natural Gas (LNG). Diameter 36’’ x 196 km & 32’’ x 450 km. Duties :To provide , as part of the PMC Team ,QA/QC input into the review ,verification and approval of procedures and technical deliverables associated with FEED engineering and EPC engineering procurement construction and commissioning undertaken by others. To report on QA/QC aspects of the PMC and contractor services to the PMC team Leader and to the client of Project Management team (PMT) personnel. To act as part of the integrated PMC/PMT. To assist in the preparation of QA/QC sections of monthly reports. Undertake QA/QC audits at office, yard and site Palembang to Maringgai as required and at FEED and EPC contractor design offices Jakarta if applicable. Monitoring and Reporting to Project Manager and QA/QC Manager at Project office, Overall responsible For QA/QC related matters and inspection in Line with Procedure, Provide technical specification for coated pipes supply bid document for Grissik to Pagar dewa to L Maringgai line pipes size 36’’ x 196 km API 5 L x 65. PSL – 2 Technical specification for coated pipes supply bid document for Pagardewa to Labuhan Maringgai line pipe size 32’’ x 272 km API 5L x 65. PSL – 2 Technical specification for coated pipes supply bid document for Muara Bekasi to Rawa Maju line pipes size 32’’ x 34 km API 5L x 65. Prepared technical evaluation work sheet to be use for selecting pipes manufacturer. Line pipe manufacturer bid proposal technical review. Check & review MPS , WPS from pipe manufacturer such as pipe forming, welding, ultrasonic, etc - 7 of 9 Since February 15th 2005 to May 22 2005 with PT. WISMAR ISPECSINDO AT PT. SEAPI PIPE MILL Bakhauni Lampung South Sumatra. Position as : NDT – Ultrasonic Inspector Duties : Ultrasonic Test of Plate and Pipes SAW each 12 m length, Project Transmission Gas & Compression Musi Barat to Pagardewa for Pertamina Dia 28’’ + 50 km. Since 15 December 2003 up to February 10th, 2005 With PT. MEINDO ELANG INDAH IN BCD 3 PROJECT LNG Plant and Pipe line Duplex ss 16’’x 80 Km PETRO CHINA JABUNG LTD (JAMBI). Position as : QA/ QC Coordinator Duties : Qualifying Welding Procedure Specification and Procedure Qualifying Records For projects through third party certification and Client Specification the Welders by Such Training, Prepared the WPS & PQR for Line pipes Duplex, Performance the Welders Test GTAW Process, Check fit up & Visual Welding of Joint 100%, Reporting & Reviewed Film 100% Each Welding Joints, Project Assignment Pipeline for Oil & Gas from Wellpad to Gatring Line Station. The Size of Dia 12” and Dia 16” and Dia 8” + 70 KM. ( Super Duplex Pipes ) Since July 7th, 2003 up to December 5th, 2003 with PT. GUNA NUSA UTAMA FABRICATOR in Grenyang Cilegon – Banten. Position as QA/QC Engineer Duties : Repot to project manager and QA/QC Manager, Prepared, PQR for Piping Duplex, cuni & carbon steel, Monitoring Performance Welder Test, Monitoring Inspecting & Reporting Process Piping Duplex Stainles Steel, Educate The Welders By Such Training for Pipe Duplex Process GTAW & SMAW – 6G. Project Assignment : Oil & Gas Platform, Jackets, Topsides Module for Total Peciko 4 East Kalimantan Since December 2th, Dec 2002 up to June 30th, 2003 for PT. TRI PATRA GULF CONSORTIUM (PMC Consultant for Perusahaan Gas Negara). Position as. QA/QC Engineer Representative Duties : Report to Project manager and QA/QC Manager at project office for pipeline (onshore & offshore) monitoring and reporting PT. Hyundai Heavy Industries, PT. GE Ocean. Offshore Project Assignment : For Natural Gas Pipe line PGN Perusahaan Gas Negara from Grissik South Sumatra Indonesia to Singapore (offshore) + 480 km dia 28” Responsibility : Monitoring and Inspecting line pipe activities check fit up, check visual after weld out & review film. Witnessed