ENHANCEMENT OF COMPRESSIVE STRENGTH PROPERTIES

advertisement

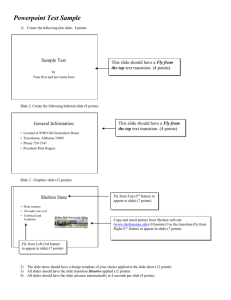

AU J.T. 14(2): 139-146 (Oct. 2010) Pozzolanic Influence of Fly Ash in Mobilizing the Compressive Strength of Lateritic Soil Agapitus Ahamefule Amadi Department of Civil Engineering, Federal University of Technology Minna, Nigeria E-mail: <agapitusahamefule4@yahoo.com> Abstract Soil mixtures with varying fly ash contents (0, 5, 10, 15 and 20%) prepared at moulding water contents ranging from dry to wet of optimum moisture content and compacted with British Standard Light (BSL), West African Standard (WAS) and British Standard Heavy (BSH) compactive efforts were tested to determine shear strength using unconfined compressive strength. Peak compressive strength values of soil mixtures cured for 28 days were about 2 folds higher than the compressive strength of the natural soil regardless of the compactive effort used. While BSL compactive effort attained peak strength on application of 10% fly ash, BSH and WAS efforts achieved peak strength value at 5% fly ash content. Expectedly, reductions in strength values were observed as the moulding water content increased from dry to wet of optimum even as the maximum strength realized in all compacted soil mixtures occurred at moisture content 2% below optimum moisture content (OMC). Furthermore, it was revealed that curing improved the strength of soil mixtures. Strength gain after a period of 28 days curing was relatively low which could be attributed to insufficient calcium oxide in the fly ash to sustain the formation of significant cementitious products. Consequently, further tests with calcium based admixtures such as lime are suggested. Keywords: Moulding, stabilization, compactive efforts, cementitious products. seasons and continually leached by rainwater causing a tendency for deterioration of its strength characteristics. The structural elements in the soils are often a less stable coarsegrained aggregation of variable strength which may break down in performance. Furthermore, their varying silt and clay content often render them moisture sensitive. (Maigien 1966; BRRI/Lyon Associates 1971; Ola 1978; Charman 1988; Nicholson and Kashyap 1993). The aforementioned properties give indication of their limitations in engineering applications or at best are restricted to minor engineering projects. Common practice is to excavate and cart away such materials and/or to import large quantities of select fill material, both costly remedies. A more economic solution for improving the performance characteristics of such problematic lateritic soils for development and construction purposes is by appropriate stabilization, which among other things enhances cementation of aggregates, increases Introduction Originally, utilization of lateritic soil was only discussed in connection with mining of solid minerals such as Iron, Aluminum, Bauxite, and Manganese (Maignien 1966). Later, the civil engineering aspect mostly in connection with road pavements, dams, embankments, buildings became the subject of numerous studies. Considering the vast areas and abundance of lateritic soil in the tropics and the present use of the soil, it is the apparent that the diverse engineering potential of this soil is utilized only to a very small extent. Among the numerous questions that must be answered in order to utilize this soil to the full extent of its potentials are mainly directly related to the strength properties. Lateritic soils are weathered under conditions of high temperatures and humidity with well-defined alternating wet and dry Technical Report 139 AU J.T. 14(2): 139-146 (Oct. 2010) its strength, reduces the sensitivity of the soil to moisture changes and subsequent loss of strength. Lateritic soils have been traditionally stabilized by cement and/or lime but the current drive towards sustainable development requires that fewer wastes be generated and whenever possible the wastes that are generated be reused in some other applications. This has given an incentive to evaluate the beneficial reuse of fly ash, an industrial by product of power plants as a soil stabilizer by several researchers. The improved engineering properties of compacted lateritic soil resulting from the addition of fly ash may be very appropriate in this direction as it brings environmental and economic benefits. The purpose of fly ash addition is to ensure that there will be enough pozzolans