Design of Commercial Building In Syracuse

advertisement

Table of Content

S.No.

Title

Table of contents

List of Figures

List of Tables

Acknowledgement

1

Introduction

1.1

General information

1.2

Layout of the report

2

Slab design

2.1

Flat plate design

2.2

Flat slab design

2.3

Slab with interior beam

3

Beam and Column design

3.1

General information

3.2

Edge beams

3.3

Interior beams

3.4

Corner columns

3.5

Edge column

3.6

Interior column

4

Staircase design

4.1

General information

`4.2

Staircase design

5

Shear wall design

5.1

General information

5.2

Shear wall design for staircase

5.3

Shear wall design for elevator

6

Foundation design

6.1

General information

6.2

Footing under column

6.3

Footing under edge column

6.4

Footing under interior column

6.5

Combined footing under two adjacent corner edge

columns

6.6

Staircase foundation

6.7

Shear wall foundation

Page

No

1

1

4

6

19

29

35

35

36

49

66

69

74

79

79

79

93

93

93

99

109

109

109

113

117

120

127

132

i

7

7.1

7.2

8

9

145

145

158

179

180

Retaining wall

General information

Green engineering

Concrete material estimation

References

List of figures

Figure No.

Content

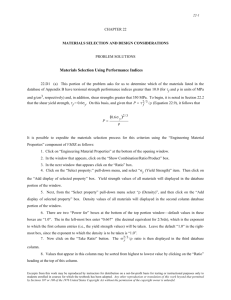

Figure 1.1 Structural feature of the office building

Page no.

1

Figure 1.2

2

The top view of the office building project using

25’x25’ panels

Figure 2.1 The four types of slab for the office building

Figure 2.2 The position of the use of the expansion joint on

each floors

Figure 2.3 The expansion joint (Source by Design Handbook:

section 4 from

Figure 2.4 Panel assignment

Figure 2.5 Bars arrangement

Figure 2.6 Shear check for flat slab with drop panel

Figure 3.1 Panel load share that goes to an Edge Beam

Figure 3.2 Glazing load dispersion diagram

Figure 3.3 Loaded Frame on Axis ((A1-A2-A3-A4- A5)

Figure 3.4

Loading and shear force diagram for beam A1-A2

of the flat plate floor

Figure 3.5 Loading diagram (axis 1B-2B-3B-4B-5B) for the

purpose of calculating additional moments due to

self weight of beam

Figure 3.6 Loading diagram (axis 1B-2B-3B-4B-5B) for the

purpose of calculating shear in internal beams due

to loads from slab

Figure 3.7 Corner column attachment and section of beams

attached to it

Figure 3.8 Load transfer to an edge column

Figure 3.9 Edge Column attachment to slabs/ beams in both

directions

Figure 3.10 Interior Column attachment to slabs/ beams

4

5

6

6

11

20

37

38

40

47

50

50

67

70

71

75

ii

Figure 4.1

Figure 4.2

Figure 5.1

Figure 6.1

Figure 6.2

Figure 6.3

Figure 6.4

Figure 6.5

Figure 6.6

Figure 6.7

Figure 6.8

Figure 6.9

Figure 6.10

Figure 6.11

Figure 6.12

Figure 6.13

Figure 6.14

Figure 6.15

Figure 6.16

Figure 6.17

Figure 6.18

Figure 7.1

Figure 7.2

Figure 7.3

Figure 7.4

Figure 7.5

Figure 8.1

Figure 8.2

Figure 8.3

Figure 8.4

Figure 8.5

Building Plan View

Staircase Plan View

Shear force and bending moment due to wind load

Footing load elements

Corner Footing Bearing Pressure distribution

Corner Footing Critical Sections: a) two way shear

, b) one way shear and c) bending moment

Edge footing Bearing Pressure distribution

Edge Footing Critical Sections: a) two way shear ,

b) one way shear and c) bending moment

Interior footing Bearing Pressure distribution

Interior Footing Critical Sections: a) two way

shear , b) one way shear and c) bending moment

Common footing Bearing Pressure distribution

Common Footing Critical Sections: a) two way

shear , b) one way shear and c) bending moment

Load at typical floor on wall

Critical section for shear

Critical section for shear

Plan of shear wall & vertical forces acting on

footing

Plan of footing integrated with beams 1, 2, 3

showed in red hatch

load & reactions on strip A

load & reactions on Beam 1

load & reactions on Beam 2

load & reactions on Beam 3

Example of Retaining Wall

Drainage system in retaining wall

Free body of soil & pressure

Footing Details

Critical section for shear in toe

Increases in Environmental Regulation

Graphs on Emission in Industrial

Typical Unitized Curtain Wall Systems

Typical Unitized Curtain Wall System Assembled

product

Typical Unitized Curtain Wall System Air Vapor

Barrier

79

81

94

109

110

110,112

114

114,115,116

118

118,119

121

123,124

127

129

130

132

134

134

137

139

141

145

146

147

151

155

163

164

169

169

171

iii

Figure 8.6

Figure 8.7

Figure 8.8

Figure 8.9

Figure 8.10

Figure 8.11

Load Transfers

Glass Panel Sizes at different floors

Components of Roofing System

Positive Drainage for healthy roots

Fixing Method

Scheme representation of Sewage Treatment Plant

174

175

177

178

178

180

List of Tables

Table 2.1

Table 2.2

Table 3.1

Table 3.2

Table 3.3

Table 3.4

Table 3.5

Table 3.6

Table 3.7

Table 3.8

Table 3.9

Table 3.10

Table 4.1

Table 5.1

Table 7.1

Table 8.1

Table 8.2

Description of different types of panel

Minimum thickness of slabs without interior beams

(ACI table 9.5c)

Summary of loading on Edge Beams

Design Moments from SAP analysis output for frame

on Axis ((A1-A2-A3- A4- A5)

Design Moments for internal beams on axis 1B-2B3B-4B-5B

Design Shear forces for internal beams on axis 1B2B-3B-4B-5B

Corner column loading from frame analysis

Design Loads Summary and Reinforcement provide

for a Typical Corner

Column

Acting design loads before magnification for edge

column

Design Loads Summary and Reinforcement provided

for a Typical Edge Column

Acting Column Axial loads for an interior column

Design Loads Summary and Reinforcement provided

for a Typical interior Column

Detailing of reinforcement

Specification of elevators

Vertical forces and moment acting at the toe of the

footing

Materials considered in green engineering

Glass weight

7

10

39

40

51

51

66

69

71

74

75

77

88

102

149

161

169

iv

Acknowledgment

Our deepest gratitude goes to Prof Riyad S. Aboutah for his continuous and constructive

advise and follow up. His successive advisories and comments were the pillars in our

every step during the design process of the building and its comments. We are thankful

to him for the fact that he has inspired and helped us know about the ACI Code, the

concepts and ways of analysis and design of Shear walls, staircases, beams, column,

foundations and retaining walls.

We are also thankful to our peers who helped us in one way or another in bringing this

project into the shape it has assumed now.

v

1. Introduction

This is a report for a design project of a three-story office building which is located in the

city of Syracuse, New York. The main structure of the office building project is wholly

made of reinforced concrete. The height of the building is 58 feet, and story heights of

each floor are as specified in Figure 1.1 Each panel size of the building is 25’x 25’.

Figure 1.1: Structural feature of the office building

In addition, the building is designed for fire safety purpose by having two staircases

situated at both corners of the building. For the convenient usage, the building is also

comprised of two elevators and two freight elevator in the middle part of the building.

Moreover, the outside parts of property include the parking lot, and retaining wall with

the height of 10 feet run through the edge area of the property. This is illustrated in the

figure 1.2 in the next page

1

Figure 1.2: The top view of the office building project using 25’x25’ panels

The flooring system used in the design of the building is fashioned in such a way that the

design project will give an opportunity to design different slab types. In line to this, slabs

of flat plate type on the top floor, slab of flat slab type on the middle floor and slabs with

interior beams on the first floor are used. On the top of the building along the peripheries

there is a 1-ft high parapet wall. At the edges of the panels of staircase and elevators,

shear wall will be incorporated for the design from the roof slab through ground slab. The

thick square lines at the panel edges represent shear wall to be used. On the roof slab, a

mechanical room is placed next to the two elevators in the same panel.

Furthermore, as green engineering is becoming a big concern for the recent world

environment, the design the building intends to include the aspects of the use of green

roof at the top of the building (roof slab), glass panels placed outside on all sides of the

building and Sewage Treatment Plant which gives the clean water as required for clean

environment. In Building Sewage Treatment plant is fixed at the parking lot as it is a

2

modular system .Apart from that few finishes items are explained like waterproofing,

Paints were its advantages to the environment are explained

Throughout this project design a concrete strength capacity of 6000 psi and the steel

strength capacity of 60000 psi are used. The design procedures are pertinent to those

specified in the ACI-318 code and international building code design.

