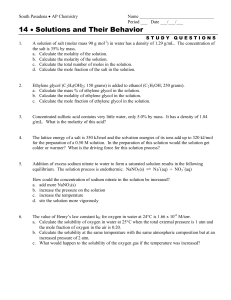

Production of Materials Notes (Student Produced)

advertisement

9.2 Production of Materials – Yr 12 2008 Written by Sam Jiang 1. Fossil fuels provide both energy and raw materials such as ethylene, for the production of other substances Identify the industrial source of ethylene from the cracking of some of the fractions from the refining of petroleum. Ethene (IUPAC or systematic name), Ethylene is a material that present in trace amounts in nature and it is produced by cracking petroleum, those are various fractions produced by fractional distillation of crude oil, called petrochemical feedstock. Process used to produce ethylene and other small china hydrocarbons is called cracking. It takes the raw material crude oil (very long chains of hydrocarbon) and splits it up into smaller parts. Whenever an alkane is cracked, an alkene always results as one of the by products. There are three types of cracking: Steam cracking 750-900 degrees Celsius (A) Initiation Hydrocarbon chins split at high temperature into fragments, they become free radicals and are reactive as they have unpaired electrons. (Decane to Pentyl free radicals) (B) Propagation Free radicals decompose to produce smaller free radicals and release alkenes. (Pentyl free radical to propyl radical + ethylene) (C) Termination Free radicals may react with other free radicals to form hydrocarbon molecules. (propyl radical+ propyl radical to hexane) Thermal cracking Catalytic cracking 500 degrees Celsius and 200kPa pressure Used to boost yield of petrol to meet demand During catalytic cracking, octane and zeolite (inorganic compound, often aluminosilicate) are commonly used. Endothermic process, air is excluded to prevent explosion with oxygen. Catalytic cracking lowers activation energy to allow the process to be achieved at a lower temperature and reduces fuel consumption. Surface area is important in cracking, the molecules bond with the surface of the catalyst breaks the carbon-carbon bond. Identify that ethylene, because of the high reactivity of its double bond, is readily transformed into many useful products Many materials originate from ethylene such as Ethanediol (antifreeze), ethanol, dibromoethane (petrol additive), styrene to polystyrene, polyethylene, Vinyl chloride to PVC. Ethylene reacts with other molecules by addition process, Hydrogenation (addition of Hydrogen), Halogenation (addition of halogen gases, like chloride and bromine), Hydrohalogenation (addition of HX molecules like HCl, HBr) Identify that ethylene serves as a monomer from which polymers are made Monomer is compound with small molecules able to join together to form long chain polymer molecule Polymer is long chian molecules formed by joining monomer structures. Sometimes called macromolecules. Polymer chains often contain thousands of monomers. E.g. polyethylene generally has 10000-20000 ethylene molecules joined together. Ethylene is a monomer from which polymers such as Polyethylene, Poly vinyl Chloride and Polystyrene are formed. Identify polyethylene as an addition polymer and explain the meaning of this term Addition Polymerisation is where same double bonded monomers combine to form polymer without loss of any atoms. Outline the steps in the production of polyethylene as an example of a commercially and industrially important polymer The production of polyethylene is a three step chain reaction. 1. Initiation An unstable substance, usually organic peroxide is used to initiate the reaction. This is because ethylene does not react with itself unless under pressure. The initiator will bond with ethylene, breaking the double bond and the free electron migrates to the other end, allowing that ethylene to become a free radical and react with other ethylene molecules to form a long chain. 2. Propagation Growing of the chains. The chain of ethylene grows until this free radical ethylene chain combines with another free radical ethylene chain to form a complete polyethylene molecule. 