Cinnamate modified the application of UV absorbers

advertisement

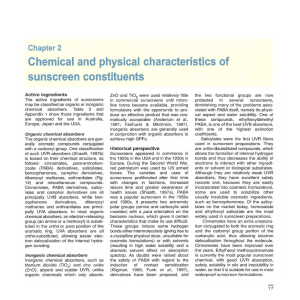

Cinnamate modified the application of UV absorbers Disinfection with ultraviolet light, physical health, promote vitamin D synthesis and other functions beneficial to humans, but, UV also brought a lot of harm to human beings. Now commonly used UV absorbers include salicylic acid esters, the amino acid esters, Benzophenone, p-methoxy cinnamic acid esters, benzotriazole, instead of acrylonitrile type, diphenyl formyl methane. These UV absorbers have been widely used in various polymer materials, sunscreen cosmetics, anti-UV fabric, UV coatings and many other fields. However, UV absorbers are small molecules, in the application process there are disadvantages: Mostly UVB areas UV absorbers, light thermal stability; When used for cosmetic anti-poor water resistance, sweat, easy loss, irritation, allergy prone skin; When applied to polymer compatibility is poor, the polymer molding and extrusion processing, storage, use may evaporate from the plastic, migration, leaking, and some heat, poor weather, but also may reduce polymer strength, when applied to textiles is not easy fixing, easy to spread, poor wash fastness, may cause skin allergy. To overcome these shortcomings of conventional UV absorbers, researchers in Isotope Institute of Henan Academy of Sciences, with cinnamic acid derivatives and γ-chloropropyl trimethoxysilane the main raw material for the synthesis of the seven groups containing reactive organic silicon-based UV absorbers. By NMR, 13C NMR, IR, its structure was identified by its UV absorption properties of UV analysis, found that p-methoxy cinnamic acid trimethoxy-acrylic ester is an ideal area of UVB ultraviolet reactive absorbent; 4-- dimethylamino-trimethoxy-acrylic acid ester is an ideal reactive UV absorber UVA area. The two mixtures, can form an excellent full-band (280 ~ 400nm) reactive UV absorbers. Further experiments found that the UV absorbent compound there are several good application the following: 1, by spraying or dipping the surface treatment method of the receptor, and then by heating, irradiation, etc. to the surface of the receptor molecule chemical reactions, thereby permanently firmly with the receptor surface.This way can be easily prepared by UV glass, UV glasses, anti-UV fabric and UV aging of rubber products. As the production process is simple and limited to surface treatment, it can significantly reduce costs;2, the use of the product and D4 copolymerization with UV absorbers of polysiloxane side groups, can be easily applied to preparation of sunscreen cosmetics, and thus reduce or even eliminate the irritating chemical sunscreen class, improve the anti-sweat water resistance; 3, the use of the product of the inorganic sunscreens, can be easily used to prepare a variety of high SPF sunscreen cosmetics. 4, through the blending method for the preparation of UV aging of rubber and plastic products and UV coatings, due to the presence of organic silicon coupling agent, product compatibility and the strength of the final products, will greatly increase the water resistance.