Nonetheless to mention, aesthetics as an integral part of a building design, though not

thoroughly dealt, has been tried to be incorporated. For this aspect, glass walling has been

used as façade for the external part of the building. Material use estimation with a focus

on concrete usage is also a part of the design project.

The report is organized in such a manner that it will have flow when read. The second

chapter is devoted to the design of slabs. Chapter three presents the design of beams and

columns followed by design of stair case and shear wall in chapter four. In chapter six

designs of foundations for the building and the shear walls is addressed. The green

engineering and aesthetics part is included in chapter eight proceeded by retaining wall in

chapter six. At the end comes the Concrete estimation followed by references.

3

2. Slabs Design

2.1

General information

This office building uses the different type of design on each slab. Therefore, four types

of slab will be used as specified by a plan requirement. These four slabs are designed

using two-way slab systems, direct design method. A flat plate is used for a design for a

roof slab which has supporting beams running over along the edge of the roof slab. Next,

a flat slab is implemented for a design for the second floor. It also has supporting beams

running over along the edge of the floor like the way it is done on the flat plate. However,

they are different in that the flat slab makes a use of drop panels on the top of columns

supporting the flat slab, resulting in a use of a less slab thickness than that of flat plate.

For the first floor, the slab with interior beams is used. In this case, supporting beams at

four sides of each panel squarely connect all the columns below the slab. Finally, the

ground slab is designed to be used on the first floor of the building. The illustration of the

slab design is shown below.

Figure 2.1: The four types of slab for the office building

4

Moreover, expansion joint is provided for this building. Due to the temperatureproduced change, a potential impact is likely to occur to the office building. The

utilization of the expansion joint brings a benefit for the office building in terms of the

structural integrity and building serviceability. Before the concrete is placed, the

expansion joint will be constructed by installing pre-formed or pre-molded

elastic/resilient material. The thickness of such material to be incorporated at edge of

slabs is half inch with the wideness of each slab types. Once the material has been

inserted, the brass or bronze cover plate will be attached. The feature below shows the

use of expansion joint at the interior edges of the office building on each floors and a

feature example of this usage.

Figure 2.2: The position of the use of the expansion joint on each floors

5

Figure 2.3:

The expansion joint (Source by Design Handbook: section 4 from

http://www.copper.org/homepage.html)

2.2

Flat plate

Figure 2.4: Panel Assignment

6

The slab has been divided into panels (as indicated) for the purpose of design

using the Direct Design Method as adopted by ACI Code. The axis coordinates have also

been assigned to the top view of the building plan in order to show the direction of the

particular strips to be considered in the calculation using excel sheet. The particular

description of the panels are as detailed in the next page.

Table 2.1: Description of different types of panel

Panel 1

An exterior ( but not on the corner) panel in

An exterior corner panel, both of its exterior

which its exterior side is support on edge beam,

edges are supported on edge beam

which runs over the exterior columns

Panel 2

Fulfills the requirements stated for direct design

Fulfills the requirements stated for direct design

method as per ACI Code

method as per ACI Code

Panel 3

Panel 4

An interior panel

Fulfills the requirements stated for direct design

method as per ACI Code

An exterior panel like with support conditions

like Panel 1

Does not meet, the requirement for the presence

of at least three continuous panels

direction

7

each

Preliminary design of minimum column dimension

In order to obtain a value of (ln) , the preliminary column dimension must be determined.

The typical column considered is an interior column with the following tributary

area.

Assume the depth of slab to be 8 inches.

Loads on this tributary area include snow load, live load, dead load, rain load.

Rain load, RL

=

62.5 psf

Snow load, SL

=

46.2 psf

Roof Live load, Lr =

12.0 psf

Dead load

=

150 lb/ft3 *(8/12) ft = 100 psf

Topping load

=

20 psf

Live load

=

50 psf

Finishing load

=

20 psf

Load combination (preliminary)

This formula below is used to determine the combination of loads (ACI code 9.2)

U

=

1.2(DL+ FL + TL) +1.6*(LL+HL) + 0.5[max (Lr, SL,RL)]

=

1.2(100 + 0 + 20) + 1.6(0 + 0) + 0.5*62.5

=

175.25 psf

=

1.2(100 + 20 +0) + 1.6(50 + 0) + 0.5 (0)

=

224 psf

For flat plate

U

For flat slab

U

For slab with beams

8

U

=

1.2(100 + 20 +0) + 1.6(50 + 0) + 0.5 (0)

=

224 psf

Load on Column

Pu

=

0.80 [0.85

(Ag -Ast) +

Ast]

=

specified constant by code = 0.7 for tied columns

=

6,000 psi

=

60,000 psi

Assume Ast is equal to 1.5% of Ag = 0.015 Ag

For flat plate,

P

=

175.25 * (25’*25’)

Pu

=

1.5* P = 1.5 * 109.53 = 164.3 kips

164.3 =

= 109.53 kips

0.7 *0.8 [0.85 * (6,000/1,000) * (Ag -0.015Ag) + (60,000/1,000) *

0.015Ag]

Ag

=

50 in2

Required column size = 7” x 7”

For flat slab,

Pu

368.7 =

=

164.3 + 1.5[218 * (25’*25’)] =

368.7 kips

0.7 *0.8 [0.85 * (6,000/1,000) * (Ag -0.015Ag) + (60,000/1,000) *

0.015Ag]

Ag

=

111.15 in2

Column size = 11” x 11”

For slab with beams,

Pu

573.07 =

=

368.7 + 1.5[190.25 * (25’*25’)]

=

573.07 kips

0.7 *0.8 [0.85 * (6,000/1,000) * (Ag -0.015Ag) + (60,000/1,000) *

0.015Ag]

Ag

=

172.76 in2

Column size = 14” x 14”

9

As a result, the column size to be used is 14”x 14” in the design for flat plate, flat slab,

and slab with beams.

Depth requirements

For the specified design concrete strength, as per ACI (table 9.5c) the minimum

thickness required for flat slab and flat plate is

Table 2.2: MINIMUM THICKNESS OF SLABS WITHOUT INTERIOR BEAMS (ACI

table 9.5c)

fy, psi

Without drop panels

Exterior panels

With drop panels

Interior

Exterior panels

Interior

panels

panels

With edge

Without

With edge

Without

beams

edge

beams

edge

beams

60000

ln/33

ln/30

beams

ln/33

ln/36

ln/33

ln/36

Minimum slab depth requirement for flat plate

hmin

=

ln/33 ;

ln

=

25-(14’/12’) = 23.833’

=

23.833/33

=

0.722’ = 8.667”

As a result, we try hmin = 9 inches.

New design load for roof flat plate

DL

= 150 * (9/12) = 112.5 psf

Ud

= 175.25 + 1.2 (112.5 – 100) = 190.25 psf

With the green roof load, an additional load of 30 psf is included.

Ud

= 190.25 + 1.2 (30)

= 226.25 psf

Static Moment for all panels of flat plate

Mo

= (Ud l1 ln2)/8

(ACI code 13-4)

= 226.25 * 25 * [25-(14/12)2] / (8*1000) = 401.613 ft-k

10

Consider bar arrangement as follows

Figure 2.5: Bars arrangement

dx= depth for bars spanning in x-direction

dy = depth for bar spanning in y-direction

For an assumed j=0.925, compute trial area As, at a section of maximum moment, in this

case (first interior negative column strip) with Mu = 210.85 ft-kips

Shear check for flat plate

Bars # 5 are used for reinforcement.

dx = 9-3/4-(0.625/2) = 7.9375”

dy = 7.9375 – 0.625 = 7.3125”

dav = (7.9375+7.3125)/2 = 7.625”

b0 = (2) (14” + 7.625”) + (2) (14”+7.625”) = 86.5”

Vu

ØVc

=

[(25’*25’)-{(14”+7.625”)/12}2]*(226.25/1000)

=

140.827 kips

=

=

Ø4

*b0 * d

(0.85) * 4 *

=

173.704 kips > 140.827 kips OK

(ACI code 11-35)

* (86.5) * (7.625)/1000

11

12

13

14

15

16

17

18

2.3

Flat Slab

Depth requirement

From table 2.2, minimum slab depth requirement for flat slab

hmin

=

ln/36 ;

ln

=

25-(14’/12’) = 23.833’

=

23.833/36

=

0.662’ = 7.944”

As a result, we try hmin = 8 inches.

This thickness is the same as one assumed before. Therefore, Ud remains the same as one

calculated from the preliminary design for a column dimension.

