Chemistry Notes - Bored of Studies

advertisement

Chemistry Notes

HSC Core Topic 1

The Identification and Production of Materials

Humans have always exploited their natural environment for all their needs including food, clothing

and shelter. As the cultural development of humans continued, they looked for a greater variety of materials

to cater for their needs.

The twentieth century saw an explosion in both the use of traditional materials and in the research

for development of a wider range of materials to satisfy the specialist needs of space travel and the

information technologies. Added to this was a reduction in the availability of the traditional resources to

supply the increasing world population.

Chemists and chemical engineers continue to play a pivotal role in the search for new sources of

traditional materials such as those from the petrochemical industry. As the fossil organic reserves dwindle,

new sources of the organic chemicals presently used have been found. In addition, chemists continually

searching for compounds to be used in the design and production of materials to replace those that have

been deemed no longer satisfactory for needs.

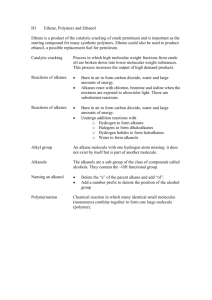

1. Fossil fuels provide both energy and raw materials such as

ethene, for the production of other substances.

Identify the industrial source of ethene from the catalytic cracking of some of

the fractions from the refining of petroleum.

Ethene is obtained from refined petroleum via catalytic cracking (use of catalyst to break

larger chains into smaller ones, to meet demand) NOTE that ethene is a by-product of cracking

used to produce other alkanes.

(1) When an alkane is cracked,

H H H H H

(2) there are 2 more hydrogens required

where bond was broken

therefore, 1 hydrogen moves from one

cracked part to the other

C

C

C

C H

H

H

H

H

H

H

H C

H

(3) the one missing 2 Hs will form a

double bond, to make an alkane and an

alkene

H C

H

C

H

H

C

H

H

C

H

H

C

H

H

H

C

H

H

C

H

H

C

H

H

C H

H

H

C H

H

Explain that catalytic cracking is an example of an industrial process that

involves surface reactions with inorganic catalysts.

The catalysts in the industrial process of catalytically cracking petroleum are structured

aluminosilicate called zeolites. This structure causes zeolites to have large surfaces. The

cracking reaction occurs on the inner surfaces of the catalysts, thus a surface reaction.

Since the zeolites are solid and the reactants are liquid/gas, this reaction is heterogeneously

catalysed.

Example:

Decane

zedite catalyst

500C

ethene

+

2-methylheptane

Explain the relationship between the properties of alkanes and alkenes and

their non-polar nature and weak dispersion forces between molecules.

Identify data, plan and perform a first-hand investigation to compare the

reactiveness of appropriate alkenes with the corresponding alkanes in

bromine water in solution.

Since alkanes and alkenes are non-polar and only have weak dispersion forces between their

molecules, they have similar (low) boiling points and melting points, as well as similar

solubility (in non-polar solvents, not soluble in water). Short chains (1-4) are gases, and

higher are liquids.

Alkenes are much more reactive than alkanes. While alkanes are useful since they burn in air,

alkenes react much more readily with halogens (and decolourise Cl, Br, I). Alkanes require

UV light and undergo a substitution reaction, while alkenes allow addition reactions by easily

breaking their double bonds.

C6H14(l) + Br2(soln) --> C6H13Br(soln) + HBr(aq)

Hexane + Bromine --> 1-Bromohexane + Hydrogen bromide

CH3–CH2–CH=CH-CH2–CH3 + HCl --> CH3 –CH2-CH2-CH-CH2-CH3

|

Cl

3-Hexene + Hydrogen chloride --> 3-chlorohexane

Alkanes

Saturated hydrocarbons of the general formula CnH2n+2 (where n = 1, 2, 3…)

Commonly called paraffins (Latin: little reactivity) because of their relative

unreactivity

They are non-polar molecules, single covalent bonds linking carbon atoms with

hydrocarbon chain. Dispersion forces exist between alkane molecules, strength of this

force increases with increasing molar weight, therefore melting and boiling points

increase as chain length increases

Isomers exist because chains may branch

Dissolve in other non-polar solvents but insoluble in water. Long chain solids will

dissolve in liquid alkanes of shorter chain length

Obtained by fractional distillation of crude oil

Reactions

For alkanes there are only two important reactions:

1. Alkanes burn in air to form carbon dioxide and water. In doing so they liberate large

amounts of heat, for example:

For propane: C3H8(g) + 5O2(g)

For octane:

C8H18(g) + 121/2O2(g)

3CO2(g) + 4H2O(g)

8CO2(g) + 9H2O(g)

It is this combustion reaction that makes alkanes useful to us as fuels.

2. Alkanes react with chlorine, bromine and iodine when the mixtures are exposed to

ultraviolet (u.v.) light, for example:

For methane: CH4(g) + Cl2(g)

For hexane:

C6H14(l) + Br2(soln)

CH3Cl(g) + HCl(g)

(chloromethane)

C6H13Br(soln) + HBr(aq)

(bromohexane)

A variety of products can be formed by these reactions, depending on conditions used.