in the soil mixtures to combine with the silica and alumina components of the lateritic soil in both short and long term chemical reaction to form insoluble cementitious compounds made up of hydrated calcium silicate gel (CSH) and calcium aluminate gel (CAH). Such compounds as shown in Eqns. 1 and 2 are capable of producing strong permanent matrices and the soil mixtures are transformed into a new material that exhibits significant permanent strength. It is also expected that other engineering problems of low grade lateritic soils will be substantially alleviated by the use of this additive: Ca 2OH SiO 2 CSH (1) , fly ash on strength properties of lateritic soil with a view to exploiting the great possibilities that the soil offer in engineering construction. Materials and Methods Study Soil The study soil was obtained by disturbed sampling from a borrow pit at depths of between 1.0 and 2.0 m in Shika, Zaria (Latitude 11o15’ N and Longitude 7o45’ E) Nigeria. The soil is reddish brown in colour and the clay mineral identified in soil sample is primarily kaolinite. The properties and oxide composition of the soil are shown in Tables 1 and 2. Table 1. Properties of soil mixtures. Properties Natural Moisture content (%) Specific gravity Liquid Limit (%) Plasticity Index (%) Linear shrinkage (%) USCS classificat ion pH Color gel Ca 2OH Al 2 O3 CAH . (2) gel Much data is available on fly ash, soil stabilization with fly ash, the mechanism of strength development and are extensively covered in various papers and studies (Usmen and Bowders 1990; Edil et al. 1992; Chu and Kao 1993; Ferguson 1993; Keshawarz and Dutta 1993; Maher et al. 1993; Nicholson and Kashyap 1993; Smith 1993; Consoli et al. 2001). But because of variability in soil behaviour, it will be technically inappropriate to extrapolate results obtained from testing one type of soil to another. The present study therefore was undertaken to provide research data demonstrating the influence of pozzolanic Technical Report Dominant Clay Mineral 0 5.80 Fly Ash content (%) 5 10 15 - 20 - 2.76 2.66 2.55 2.49 2.42 42.20 36.50 34.00 31.24 29.53 22.22 15.87 12.06 7.78 3.54 9.50 7.82 6.70 4.56 2.88 CL CL CL CL ML 6.67 Reddish brown Kaolinite 8.14 8.60 8.80 9.20 Fly Ash The fly ash used in this study was obtained from an old stockpile at Oji River thermal station, Enugu State, Nigeria. It is black in color and has a specific gravity of 2.06. Only fractions passing BS sieve No. 200 (75 µm) was used throughout the test without additional treatment. Mineralogical analysis by 140 AU J.T. 14(2): 139-146 (Oct. 2010) Atomic Absorption Spectrometer showed that the fly ash is composed of the following principal constituents presented in Table 2. (Nigerian General Specification 1997; Osinubi 1998). Unconfined Compression Test The unconfined compression test was carried out in accordance with the procedures outlined in BS 1377 (1990) and Head (1994b). The test was conducted on specimens mixed with tap water equivalent to 2% dry of optimum, optimum and 2% wet of optimum moisture content as determined from the three compactive efforts namely, British Standard light (BSL), West African Standard (WAS) and British Standard heavy (BSH) used in this study. Specimens were then extruded from the mould, wrapped in cellophane bags and kept in humid environment for the required curing periods (7, 14, 21 and 28 days). The test was performed on cylindrical specimens having a diameter and length of 38mm and 76mm respectively, which were trimmed from the larger compacted cylinders. The samples were tested in triaxial compression test machine without applying cell pressure. Table 2. Oxide composition of lateritic soil and fly ash. Oxide CaO SiO2 Al2O3 Fe2O3 MgO SO3 MnO2 Na2O K2O Loss on ignition Concentration (%) Lateritic Soil* Fly Ash 0.28 1.78 35.60 46.02 27.40 24.16 24.0 13.68 0.22 1.91 0.85 ND 2.0 0.56 ND 5.31 ND 5.58 1.46 1.3 * Adapted from Osinubi (1998); ND - Not determined. Compaction Test Compaction tests were conducted in accordance with BS 1377 (1990), Head (1994a) as well as Nigerian General Specification (1997) in order to establish the compaction characteristics of laterite soil – fly ash mixtures. Specimens were prepared to include a wide range of compaction conditions and lateritic soil – fly ash mixtures. For specimens that contain fly ash, appropriate soil samples were mixed with varying concentrations of fly ash (0, 5, 10, 15 and 20%) and wetted with tap