3. Termination The combination of free radicals is called termination High pressure produce branched polyethylene, low pressure produce unbranched polyethylene Identify the following as commercially significant monomers: – Vinyl chloride (chloroethene) – Styrene (ethenylbenzene) Describe the uses of the polymers made from the above monomers in terms of their properties Polymer Properties/Structure Low Density Highly branched, the side branches disrupt Polyethylene packing of polymer chains, therefore fewer (LDPE) crystalline regions. Low Melting Point 80 degrees. Soft, flexible (weak dispersion forces), Transparent (less scattering and refraction of light) and waxy surface, scratches easily. Chemically inert, water proofing, electrical insulation and good impact strength. High Density Polyethylene (HDPE) Minimal side branching, linear polymer backbone, chains closely packed together, hence strong dispersion force, high crystallinity therefore scatter refract light. High density. Melting Point 135 degrees Hard, rigid, tough, very stiff. Can take high pressures, slows corrosion Waxy surface and translucent/white. High tensile Stength Poly Vinyl Rigid, hard, brittle, electrical insulator, resists Chloride effects of weathering (PVC) Adding a plasticiser, soften PVC (decrease dispersion force) Adding a heat stabiliser (lead compound), improves its resistance to head decomposition Adding a Flame retardant (auntimony(iii) oxide) lowers its flammability (gives off toxic corrosive HCl) Adding a UV absorber (titanium oxide), prevents UV decomposition of the plastic when exposed to sunlight. Polystyrene Versatile thermoplastic (no crosslinks or (PS) bonding between chain, can be remoulded or recycled) Crystal polystyrene Clear amorphous polymers, very stiff, brittle, good insulator, sparking clarity transparent, can be moulded easily, low softening Uses Shopping and garbage (plastic) bags. Food Containers, packaging for frozen food Milk and fruit juice packs Squeeze bottles Electrical insulation Cling wrap Lining of cardboard milk bottles Bags Gas pipes, agric pipes Kitchen containers and utensils (bowls, freezer bag) Milk crates Plastic furniture (bucket, wheelie bins) Car parts Building material House walls, window components, Electrical conduit, credit card. Flexible tubing, guttering, upholstery covering, surgeon gloves, shower curtains, raincoat, toys. Hot PVC water pipes PVC outdoor products Building panels (pigments incorporated for colouring) Food packaging, medical care products (disposable), drinking glasses, CD cases. Plastic for heat-pressed food packaging, washing machines, TV backing, hair dryers. temperature Portable coolers, vacuum Expanded polystyrene flasks, foam packing, surf White, has good heat, cold and sound boards, marker buoys, bike insulation, low density, resists high impact helmets. 2. Some scientists research the extraction of materials from biomass to reduce our dependence on fossil fuels Discuss the need for alternative sources of the compounds presently obtained from the petrochemical industry The raw materials for making polymers come from crude oil. There is concern the world will use up all its available oil reserves within the next few decades as the analysts predict. Currently there is a pressure to reduce energy use and develop alternative fuels, because 1) Green house effect and damage to ozone layer 2) As supplies of oil diminish, cost will increase. Petrochemical industry (mainly plastics) consumes 3 to 5% of the total oil used in the world today, and, hence is less affected by the price rise Different arguments are Because oil supplies are going to run out in the foreseeable future, we should be developing alternative sources of the raw materials for plastics. As oil supplies diminish, costs will increase and oil will become too expensive to use as a fuel. Alternative fuels will become cost effective. Petrochemical industry will be less affected by price rises (the cost of raw material is smaller proportion of cost of finished product) and thus can still afford to use oil. Hence remaining oil will be exclusive domain of petrochemical industry and last for many more decades. However it is still advisable to develop alternative sources of ethylene. Ethanol is the main candidate for an alternative source of ethylene. Ethanol can be produced by fermentation from a variety of agricultural crops, and cellulose is also a possible source of ethylene. Use available evidence to gather and present data from secondary sources and analyse progress in the recent development and use of a named biopolymer. This analysis should name the specific enzyme(s) used or organism used to synthesise the material and an evaluation of the use or potential use of the polymer produced related to its properties Biopol, PHB-PHV is a copolymer of consisting of two monomers, 3-hydroxybutyrate and 3-hydroxyvalerate. They can be produced from “Alcaligenes eutrophis” bacteria. Alcaligenes eutrophis bacteria are grown in a high glucose high valeric acid, low nitrogen environment. They are provided with a carbon based food source. They are fed appropriate nutrients so it multiplies rapidly and grows into a large quantity. The polymer is then isolated and purified. The diet is changed, and nutrient restriction means that the bacteria no longer increases production but instead begins to make desired polymer and stores it for later use as