Alkanes do not react with (decolourise) chlorine, bromine or iodine solutions in the

absence of u.v. light but they do react (quite slowly for the liquid ones) in the presence

of u.v. light. This contrasts with the behaviour of alkenes.

Alkenes

Unsaturated hydrocarbons of general formula CnH2n (where n = 2, 3, 4…). Molecules

are unsaturated because they do not contain maximum number of hydrogen atoms per

molecule

Commonly called olefins (Latin: oil-loving) due to oily nature of liquid alkenes. They

are reactive molecules.

They are non-polar molecules in which one double covalent bond links a pair of carbon

atoms. The presence of this double bond has an effect on the dispersion forces between

molecules. They tend to have similar or slightly lower boiling points than alkanes of the

same chain length

Isomers exist because chains may branch

Dissolve in non-polar solvents and are insoluble in water

Obtained by chemical processes involving the breakdown of products derived from

crude oil distillation

Reactions

The presence of the double bond in alkenes makes them very reactive. There are many

substances that react with alkenes by opening out the double bond to form two single bonds.

These are called addition reactions.

Identify that ethene, because of the high reactivity of its double bond is

readily transformed into many useful products.

Ethene’s double bond allows a high reactivity in addition reactions with various important

compounds.

(1) Forming ethanol:

3

4

C2 H 4 H 2O

CH 3 - CH 2 - OH

H PO

300 C

performed industrially at high pressure/temperature, using H3PO4

(2) Ethylene oxide:

1

C 2 H 4 O 2 Ag

catalyst

C 2 H 4 O

250 C

2

reacted with water (H+ catalyst) to form ethylene glycol (1,2-ethanediol), used in

polymer manufacture

(3) Vinyl chloride:

(not an addition reaction)

1

2 catalyst

2CH 2 CH 2 Cl 2 O 2 CuCl

2CH 2 CH Cl H 2 O

150 C

2

used in making PVC – poly(vinyl chloride)

Identify that ethene serves as a monomer from which polymers are made.

Ethene is the monomer used in making poly(ethene)

, or polyethylene . It is

also the basis for other monomers (eg. vinyl chloride) that make up polymers.

Identify poly(ethene) as an addition polymer and explain the meaning of this

term.

Polyethene is called an addition polymer. Like addition reactions, addition polymers are

formed by joining molecules, without the loss of any atoms (each double bond opens and joins

another).

Outline the steps in the production of poly(ethene) as an example of a

commercially and industrially important polymer.

Polyethene is the systematic name for this substance, but polyethylene is the IUPAC

(International Union of Pure and Applied Chemistry) preferred name.

The most important reaction of ethene is its conversion to polyethylene (or polyethene) in a

reaction that is called polymerisation.

Polymerisation is a chemical reaction in which many identical small molecules

combine together to form one large molecule. The small molecules are called monomers while

the large product molecule is called a polymer. These polymers are essentially long alkane

molecules: each molecule contains from a few hundred to a few thousand monomer units.

Production of poly(ethene)

branched chains (amorphous)

gas phase process

high temperature, high pressure (300C, 2000atm)

initiator (organic peroxide) used

causes a lot of chain branching

uses:

–

wrapping materials

–

carry bags

–

milk bottles, squeeze bottles

linear chains (crystalline)

Ziegler-Natta process

moderate temperatures & pressures (60C, ?atm)

catalysed (TiCl3 & tryalkylaluminium compound)

causes unbranched polymers, packing in orderly fashion: higher density, more

crystalline

uses:

–

kitchen utensils

–

toys

–

grocery bags

–

building materials

Single strands are held together to other strands by strong dispersion forces.

High Density Polyethene (HDPE) is made of closely fitting polyethene chains and is heavier.

Low Density Polyethene (LDPE) has chains with many cross-links and side chains and is

more flexible but weaker.

Identify the following as commercially significant monomers: vinyl chloride,

acrylonitrile and styrene (by both there systematic and common names).

Account for the uses of the polymers made from the above monomers in terms

of their properties.