Ud

=

224 psf

Static Moment for all panels of flat slab

Mo

= (Ud l1 ln2)/8

= 226.25 * 25 * [25-(14/12)2] / (8*1000) = 401.613 ft-k

Note:

Height of drop panel >= ¼ of slab thickness

Width of drop panel extension on each side >=1/6 of span length measured

center-to-center of supports

f for each beam is considered the smallest value 0.8

19

Shear check for flat slab with drop panel

Figure 2.6: Shear check for flat slab with drop panel

There are 2 critical sections for slab with drop panel (dash line)

h

=

8”

hd

≥

h/4

8”/4

=

2”

Therefore, the thickness of drop panel = 8” + 2”

=

10”

;

hd

=

Assume bar #5 to be used for reinforcement.

Determine d1

d1

=

10” –

– 0.625”

=

8.625”

Determine d2 by using

dx

=

8”-3/4-(0.625”/2)

=

6.9375”

dy

=

6.9375” – 0.625”

=

6.3125”

d2

=

(6.9375”+6.3125”)/2 =

L/6

=

25’/6 =

6.625”

4.167’

Consequently, use 4.2’ for a length of drop panel from the center of the column.

20

Check shear at the edge of drop panel

b0

Vu

ØVc

=

2[(4.2’*12”) + (6.625”)] + 2[(4.2’*12”) + (6.625”)]

=

228.1”

=

[25’ * 25’ – {4.2’+ (6.625”/12”)} 2] * (224/1000)

=

134.942 kips

=

(0.85) 4

=

(0.85) 4

=

397.984 kips > 134.942 kips OK

b0 d

* 228.1” * 6.625”

Check punching shear at the column

Since the drop panel is thicker than the thickness of flat slab, the adjustment must be

implemented.Therefore, The new U for the section over the drop panel

Upanel =

b0

Vu

224 psf + 1.5 * 150 psf * [(10”-8”)/12]

=

261.5 psf

=

2(14”+8.625”) + 2(14”+8.625”)

=

90.5”

=

[(25’*25’ – 4.2’*4.2)*224/1000’] + [4.2’*4.2’ –

{(14”+8.625”)/12”}2]261.5/1000

Vc

=

139.732 kips

=

(0.85) 4

=

205.571 kips > 139.732 kips OK

* 90.5 * 8.625/1000

For a flat slab, the slab thickness to be used for design is 8”.

Ud = 224 psf

Static moment = 397.619 ft-k

21

22

23

24

25

26

27

28

2.3

Slabs with interior beams between columns

In order direct design method to be applicable the following condition shall be satisfied

(ACI 318 section 13.6.1.6)

0.2≤

where

Step 1 : Slab thickness and beam size:

If

>1 for all beams all the shear is transferred to the columns by beams, making it

unnecessary to check shear while selecting the slab thickness

Assume all beams to have sizes of 14 in width and 20 in depth

The calculated α for both the edge and interior beam respectively are 1.86 and 2.1

respectively and this satisfy the above condition no shear failure checking required

for slabs

Corresponding average α values for a corner panel and interior panel are then

The slab thickness will be determined by the thickness of the interior panel

But not less than

Therefore the assumed h= 7 inches can be comfortably selected as the thickness of the

slab with interior beams running between columns

29

Loading , based on h= depth of slab 7 in considered

U= 1.2 (150*7/12+15) +1.6*(50) =203 Psf

Design static bending moment, Mo

The design static moments for edge strips and interior strips are

Edge strip

L2= 12.5+ (4/12) = 12.83 ft ln= 25 ft

Interior strip

l2= 25 ft ln= 25 ft

Reinforcement Calculation

Assume bar # 5 is used , the depths, d, in the orthogonal direction are

dx= depth for bars spanning in x-direction

dy = depth for bar spanning in y-direction

For an assumed j=0.925, compute trial area As, at a section of maximum moment,

in this case (first interior negative middle strip) with Mu=-64.43 ft-kips per 12. Ft

length

30

=2.915 in2

Compute a and a/d and check ρ≤ 0.75 ρb

For ρ= 0.75 ρb from a table a/d= 0.444, the value obtained above is much less than this

hence the slab thickness is safe against bending.

Maximum spacing of shrinkage reinforcement in slabs

18in

Smax=

i.e Smax=18 in

2h

31

32

33

34

3. Beam and Column Design

3.0 General Information

The beam and column design is done as per the requirements of the ACI code and

particular procedures has been adopted from the book “Reinforced Concrete: Mechanics

and Design” by James G. Macgregor, second edition.

The beams designed include the edge beams in all floor and the interior beams in the first

floor. In designing the columns, however, the regularity of the building both in plan and

elevation has been considered in selecting representative columns. The panel dimensions

are all the same between columns. This condition of the building integrity has made it

easy in selecting representative columns, in which only these representative columns are

designed and duplicated every where in the building where the category falls into.

Accordingly, each column of the building will fall in any one of the following three

categories. Moreover, as the frames are braced by shear walls as indicated in plan, the

frame is considered as braced against side sway.

Category one: A corner column

This column is found in corner of each of the building units separated by expansion joint.

This column is subjected to a biaxial bending which is attributed to the bending actions

coming from the frames in each direction but balanced in opposite directions.

Category two: An edge column

This column is found on the periphery of the building units and is subjected to a small

amount of bending in one direction and a substantial amount of bending in the other

direction (that accounts to the bending due to an interior frame that joins the edge column

and which not balanced on the other side)

Category three: An interior column

Pertaining to the uniformity in panel dimensions of the panels surrounding an interior

column, the unbalanced moments that are transferred to an interior column is

35

insignificant. Thus, this column will be designed for an axial loading and minimum

moments that will take care of accidental eccentricities.

3.1 Edge Beam Design

The Edge beams designed include those beams on axes namely: Axis (A1- A2-A3-A4A5), Axis (5E-5D-5C-5B-5A), Axis (1A-1B-1C-1D, Axis (B6-B7-B8-B9-B10), and Axis

(6B-6C). The choice of axes for design covers all the edges on all the three floors and the

design have been made separately, for each floor as the loading is different.

Flat plate Edge beam Design

The flat plate edge beams are subjected to the following loads

Share of the Bending moments in the edge column strips of the slab analysis by

direct design method

Weight of the stem of the beam

Weight of the 1ft high parapet wall

Loads due to the glass wall claddings

For easiness of analysis, the bending moments from the column strips has been

alternatively considered by just analyzing the beam by subjecting to a load share of the

slab weight and floor loading of each panel adjacent to the beam. The load share to each

beam from a particular panel is as shown in figure 3.1 below. This approach of loading

the beam results in a slightly magnified moment as compared to the moments computed

using the direct design method of the ACI code.

36

Where

w= 12.5 ft * Pu ( panel )

w = 12.5 ft * 226.25 lb / ft 2 *

1k

2.82k / ft

lb

Figure 3.1 Panel load share that goes to an Edge Beam

The thickness of parapet wall (assuming made of concrete) has been decided based on a

guideline obtained from (www.carryduff.designes.co.uk/ technical/limiting-height-ofchimney-and-parapet-walls.html). As per this guideline;

For 1ft high parapet wall the thickness of wall t= 6 in

Factored Dead load of parapet wall

= 1.2*12in *6in *

150lb 1 ft 2

1k

k

*

*

0.09

3

2

ft

144in 1000lb

ft

Factored Dead weight of the beam stem/web (on the assumption that the total

depth of the beam is 16 in and its width is 12 in). For instance, the thickness of the

flat plate is 9 in, which has been already included in the floor loading, the

corresponding beam stem load will be

150lb 1 ft 2

1k

k

= 1.2*12in *7in * 3 *

*

0.11

2

ft

144in 1000lb

ft

Similarly for the edge beams in other floor the factored beam stem loads will be

o on the edge beams on the floor with flat slab ( thickness of slab = 8 in)

= 0.11

k 8

k

* 0.125

ft 7

ft

o on the edge beams of the floor slab with beams ( thickness of slab = 7 in)

= 0.11

k 9

k

* 0.141

ft 7

ft

37

The Glass curtain wall is assumed to be made from a 10mm (3/8 in) thick insulating glass

unit paneled into vertical mullions which are 5ft apart on center to center and a horizontal

mullion fitted into the vertical mullions to divide the storey glazing into Vision area and

the Spandrel area. The glass curtain wall is hanging from the floor edges beams with

vertical mullions attached to the edge beams. Therefore, the weight of the glass curtain

wall which consists of: the glass itself, vertical and horizontal mullion, capping,

connection to fix it in to the floor edge beams will be transferred into the edge beams as

concentrated loads. However the following approximation has been made to simplify the

load calculations attributed to the difficulty we face in understanding the details of the

connections and finding out the detailed sizes of the vertical and horizontal mullions plus

the capping. Approximations made

o The weights of the connections, horizontal and vertical mullions and

capping are assumed to amount as 50% of the glass weight

o The load transferred to the edge beams is taken as distributed allover the

length rather than concentrated at the points of connections.