an energy source (30-80% dry weight). This excess energy is stored in their cell walls as granules of PHB-PHV Hot liquid chloroform (CHCl3) is used to dissolve the copolymer and it is evaporated off to leave biopol granules. The solid waster is removed by centrifuging, precipitating the PHB from solution and drying the powder. Properties Biocompatible and biodegradable Similar to polypropylene Insoluble in water Permeable to oxygen Resistant to UV light, acids and bases Soluble in chlorinated hydrocarbons High melting point, high tensile strength, more dense than water but non toxic Uses Disposable items such as razors, rubbish bags, nappies, fast food utensils and paper plate Disposable plastic items such as shapoo bottles and cosmetics Injection moulded into plastic items that is likely to be left in the environment such as fishing lines, gold tees, ag pipes Disposable hospital material and medical supplies However currently the biopolymer cost far more to produce than the crude oil based polymers, and the production rate is too small. Scientists are researching in different way to improve it. Genetical engineering allow bacteria like Escherichia coli or plants like potatoes to grow biopolymer just like Alcaligenes eutrophis, therefore has faster growth, better yields, easier recovery and production of less waste biomass. Alternatively to allow Alcaligenes eutrophis produce large quantity of biopolymer from inexpensive sources of carbon, hence lower the cost. Since Biopolymers have the advantage of being biodegradable thus allowing better waste management and they are being made from renewable sources, they hold great potential in the future as crude oil based polymers are using precious fossil fuels that are going to be used up soon. Explain what is meant by a condensation polymer They are polymers that form by the elimination of a small molecule (often water) when pairs of monomer molecules join together. Each monomer has two identical functional groups Reaction between the functional groups on each monomer Releases a small molecular weight molecule Generally slower than additional polymerisation. If two different monomers are present, such polymers are often called copolymers. Describe the reaction involved when a condensation polymer is formed Condensation polymers result in a by product that is commonly a small molecule. E.g. water or hydroxide. For example, cellulose is a naturally occurring condensation polymer. The monomer from which it forms is glucose. Polymerisation occurs by the elimination of water molecules from between pairs of glucose molecules. n (OH-C6H10O4-OH) H - (O-C6H10O4) n – OH + (n-1) H2O This is saying that n molecules of glucose combine to form one molecule of cellulose (containing n glucose units) by eliminating (n-1) molecules of water Describe the structure of cellulose and identify it as an example of a condensation polymer found as a major component of biomass Cellulose is a linear condensation polymer containing 1800-3000 beta glucose units per molecule. Cellulose is made from beta glucose, which is when the hydroxyl group of the first carbon atom is on the same side as the CH2OH group. It has 5 carbon atoms and an oxygen atom forming a puckered ring. There are OH groups on 5 of the C atoms. For bonding to occur alternate glucose units must be inverted This bonding produces a very linear molecule, caused by the geometry of the rings and the C-O-C bond angle. Bulky CH2OH groups are on alternate sides, creating a flat straight and rigid molecule The number of hydroxyl groups facilitates hydrogen bonding, causing molecules to bond side by side, resulting in the rigidity of the molecule Long, strong cellulose fibres (wood) make good building material Because hydroxyl groups are engaged in hydrogen bonding to adjacent molecules, there are reduced hydroxyl groups to bond with water, very large bonded molecules are thus insoluble in water More resistant to chemical attack. Biomass is organic matter, or material produced by living organisms. It is mainly plant material, though the term also includes animal excreta and material made by algae. Cellulose is the major component of biomass. Identify that cellulose contains the basic carbon-chain structures needed to build petrochemicals and discuss its potential as a raw material Each glucose unit of cellulose has five carbon atoms joined together in a chain, so it could be regarded as a basic structure for making starting molecules for petrochemicals molecules such as ethylene, propene and butene. Plants produce far more cellulose than starch or other biopolymers, and thus there would be great benefits if we could use cellulose as a source of materials we currently make