Polymer

Poly(vinyl

chloride)

Polyacrylonitrile

Monomer

Vinyl chloride

[chloroethene]

CH2=CH-Cl

C2H3Cl

Acrylonitrile

[propenenitrile]

Properties

Resists weathering,

fire resistant, cheap

to make and process,

electrical insulator

Forms fibres

Uses

Electrical insulation,

sewerage pipes,

guttering, garden

hoses

Wool substitute in

clothing, soft

CH2=CH-C N

Polystyrene

C3H3N

Styrene

[phenylethene]

CH2=CHC8H8

furnishings, carpet

Rigid, electrical

insulator, low cost,

not chemically

reactive, heat and

cold insulator, low

density, resists high

impact

Tool (screwdriver)

handles, foam cups,

foam packing,

containers, insulation,

toys, vacuum flasks

Properties of polymers relating to use:

(1) melting point

(2) stability in heat and light

(3) chemical stability

(4) mechanical strength

(5) rigidity

These relate to:

(1) Average molecular weight (chain length)

number of monomer units in one molecule

longer chain -> higher melting point -> harder substance

(2) Crystallinity (chain branching)

less branching -> crystallinity -> higher density -> harder substance

more branching -> amorphous -> flexible

eg. HD polyethylene ‘crackles’, and LD is softer and ‘clingy’

(3) Chain stiffening

chain stiffening is putting a side group into a linear chain to reduce flexibility (eg

replacing H with CH3, polyethylene -> polypropylene)

causes rigidity and stiffness

[PVC is plasticised to soften it]

(4) Crosslinking

linear chains connected to form 2D-network

more common in condensation polymers than addition polymers

increases rigidity, or causes elasticity (used in rubber/elastic)

Stability:

PVC: C-Cl bonds are weaker than C-H and break with UV light.

Additives are used to protect PVC from sunlight

In high temperatures, forms HCl, extremely corrosive

Acrylics: when heated strongly, forms hydrogen cyanide, extremely poisonous

gas

2. Some scientists continue to research the extraction of

materials and energy from biomass to reduce our dependence

on fossil fuels

Discuss the need for alternative sources of the compounds presently obtained

from the petrochemical industry.

At society’s current rate of consumption of crude oil-based products (mostly fuels for

transportation), there is concern that it will all be used up in a few decades and cost will

increase. While alternative fuels are being researched, this does not help the industries based

on by-products of crude oil refining, such as the petrochemical industry.

As crude oil diminishes and costs increase, alternative sources are required for the

products we gain from petrochemicals. Thus we need a new source of ethene.

Cellulose is the important biopolymer (naturally occurring polymer) that can be used and is

readily available in most countries. Ethanol is the prime candidate for an alternative source of

ethene. Ethanol can be produced by fermentation from a variety of agricultural crops and it

can be easily converted to ethene.

Explain what is meant by a condensation polymer and describe the reaction

involved when a condensation polymer is formed.

A condensation polymer is a polymer formed by eliminating a small molecule, usually

water, when monomers join together – outer parts of the molecules combine to form the

eliminated substance, while the rest joins to become a polymer.

Describe the structure of cellulose and identify it as an example of a

condensation polymer found as a major component of biomass.

Glucose condenses into cellulose by the elimination of water:

HO—C6H10O4—OH HO—C6H10O4—OH HO—C6H10O4—OH HO—C6H10O4—OH

nC6 H12O6 H O C6 H10O 4 OH n 1H 2 O

H

CH2OH

O

OH

H

OH

OH

Glucose:

H

OH

H

H

CH2OH

CH2OH

O

O

O

O

O

O

Cellulose:

CH OH

2

O

O

CH OH

2

Note glucose is inverted to bond, and linearity of cellulose

Cellulose is the major component of plant material (which is biomass), which makes it

readily available to be used.

In starch the - glucose units add from C1 to C4 to form a helix structure. Strength + Shape

+ Fibre (in diet), energy source enzymes present in humans for digestion.

In cellulose the - glucose units add from C1 to C4 to form a linear structure. No enzymes in

humans for digestion. Enzymes do occur in termites and bacteria (cow guts).

Identify that cellulose contains the basic carbon-chain structure needed to

build petrochemicals and discuss its potential as a raw material.

Cellulose (already used in cotton, paper, cardboard) contains glucose’s carbon chain,

meaning it could possibly be used to derive a source for ethene, propene or butene, yet

currently there is no simple way to break it down into glucose (while small organisms do

this, they break it down further).

Starch is more useful, but there is much more cellulose in biomass and it can be obtained from

wastes, which would make it a good source of chemicals. Cellulose is a potential source of

petrochemicals because of its carbon chain structure.

Bacteria that live in the intestine of termites and ruminants produce enzymes to break

down cellulose into glucose monomers. Enzymic breakdown of cellulose is the first step in the

production of petrochemicals. The glucose can be fermented to form ethanol, which can be

readily dehydrated to form ethene. From ethene a wide variety of petrochemicals (eg.

Halogenated hydrocarbons and polymers) are currently manufactured.

Assess current developments in the use of biopolymers and describe a

process currently used industrially to produce polymers.

Use available evidence to gather, process and present data from secondary

sources and analyse progress in the development and use of a named

biopolymer. This analysis should name the specific enzyme(s) used or

organism used to synthesise the material and an evaluation of the use or

potential use of the polymer produced related to its properties.

Partially synthetic biopolymers have been in use for decades, but their use has been

declining as petroleum based polymers have been taking over.

Eg. rayon, viscose rayon, viscose, cellophane, cellulose nitrate (film, explosive), cellulose

acetate (projector slides)

Biopolymers, though, unlike petroleum-based polymers are biodegradable.