water and blended to a uniform consistency. Specimens were prepared with three compactive efforts namely British Standard Light (BSL), West African Standard (WAS) or “intermediate effort” and British Standard Heavy (BSH) compaction to represent the range of compactive efforts expected in the field without compaction delay. The WAS compaction is the conventional energy level commonly used in the region and consists of the energy derived from a 4.5 kg rammer falling 450mm onto five layers in a British Standard mould, each receiving ten (10) blows Technical Report Results and Discussion Index Properties The index properties and classification of the natural soil and soil – fly ash mixtures are presented in Table 1. The particle size data for the lateritic soil together with that of fly ash used in this study are presented in particle size distribution curves shown in Fig. 1. Although the soil and the fly ash particle size distribution curves are different, the addition of fly ash improved the gradation characteristics of the lateritic soil by reducing the amount of clay size particles. The aggregation or clusters of clay-minerals and clay-size mineral fragments due to ion exchange at the surface of the soil particles resulted in more stable silt-sand like structures. With increasing percentage of fly ash, the soil becomes more granular in nature. 141 100 90 80 70 60 50 40 30 20 10 0 0.001 Lateritic soil Fly Ash 0.01 0.1 1 10 Maximum Dry Unit Weight 3 (kN/m ) The addition of fly ash to lateritic soil obviously affected the compaction characteristics primarily due to alteration of gradation of soil mixtures. Typical of such mixtures, the maximum dry unit weight decreased with higher fly ash content since the ash is a low specific gravity material (Osinubi et al. 2006). The optimum moisture content on the other hand was raised by the addition of fly ash. This increase could be as a result of the increasing demand for water by the soil mixtures for hydration reaction. The variation of maximum dry unit weight with fly ash content for the various soil mixtures is reported in Fig. 2 while the data in Fig. 3 show the variation of optimum moisture content with fly ash content of soil mixtures. WAS BSH 17 16 15 15 20 Fly Ash Content (%) Fig. 2. Variation of maximum dry unit weight with fly ash content. Technical Report 16 13.5 11 5 10 15 20 Strength development in soil mixtures prepared over a range of moulding water contents (dry to wet of optimum moisture content) after a curing period of 28 days was assessed by plotting values of UCS against fly ash contents as reported in Figs. 3, 4 and 5 for BSL, WAS and BSH compactive efforts respectively. It is readily observed in Figs. 3, 4 and 5 that UCS values increased with higher fly ash content up to the peak values after which there were drops in strength values. Generally, strength values dropped in the region of higher fly ash content after attaining peak value. Excessive fly ash content was probably responsible for these reductions in the UCS. The influence of fly ash in improving the strength of mixtures was evaluated by comparing the measured strength values obtained for the natural soil and lateritic soil fly ash mixtures after 28 days curing period. It is pertinent to note here that curing was not necessary for specimens without fly ash additive. Peak UCS values for specimens prepared at 2% dry of optimum moisture content, optimum and 2% wet of optimum moisture content were about 2 folds higher than that of the natural soil regardless of the compactive effort. These peak strengths were established when 10% fly ash was added in the case of BSL compactive effort (Fig. 4). Unlike 18 10 18.5 Unconfined Compressive Strength (UCS) 19 5 BSH Fig. 3. Variation of optimum moisture content with fly ash content. Compaction Characteristics 0 WAS Fly Ash Content (%) Fig. 1. Particle size distribution curves. BSL BSL 21 0 Particle Size (mm) 20 Optimum Moisture Content (%) Percent Passing AU J.T. 14(2): 139-146 (Oct. 2010) 142 AU J.T. 14(2): 139-146 (Oct. 2010) the BSL compactive effort, which achieved peak strength at 10% fly ash content, WAS and BSH compactive efforts had peak UCS values at 5% fly ash content for dry of optimum as well as optimum compaction (Figs. 5 and 6). 2 UCS (kN/m ) 2300 2% Dry of Opt. Opt. 2% Wet of Opt. 1400 500 2 UCS (kN/m ) 1700 800 1150 950 200 750 0 550 5 10 15 20 Fly Ash Content (%) 350 Fig. 6. Variation of UCS with fly ash content for soil mixtures compacted with BSH effort at the various compaction states. 