from oil. Bacteria can digest cellulose into glucose, and further ferment glucose into ethanol. The ethanol can be dehydrated into ethylene, which is used to produce other polymers. Bacteria in ruminants and intestines of termites produce enzymes to break down cellulose into glucose monomers. The fact that there is no simple or efficient chemical way currently of breaking cellulose into glucose has been a stumbling block for using cellulose as a raw material for chemicals. Biomass fuels currently cost more to produce than fossil fuels. Energy is needed to plant tend and harvest crops Arable land must be used to grow dedicated energy crops, reducing the land available for food crops. Vast crops can alter local water table and demand for soil nutrients. Cellulose is used for cotton, especially for textiles, paper and cardboard 3. Other resources, such as ethanol, are readily available from renewable resources such as plants Describe the dehydration of ethanol to ethylene and identify the need for a catalyst in this process and the catalyst used Ethylene is made from ethanol by dehydration. This is a reaction that involves the removal of water. The ethanol is heated with concentrated sulphuric or phosphoric acid, which acts as a catalyst. It is needed in this reaction because ethanol itself will not decompose spontaneously into ethylene and water upon heating. C2H5OH (l) Concentrated Acid C2H4 (g) + H2O (l) Describe the addition of water to ethylene resulting in the production of ethanol and identify the need for a catalyst in this process and the catalyst used The reverse reaction, the addition of water to ethylene is called hydration. It too needs heat and a catalyst which is generally dilute aqueous sulphuric acid. A catalyst is necessary, because the water molecule is not reactive enough to attack the bonds of ethylene to form ethanol. C2H4 (g) + H2O (l) DiluteAcid C2H5OH (l) Process information from secondary sources to summarise the processes involved in the industrial production of ethanol from sugar cane Sugar cane contains molasses, which contains sucrose. Sucrose C12H22O11 is hydrolysed to form the isomers glucose C6H12O6 and fructose C6H12O6. Both glucose and fructose can be fermented to carbon dioxide and ethanol C12H22O11 (aq) +H2O (l) C6H12O6 (aq) + C6H12O6 (aq) Sucrose C6H12O6 (aq) Water Glucose Fructose ( zymase) Yeast 2C2H5OH (aq) + 2CO2 (g) Glucose/Fructose Ethanol Carbon dioxide Describe and account for the many uses of ethanol as a solvent for polar and non-polar substances Ethanol is widely used as solvent in industry and home for cosmetics (perfumers, deodorants, after shaves), food colouring and flavourings (cochineal, vanilla essence), medicinal preparations (antiseptics) and some cleaning agents. Ethanol is a good solvent because its alkyl group and hydroxyl group. In its hydroxyl group the C-O and O-H bonds makes the molecule polar because O is more electronegative than C or H and the function group form an angle. Like dissolve like, Ethanol is therefore a good solvent for polar substances (salts) as ethanol can form dipole dipole force with them. The hydroxyl group also form hydrogen bond with many other substances such as water, glucose and some proteins, therefore ethanol is completely miscible in water. The alkyl group is non polar and allows ethanol to act as a solvent for some non polar substances including some hydrocarbons, oils and resins. It forms dispersion forces with non polar substances. Process information from secondary sources to summarise the use of ethanol as an alternative car fuel, evaluating the success of current usage Air pollution concerns led to introduction of cleaner burning fuels and renewable fuels or fuel additive. Ethanol can be used as a petrol extender, while petrol containing 10-20% ethanol (anhydrous) can be used in ordinary petrol engines without any modification, higher percentage of ethanol (hydrous) require engine modification. Brazil is the largest producer of ethanol in the world, in 1975 Brazil implemented biofuels program and adopted ethanol as its major fuel for cars. It grew sugar cane specifically for conversion to ethanol. Political and economic pressures (expense) delayed implementation of biofuels program and it was cancelled after a while, however it is picked up again due to its success. The outlook is positive but program will proceed at slower rate. USA, Canada and Australia use ethanol as extender (10-20%) Outline the use of ethanol as a fuel and explain why it can be called a renewable resource Ethanol is often blended with petrol when used as a fuel. Ethanol burns cleaner than oil, and less carbon is deposited in the engine. Spark plugs thus last longer. Ethanol has