PHAs [poly(β-hydroxy-alkanoate)] can be formed from certain bacteria in specific conditions,

producing a polymer similar to polypropylene, except that they are biodegradable.

Biopolymers are polymers that are made totally or in large part by living organisms.

Originally the word meant biologically synthesised polymers such as cellulose, starch, proteins

and nucleic acids. However the word now includes polymers that are chemically modified

versions of natural polymers and polymers that can be produced by ‘manipulating’ biological

organisms.

Partially synthetic biopolymers based on cellulose have been used commercially for nearly a

century. Rayon, or in recent decades viscose rayon or just viscose, is a reconstituted

cellulose as is cellophane. Cellulose nitrate is a synthetically modified cellulose that was

widely used for photographic and movie film early this century: it was also used as an

explosive (gun cotton) and as a plastic called celluloid. Unfortunately it was highly flammable

and has been largely replaced by other plastics. Cellulose acetate, which is much less

flammable, is still widely used, for example for overhead projector slides.

The major problem with petroleum-based polymers is that they are not biodegradable. This

means that they do not decompose when discarded into the environment or put into rubbish

dumps. Carelessly discarded synthetic plastics are causing harm and often death to marine

and bird life and remain almost indefinitely as eyesores in landscapes.

Polylactic acid (PLA)

Bacteria are fed starch which forms lactic acid (CH3CHOHCOOH) that is them polymerised. At

present, the use of PLA polymers is limited to medical implants. Compatibility of PLA

homopolymers with other biopolymers is being examined for direct application in packaging

and extrusion processing.

Development work

Research is also being focused on developing low cost biodegradable starch-based packaging

material (starch biopolymers) as alternatives to conventional plastic packaging. Industry

worldwide is examining new ways to reduce plastic waste and the use of non-renewable

resources, namely, petroleum-based products, from which plastics are made. A starch-based

biodegradable alternative to polyethylene film, including a black plastic now used as mulch

flim, is being developed.

A major obstacle to the use of starch biopolymers is the need to enhance moisture stability

while controlling processing and biodegradability. These problems are also the basis of current

research programs.

Solve problems and perform a first-hand investigation to identify cellulose

and analyse information to examine the effect of decay bacteria on cellulose.

Decay bacteria on cellulose: many bacteria, fungi and insects can decompose cellulose into

simple molecules (like glucose) and yet continue to form carbon dioxide and water. Eg. Rotting

timber, decaying compost.

Process data from secondary sources to analyse the efficiency of conversion

of plant material to ethanol.

Ethanol can be obtained by fermenting starches & sugars with yeast. Glucose is broken down

by the enzymes in yeast to ethanol and CO2. Enzymes first break down the more complex

sugars, and others break down the simple sugars into the products.

Yeast can produce ethanol up to 14%, before killing the yeast. It is necessary to distil the

alcohol for higher concentrations.

It is inefficient to grow plants for the purpose of producing ethanol. Molasses (leftover sugar

from milling), leftover starchy grains could be used to increase efficiency of the entire process

by using by-products.

Fermentation also produces heat, which causes less efficient energy change.

3. Other resources, such as ethanol, are readily available from

plants. Such renewable resources will be of increasing

importance as fossil fuel reserves are depleted

Describe the dehydration of ethanol to ethene and identify the need for a

catalyst in this process and the catalyst used.

Dehydration of ethanol is removal of water from the compound, to create ethene and water.

Ethanol is heated with concentrated sulfuric or phosphoric acid catalyst.

catalyst

Dehydration of ethanol: CH 3 - CH 2 - OH H2SO

4

CH 4 H 2 O

Describe the addition of water to ethene resulting in the production of ethanol

and identify the need for a catalyst in this process and the catalyst used.

The reverse, hydration, requires heat and a catalyst, dilute H2SO4

2SO 4 catalyst

Hydration of ethene: CH 4 H 2 O dilute

H

CH 3 - CH 2 - OH

Describe the uses of ethanol as a solvent and relate this to the polar nature of

the ethanol molecule.

Plan, choose equipment and perform a first-hand investigation to gather

information about the range of substances which can be dissolved by ethanol.

Ethanol is the 2nd most important solvent after water and is used in:

Cosmetics (eg. Perfumes and deodorants)

Food colourings and flavouring (eg. Vanilla essence)

Medicinal preparations (eg. Antiseptics)

Some cleaning agents

It is biodegradable in sunlight and is also widely used as a solvent in industry.

It is a good solvent since it is very polar, the O is much more electronegative than H or C (ie.

In the COH bond, O is -, and the others are +). It is therefore a good solvent for polar

substances. It also can form hydrogen bonds with other substances (and is miscible with

water).

Outline the use of ethanol as a fuel and explain why it can be called a

renewable resource.

