MEC 3500 - FINITE ELEMENT ANALYSIS I

advertisement

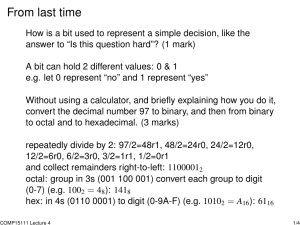

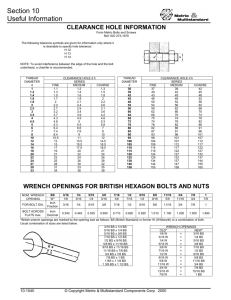

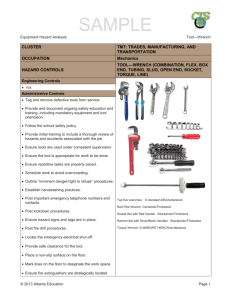

LECTURE 5 STRUCTURAL ANALYSIS GUIDE READ ‘OVERVIEW OF STRUCTURAL ANALYSIS’ IN THE ‘STRUCTURAL ANALYSIS GUIDE’ (30 MINS) STRUCTURES INCLUDE Bridges Buildings Ship hulls Aircraft bodies Machine housings Pistons Machine parts etc The primary unknowns in a structural analysis are DISPLACEMENTS TYPES OF STRUCTURAL ANALYSES: Static analysis Modal analysis Harmonic analysis Transient Dynamic analysis Spectrum analysis Buckling analysis Explicit Dynamic analysis IN ANSYS WE CAN CARRY OUT ANALYSIS INVOLVING FRACTURE MECHANICS, MECHANICAL FATIGUE, COMPOSITE MATERIALS ELEMENTS USED IN STRUCTURAL ANALYSES Spar Beams Pipes 2-D Solids 3-D Solids Shells Interface Contact Coupled field Other special elements STRUCTURAL STATIC ANALYSIS: STATIC ANALYSIS IS USED TO DETERMINE THE DISPLACEMENTS, STRESSES, STRAINS, AND FORCES IN STRUCTURES CAUSED BY LOADS THAT DO NOT INDUCE SIGNIFICANT INERTIA AND DAMPING EFFECTS. THE KINDS OF LOADING THAT CAN BE APPLIED IN A STATIC ANALYSIS INCLUDE: Externally applied forces and pressures Steady-state inertial forces (such as gravity) Imposed (nonzero) displacements Temperatures (for thermal strain) WE CAN HAVE BOTH LINEAR & NON-LINEAR STATIC ANALYSES. PERFORMING A STRUCTURAL STATIC ANALYSIS: 1. BUILD THE MODEL 2. SET SOLUTION CONTROLS i. ANTYPE ii. iii. iv. v. vi. vii. viii. ix. x. xi. xii. 3. NLGEOM TIME AUTOTS NSUBST OUTRES EQSLV NEQIT SSTIF NROPT PSTRES ERESX APPLY LOADS i. Displacements ii. Forces iii. Pressures iv. Temperatures YOU CAN DEFINE LOADS ON THE SOLID MODEL OR ON THE FINITE ELMENT MODEL 4. SOLVE 5. REVIEW THE RESULTS Primary data: Nodal displacements (UX, UY, UZ, ROTX, ROTY, ROTZ) Derived data: Nodal and element stresses Nodal and element strains Element forces Nodal reaction forces and so on POSTPROCESSORS POST1 & POST26 POST1 is used to review results over the entire model at specific substeps (time-points). Commands normally used are SET, PLDISP, PRESOL, PRNSOL, PRRSOL, FSUM, NFORCE, NSORT, ESORT, PLNSOL (averaged) , PLESOL, ETABLE, PLETAB, PLLS, PLVECT, PRVECT POST26 is used in nonlinear static analyses to track specific result items over the applied load history. READ ‘STRUCTURAL STATIC ANALYSIS’ IN THE ‘STRUCTURAL ANALYSIS GUIDE’ (1 Hour) WORK THROUGH ‘A SAMPLE STATIC ANALYSIS’ IN ‘STRUCTURAL STATIC ANALYSIS’ IN THE ‘STRUCTURAL ANALYSIS GUIDE’ (2 Hours) – given below /FILNAME,pm02! Jobname to use for all subsequent files /TITLE,Static analysis of an Allen wrench /UNITS,SI ! Reminder that the SI system of units is used /SHOW ! Specify graphics driver for interactive run; for batch ! run plots are written to pm02.grph ! Define parameters for future use EXX=2.07E11 ! Young's modulus (2.07E11 Pa = 30E6 psi) W_HEX=.01 ! Width of hex across flats (.01m=.39in) *AFUN,DEG ! Units for angular parametric functions W_FLAT=W_HEX*TAN(30) ! Width of flat L_SHANK=.075 ! Length of shank (short end) (.075m=3.0in) L_HANDLE=.2 ! Length of handle (long end) (.2m=7.9 in) BENDRAD=.01 ! Bend radius of Allen wrench (.01m=.39 in) L_ELEM=.0075 ! Element length (.0075 m = .30 in) NO_D_HEX=2 ! Number of divisions on hex flat TOL=25E-6 /PREP7 ! Tolerance for selecting nodes (25e-6 m = .001 in) ET,1,SOLID45 ! Eight-node brick element ET,2,PLANE42 ! Four-node quadrilateral (for area mesh) MP,EX,1,EXX ! Young's modulus for material 1 MP,PRXY,1,0.3 ! Poisson's ratio for material 1 RPOLY,6,W_FLAT ! Hexagonal area K,7 ! Keypoint at (0,0,0) K,8,,,-L_SHANK ! Keypoint at shank-handle intersection K,9,,L_HANDLE,-L_SHANK ! Keypoint at end of handle L,4,1 ! Line through middle of hex shape L,7,8 ! Line along middle of shank L,8,9 ! Line along handle LFILLT,8,9,BENDRAD /VIEW,,1,1,1 ! Line along bend radius between shank and handle ! Isometric view in window 1 /ANGLE,,90,XM ! Rotates model 90 degrees about X /PNUM,LINE,1 ! Line numbers turned on LPLOT /PNUM,LINE,0 L,1,4 ! Line numbers off ! Hex section is cut into two quadrilaterals ASBL,1,7,,,KEEP ! to satisfy mapped meshing requirements for bricks CM,BOTAREA,AREA ! Component name BOTAREA for the two areas ! Generate area mesh for later drag LESIZE,1,,,NO_D_HEX ! Number of divisions along line 1 LESIZE,2,,,NO_D_HEX LESIZE,6,,,NO_D_HEX TYPE,2 MSHAPE,0,2D ! PLANE42 elements to be meshed first ! Mapped quad mesh MSHKEY,1 SAVE ! Save database before meshing AMESH,ALL /TITLE,Meshed hex wrench end to be used in vdrag EPLOT ! Now drag the 2-D mesh to produce 3-D elements TYPE,1 ESIZE,L_ELEM ! Type pointer set to SOLID45 ! Element size VDRAG,2,3,,,,,8,10,9 ! Drag operation to create 3-D mesh /TYPE,,HIDP ! Precise hidden line display /TITLE,Meshed hex wrench EPLOT CMSEL,,BOTAREA ACLEAR,ALL ! Select BOTAREA component and ! delete the 2-D elements ASEL,ALL FINISH ! Apply loads and obtain the solution /SOLU ANTYPE,STATIC ! Static analysis (default) /TITLE,Allen wrench -- Load step 1 ! First fix all nodes around bottom of shank CMSEL,,BOTAREA LSEL,,EXT NSLL,,1 D,ALL,ALL ! Bottom areas of shank ! Exterior lines of those areas ! Nodes on those lines ! Displacement constraints LSEL,ALL /PBC,U,,1 ! Displacement symbols turned on /TITLE,Boundary conditions on end of wrench NPLOT !Now apply pressure on handle to represent 100-N (22.5-lb) finger force ASEL,,LOC,Y,BENDRAD,L_HANDLE ASEL,R,LOC,X,W_FLAT/2,W_FLAT NSLA,,1 ! Areas on handle ! Two areas on one side of handle... ! ...and all corresponding nodes NSEL,R,LOC,Y,L_HANDLE+TOL,L_HANDLE-(3.0*L_ELEM)-TOL ! Reselects nodes at ! back end of handle (3 element lengths) *GET,MINYVAL,NODE,,MNLOC,Y ! Get minimum Y value of selected nodes *GET,MAXYVAL,NODE,,MXLOC,Y ! Get maximum Y value of selected nodes PTORQ=100/(W_HEX*(MAXYVAL-MINYVAL)) ! Pressure equivalent to 100 N SF,ALL,PRES,PTORQ ALLSEL /PSF,PRES,,2 ! PTORQ pressure on all selected nodes ! Restores full set of all entities ! Pressure symbols turned on /TITLE,Boundary conditions on wrench for load step 1 NPLOT LSWRITE ! Writes first load step /TITLE, Allen wrench -- load step 2 ! Downward pressure on top of handle, representing 20-N (4.5 -lb) force PDOWN=20/(W_FLAT*(MAXYVAL-MINYVAL)) ASEL,,LOC,Z,-(L_SHANK+(W_HEX/2)) ! Area on top flat of handle... NSLA,,1 ! ...and all corresponding nodes NSEL,R,LOC,Y,L_HANDLE+TOL,L_HANDLE-(3.0*L_ELEM)-TOL ! Reselects nodes at ! back end of handle (3 element lengths) SF,ALL,PRES,PDOWN ! PDOWN pressure at all selected nodes ALLSEL /TITLE,Boundary conditions on wrench for load step 2 NPLOT LSWRITE ! Writes second load step SAVE ! Save database before solution LSSOLVE,1,2 ! Initiates solution for load step files 1 and 2 FINISH !Review the results /POST1 SET,1 ! Reads load step 1 results PRRSOL ! Reaction solution listing /PBC,DEFA ! No BC symbols /PSF,DEFA ! No surface load symbols /EDGE,,1 ! Edges only, no interior element outlines /TITLE,Deformed allen wrench caused by torque PLDISP,2 ! Deformed shape overlaid with undeformed edge plot /GSAVE,pldisp,gsav ! Saves graphics specifications on pldisp.gsav /PLOPTS,INFO,ON ! Turns on entire legend column /PLOPTS,LEG1,OFF ! Turns off legend header /ANGLE,,120,YM,1 ! Additional rotation about model Y (to see high stress areas) /TITLE,Stress intensity contours caused by torque PLNSOL,S,INT ! Stress intensity contours /GSAVE,plnsol,gsav SET,2 PRRSOL ! Saves graphics specifications to plnsol.gsav ! Reads load step 2 results ! Reaction solution listing /GRESUME,pldisp,gsav ! Resumes graphics specifications from pldisp.gsav /TITLE,Deformed allen wrench caused by torque and force PLDISP,2 /GRESUME,plnsol,gsav ! Resumes graphics specifications from plnsol.gsav /TITLE,Stress intensity contours caused by torque and force PLNSOL,S,INT WPOF,,,-0.067 /TYPE,1,5 ! Offset the working plane for cross-section view ! Capped hidden display /CPLANE,1 ! Cutting plane defined to use the WP /VIEW, 1 ,WP ! View will be normal to the WP /DIST,1,.01 ! Zoom in on the cross section /TITLE,Cross section of the allen wrench under torque and force loading PLNSOL,S,INT FINISH /EXIT,ALL ANOTHER EXAMPLE: FEA1 – COURSEWORK TEST 2 – JANUARY 2004 TIME ALLOWED 2.5 Hours You are reminded to concentrate only on your work during the test. Failure to do so may result in some marks being deducted. IMPORTANT NOTE : Here you are faced with a real design problem – an open ended problem – in which you have to start working on the problem and improve on it. I think that you will not have enough time (and energy) to finish the problem in the allowed time unless you happen to hit on the right way of approach immediately. Do your best during the test – you may even finish the problem if you really concentrate ……………. But allow 15 minutes at the end to give me a description on how you would re-tackle the problem once you have worked through it once. Hand in a file of your work on a floppy disc and a hard copy version of it (if possible). To accompany your work you must also hand in a hand-written report in which you can include sketches. Given the socket and specifications shown in Figure 1, build a finite element model of the socket (6 marks) and perform a static structural stress analysis. You have to take assumptions of how to apply the loading and boundary conditions. In the hand-written report describe (i) the element used (2 marks) (ii) the assumptions taken, etc. (8 marks) From your analysis deduce the position/s of the weakest point or points of the socket. State the maximum von Mises stress reached in the socket and where it occurs. (9 marks) Figure 1 OTHER EXAMPLES Beam problem Thick cylinder Thin cylinder Framework (Beam3, Link1) 2-D/3-D Nozzle/Sphere C-spanner

![%SYS-3-OVERRUN : Block overrun at [hex] (red zone [hex])](http://s3.studylib.net/store/data/007301636_1-ac70f3209bae6dd18e3a1bf696206cf5-300x300.png)