been promoted as a fuel on the grounds that it is a renewable resource. It is made from carbon dioxide, water and sunlight (carbohydrates) and when it is burnt it returns to carbon dioxide and water, which can be reconverted to ethanol. Hence it is advocated also as a fuel that is neutral with respect to the greenhouse effect. The carbon dioxide liberated when it burns is that which was used in its synthesis. However fertilisation and distillation process require much energy. Obtained from molasses, the left over syrup from sugar milling. Describe conditions under which fermentation of sugars is promoted Fermentation is a process in which glucose or fructose is broken down into ethanol and carbon dioxide by the action of enzymes present in yeast. It requires Suitable grain or fruit which contain sugar mashed up with water Yeast is added, Air is excluded (if oxygen is present, yeast will reproduce instead of fermenting), Temperature around 37 and *Ethanol is continuously removed from it. Summarise the chemistry of the fermentation process Enzymes (biological catalysts) first convert any starch or sucrose in the mixture into glucose and or fructose, then other enzymes convert glucose or fructose into ethanol and carbon dioxide. Bubbles of carbon dioxide are slowly given off. Yeast can produce ethanol contents up to about 15%. Alcohol concentrations above this kill the yeast and stop further fermentation. Higher alcohol contents require distillation of the liquid. Define the molar heat of combustion of a compound and calculate the value for ethanol from first-hand data The molar heat of combustion of a substance is the heat liberated when one mole of the substance undergoes complete combustion with oxygen at a constant pressure of exact one atmosphere with the final products being carbon dioxide gas and liquid water. The enthalpy change is always energy absorbed. Since combustion is exothermic, it always has a H sign that is negative. Molar heat of combustion for ethanol C2H5OH (l) + 3O2 (g) 2CO2 (g) + 3H2O (l) H =-1367 kJ/mol Octane, petrol component C8H18 (l) + 25 O2 (g) 8CO2 (g) + 9H2O (l) H =-5464 kJ/mol 2 Assess the potential of ethanol as an alternative fuel and discuss the advantages and disadvantages of its use Ethanol is a fuel that readily burns C2H5OH (l) + 3O2 (g) 2CO2 (g) + 3H2O (l) Advantage Disadvantage Renewable resource, avoid further use of Large areas of land required for production non renewable fossil fuel which is running of raw materials. Less land for growth of low at supply crops. Also cause soil erosion, deforestation, fertiliser run off and salinity Reduce greenhouse gas emission Contain oxygen therefore help to combust Disposal of smelly waste fermentation more completely, reduce toxic emission such liquors after removal of ethanol would as carbon monoxide and carbon to the present major environmental problems. environment Excellent solvent, deposits that have built up Does not release as much energy as petrol on over time will be dissolved in ethanol, fuel complete combustion. filters last longer, providing a cleaner system Higher flash point, combust mixtures of Ethanol sources currently are less efficient ethanol vapour are not as readily formed in than petrochemical fuels, cost more to cold climates produce As fossil fuels are running out very soon, the cost of petrochemical fuels rises, and as technology improve, scientists are researching for better, cheaper method of producing ethanol, therefore ethanol holds great potential as an alternative fuel. Identify the IUPAC nomenclature for straight-chained alkanols from C1 to C8 1 2 3 4 5 6 7 8 Methanol Ethanol Propanol Butanol Pentanol Hexanol Heptanol Octanol 4. Oxidation- reduction reactions are increasingly important as a source of energy Explain the displacement of metals from solution in terms of transfer of electrons a galvanic cell is produced A displacement reaction is a reaction in which a metal converts the ion of another metal into the neutral atom. One species of the reaction is oxidised whilst the other species is reduced (one species donates electrons, whilst the other species gains these electrons). Active metals will displace less active metal ions from solution: for example zinc will displace copper ions. Zinc releases electrons from its outer shell and they are accepted by the copper ions in solution displacing it from solution. Oxidation is the loss of electrons (charge increases) Reduction is the gain of electrons (charge decreases) Types of redox reaction apart from metal displacement reaction Metal/ non metal reactions 2Na(s) + Cl2 2Ag(s) + Cu2+(aq) Metals reacting with dilute acids Zn(s) + 2H+(aq) Zn2+(aq)+ H2(g) Active metals reacting with water 