Ethanol has been promoted as a fuel on the grounds that it is a renewable resource. Ethanol

readily burns, and as a liquid is easily transportable, making it a useful fuel. 10-20%

ethanol can be used in normal car engines, but pure ethanol would require modification of

engines.

It is a renewable resource in that it can be obtained from glucose, which is create by plants

from CO2, H2O, and sunlight, which are basically the products of using ethanol as a fuel.

Therefore it is a cycle.

Describe conditions under which fermentation of sugars is promoted.

Summarise the chemistry of the fermentation process.

Present information from secondary sources by writing a balanced equation

for the fermentation of glucose to ethanol.

Fermentation is a process in which glucose is broken down to ethanol and carbon dioxide

by the action of enzymes present in yeast.

For fermentation:

Suitable grain or fruit is mashed up with water

Yeast is added

Air is excluded, and

The mixture is kept at about blood temperature, 37C.

Enzymes (biological catalysts) in the mixture first convert any starch or sucrose in the

mixture into glucose and/or fructose, the other enzymes convert glucose or fructose into

ethanol and carbon dioxide:

C6H12O6(aq)

yeast

2CH3-CH2-OH(aq) + 2CO2(g)

Bubbles of carbon dioxide are slowly given off: hence the name, fermentation.

Yeast can produce ethanol contents up to about 15%. Alcohol concentrations above

this level kill the yeast and stop further fermentation. To produce higher alcohol contents it is

necessary to distil the liquid.

If the aqueous mixture from a fermentation process is subjected to fractional

distillation, 95% ethanol can be obtained. This is common industrial or laboratory alcohol. To

obtain 100% ethanol more elaborate distillation procedures are needed.

Fermentation and distillation have been used to produce ethanol for centuries.

Ethanol was one of the earliest organic compounds to be synthesised and obtained in nearly

pure form.

‘Suitable grain or fruit’ for fermentation is plant material that has a high content of

starch or simple sugars (sucrose, glucose, fructose). Starchy grains (such as wheat, maize or

corn, barley), tubers (such as potatoes, cassava or tapioca), and fruits (such as grapes,

apples) with high simple sugar contents are commonly fermented to ethanol.

Molasses, the leftover syrup from sugar milling, is also widely used. Sucrose has a

very high solubility in water; this means that the mother liquor left over after sucrose has been

crystallised out still has a high sucrose content, so ethanol can be obtained from an otherwise

useless waste product of sugar production.

Define the molar heat of combustion of a compound and calculate the value for

ethanol from first-hand data.

The molar heat of combustion of a substance is the heat liberated when one mole of

the substance undergoes complete combustion with oxygen at a constant pressure of exactly

one atmosphere with the final products being carbon dioxide gas and liquid water.

The molar heat of combustion is minus the enthalpy change for the combustion

process (because enthalpy change, H, is always energy absorbed).

In practise, when we burn a fuel the water generally forms a gas. However the values

we tabulate are the ones we would get if the water formed as a liquid. In particular for ethanol

the molar heat of combustion is 1360 kJ/mol. This means that for:

C2H5OH(l) + 3O2(g) --- 2CO2(g) + 3H2O(l)

H = -1360 kJ/mol

Assess the potential of ethanol as an alternative fuel and discuss the

advantages and disadvantages of its use.

Ethanol as a car fuel alternative

Advantages

Theoretically lower greenhouse

emissions / more energy efficient

(if solar energy used)

Different fuel properties

Works as a solvent to clean

engine

Cleaner air (less prone to

incomplete combustion)

Less dependence on fossil fuels

(renewable unlike crude oil)

Disadvantages

Petrol engines are designed for

octane

Industry already developed

Inefficiency of crops to produce

ethanol

Land required for crops – soil

salinity, erosion, deforestation

problems

Distillation & fermentation require

energy -> waste

Requires water removal from end

product

Process information from secondary sources to summarise the processes

involved in the industrial production of ethanol from sugar cane.

Industrially, ethanol is fermented from sugar cane:

C12H22O11 + H2O 2C6H12O6 4C2H5OH + 4CO2

As above, this is inefficient if crops are grown for the purpose, and molasses or leftover

starchy grains should be used.

Ethanol is then used as a fuel, solvent, alcoholic beverage, production of ethene.

Process information from secondary sources to summarise the use of ethanol

as an alternative car fuel, evaluating the success of current usage.

Current usage & successes

Used as a fuel extender in some petrol mixes (10-20% without needing engine

modifications)

Success depends on support of government, cost / benefit analysis

In the 80s in Brasil, sugar cane crops were grown for the purpose of producing

ethanol for fuel – not economically viable: abandoned

No successful application as a fuel replacement

4. Electrochemical methods are important in producing materials

and making energy available

Explain the displacement of metals from solution in terms of transfer of

electrons.

Recall:

Oxidation is the gain of oxygen and/or loss of hydrogen, also the loss of electrons.

Reduction is the loss of oxygen and/or gain of hydrogen, also the gain of electrons.