150 0 10 20 Fly Ash Content (%) Several mechanisms are responsible for strength development in soils stabilized with fly ash. The main generator of strength in the soil mixtures is the pozzolanic cements formed from the reaction of silica and alumina components of clay fractions of the soil with calcium ions and water (Eqns. 1 and 2). Additional strength is mobilized by granular packing in the matrix formed with fly ash acting as filler (Consoli et al. 2001). The data in Figs. 7, 8 and 9 present peak strength values established at the various fly ash contents and strength at the optimum moisture content for the various soil mixtures compacted with BSL, WAS and BSH compactive efforts respectively. These data indicate that peak strength values are generally higher than strength values at optimum moisture content (i.e. maximum dry unit weight). The implication is that moisture control should be based on moisture – strength relationship rather than moisture – density relationship for applications requiring maximum strength. The maximum strengths realized in soil – fly ash mixtures generally occurred at moisture content 2% dry of OMC. Lower UCS values were achieved for soil mixtures prepared on the wet side of optimum moisture content. Fig. 4. Variation of UCS with fly ash content for soil mixtures compacted with BSL effort at the various compaction states. 2% Dry of Opt. Opt. 2% Wet of Opt. 1750 1500 2 2000 1100 1350 UCS (kN/m ) 2% Dry of Opt. Opt. 2% Wet of Opt. 1250 1000 750 500 250 0 10 20 Fly Ash Content (%) Fig. 5. Variation of UCS with fly ash content for soil mixtures compacted with WAS effort at the various compaction states. Technical Report 143 AU J.T. 14(2): 139-146 (Oct. 2010) Effect of Curing Period Peak Strength Strength at OMC UCS (kN/m2) 1400 The trend of strength mobilization with curing time monitored over a period of 28 days for soil mixtures prepared at optimum moisture content is presented in Figs. 10, 11 and 12 for BSL, WAS and BSH compactive efforts respectively. Evaluation of data in Figs. 10, 11 and 12 revealed that the UCS of all soil mixtures improved with time. The strengths achieved after 28 days of curing were considerably (2 - 3 times) greater than those realized for soil mixtures at 7 days. However, it is interesting to note that a significant percentage of this increase was recorded in the first 14 days of curing. This behaviour is suggested to result from the coupled effects of the two main generators of strength in the soil mixtures namely, the structure imparted by compaction and the formation of cementitious matrix in the first 14 days. As curing progressed beyond 14 days, the increase in UCS was at a lower rate, approximately constant in some cases. It is suggested from the behaviour observed in Figs. 10, 11 and 12 that significant pozzolanic reaction could not be sustained after 14 days. This is probably correlated to low content of calcium oxide in the fly ash utilized for this study (Table 1). 1200 1000 800 600 400 200 0 0 5 10 15 20 Fly Ash Content (%) Fig. 7. Peak strengths and strengths at OMC for soil mixtures compacted at BSL compactive effort. Peak Strength 1750 Strength at OMC UCS (kN/m2) 1500 1250 1000 750 500 250 0 0 5 10 15 20 Fly Ash Content (%) Fig. 8. Peak strengths and strengths at OMC for soil mixtures compacted with WAS compactive effort. 900 2 UCS (kN/m ) Peak Strength Strength at OMC 2500 2000 2 UCS (kN/m ) 5% Fly Ash 10% Fly Ash 15% Fly Ash 20% Fly Ash 1100 1500 700 500 1000 300 7 500 14 21 28 Curing Time (Days) 0 0 5 10 15 Fly Ash Content (%) 20 Fig. 10. Effect of curing time on UCS for soil mixtures compacted with BSL compactive effort. Fig. 9. Peak strengths and strengths at OMC for soil mixtures compacted with BSH compactive effort. Technical Report 144 AU J.T. 14(2): 139-146 (Oct. 2010) Fig. 11. Effect of curing time on UCS for soil mixtures compacted with WAS compactive effort. Test results revealed that the unconfined compressive strength of all the mixtures increased with higher fly ash content up to a peak value, beyond which reductions in strength values occurred. The strength reduction is attributed to excess fly ash in the soil mxtures beyond the peak strength values. Results also showed that curing improved strength of fly ash treated lateritic soil. Strength gain was however comparatively low probably due to the low calcium content of the ash utilized which could not maintain adequate pozzolanic reactivity to fully mobilize the compressive strength of the mixture. Further tests with additives such as lime to initiate extensive pozzolanic reaction are suggested. 