2Na(s) + 2H2O(l) 2NaOH(aq) + H2(g) Non metal displacement reactions F2(g)+2Br-(aq) 2F-(aq) + Br2(l) Identify the relationship between displacement of metal ions in solution by other metals to the relative activity of metals Of two metals, the more reactive metal is the one which will displace the other metal from a solution of its ions. More active metals lose electrons more easily; become oxidised. Less active metals are displaced from solution; become reduced Account for changes in the oxidation state of species in terms of their loss or gain of electrons For positive monatomic ions the oxidation state is the charge on the ion. The oxidation number is an arbitrary charge assigned to an atom. An increase in oxidation state shows the atom has been oxidised A decrease in oxidation state shows that the atom as been reduced To determine the oxidation number: Elements in elemental state: oxidation number = 0 Compounds of O: oxidation number = -2 except in peroxides = -1, F2O = +2 Monatomic ions: oxidation number = charge on ion (e.g. Cu2+=+2) Compound of H: oxidation number = +1 (except metal hydrides = -1) Polyatomic species: sum of oxidation numbers of all species equals charge on ion or molecule Describe and explain galvanic cells in terms of oxidation/reduction reactions A galvanic cell or electrochemical cell is a cell where a spontaneous chemical reaction occurs, converting chemical energy to electrical energy (producing current) Strong oxidants generally contain an element in a high oxidation state (e.g. Cr2O72- is a strong oxidant as Cr has a +6 oxidation state) Strong reductants generally contain an element in a low oxidation state (e.g. active metals such as K are strong reductants; 0 oxidation state) The more active metal is oxidised at the anode, less active metal is reduced at cathode Outline the construction of galvanic cells and trace the direction of electron flow Redox reactions involve transfer of electrons from one reactant to another. An electric current is a flow of electrons through a wire. Redox reactions can generate electricity by arranging for the oxidation and reduction half reactions to occur at different locations, and by providing a wire for the electrons to flow through. Conductors of a cell connected to the external circuit are called electrodes. The electrodes must be conductors, and may not be insulators. The electrolyte is a substance which in solution or molten conducts electricity Chemical reactions occurring at the electrodes are called electrode processes or electrode reactions. Salt bridge is essential for migration of ions and completing the circuit. The substances (ion) in salt bridge should not react with any substances in the cells, nor form precipitate. KNO3 is a good choice. – Anode: Electrode where oxidation occurs. Negatively charged, electrons are released into the external circuit at the anode – Cathode: Electrode where reduction occurs. Positively charged, electrons are removed from the external circuit at the cathode. – Electrodes: Conductors (metals or graphite) which are the interface between the external and internal circuit. Electrodes can be reactive (e.g. Zn) or inert (e.g. Pt, C). Reactions can also occur on the interface between electrode and electrolyte. – Electrolyte: An aqueous solution containing free, mobile cations and anions. Electrolytes exist in the anode and cathode compartments and the salt bridge. Electrons cannot flow through an electrolyte. – Salt bridge: constructed of a glass U-tube or a strip of filter paper. The salt bridge is filled/ saturated with an inert electrolyte (e.g. KNO3). The salt bridge allows the migration of ions between the anode and cathode compartments to maintain electrical balance/neutrality. – External circuit: composed of conductors where electrons can flow (electrodes, – – – – – connecting wires, voltmeter, ammeter, load) Oxidant: The ion species in the cathode compartment, which becomes reduced. The oxidant is located in the electrolyte. Reductant: the ion species in the anode compartment which becomes oxidised. Reductant can be in the electrolyte or the anode itself. Standard Electrode Potential (Eo) is the potential of that electrode in its standard state relative to the standard hydrogen electrode. Electron flow: electrons flow from negative anode to positive cathode. Electrons cannot flow through electrolyte. Ion flow: Ions flow (migrate) slowly in the electrolyte solutions. Negative ions (anions) flow towards anode compartment. Positive ions (cations) flow toward cathode compartment. Define the terms anode, cathode electrode and electrolyte to describe galvanic cells A galvanic cell is a device that allows a spontaneous redox reaction to take