Oxidation and reduction always occur together

Redox reactions are very important since they are involved in things such as:

These

Corrosion of metals

Combustion reactions (burning)

Production of metals from ores

Cells and batteries

Electrolysis to produce some metals and compounds

all involve the loss and gain of electrons.

A displacement reaction is a reaction in which a metal converts the ion of another metal to

the neutral atom.

Oxidation-reduction reactions are also called redox reactions and electron transfer

reactions.

When a more reactive metal (M) is added to a solution in which a less reactive metal (L) is

ionised, M is oxidised and loses its valence electrons to L, which is reduced. Thus L is displaced

from solution, and M is dissolved.

Identify the relationship between displacement of metal ions in solution by

other metals to the relative reactivity of metals.

{Na, K} > {Li, Ca, Ba} > {Mg, Al, Fe, Zn} > {Sn, Pb} > Cu > {Ag, Au, Pt}

(Species within curly brackets have equal activities).

Only a more reactive metal will displace the metal ions of a less reactive metal. See

activity series.

Once it has been established we can use this activity series to decide which metal (of a given

pair) displaces which from solution:

The metal further to the left will displace the other metal from a solution of its ions.

It other words, the metal further to the left loses electrons more easily or is more easily

oxidised. Oxidation and reduction or electron transfer has some implications for the way we

name certain species.

Account for changes in the oxidation state of species in terms of their loss or

gain of electrons.

Recall: the valence of various metal ions and of the need with some of these ions to state the

valence (in capital Roman numerals) in the name: tin(II) oxide, iron(III) chloride, copper(I)

sulfide and the like. What we referred to there as valence is also called the oxidation state of

the element.

For positive monatomic ions the oxidation state is the charge on the ion.

The oxidation state:

of copper in the oxide Cu2O (2Cu+ O2-) is +1

of iron in the sulfide FeS (Fe2+ S2-) is +2

of titanium in the chloride TiCl3 (Ti3+ 3Cl-) is +3

The oxidation state of a species increases with its loss of electrons, thus the species

is oxidised. The oxidation state decreases when electrons are gained; the species is reduced.

Describe and explain galvanic cells in terms of oxidation/reduction reactions.

By reduction and oxidation within a system occurring at different locations, charged particles

pass through an attached wire, causing a current. This is a galvanic cell.

It requires a difference in potential between the redox reactions occurring at either

electrode, in order for there to be any reaction. Electrons are removed from the anode and

pass through the circuit to the cathode, whose ions in solution are then reduced.

Outline the construction of galvanic cells and trace the direction of electron

flow.

external circuit

e

-ve ions

+ve ions

e

salt bridge

anode

cathode

The salt bridge is required in order for ions to be transferred/migrate, and thus for the

electrolytes. Positive ions from the anode solution migrate to the cathode across the salt

bridge, pushing the positive ions in the salt bridge. Equally, negative ions migrate in the

opposite in order to equal out the charges on either side of the cell.

It is important to use a solution in the salt bridge that does not precipitate with other ions in

the cell. This is why KNO3 is used (neither precipitates with any ions).

A cell can be described by A | A+ || C+ | C, where the left is based on the oxidation halfequation, and the right is the reduction half-equation. The | represents a change in phase, and

the || represents a salt bridge.

Identify the use the terms anode, cathode, electrode and electrolyte to

describe galvanic cells.

The anode is the electrode at which electrons are released, ie oxidation occurs / negative

electrode

The cathode is where reduction occurs (ie. Positive electrode)

The electrolytes are the solutions or molten substances used within the cell that conduct

electricity.

In summary:

A cell consists of:

2 electrodes:

An anode (-) where oxidation occurs

A cathode (+) where reduction occurs

And an electrolyte which is a conduction paste or solution contain mobile ions.

Electrons are carried by external wires and a salt bridge, which is paper or gel which contains

ions, usually K+, Na+ and NO3-.

A battery is two or more cells joined together.

A common cell in use consists of two metal half-cells in which a metal electrode is a solution

of the same metal ions.

We can represent cells using a short hand notation:

Anode / electrolyte /Salt bridge/ electrolyte / Cathode

Eg. Fe(s) / Fe2+(aq) // Sn2+(aq) / Sn(s)

Redox reactions involve transfer of electrons from one reactant to another.

Describe the industrial use of electrolysis for refining a named metal

identifying: oxidant, reductant, electrolyte used, and conditions under which

the electrolysis must occur and the reasons for these conditions.

Electrolysis is the causing of a (redox) reaction to occur by supplying a voltage across the

reaction (reverse of galvanic/voltaic cell).

Copper can be purified by electrolysis, whereby impure (blister copper) is electro-refined

into pure copper.