The glass loading and its accessories of a given panel along the story height is carried

towards to the top and bottom floor edge beams equally. A diagrammatic representation

of the load transfer is as indicated below.

Figure 3.2 Glazing load dispersion diagram

Load due to glass curtain wall

Weight of a 10mm (3/8 in) glass is 5psf (glass information bulletin)

Weight of connections, mullions, capping = 0.5*5= 2.5 psf

Total weight of glass curtain wall = 7.5 psf

38

Accordingly, the loads due to curtain wall that will go to the edges beams as uniformly

distributed loads will be as shown below, which is also clearly indicated in Table 3.1 that

shows the summary of loading on edge beams

Floor level

Flat plate

Flat slab

Floor with beams

Grade beams

Factored load to beams due to glazing

1.2( 7.5*16/2) =72lb/ft = 0.072k/ft

1.2(7.5*(16/2+16/2)= 144 lb/ft = 0.144 k/ft

1.2(7.5*(16/2+26/2)=189 lb/ft =0.189 k/ft

1.2*(7.5*26/2)=117 lb/ft =0.117 k/ft

Table 3.1 Summary of loading on Edge Beams

Floor level

Due to

parapet wall

Udl- k/ft

Flat plate

0.09

Flat slab

0

Floor with beams 0

Grade beams

0

Factored Design loads

Due to self weight

of beam stem/web

Udl- k/ft

0.11

0.125

0.141

0.251

Due to glass

curtain walls

Udl – k/ft

0.072

0.144

0.189

0.117

Weight from slabs

( triangular)

w (k/ft)

2.82

2.79

2.61

0

In soliciting out the design actions (bending moment and shear forces) for the edge beams

a frame analysis using SAP 2000 is done to analyze the frame consisting of edge beams

from top to bottom. Frame on axis (A1- A2-A3-A4-A5), one of the frame types analyzed,

with full loading is as shown in figure 3.3 below.

In addition the edge beams will be designed for torsion moments which are the negative

exterior column strip moments of the column strips spanning into the edge beams from

the slab analysis using the directed design method.

The output of the frames analyzed for the beams has been hand picked. The outputs taken

are the negative moments at the supports and the span moments plus the shear forces at

each end of the beam. A sample of the outputs selected for the frame on axis (A1-A2-A3A4- A5) is shown in Table 3.2.

39

Figure 3.3 Loaded Frame on Axis ((A1-A2-A3-A4- A5)

Table 3.2 Design Moments from SAP analysis output for frame on Axis ((A1-A2-A3-A4- A5)

Moments (kips-ft)

Beams

@level

Flat plate

Flat Slab

Slab

w/beams

Ground

A1

support

66.75

90.53

74.42

A1-A2

span

76.01

65.43

68.6

A2

support

118.74

110.00

111.71

A2-A3

span

59.64

60.2

57.58

A3

support

103.49

105.26

100.73

A3-A4

span

59.64

60.2

57.88

A4

support

118.74

110

111.71

A4-A5

span

76.01

65.43

68.6

A5

support

66.75

90.53

74.42

18.21

9.77

19.5

9.45

19.29

9.45

19.5

9.77

18.21

40

Reinforcement calculations

Checking assumed depth of beam for moment and shear capacity.

Maximum moment every where in the beams is Mu = 118.79 kips-ft i.e. at the Flat plate

edges beam at support A2

Assuming no compression reinforcement, the minimum depth required is given by

Mu

knbd 2

12000

d

1200M u

; b(in) M u (k ft )

kn b

Assume the values of the steel ratio as follow

0.5b ; b 0.0377 for f c' 6000 psi and f y 60000 psi

0.019

for 0.019 kn 911 j 0.888

d 12.76in

The required over all depth of beam D for the width b= 12 in is then

D= 12.76 in +1.5in (cover) +.375in ( dtirrup)+.5 ( half bar diameter# 8) = 15.135 in

D= 16 in used is ok!

Checking shear capacity

Maximum shear in the beams is Vmax = 22. 18 kips. This shall not be greater than the

maximum allowed shear Vu , which is calculated based on the concrete strength , steel

strength and the depth of the cross-section

Vu= (Vc+Vs) = 2 fc/ bwd 8 f c/ bwd 106.65 kips is greater than the

maximum applied shear so depth is satisfactory and can proceed with design

of

reinforcements.

Longitudinal Reinforcement Calculations

a) Support/ Negative moments (compression on web) – section is rectangular

As

M u (k ft )*12000

;

f y jd

d 16 2.5 13.5in Mu,max = 118.79 k-ft

b= 12 in

and assume j = 0.875

As= 2.24 in2

41

Corresponding a = 2.2 in

Since compression is on the web the beam behaves as rectangular with b= bw= 12 in and

its ductile failure can easily checked that ≤b by checking if a/d ≤ 0.75(ab/d)

a/d = 0.163 ≤ 0.333 ok ( failure is ductile failure)

Using the above value of a re-compute As, this will result in a slightly more

reinforcement than required. Thus,

As

M u (k ft )*12000

0.018M u

f y (d a / 2)

This formula is used to calculate the reinforcements for all support moments.

b) Span/ Positive moments

Mu,max = 76.01 k-ft

Assume that compression zone rectangular and like with in the depth of the slab for the

section of the beam to be considered (that accounts part of the slab as an effective flange)

shown below.

Assuming j = 0.95

M (k ft ) *12000

As u

1.31in 2

f y jd

Then

a

As f y

0.85* f c'b

0.815 in

a< h , therefore the assumption is correct

compression zone lies on the flange

Since compression zone lies all in all on the flange and section of beam beam is

rectangular with b= 19 in it can easily checked that ≤b by checking if a/d ≤

0.75(ab/d)

a/d = 0.06 ≤ 0.333 ok ( failure is ductile failure)

Therefore, for the positive moment regions, As can be calculated from

42

As

M u (k ft )*12000

0.017 M u

f y (d a / 2)

This formula is used to calculate the reinforcement in span of the edge beams. All the rest

of the calculations are done in an excel sheet presented below

Flat Plate Edge beams

Longitudinal Reinforcement

bw(in)= 12

Beam (bw=12 in; d=14.5in)

Support Moment

A1

A2

-66.18

59.8

2.1528

1.2939

0.54

0.54

1.1912 1.2939

-66.18

76.56

1.854

2.1528

1.01062

0

1.01062

0.54

0.54

0.54

2.1528 1.01062

1.854

1.01062

0.54

A5

-119.6

59.8

1.1912

Min. reinf

A4

-103

76.56

Req'd reinf.(in2), span

Reinf Provide

A3

-119.6

Span Moment

Req'd reinf.(in2), supp

d(in)= 13.5

1.19124

1.293864

0.54

0.54

0.54

2.1528 1.293864

1.19124

Bar # used

7

7

8

7

8

7

8

7

7

area of bar

0.6

0.6

0.79

0.6

0.79

0.6

0.79

0.6

0.6

1.9854 2.1564 2.7250633 1.68437 2.346835 1.684367 2.725063

2.15644

1.9854

#bars req'd

bars used

2#7

2#7+1#6 3#8

bw(in)= 12

Beam (bw=12 in; d=14.5in)

Support Moment

1B

-66.02

Reinf Provide

-119.8

1.1884

Req'd reinf.(in2), span

2#8 +1#7

2#7+1#6

-102.8

2.1564

0.54

1.1884 1.2934

1D

-113.06

60.2

1.2934

0.54

2#7

1C

76.53

Min. reinf

2#8 + 1 #6

d(in)= 13.5

1A

Span Moment

Req'd reinf.(in2), supp

2#7

61.22

1.8504

1.01738

0.54

0.54

2.1564 1.01738

2.03508

0 1.034618

0.54

0.54

0.54

1.8504 1.034618

2.03508

Bar # used

7

7

8

7

8

7

8

area of bar

0.6

0.6

0.79

0.6

0.79

0.6

0.79

#bars req'd

bars used

1.9806 2.1556 2.7296203 1.69563 2.342278 1.724363 2.576051

2#7

2#7+1#6 3#8

2#7

2#8 + 1 #6

2#7

2#8 +1#7

43

2#7

bw(in)= 12

Beam (bw=12 in; d=14.5in)

Support Moment

6B

6C

58.44

125.83

Span Moment

Req'd reinf.(in2), supp

72

1.0636

Req'd reinf.(in2), span

2.290106

1.2456

Min. reinf

0.54

Reinf Provide

d(in)= 13.5

0.54

0.54

1.0636 1.2456

2.290106

Bar # used

7

7

8

area of bar

0.6

0.6

0.79

#bars req'd

1.7727

2.076 2.8988684

# bars used

2#7

2#7 +1#6 3#8

Beam (bw=12 in; d=14.5in)

5E

5D

Support Moment

-64.08

-115.04

Span Moment

Req'd reinf.(in2), supp

1.1534

2.07072

0

1.1534 1.2498

57.52

1.79496

0.98071

0

0

-66.42

76.56

2.13228

0 0.972088

0

2.07072 0.98071

5A

-118.46

58.03

1.2498

Min. reinf

5B

-99.72

73.95

Req'd reinf.(in2), span

Reinf Provide

5C

0

1.293864

0

1.79496 0.972088

1.19556

0

0

0

2.13228 1.293864

1.19556

Bar # used

7

7

8

7

8

7

8

7

7

area of bar

0.6

0.6

0.79

0.6

0.79

0.6

0.79

0.6

0.6

1.9224 2.0829 2.6211646 1.63451 2.272101 1.620147 2.699089

2.15644

1.9926

#bars req'd

bars used

2#7

2#7+1#6 2#8 +1#7

2#7

2#8 + 1 #6

2#7

2#8 +1#7

2#7+1#6

2#7

.