5% Fly(BSH) Ash Curing 10% Fly Ash References 15% Fly Ash 20% Fly Ash 5% Fly Ash 10% Fly Ash 15% Fly Ash 20% Fly Ash 2 UCS (kN/m ) 1450 1250 1050 850 650 7 14 21 28 2 UCS (kN/m ) Curing Time (Days) BRRI/Lyon Associates. 1971. Laterites and lateritic soils and other problem soils of Africa. An engineering study for USAID. AID/csd- 2164, Baltimore, MD, USA. BS 1377. 1990. Methods of tests for soils for civil engineering purposes. British Standards Institutions, London, UK. Charman, J.H. 1988. Laterite in road pavements. Construction Industry Research and Information Association (CIRCA), Special Publication 47, Westminster, London, England, UK. Chu, S.C.; and Kao, HS. 1993. A study of engineering properties of a clay modified by fly ash and slag. Fly ash for soil Improvement ’93. Sharp, D.K. (ed.). GSP No. 36, ASCE, New York, NY, USA. Consoli, N.C.; Prietto, P.D.M.; Carraro, J.A.H.; and Heineck, K.S. 2001. Behaviour of compacted soil - fly ash - carbide lime mixtures. J. Geotech. Geoenv. Engrg., ASCE 127: 774-82. Edil, T.B.; Sandstrom, L.K.; and Berthoux, P.M. 1992. Interaction of inorganic leachate with compacted pozzolanic fly ash. J. Geotech. Engrg., ASCE 118: 1,410-30. Ferguson, G. 1993. Use of self cementing fly ashes as a soil stabilization agent. Fly ash for Soil Improvement ’93. Sharp, D.K. (ed.). GSP No. 36, ASCE, New York, NY, USA, pp. 1-14. 1800 1400 1000 7 14 21 28 Curing Time (Days) Fig. 12. Effect of curing time on UCS for soil mixtures compacted with BSH compactive effort. Summary and Conclusions The present study is an attempt to assess strength improvements resulting from fly ash stabilization of lateritic soil with a view to adopting it in remedying deficient soils/sites. Compacted soil mixtures with varied amounts of fly ash (0, 5, 10, 15, 20%) prepared at different compaction states equivalent to 2% dry of optimum, optimum and 2% wet of optimum moisture content as determined from the three compactive efforts namely, British Standard light (BSL), West African Standard (WAS) and British Standard heavy (BSH) were tested for unconfined compressive strength. Technical Report 145 AU J.T. 14(2): 139-146 (Oct. 2010) ash for Soil Improvement ’93. Sharp, D.K. (ed.). GSP No. 36, ASCE, New York, NY, USA. Ola, S.A. 1978. Geotechnical properties and behaviours of some stabilized Nigerian lateritic soils. Tropical Soils of Nigeria in Engineering Practice. Ola, S.A. (ed.). A.A Balkema, Rotterdam, The Netherlands, pp. 61-84. Osinubi, K.J. 1998. Influence of compactive efforts and compaction delays on limetreated soil. J. Transport. Engin., ASCE 124(2): 149-55. Osinubi, K.J.; Amadi, A.A.; and Eberemu, A.O. 2006. Shrinkage characteristics of compacted laterite soil - fly ash mixtures. NSE Technical Transaction 41: 36-48. Smith, R.L. 1993. Fly ash for use in the stabilization of industrial wastes. Fly Ash for Soil Improvement ’93. Sharp, D.K. (ed.). GSP No. 36, ASCE, New York, NY, USA, pp. 58-72. Usmen, M.A.; and Bowders, J.J., Jr. 1990. Stabilization characteristics of class F fly ash. Transportation Research Record 1288. Transportation Research Board, Washington, DC, USA, pp. 59-60. Head, K.H. 1994a. Manual for soil laboratory testing. Vol. I. Soil classification and compaction tests. Halsted Press, New York, NY, USA. Head, K.H. 1994b. Manual of soil laboratory testing. Permeability, shear strength and compressibility tests. Vol. 2, 2nd ed., Pentech Press, London, England, UK. Nigerian General Specification. 1997. Nigerian General Specification for roads and bridges, Federal Ministry of Works and Housing, Abuja, Nigeria. Keshawarz, M.S.; and Dutta, U. 1993. Stabilization of South Texas soils with fly ash. Fly Ash for Soil Improvement ’93. Sharp, D.K. (ed.). GSP No. 36, ASCE, New York, NY, USA. Maher, M.H.; Butziger, J.M.; Disalvo, D.L.; and Oweis, I.S. 1993. Lime sludge amended Fly ash for utilization as an engineering material. Fly Ash for Soil Improvement ’93. Sharp, D.K. (ed.). GSP No.36, ASCE, New York, NY, USA. Maigien, R. 1966. Review of research on laterites. Natural Resources Research IV, United Nations Educational Scientific and Cultural Organisaton, Paris, France. Nicholson, P.G.; and Kasyap, V. 1993. Fly ash stabilization of tropical Hawaiian soils. Fly Technical Report 146