+

e

anode:

blister

copper

anode

mud

Cu 2+

cathode:

pure

copper

electrolyte:

acidified

CuSO 4

Note Blister copper anode (+ve Cu --> Cu2+ + 2e disintegrates in reaction

Pure copper sheet cathode Cu2+ + 2e– --> Cu deposits on cathode

Concentrated Cu2+ electrolyte, acidified slightly for increased conductivity

[Too acidic could cause H+ to reduce, alkali and Cu(OH)2 precipitates]

Voltage (PD) across cell is controlled such that it is enough to reduce Cu 2+, not to oxidise less

active metals (anode mud: Ag, Au, etc) and give a good rate of deposition of copper, not to

reduce more active metal ions (Fe2+, Zn2+, etc).

Identify an example of the use of electroplating and explain why the process is

used.

Electroplating is used in order to coat a metal object evenly with a thin film of another. The

metal to be coated is used as the cathode, in order to attract metal ions from the anode (and

electrolyte with plating ions). An example of its use is in coating cutlery with silver or jewellery

with gold (cheaper coated with more expensive, or chroming to protect soft metals with harder

[eg car parts, taps]).

Gather, process and present information on the structure and chemistry of a

dry cell or lead-acid cell and evaluate it in comparison to: button cell, mercury,

vanadium redox cell, lithium, liquid junction photovoltaic device (eg the

Gratzel cell) in terms of: chemistry, cost and practicality, impact on society,

and environmental impact.

Standard batteries compared:

(1) Dry cell

Chemistry

–

Zn | ZnCl2, NH4Cl | MnO2, C

+

NH4Cl paste

Anode (Zn)

MnO 2 + C

Cathode (C)

–

O: Zn --> Zn2+ + 2e–

–

R: NH4+ + MnO2 + H2O + e– --> Mn(OH)3 + NH3

Cost & Practicality

–

Relatively cheap

–

Useful when small currents are needed

–

Easy to store and use, standard

–

Bad: low current for its size, can leak

Impact on society

–

First commercialised battery

–

Therefore made portable items (torches, radios, clocks) possible

Environmental impact

–

Minimal: Mn3+ oxidised in the environment, small amounts of Zn not

problematic, NH4 salts, C are harmless

–

Not rechargeable

(2) Button cell

Chemistry

–

Zn, ZnO | KOH (paste) | Ag2O, Ag

Zn + ZnO

Insulating sealant

KOH paste

(in porous medium)

Ag2O, Ag

+

–

O: Zn + 2OH– --> ZnO + H2O + 2e–

–

R: Ag2O + H2O + 2e– --> 2Ag + 2OH–

Cost & Practicality

–

Very small

–

Can produce considerable amounts of electricity

–

Constant voltage (1.6V)

–

Relatively long lifespan

–

More expensive than dry cell

Impact on society

–

Allows for miniature electrical appliances (watches, hand-held calculators,

hearing aids)

–

Non-toxic (so possible inside the body)

Environmental impact

–

Not rechargeable

(3) Mercury battery

Chemistry

–

Button style

–

O: Zn + 2OH– --> ZnO + H2O + 2e–

–

R: HgO + H2O + 2e– --> 2Ag + 2OH–

Cost & Practicality

–

Small

–

Steady output (1.6V)

–

Lasts longer on a steady voltage than dry cell

–

Mercury ores not abundant

Impact on society

–

Useful where compactness is required

Environmental impact

–

Not rechargeable

–

Toxic mercury released

–

Waste is poisonous, causes landfill

(4) Vanadium redox battery

Chemistry

+

Anode

+

2+

VO2 / VO

Cathode

2+

V /V

3+

Graphite felt

–

–

V2+ <--> V3++e–

–

VO2++2H+ <--> VO2++H2O

Cost & Practicality

–

Easy maintenance

–

Flexible voltage

–

Fully rechargeable, quickly (readily reversed, 2V can recharge 100V)

–

Vanadium is plentiful

–

Safe (electrolytes are not dangerous together)

Impact on society

–

Large power supply

–

Can be used as solar/wind energy storage

–

Underground storage possible

Environmental impact

–

Little waste, doesn’t need to be thrown away

–

Easy recharge

–

Independent of fossil fuels

–

Can be used to replace fossil fuels -> improved air quality

(5) Lithium battery

Chemistry

–

O: Li --> Li+ + e–

–

R: I2 + 2e– --> 2I–

Cost & Practicality

–

Small, button

–

Higher voltage than dry cell (2.8V)

–

More expensive than dry cell

Impact on society

–

Small

–

Higher output useful for new applications

Environmental impact

–

Not rechargeable

(6) Liquid junction photovoltaic device (Gratzel cell)

Chemistry

–

Converts light energy to chemical

–

Light is absorbed by a dye, D

–

O: D --> D+ + e–

–

Electron goes to mediator 2D+ + 3I– + e– --> 2D + I3–

–

R: I3– + 2e– --> 3I–

Cost & Practicality

–

More expensive than dry cell – different application

–

One-off cost

–

Easier to produce & cheaper than other photovoltaic cells

Durable

Titanium oxide, and other metal oxides used to absorb light are easily

obtainable

Impact on society

–

Cheaper solar power may increase the use of solar power

Environmental impact

–

Clean source of energy

–

Materials are non-toxic

–

–

5. Nuclear chemistry provides a range of materials to assist in

tracing and thus better understanding complex chemical

reactions

Distinguish between stable and radioactive isotopes and describe the

conditions under which a nucleus is unstable.