Flat Slab Edge beams

Longitudinal Reinforcement

bw(in)= 12

Beam (bw=12 in; d=14.5in)

Support Moment

A1

Req'd reinf.(in2), supp

Req'd reinf.(in2), span

A2

-83.53

Span Moment

d(in)= 13.5

A3

-99.74

59.39

1.5035

-96

55.2

1.79532

1.0037

A5

-99.74

-83.53

55.2

1.728

0.93288

A4

0

59.39

1.79532

0.93288

1.50354

1.003691

44

Min. reinf

Reinf Provide

0.54

0.54

0.54

1.5035 1.0037

0.54

0.54

0.54

1.79532 0.93288

1.728

0.93288

0.54

0.54

0.54

1.79532 1.003691

1.50354

Bar # used

7

7

8

7

8

7

8

7

7

area of bar

0.6

0.6

0.79

0.6

0.79

0.6

0.79

0.6

0.6

2.5059 1.6728

2.272557

1.5548 2.272557 1.672818

2.5059

#bars req'd

bars used

2#7+1#6 2#7

2#8 +1#6

bw(in)= 12

Beam (bw=12 in; d=14.5in)

Support Moment

-83.41

-99.9

59.37

1.7982

1.0034

0.54

2#7

2#8 +1#6

2 #7

1C

1D

-94.84

-101.2

55.45

1.5014

Min. reinf

2#8+1#6

1B

Req'd reinf.(in2), span

Reinf Provide

2#7

1.70712

1.8216

0.93711

0

0.93119

0.54

0.54

0.54

0.54

1.7982 0.93711

1.70712

0.93119

1.8216

0.54

0.54

1.5014 1.0034

55.1

Bar # used

7

7

8

7

8

7

8

area of bar

0.6

0.6

0.79

0.6

0.79

0.6

0.79

#bars req'd

bars used

2.5023 1.6723 2.2762025 1.56184 2.160911 1.551983 2.305823

2#7+1#6 2#7

2#8 +1#6

bw(in)= 12

Beam (bw=12 in; d=14.5in)

Support Moment

Reinf Provide

77.74

2#8 +1#6

59.82

1.4149

1.921192

1.0349

0.54

0.54

0.54

1.4149 1.0349

1.921192

7

7

8

area of bar

0.6

0.6

0.79

# bars used

2#7

105.56

Bar # used

#bars req'd

2#8+1#6

6C

Req'd reinf.(in2), span

Min. reinf

2#7

d(in)= 13.5

6B

Span Moment

Req'd reinf.(in2), supp

2#7+1#6

d(in)= 13.5

1A

Span Moment

Req'd reinf.(in2), supp

1.5548 2.187342

2.3581 1.7248 2.4318886

2#7+1#6 2#7

2#8 +1#6

45

Edge beams on floor slab with interior beams

Longitudinal Reinforcement

bw(in)= 12

Beam (bw=12 in; d=14.5in)

Support Moment

A1

A2

-69.34

Span Moment

Req'd reinf.(in2), supp

A3

-104.5

0.54

0.54

1.2481 1.0955

64.82

1.6938

0.91784

0.54

-69.34

54.31

1.881

1.0955

A5

-104.5

54.31

1.2481

Min. reinf

A4

-94.1

64.82

Req'd reinf.(in2), span

Reinf Provide

d(in)= 13.5

1.881

0 0.917839

0.54

0.54

1.881 0.91784

1.24812

1.095458

0.54

0.54

1.6938 0.917839

0.54

0.54

1.881 1.095458

1.24812

Bar # used

7

7

8

7

8

7

8

7

7

area of bar

0.6

0.6

0.79

0.6

0.79

0.6

0.79

0.6

0.6

2.0802 1.8258 2.3810127 1.52973 2.144051 1.529732 2.381013 1.825763

2.0802

#bars req'd

bars used

2#7

2#7

2#8 +1#6

bw(in)= 12

Beam (bw=12 in; d=14.5in)

1B

-69.4

Reinf Provide

1.881

1.0951

0.54

2 #7

-99.8

55.13

1.6812

0.92156

0.54

0.54

1.2492 1.0951

0.54

1.881 0.92156

1.7964

0 0.931697

0.54

0.54

0.54

1.6812 0.931697

1.7964

Bar # used

7

7

8

7

8

7

8

area of bar

0.6

0.6

0.79

0.6

0.79

0.6

0.79

#bars req'd

bars used

2.082 1.8252 2.3810127 1.53593 2.128101 1.552828 2.273924

2#7+1#6 2#7

2#8 +1#6

bw(in)= 12

Beam (bw=12 in; d=14.5in)

Support Moment

6B

2#7

2#8+1#6

2#7

2#8 +1#6

d(in)= 13.5

6C

64.97

Span Moment

Req'd reinf.(in2), supp

2#7+1#6

1D

54.53

1.2492

Min. reinf

2#8 +1#6

-93.4

64.8

Req'd reinf.(in2), span

2#7

1C

-104.5

Span Moment

Req'd reinf.(in2), supp

2#8+1#6

d(in)= 13.5

1A

Support Moment

2#7

111.56

63.92

1.1825

2.030392

46

Req'd reinf.(in2), span

1.1058

Min. reinf

0.54

Reinf Provide

0.54

0.54

1.1825 1.1058

2.030392

Bar # used

7

7

8

area of bar

0.6

0.6

0.79

#bars req'd

1.9708

# bars used

2#7

1.843 2.5701165

2#7

2#8 +1#7

Design for Shear and Torsion

For the edge beams the analysis results showed that the shear forces at critical sections

are almost the same for all the edge beams in a floor with a slight difference of only

2kips. Therefore all edge beams are designed for the highest shear forces value in the

beams in each floor. The load and shear force diagram for the edge beam with the larger

shear, which is found on the flat plate floor, is as depicted in figure 3.4.

Figure 3.4 loading and shear force diagram for beam A1- A2 of the flat plate floor

Design shear at d distance from face of support is

Vd = 23.1 -.5*(.248*20.5/12+.27)*20.5/12

= 22.5 kips

Design for shear

Vn

Vd

22.5

26.4kips

0.85

47

Check if stirrups are required as per ACI 11.5.5

Vc

2 fcbw d

25.1kips

Vn

26.4kips

is greater than

Vc

2

12.54

Therefore stirrups are required

Check selected stirrups for anchorage and maximum spacing

Try No. 3 double leg stirrups with fy = 60000psi in which case Av= 0.22 in2 . Since the

bar used for stirrups is less No. 6 ACI recommends that the stirrups be anchored by a 900

hook around a bar.As per ACI 11.4.5, the maximum spacing shall be the smaller of the

following

Smax

0.5d 6.75in

d / 4 3.375 if Vn

6 f c' bw d 75.3 kips (not to beused )

f

y Av ,min 60000*0.22 14.7 in

50*12

50bw

Smax = 6.75 in

Compute the required stirrup spacing to resist the design shear forces

For vertical stirrups

s

Av f y d

Vn Vc

.22*60000*13.5

137in

(26.4 25.1)*1000

use double leg # 3 bars at a spacing s=6.75 in all over the beam. As this is the

maximum shear, the same spacing of stirrup is to be used all over the edge beams.

Torsion Consideration at Edge Beams

The torsional constant of the section is given by

x

x

x

2

y max{(92 *19 7 2 *12), (162 *12 7 2 *9)}

2

y max{2127,3198}

2

y 3198in3

48

The torsion moment that acts on the edge beam is equal to the negative moment in the

column strips of the floor system that span into the edge beams. That is the moments at

the exterior supports of the flood system shown in the tables in the slab design section.

