ee128Fa08-Lab2-SOLUT..

advertisement

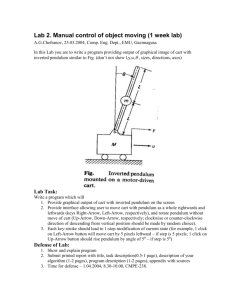

EE128 Fall 2008 University of California, Berkeley Lab 2 SOLUTIONS Rev. 1.00 CONFIDENTIAL Lab 2: Introduction to MATLAB Real Time Workshop and Inverted Pendulum Dynamics SOLUTIONS I. Prelab SOLUTIONS 1. Inverted Pendulum Dynamics Figure 1. Inverted Pendulum Free Body Diagram Step 1. Applying Newton’s law to the cart: mc x F Fa N (0) Step 2. Equations of motion for the pendulum using the pendulum free body diagram. Horizontal: mp x N d2 x Lp sin( ) N dt 2 d mp x L p cos( ) N dt mp m p x L p sin( )( ) 2 L p cos( ) N (1) EE128 Fall 2008 University of California, Berkeley Lab 2 SOLUTIONS Rev. 1.00 CONFIDENTIAL Vertical: mp y P mp g d2 Lp cos( ) P dt 2 d mp g mp sin( ) P dt mp g mp m p g m p sin( ) cos( )( ) 2 P (2) Step 3: Moment of inertia computations: For this part, it will be helpful to do a moment diagram so you can clearly see the torques acting on the pendulum. The moment diagram is shown in figure 2. Figure 2. Moment diagram for the pendulum Based on figure 2, we can see that using the right-hand rule, torque N causes a clockwise rotation of the pendulum about the pivot and hence this torque is negative. Torque P causes a counter-clockwise rotation about the pivot and hence this torque is positive. I PLP sin( ) NLP cos( ) (3) Step 4: Substituting equation (1) in equation (0) and simplifying, we get: Fa = (mc+mp)x''+mpLpcos(θ)θ''-mpLpsin(θ)(θ')2 (4) This is equation (1) in the lab guide. Substituting equations (1) and (2) in equation (3), we get: Iθ''=mpgLpsin(θ)-mpx''Lpcos(θ)-mpLp2 θ'' This is equation (2) in the lab guide. (5) EE128 Fall 2008 University of California, Berkeley Lab 2 SOLUTIONS Rev. 1.00 CONFIDENTIAL 2. Linearization of Inverted Pendulum Dynamics The states of the system are defined as x [ x; x; ; ] . The mathematical procedure for linearizing a system about an equilibrium point is called Jacobi Linearization. However, for this simple system, we can simply use the following approximations (the Jacobi Linearization will simplify to these approximations): sin( ) cos( ) 1 Ignore nonlinear term: 2 Notice that since we defined the pendulum angle as being from the vertical (instead of the horizontal), we avoided an offset of . 2 Using the approximations above and ignoring the moment of inertia, equations (4) and (5) above simplify to: Fa = (mc+mp)x''+mpLpθ'' 0 = mpgLpθ-mpx''Lp-mpLp2 θ'' (6) (7) Notice that (7) can be further simplified to: 0 = gθ-x''-Lp θ'' (8) Using the definition of the state vector and the given information that the outputs are the cart position (x) and pendulum angle (θ), we get the following state space representation of the system: 0 x 0 x x 0 0 1 0 0 0 0 0 m p x 1 g 0 x mc mc Fa 0 1 0 1 (mc m p ) g 0 mc LP mc LP 0 x 1 0 0 0 x y 0.Fa 0 0 1 0 Notice that the system is a “SIMO” (Single Input, Multiple-Output) system. EE128 Fall 2008 University of California, Berkeley Lab 2 SOLUTIONS Rev. 1.00 CONFIDENTIAL 3. Motor Dynamics Using the directions given in the lab guide, simple algebra gives the following relationship between the motor voltage and the applied force: Fa Km K g K V m Kg 2 x Rm r Rm r 2 Substituting Fa in your state space description and simplifying gives you the model of your plant: 0 x 0 x x 0 0 1 (Km K g ) 0 0 m p x 1 Km K g g 0 x m R r mc c m V 0 1 0 K K (mc m p ) 1 m g g 0 mc LP mc LP Rm r 0 2 mc Rm r 2 0 ( K m K g )2 mc Lp Rm r 2 x 2 K K Km K g 1 0 0 0 x m g y 0. V Rm r Rm r 2 0 0 1 0 II. Lab SOLUTIONS x 1, 2 and 3. Inverted Pendulum Dynamics Here are the parameters for the inverted pendulum system [2] for use by the students while designing the controller. Parameter Back EMF Motor coil resistance Gearbox ratio Motor pinion diameter Cart mass Pendulum mass Pendulum half length Symbol Km Rm Kg r mc mp Lp Value 0.00767 2.6 3.7 0.00635 0.815 0.210 0.305 Units V/rad.sec-1 Ω None m Kg Kg m Some other useful parameters are the motor pinion teeth # = 24, Rack pitch = 6.01 teeth/cm, Cart encoder teeth # = 56, Cart encoder resolution = 512*4 count/revolutions, Cart encoder calibration constant = 0.00454 cm/count, pendulum angle encoder resolution = 1024*4 count/rev and pendulum angle calibration constant = 0.08789 deg/count EE128 Fall 2008 University of California, Berkeley Lab 2 SOLUTIONS Rev. 1.00 CONFIDENTIAL 4. Demonstration of Quanser System Demonstrate the simple sinusoidal motion of the cart by using the demo Simulink program in the ee128Fa08 folder on the desktop (ee128Fa08\motorSine). The model can be opened in simulink. The important settings that you need to be aware of in Simulink are: 1. Under Simulation→Parameters→Real-Time Workshop, make sure the “System Target File” is set to: wincon.tlc –aAllSignals=1 –aAllParameters=0 (section 4.2 in [3]). 2. Under Simulation→Parameters→Real-Time Workshop, make sure the “Template Makefile” is set to: wc95_msvc.tmf (section 4.2 in [3]). 3. Under Simulation→Parameters→Real-Time Workshop, make sure the “Make Command” is: make_wc (section 4.2 in [3]). 4. Under Tools→External Mode Control Panel→Target Interface, make sure the “MEX file for external interface” is set to: wc_comm (section 4.3 in [3]). III. Revision History Semester Summer 2008 Author(s) Bharathwaj Muthuswamy Comments 1. Typed up solutions IV. References 1. Franklin, Gene F., Powell, David J. and Emami-Naeini Abbas. Feedback Control of Dynamic Systems. 5th Edition. 2006, Prentice-Hall Inc. 2. Quanser Consulting Inc. Self Erecting IP User’s Manual, 1996. 3. Quanser Consulting Inc. WinCon 3.0.02a User's Manual, 1996