Radioactive isotopes (as opposed to stable) emit radiation from their nuclei to become stable.

Nuclei are most stable at a certain ratio (1-1.5) of neutrons to protons for the isotope.

decay is 42 He decay is -10 e

Describe how transuranic elements are produced in nuclear reactors.

Elements past U, ie, atomic numbers 92 to 118 are transuranic, and don’t occur naturally.

Natural elements are bombarded with neutrons (or other particles) in nuclear reactors to

produce the higher elements.

Describe how commercial radioisotopes are produced in nuclear reactors.

Commercial (industry & medicine) radioisotopes are produced similarly in nuclear reactors,

specifically made to obtain a certain radioisotope.

Identify instruments and processes that can be used to detect radiation.

Instruments for the detection of radiation

Photographic film

darkening is quantitative measure of radiation

Cloud chamber

air-tight, with supersaturated water/alcohol vapour

radiation ionises air, vapour condenses around ions

this is visible

alpha gives straight, dense trails

beta gives lighter zigzags

gamma gives fainter tracks

Geiger-Mueller

metal tube with thin micra film window (to allow

counter

and particles to enter)

+

counter

Scintillation counter

filled with argon gas

radiation ionises Ar, ions go to terminals, e– causes

more ionisation

causes pulse, collected by counter

can detect small doses of radiation (one particle)

phosphors emit flashes of light when radiation strikes

these can be amplified and electronically counted

Identify one use of a named radioisotope: in industry, in medicine, and to

determine and/or verify reaction mechanisms in chemistry.

Describe the way in which the above named radioisotopes are used and relate

this to the chemical properties of the radioisotopes described.

Examples of commercial isotopes:

Industry:

Co (half-life 5.27y, --bombard 59Co)

o means can be reused, and is not very harmful once disposed

o ideal intensity not to make subject radioactive, but to destroy what is

required

food irradiation

60

damages DNA

slows ripening, sprouting, spoilage; kills some bugs

problems: can create new, unknown chemicals in food, destroys thiamine, some

foods unsuitable, radiation exposure due to negligence

Medicine:

Cobalt

o beta is soft and can be filtered out

o gamma is constant and allows for accuracy

o cheap and easy to manufacture

rods of 60Co are placed in a teletherapy unit

directs gamma rays to specific area of body

destroys DNA in carcinoma, and thus reduces or eradicates them

60

Reaction mechanisms:

Since radioactive isotopes react chemically the same, they are used to

determine positions of broken bonds, etc in reactions

Known as isotopic tracers, since their movement is observable as a member of a

chemical reaction

Isotopic labelling is where one element in the reactants is radioactive and then is

traced in the end of the reaction to determine which reactants were involved in

producing the product

18

O shows where the OH comes from in the hydrolysis of methyl acetate *methyl acetate +

water --> acetic acid + methanol

H

O

H

H C

C O C

H

H

H

H C

H

O

C

18

H + H2 O

H

18

OH + H C

H

OH

Process and analyse information from secondary sources by using a flow

diagram to trace the sequence of fission products released during the decay of

uranium.

Fission is where a radioisotope divides into two roughly equal parts, releasing enormous

amounts of energy and neutrons. These neutrons are either absorbed or cause fission with

another of the original element. For controlled fission, all but one of the neutrons are allowed

to continue (others absorbed).

141

92

1

Eg 01n 235

92 U 56 Ba 36 Kr 3 0 n energy

n

U

?

?

n n n

U

U

U

?

? ?

n n n

?

n n n

?

?

n n n

Process information from secondary sources to describe recent discoveries of

elements.

Recent discoveries of elements: element 118 (Uuo Ununoctiom) produced from fusion of

86

208

295

1

36 Kr 82 Pb118 Uuo Ununoctiom 0 n [krypton ion beam accelerated by electrical and magnetic

fields into lead target by team at Berkley national lab June '99]. Six alpha decays 106Sg

(Seaborgium).

Use available evidence to analyse benefits and problems associated with the

use of radioactive isotopes in identified industries and medicine.

Benefits and problems of the use of radioisotopes

Benefits

Problems

allows treatment and tracing of

requires nuclear reactors:

medical illnesses and problems

accidents of operation

allows development in chemistry

emissions produced and disposed

allows safer, and longer-lasting

radioactive waste

foods

can cause damage to organisms if

production of materials (with

not used and stored safely

thickness gauges)

(infection, cancer, tissue damage)

leak detection tracing

in medical diagnosis, waste needs

medical sterilisation

to be removed quickly, due to

smoke alarms

chemicals formed