For Flat Plate floor edge beams, the maximum exterior negative column strip moment is

114.89 k-ft per 12.5 ft strip

Td =114.89/12.5 = 9.19 k-ft

Check whether torsion reinforcement is required or not

fc/ x2 y .85* 6000 *3198/12000 17.54k ft

Td = 9.19 is less than to 17.54 k-ft , therefore no torsion reinforcement is required .

Thus provide reinforcement for the edge beams as per the specification stated in the

tables below for main reinforcement and provide #3 bar double-legged stirrup @ 6.75 in

center-to-center

3.2 Interior beams

Interior beams are only present at the second floor of the building. The loads to which

these beams are subjected include

o Self weight of the beam

o Floor loads and floor weight

In the analysis of direct design method, the moments from the slabs carried by an

adjacent beam to a column strip of the slab has been calculated during slab analysis.

Therefore the moment due to floor weight and floor loading are picked from the table of

moments done for slab analysis. However, the beams shear forces and additional moment

due to its unit weight need to be calculated in a different manner. For which two different

frame analyses has been done for each axis of beams, one for additional moment

calculation and the other for shear calculation(assumption all the shear is transferred to

the column through shear force in beams). Figures 3.5 and 3.6 show the frame loadings

for axis (axis 1B-2B-3B-4B-5B) for this purpose.

49

Figure 3.5 Loading diagram (axis 1B-2B-3B-4B-5B) for the purpose of calculating

additional moments due to self weight of beam

Figure 3.6 loading diagram (axis 1B-2B-3B-4B-5B) for the purpose of calculating

shear in internal beams due to loads from slab

However, the shear calculated using the diagram in figure 3.6 need to be adjusted by

multiplying by

1l2

l1

if

1l2

l1

1.0 as per ACI 13.6. Therefore the total shear force

used in design for the design of the beam will be the shear force obtained from figure 3.5

50

and the adjusted shear from figure 3.6 . For an interior beam with the beam the value of

1l2

l1

is calculated as follows

3

0.7165* 25

E b a

0.72

f cb f 1l2 l

1

25

Ecs l h

b,ft

h,ft

a

1 0.583333

f

L,slab

1.5

a/h

b/h

1.333333 2.285714 1.714286

α

25

0.716501

The design moments and shear forces for the internal beams on axis 1B-2B-3B-4B-5B

are as indicated in Table 3.3 and Table 3.4 respectively.

Table 3.3 Design Moments for internal beams on axis 1B-2B-3B-4B-5B

Interior

beams

From slab

Due to own

weight

Md, Design

Moment

1B

support

34.75

4.95

1B-2B

span

96.7

4.41

2B

support

118.78

8.21

Moments (kips-ft)

2B-3B 3B

3B-4B

span

support span

59.39 110.3

59.39

3.52

7.14

3.52

4B

support

118.78

8.21

4B-5B

span

96.72

4.41

5B

support

34.75

4.95

39.7

101.1

127

62.91

127

101.1

39.7

117.44

62.91

Table 3.4Design Shear forces for internal beams on axis 1B-2B-3B-4B-5B

Interior beams

From slab ( 1)

Adjusted shear

from slab (1)*0.72

Due to own

weight

Vd , design shear

1B

support

31.2

22.46

2B support

Left

right

37.55

34.82

27

25.1

3B support

left

right

33.93

33.93

24.43

24.43

4B support

left

right

34.87

37.55

25.1

27

5B

support

31.2

22.46

1.62

1.88

1.77

1.73

1.73

1.77

1.88

1.62

24.08

28.88

26.87

26.16

26.16

26.87

28.88

24.08

51

There will no be torsion load in internal beams as the panels on both sides of the beams

are having the same loading and the same dimensions. Therefore the interior beams will

be designed for shear and bending only.

Reinforcement calculations

Checking assumed depth of beam for moment and shear capacity.

Maximum moment every where in the interior beams is Mu = 118.78 kips-ft i.e. at the

support 2B

Assuming no compression reinforcement, the minimum depth required is given by

Mu

knbd 2

12000

d

1200M u

; b(in) M u (k ft )

kn b

Assume the values of the steel ratio as follow

0.5b ; b 0.0377 for f c' 6000 psi and f y 60000 psi

0.019

for 0.019 kn 911 j 0.888

d 12.76in

The required over all depth of beam D for the width b= 12 inches is then

D= 12.76 in +1.5in (cover) +.375in ( dtirrup)+.5 ( half bar diameter# 8) = 15.135 in

D= 16 in used is ok!

Checking shear capacity

Maximum shear in the beams is Vmax = 28. 88 kips. This shall not be greater than the

maximum allowed shear Vu , which is calculated based on the concrete strength , steel

strength and the depth of the cross-section

Vu= (Vc+Vs) = 2 fc/ bwd 8 f c/ bwd 106.65 kips is greater than the

maximum applied shear so depth is satisfactory and can proceed with design

of

reinforcements.

52

Longitudinal Reinforcement Calculations

a) Support/ Negative moments (compression on web) – section is rectangular

As

M u (k ft )*12000

;

f y jd

d 16 2.5 13.5in Mu,max = 118.789 k-ft b= 12 in

and assume j = 0.875

As= 2.24 in2

Corresponding a = 2.2 in

Since compression is on the web and beam section is rectangular with b= bw= 12 inches

and it can easily checked that ≤b by checking if a/d ≤ 0.75(ab/d)

a/d = 0.163 ≤ 0.333 ok ( failure is ductile failure)

Re-compute As

As

M u (k ft )*12000

0.018M u

f y (d a / 2)

This formula is used to calculate the reinforcements for all support moments.

b) Span/ Positive moments

Mu,max = 101.1 k-ft

Assume that compression zone rectangular and lies within the depth of the slab for the

section of the beam to be considered (that accounts part of the slab as an effective flange)

shown below.

Assuming j = 0.95

M (k ft ) *12000

As u

1.743 in 2

f y jd

Then

a

As f y

0.686 in

0.85* f c'b

a< h , therefore the assumption is correct

compression zone lies on the flange

Since compression zone lies all in all on the flange and beamsecion is rectangular with

b= 19 inches and it can easily checked that ≤b by checking if a/d ≤ 0.75(ab/d)

a/d = 0.051 ≤ 0.333 ok ( failure is ductile)

53

Therefore, for the positive moment regions, As can be calculated from

As

M u (k ft )*12000

0.0169M u

f y (d a / 2)

This formula is used to calculate the reinforcement in the span of the interior beams. All

the rest of the calculations are done in an excel sheet presented below

Interior Beams

Beam (bw=12 in; d=14.5in)

Support Moment

Span Moment

Req'd reinf.(in2), supp

Req'd reinf.(in2), span

Min. reinf

Reinf Provide

Bar # used

area of bar

#bars req'd

bars used

Beam (bw=12 in; d=14.5in)

Support Moment

Span Moment

Req'd reinf.(in2), supp

Req'd reinf.(in2), span

Min. reinf

Reinf Provide

Bar # used

area of bar

#bars req'd

bars used

Beam (bw=12 in; d=14.5in)

Support Moment

Span Moment

Req'd reinf.(in2), supp

Req'd reinf.(in2), span

Min. reinf

Reinf Provide

Bar # used

area of bar

#bars req'd

bars used

bw(in)= 12

d(in)= 13.5

B1

B2

B3

-41.75

-130.5

-120.5

103.03

64.3

0.752

2.349

2.169

1.7412

1.08667

0

0.54

0.54

0.54

0.54

0.54

0.752 1.7412 2.349 1.08667 2.169

7

7

8

7

8

0.6

0.6

0.79

0.6

0.79

1.253 2.902 2.9734 1.81112 2.7456

2#6

3#7

bw(in)= 12

8B

-41.75

3#8

2#7

d(in)= 13.5

8C

-130.5

96.72

0.752

1.6346

1.08667

0.54

0.54

0.54

0.54

0.752 1.6346 2.349 1.08667

7

7

8

7

0.6

0.6

0.79

0.6

1.253 2.7243 2.9734 1.81112

2#6

2#7 +1#6 3#8

2#7

64.3

8D

-120.5

8E

-120.5

0.54

2.174

7

0.6

3.624

3#8

2#7

3#8

2#7

3#7

64.3

3#8

2#6

8F

-131

64.3

2.169

8G

-42

96.75

2.349

0.75

1.09

1.0867

1.6351

0.54

0.54

0.54 0.54

0.54 0.54

1.09

2.169 1.0867 2.349 1.6351 0.75

7

8

7

8

7

7

0.6

0.79

0.6 0.79

0.6 0.6

1.81 2.74557 1.8111 2.973 2.7251 1.25

2#8+1#7 2#7

d(in)= 13.5

D3

D4

-120.8

-120.8

64.12

64.12

2.1744

2.1744

1.0836

1.08363

0

0.54

0.54

0.54

0.54

1.0836 2.1744 1.08363 2.1744

7

8

7

8

0.6

0.79

0.6

0.79

1.806 2.7524 1.80605 2.7524

0.752

1.09

1.7412

0.54

0.54

0.54 0.54

1.09

2.349 1.7412 0.752

7

8

7

7

0.6

0.79

0.6

0.6

1.81 2.97342 2.902 1.253

bw(in)= 12

D2

-120.8

2.174

103.03

3#8

2.169

0

0.54

2.169

8

0.79

2.7456

B5

-41.8

2.349

2#8+1#7 2#7

64.3

2.349

B4

-130.5

3#8

2#7 +1#6 3#8

2#7 +1#6 2#6

D5

-120.8

64.1

2.1744

1.08

0.54

0.54

1.08 2.1744

7

8

0.6

0.79

1.81 2.75241

2#7

3#8

54

Beam (bw=12 in; d=14.5in)