joint coating + Holiday test and foam/asphalt. Since April 20th, Until December 8th, 2002 for PT. HYUNDAI ENG CONT. CO. LTD. Position as QA/QC Engineer/Coordinator Duties : Ensuring Reviewed WPS &PQR ,Welder Qualification Test (WQT) are Carried out in accordance with The requirements Specification and procedure , Ensuring all Fabrication and installation work is carried out in accordance with drawing and procedure. Monitoring and reporting Project assignment: oil and LNG Plan, pipe line Gulf south Sumatra 80 KM Responsibility: monitoring & inspecting line pipes activities For dia 26” & dia 8” high-Pressure Gas pipe line installation from Grissik gathering station to suban gathering station, Checked gradingStringing-Welding -NDT Status - Hydrotest -Piging test and reviewed film. Welder performance Qualification test. Since October 10th, 2001 up to April 18th, 2002 for PT. SUCOFINDO SUPERINTENDING COMPANY OF INDONESIA IN PT. SEAPI Bakau heni Lampung South Sumatra. Position as NDT-Ultra Sonic Inspector Duties : Ultra Sonic test of plate and pipe SAW each 12 m length Project Assignment : For gulf company Oil and Gas pipe dia 26” X 80 KM Grissik to Suban. Since January 1998 August 11th, 2001 for PT. BILFINGER + BERGER INDONESIA. Beginning position as WELDING SUPERINTENDENT & WELDING INSTRUCTOR at PROJECT NEW MONT NUSA TENGGARA 8 of 9 Duties : Educate the Welder by such Training and Monitoring Fabrication, Portable Conveyor for Coal Transfer, Water Intake-Flotation Cell-Apron Feeder, Pipe Line dia 42 “12 KM From Concentrator to Tluk Senunu, ULMS (Pipe Spool) Sejorong to Concentrator (Main Pump Station) Final position as Welding Inspector Duties : Supervision For Contractor, PT. SPINDO PIPE and PT. PANCA Jasa Fab, Inspection Rubber Lining And Coating Inside and out side The Pipe Line, Prepare Scheduler and Plan Workshop Fabrication, Prepare WPS/PQR/WQR to Client, Prepare QA/QC Report, Visual Inspection fit – Up Straight Ness & Dimension check, Visual inspection after Weld out. Add Responsibility for Welding School : Educate the Welder by such Training, Ensuring the works carried through is suitable with QA & QC specification, Liaise with NDE (Nondestructive Examination) party. Since April 1996 To Dec. 1997, working for PT. BAULDERSTONE HORNOBROOK ENGINEERING J.O BILFINGER + BERGER INDONESIA Beginning position as WELDING SUPERINTENDENT & WELDING INSTRUCTOR Project Assignment : Coal Bulk Terminal On Shore To Offshore Sub Sea Structure Installation Pulau Laut Coal terminal South Kalimantan Final position as WELDING ENGINEERING Duties : Supervision for Contractor, PT. BUMI KAYA STEEL – PT. JSI – PT. ODG. & PT. SIEMENS, Prepare the Welding Procedure (WPS) and (PQR) to client, Monitoring welder test, Prepare QA/QC report, Visual Inspection fit – up straight & dimension check, Visual inspection after weld out, Witnessed Ultrasonic test by Sucofindo. Since Aug 1987 Up to Aug 1994 With PT.GEMA SEMBROWN/SUDNA STRAIT FABRICATION, PT.GUNA NUSA UTAMA FABRICATION CILEGON,DAELIM Various Company Project Conoco Belida 2 (Top Side Platform &Jacket),Total E&P Pciko Phase 2 (Platform Top Side Module &Jacket),Unocal 76 Serang (Top Side &Jacket), Maxus ses (Jacket), Codeco Slat Madura (Top Side &Jacket),Tripolyta(Chemical Plant, Piping), Uic (Plant Piping), Friport (Conveyor, Piping, Steel Structural, Crusser), Crmi(Piping &Structural) For Oil & Gas, Chemical Plant and Mining as Welder 6G/6GR Process SMAW, GTAW, GMAW, FCAW, SAW,OAW and Various Material CS, SS, DSS,SDSS, CUNI, INCOLOY, AL, TITANIUM. Member Ship: Indonesian Welding Society (IWS9902) Declaration All the above information what I have supplied in my data sheets are true for every respect I herewith certify that all matters as stated above are true and correct. Your Faithfully, (KUSWANI, ST) 9 of 9