place in such way that chemical energy is converted to electrical energy. It consists of two half cells, each containing an electrode in an electrolyte solution. Oxidation takes place in anode where reduction in cathode. Gather and present information on the structure and chemistry of a dry cell or lead-acid cell and evaluate it in comparison to one of the following: Battery Lead-acid cell Button cell Chemistry Anode: Pb Anode: Powdered Zinc Pb(s) + SO42- PbSO4(s)+2eZn + 2OH- ZnO + H2O + 2eCathode: Pb/PbO2 Cathode: Carbon and AgO + 2PbO2(s)+ 4H +SO4 +2e Ag2O(s)+H2O(l)+2e- 2Ag(s)+2OHPbSO4(s)+ 2H2O(l) Electrolyte: Potassium hydroxide Electrolyte: Sulfuric acid 1.5V 2.2V Cost and practicality Expensive, Suitable for cars and Ag cells are expensive, but small trucks, relatively bulky and size and light weight with heavy. relatively large voltage Robust and Reliable, long life, a They are used in watches, storage battery, provides a large calculators, cameras, heart burst of current to start engine. pacemakers, hearing aids. Rechargeable. Work in wide High current and maintain stable range of temperatures voltage Impact on society Allowed the development of Allowed the powering of small starters in cars and trucker, equipment such as heat efficient means of transport. pacemakers, and hearing aids, Important for charge storage in extending human life and remote regions. Can store solar improved the standard of life energy when connected to solar Environmental impact panels Explosive hydrogen gas is released on recharging Corrosive acid can pollute the environment if spillages occur Lead is toxic and electrodes and casing must be recycled Expensive silver needs to be recycled KOH electrolyte is caustic No highly toxic materials that will harm the environment 5. Nuclear chemistry provides a range of materials Distinguish between stable and radioactive isotopes and describe the conditions under which a nucleus is unstable Isotopes are atoms that have the same atomic numbers but different mass numbers. Radioisotopes are the isotopes that are unstable, radioactive and actively emit alpha, beta or gamma radiation. Stable isotopes are not radioactive, they all have atomic numbers less than or equal to 83 and a ratio of neutrons to protons between 1:1 to 3:2. Unstable isotopes are radioactive. Any atoms with an atomic number greater than 83 are unstable because the atoms are too large and the nuclear force is not strong enough to withdraw the repulsive force of protons. If the ratio of neutrons to protons is less than 1:1 or greater than 3:2, or outside the “zone of stability” in the graph below, then the atoms are unstable isotopes. The nucleus of unstable isotopes has excessive energy therefore it decomposes and undergoes radiate emission to reach ground state by releasing the excess energy. There are three type so radiation alpha particles = helium nucleus = beta particles = electrons = 0 1 4 2 He emits by most heavy elements e emits by lighter elements gamma rays = electromagnetic radiation, always accompany either alpha or beta emissions x y E Where E is the element, x is mass number which equal to proton + neutron and y is the atomic number equal to proton Describe how transuranic elements are produced In 1940 Neptunium, the first Transuranic element (elements have atomic number greater than 92, uranium) was created by Edwin Mattison McMillan’s team. It was produced by bombarding Uranium 238 with a neutron slowly, forming unstable Uranium 239 and Uranium 239 then decay into Neptunium 239 and beta particle. 238 92 u + 1 0 n 239 92 u 239 93 Np + 0 1 e Plutonium was produced by bombarding uranium with deuteron at a very high speed, accelerating by the 60-inch cyclotron. It first formed neptunium 238, and then decayed into Plutonium by beta emission. 238 92 u + 2 1 H 238 1 Np + 2 n 93 0 238 93 Np 238 94 Pu + 0 1 e Transuranic elements do not exist in nature. Uranium is the last natural element. The first few of these artificial radioisotopes are produced by bombarding the nuclei of an element by substances such as neutrons, alpha particles or deuteron (nuclei of heavy hydrogen) slowly or in particle accelerator. Describe how commercial radioisotopes are produced Commercial radioisotopes are the radioisotopes that are industrially produced and massively employed in different areas which have commercial value. For example Technetium 99m was widely employed in medicine graphic imaging of the body and Americium 241 is industrially produced and used in smoke detectors They can be produced in an accelerator which will produce neutron deficient isotopes (isotopes have extra protons) or a nuclear reactor which will produce neutron rich isotopes (isotopes have extra