Support Moment

Span Moment

Req'd reinf.(in2), supp

Req'd reinf.(in2), span

Min. reinf

Reinf Provide

Bar # used

area of bar

#bars req'd

bars used

Beam (bw=12 in; d=14.5in)

Support Moment

Span Moment

Req'd reinf.(in2), supp

Req'd reinf.(in2), span

Min. reinf

Reinf Provide

Bar # used

area of bar

#bars req'd

bars used

Beam (bw=12 in; d=14.5in)

Support Moment

Span Moment

Req'd reinf.(in2), supp

Req'd reinf.(in2), span

Min. reinf

Reinf Provide

Bar # used

area of bar

#bars req'd

bars used

bw(in)= 12

C1

-41.75

d(in)= 13.5

C2

-130.5

103.3

0.752

C3

-120.5

64.3

2.349

1.7458

1.08667

0.54

0.54

0.54

0.54

0.752 1.7458 2.349 1.08667

7

7

8

7

0.6

0.6

0.79

0.6

1.253 2.9096 2.9734 1.81112

2#6

3#7

3#8

bw(in)= 12

D7

-135.1

2#7

64.3

2.169

2.169

1.09

1.0867

0.54

0.54

0.54 0.54

1.09

2.169 1.0867 2.169

7

8

7

7

0.6

0.79

0.6

0.6

1.81 2.74557 1.8111 3.615

2#8+1#7

2#7

2#8+1#7

D9

-135.1

55

2.4318

0.9295

0.9295

0.54

0.54

0.54

0.54

2.432 0.9295 2.4318 0.9295

7

7

8

7

0.6

0.6

0.79

0.6

4.053 1.5492 3.0782 1.54917

3#7 +1#8 2#7

C5

-121

64.3

2.169

0

0.54

2.169

8

0.79

2.7456

2#8+1#7 2#7

d(in)= 13.5

D8

-135.1

55

2.432

C4

-120.5

3#7 +1#8 2#7

2.4318

0

0.54

2.4318

8

0.79

3.0782

3#7 +1#8

bw(in)= 12

d(in)= 13.5

7B

7C

-7

-198.8

111.25

0.126

3.5784

1.8801

0.54

0.54

0.54

0.54 1.8801 3.5784

7

7

8

0.6

0.6

0.79

0.9 3.1335 4.5296

2#6

2#8 +1#6 4#8 +1#6

Design for Shear

For the interior beams, the analysis results showed that the shear forces at critical sections

are almost the same for all the interior beams in the floor with a slight difference of only

2kips. Therefore all interior beams in the floor are designed for the highest shear force

55

values of 28.88 kips (shear at 2B to the left) at all interior supports and 24.1 kps (shear at

1B) at exterior support.

Vd = is taken to be the maximum shear at support as it not too large compared to shear at

d-distance as seen in the design shear force calculation for edge beams

= 28.88 kips

Design for shear

Vn

Vd

28.88

33.97kips

0.85

Check if stirrups are required as per ACI 11.5.5

Vc 2 fc/ bwd 2* 6000 *12*13.5/1000 25.1kips

Vn =33.97 kps is greater than Vc/2 = 12.55 kips, therefore stirrups are required.

Check selected stirrups for anchorage and maximum spacing

Try No. 3 double leg stirrups with fy = 60000psi in which case Av= 0.22 in2 . Since the

bar used for stirrups is less No. 6 ACI recommends that the stirrups be anchored by a 900

hook around a bar. As per ACI 11.4.5, the maximum spacing shall be the smaller of the

following

Smax

0.5d 6.75in

d / 4 3.375 if Vn

6 f c' bw d 75.3 kips (not to beused )

f

y Av ,min 60000*0.22 14.7 in

50*12

50bw

Smax = 6.75 in

Compute the required stirrup spacing to resist the design shear forces

For vertical stirrups

s

Av f y d

Vn Vc

.22*60000*13.5

20in

(33.97 25.1)*1000

Use double leg # 3 bars at a spacing s=6.75 in all over the beam as governed by the

maximum stirrup spaced for a given depth d. As this is the maximum shear, the same

spacing of stirrup is to be used all over the interior beams.

56

3.5 Beam Reinforcement Detailing/ Drawings

57

FLAT PLATE EDGE BEAMS

FLAT SLAB EDGE BEAMS

58

59

60

EDGE BEAMS ON SLAB WITH INTERIOR BEAMS

INTERIOR BEAMS

61

INTERIOR BEAMS

62

63

64

Notes:

1. Cover to reinforcements 1.5 inches

2. Concrete 6000 psi and steel 60000psi are used

3. all top reinforcements labeled 2#4 are hanging bars

65

3.6 Corner Column (A1)

Column dimensions: 14” x 14”

Table 3.5 shows corner column loads from frame analysis (frame

loading)

Table 3.5 Corner column loading from frame analysis

Column

level

Third story

Second

story

First story

Foundation

column

Axial load

P ( kips)

Moment,

ft)

Bottom

66.75

49.75

My (k-

37.82

77.9

Moment,

Mx ( k-ft)

bottom top

66.75

-49.28

49.75

-41.26

115.82

124.92

24.26

4.88

24.26

4.88

-13.33

2.13

-13.33

2.13

top

-49.28

-41.26

Consider the third story column

Moment

M 2b 66.75 k ft and M1b 49.28 k ft . These are the same for both directions.

Axial force

Pu = 37.82 kips + self weight of columns

14 in*14in*16ft* 150 lb/ft 3

= 37.82 +

(12 in/ ft) 2 *1000lb / k

37.82 3.27 41.1 kips

Check for Slenderness

ACI 10.10 considers a braced (non-sway)

Column is short if

klu

M

34 12( 1b ) 40

r

M 2b

16in

14.6 ft

12in / ft

r 0.3* column dim ension 0.3*14in 4.2in

lu 16 depth of beam 16 ft

a) Column attachments

66

b) Top and bottom beam sections

Figure 3.7 Corner column attachment and section of beams attached to it

These sections are used in determining the slenderness of the column as per ACI 10.10

Ic

Ic

14*143 in 4 1 ft

14*143 in 4 1 ft

3

16.67

in

2*

33.34in3

l

12*16

ft

12

in

l

12*16

ft

12

in

c top

c bot

Ib

163 *12in 4 93 *13in 4 13*9**3.52 in 4 1 ft

21.06in3

25 ft

12in

lb top

Ib

163 *12in 4 83 *13in 4 13* 8**42 in 4 1 ft

21.05in3

l

25

ft

12

in

b bot

t

I

I

c

b

/ lc top

/ lb top

I c / lc bot 33.74in3 1.602

16.67in3

0.791

b

21.06in3

Ib / lb 21.05in3

bot

0.7 0.05(t b ) 0.82 1.0

k

k 0.82

0.85 0.05min 0.88 1.0

klu 0.82*14.67 *12in

M

34.3 and 34 12( 1b ) 42.86 40

r

4.2in

M 2b

klu

34.3 40

r

67

Therefore, column is not slender and treated as short column.

Check for minimum moment requirements

For braced columns emin= (0.6+0.03h)= 0.6+0.03*14= 1.02 in

Pu*emin= 41.1*1.02/12= 3.49 k-ft

Actual moments are greater than this minimum moment and hence the column is

designed for actual moments.

