Report - Hobart

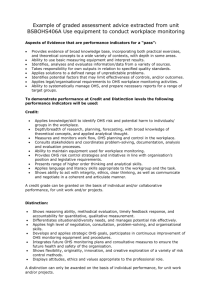

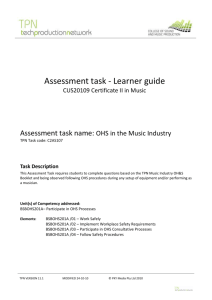

advertisement