neutrons) Particle accelerators such as cyclotrons will accelerate light ions such as protons, deuterons, helium 3 ions and alpha particles to very high speeds (close to speed of light), producing an intense high energy beams of the above ions, which then is used to bombard at nuclei of atoms, the repulsive force between the ions and the nuclei of atoms will be overcame by the very high speed. In a nuclear reactor, target nuclei are placed in the reactor core. Neutrons are used to bombard the target, producing neutron rich isotopes. Control rods inside the reactor absorb the extra neutrons to control the uranium chain reaction, making sure it is safe and releasing neutrons at a slow and controlled rate. For example Cobalt 60 was made by putting stainless steel rods containing pellets of Cobalt 59 into the reactor and releases a neutron into it. 59 27 Co + 1 0 n 60 27 Co Process information from secondary sources to describe recent discoveries of elements Ununhexium (Uuh) atomic number 116 is discovered on July 19, 2000, scientists at Dubna (FLNR) detected a single decay from an atom of ununhexium following the irradiation of a Cm-248 target with Ca-48 ions. It is very short lived (47 milliseconds) and decomposes to a known isotope of element 114. Four isotopes are currently known with masses 290-293. The most stable is Uuh-293 with a half-life of 63 ms. 248 96 Cm + 48 20 Ca 292 1 Uuh + 4 n 116 0 Identify instruments and processes that can be used to detect radiation Photographic film: darkening of the film Geiger-Muller tube and counter: Ionising properties of radiation, good for beta Cloud Chamber: consist cold super saturated vapour and they condense on ions Scintillation counter or detector: Photoelectric effect, emitting flash of light Identify one use of a named radioisotope: Describe the way in which the above named industrial and medical radioisotopes are used and explain their use in terms of their chemical properties -in industry Cobalt-60 Cobalt 60 can be used in industrial radiography. When materials are manufactured, a radioactive source is placed in one side while the detector is placed at the other side. The amount of radiation received by the detector depends on the thickness of the material, when the thickness of the material being manufactured changes the signal will differ, sending this information back to the control to optimise the manufacturing process. Cobalt has low energy emission and most of them are absorbed by manufacturing materials, hence minimise the danger of radiation, it also has a longer half life of 5.3 years, therefore factory don’t need to replace it frequently. It is also used to irradiate food, destroying insects, bacteria and micro organisms. -in medicine Technetium 99m Technetium 99m is used in gamma ray imaging of human organs. It can be injected into bloodstream and can detect blood clots, constrictions and other circulation disorders or attached to tin compound, chemically bound to red blood cell and becomes a tracer. It only emits low energy gamma rays which cause little damage to the body but are easily detected by gamma sensitive cameras. It has a half life of 6 hours, long enough to investigate the body but also short enough to minimise potential damage. It also has a number of oxidation states therefore it can be chemically bonded to different elements that different organs of the body absorb and can target a range of specific organs or tissues. Use available evidence to analyse benefits and problems associated with the use of radioactive isotopes in identified industries and medicine Medicine: Use of radioisotopes in medical imaging such as Tn 99m has allowed more effective and accurate diagnosis of diseases and has resulted in a reduced need for open surgery. This has numerous human benefits and decreases recovery time for patients, and reduces trauma that could arise from open surgery. However the nature of radioactive isotopes may become dangerous to operators and patients. Exposure could result in diseases and in some cases, cancer. Tn 99m has short half life, which is good for patient but it also means that it needs to be produced on site. Industry Use of radioisotopes in food irradiation destroy bacteria and mould, make food safe and keep it fresh longer, reducing the wastage. However it won’t necessarily kill all dangerous organisms and it destroys some vitamin content in food. It also leads to formation of harmful compound and laxity with food hygiene standards Food irradiation need gamma rays of sufficient energy to destroy bacteria, but cannot be enough energy to make food radioactive, source must have a reasonably long half life such as Cs-137 with 30 years and Co-60 with 5.3 years