Compute magnified moments

Magnified moment Mc, is given by

M c b M 2b where b

Cm

1 ( Pu / Pc )

0.75; Cm 0.6 0.4 M 1b M 0.304

2b

Pc

EI

2

klu

2

;

EI

0.4 Ec I g

1 dns

(design stage) ;

Ec 57000 f c' 4.41*106 psi I g 144 /12 3201in 4

dns

factored axial dead load

0.7 appx.

factored servive axial load

2 4.41*106 *3201lb.in 2

1kips

3303kips

(.82*16*12in) *(1 0.7) 1000lb

Cm

0.304

b

0.309 1 b 1

1 ( Pu / Pc ) 1 (41.1/(0.75*3303))

Pc

2

*

Therefore no magnification of moments is required due to curvature. And the design

moment will be

Mc = M2b = 66.75 k-ft in both directions

The reinforcement required for the factored design actions of Pu=41.1 kips and Mx=My=

66.75 k-ft is 8 # 8 bars. The Design for reinforcement is made using STAAD etc of

STAAD Pro using the option of ACI Code.

A similar procedure is followed for the columns in other stories and the results are as

indicated in table 3.6

68

Table 3.6 Design Loads Summary and Reinforcement provide for a Typical Corner

Column

Column@

level

Column

type

Design actions

P (kips)

Mx(k-ft)

Second st.

short

84.44

first

slender

foundation short

Magnified actions

Reinforcement

My(k-ft)

Mx(k-ft)

My(k-ft)

provided

49.75

49.75

49.75

49.75

4#8 bars

127.67

24.26

24.26

24.26

24.26

4#8 bars

141.39

4.88

4.88

4.88

4.88

4#8 bars

Tie design

As lateral forces taken by the shear wall and hence the shear forces in column are

insignificant. For this reason no shear is considered in the design of the columns and the

resulting tie requirement from the design software is # 3 bars ties spaced 14 inches on

center to center.

3.5 Edge Column (B1)

Column dimensions: 14” x 14”

The loading to each column of the edge column includes the loadings from the edge

frame that runs from the top of the building down to the foundation, analyzed using SAP

2000 and from the adjacent slabs through shear and moment transfer. Consider the edge

located at B1 of the top storey, the tributary area for shear and strip for moment transfer

as indicated in figures 3.8 (a) and 3.8(b)

The column loadings in the y- direction can be taken from the frame analysis done earlier

for the purpose of the design of edge beams. However, the column loading (moment and

shear) in the x- directions has to be obtained from the above two diagrams as per the ACI

code of shear and moment transfer to columns from slabs. The moment in the x-direction

will be the moment at the exterior support of column strip of the strip shown in figure

3.7(b). And the shear will be approximately the total flood load in the tributary area

shown in figure 3.7(a).

As this also includes the floor load that has been already

considered in the frame loads of the edge frame only half of the load over the area shall

be considered and added to the axial load obtained from the frame analysis.

69

a) Tributary area for shear transfer

b) strip for moment transfer

Figure 3.8 Load transfer to an edge column

The column loadings in the y- direction can be taken from the frame analysis done earlier

for the purpose of the design of edge beams. However, the column loading (moment and

shear) in the x- directions has to be obtained from the above two diagrams as per the ACI

code of shear and moment transfer to columns from slabs. The moment in the x-direction

will be the moment at the exterior support of column strip of the strip shown in figure

3.8(b). And the shear will be approximately the total flood load in the tributary area

shown in figure 3.8(a).

As this also includes the floor load that has been already

considered in the frame loads of the edge frame only half of the load over the area shall

be considered and added to the axial load obtained from the frame analysis.

Load from frame loading ( Y direction)

P = 44.42 kips M 1by= -3.74kips

M2by = 7.41 kips

Load transfer from slab

P = 0.5* 226.25 psf * 12.5ft*25ft * 1k/1000lb= 35.35 kips

M1bx = 114.89 k-ft (taken from flat plate)

M2bx = -0.5 *113.75 =56.87 k-ft (this is the moment transferred to the bottom of the third

story column B1 from the flat slab and it is shared between this column and the column

70

below it. The share of the moments is based on their corresponding stiffness which in this

case is the same and each will take half of the moment.

Total column loading

P= 44.42+33.35+ self weight of column= 77.77+3.27=81.04 kips

M 1by= -3.74kips

M2by = 7.41 kips M1bx = 114.89 k-ft M2bx = -56.87 k-ft

A similar procedure is followed for the columns in the other stories and the edge column

(B1) loadings are as indicated in table 3.7.

Table 3.7 acting design loads before magnification for edge column

Column

level

Axial load

P ( kips)

81.04

163.65

Moment,

My ( k-ft)

bottom top

-3.74

7.41

-1.96

4.12

Moment, Mx (kft) (from slab)

Bottom

top

-56.87

114.89

-28.48

56.87

third story,

Second

story

First story

Foundation

column

244.14

255

-1.02

-0.15

-28.48

0

2.35

0.48

28.48

0

For details of the calculation on magnification and slenderness of the columns, consider

the third story column B1. Figure 3.9 shows its attachment / framing to the building

elements.

Figure 3.9 Edge Column attachments to slabs/ beams in both directions

71

Check for Slenderness

ACI 10.10 considers a braced (non-sway)

Column is short if

16in

14.6 ft

12in / ft

9in

klu

M 1b

l

16

depth

of

slab

16

ft

15.25 ft

34 12(

) 40 ux

12in / ft

r

M 2b

r 0.3* column dim ension 0.3*14in 4.2in

luy 16 depth of beam 16 ft

Cross sections of beams are the same sections used in the checking of slenderness for the

corner column of the third story. The slab x-section to be used for the x-direction are

shown below

Y-direction

Ic

3

16.67in

lc top

Ic

3

2*16.67 33.34in

lc bot

Ib

3

3

2*21.06in 42.12in

lb top

Ib

3

3

2*21.05in 42.1in

lb bot

t

I

I

c

b

/ lc top

/ lb top

16.67in3

0.396

42.12in3

X-direction

Ic

3

16.67in

l

c top

Ic

3

3

2*16.67in 33.34in

lc bot

Ib

93 in3 *150in /12 1 ft

30.375in 4

25 ft

12in

lb top

Ib

83 in3 *150in 4 /12 1 ft

21.33in3

l

25

ft

12

in

b bot

t

I

I

c

b

/ lc top

/ lb top

16.67in3

0.55

30.375in3

72

Y-direction

b

I

I

c

b

/ lc bot

/ lb bot

X-direction

33.74in3

0.801

42.10in3

0.7 0.05(t b ) 0.76 1.0

k

0.85 0.05 min 0.87 1.0

k 0.76

kluy

0.76*14.67 *12in

31.8

r

4.2in

M

and 34 12( 1b ) 40.06 40

M 2b

kluy

r

b

c

b

/ lc bot

/ lb bot

33.74in3

1.58

21.33in3

0.7 0.05(t b ) 0.81 1.0

k

0.85 0.05min 0.88 1.0

k 0.81

klux 0.81*15.25*12in

35.29

r

4.2in

M

and 34 12( 1b ) 39.94 40

M 2b

31.3 40

I

I

klux

35.29 39.94

r

Therefore, column is not slender in both directions.

Check for minimum moment requirements

For braced columns emin= (0.6+0.03h)= 0.6+0.03*14= 1.02 in

Pu*emin= 81.04*1.02/12= 7.14 k-ft

Actual max end moments are greater than this minimum moment and hence the column is

designed for actual moments.

Compute magnified moments

Magnified moment Mc, is given by M c b M 2b where b

Y-direction

X-direction

Cmy 0.6 0.4

by

M 1by

M 2by

0.4

Cmy

0.4

by 1

(0.75*3303)

Cmy 0.6 0.4

bx

1 ( Pu / Pc )

1 81.04

Cm

1 ( Pu / Pc )

0.41

M 1by

M 2by

0.402

Cmy

1 ( Pu / Pc )

0.402

0.41

1 81.04

(0.75*3303)

bx 1

73

Therefore no magnification of moments is required due to curvature. And the design

moments will be

Mcy = M2by = 7.43 k-ft and Mcx=M2bx= 114.89 k-ft

The reinforcement required for the factored design actions of Pu=81.04 kips and

Mx=7.43 k- ft, My= 114.89 k-ft is 6 # 8 bars. The Design for reinforcement is made

using STAAD etc of STAAD Pro using the option of ACI Code.

A similar procedure is followed for the columns in other stories and the results are as

summarized in table 3.8

Table 3.8 Design Loads Summary and Reinforcement provided for a Typical Edge

Column

Column@

level

Column

type

Analysis actions

P (kips)

Mx(k-ft)

Second st.

short

163.65

first

slender

foundation short

Magnified actions

Reinforcement

My(k-ft)

Mx(k-ft)

My(k-ft)

provided

4.12

56.87

13.9

56.87

4#8 bars

244.14

2.35

28.48

28.66

28.66

4#8 bars

255

.48

0

21.65

21.65

4#8 bars

Tie design

As lateral forces taken by the shear wall and hence the shear forces in column are