Research Impact Narratives Lunch – April 25, 2013 For internal

advertisement

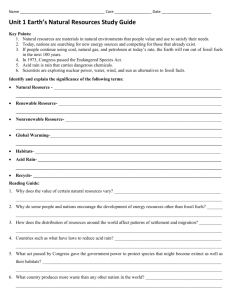

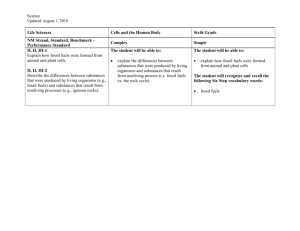

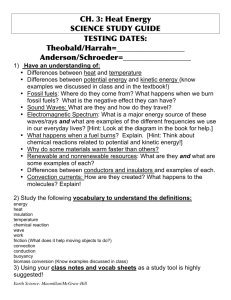

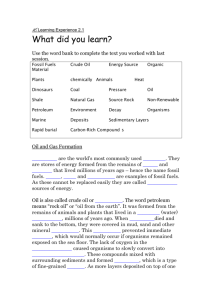

Research Impact Narratives Lunch – April 25, 2013 For internal University of Toronto Engineering use only David Sinton, Mechanical & Industrial Engineering (MIE) Small-scale Plumbing for Cleaner Energy Professor David Sinton (MIE) and his fluidics and energy research team study small-scale fluid mechanics for use in energy systems and analysis. His lab focuses on the small-scale “plumbing” involved in the creation and extraction of fuels. The Problem The burning of fossil fuels has powered the development of the modern world, but the resulting carbon dioxide emissions are forcing us to find cleaner energy sources. While solar, wind and geothermal energy offer promising solutions, fuels still account for about 86 percent of the global energy mix. The extraction process itself consumes a significant amount of energy – about the equivalent of one-third of each barrel of oil extracted, for example. The Answer Professor Sinton’s work addresses the energy problem from both directions. In his fluidics and energy lab, researchers are working on more efficient ways to grow biofuels and to optimize current methods of fossil fuel extraction. His biofuels research focuses on delivering just the right amount of light and fluids to photosynthetic bacteria to maximize the growth of compact, high-density algae ponds. One current project involves fiber optics nested within a block of algae, which help retain light for maximum growth. To increase efficiency in the extraction of traditional fossil fuels, Sinton analyzes the fluidic processes involved to better understand the optimal temperature and pressure. He also investigates how certain additives can help to more easily free fuels from reservoirs, reducing the energy input required and the associated carbon footprint. The Impact Sinton’s collaborations with other researchers are helping make algae growth more efficient and bringing biofuels closer to becoming a sustainable, commercially viable Research Impact Narratives Lunch – April 25, 2013 For internal University of Toronto Engineering use only alternative to fossil fuels. The key will be increased operational energy density, and his recent work indicates that improvements of two to three orders of magnitude are possible. His work also holds the promise of dramatically decreasing the carbon footprint of existing oil extraction processes. His recent research indicates potential for a 50 percent improvement in operational efficiency. If these findings lead to even a five percent increase in extraction efficiency, it would decrease Canadian carbon dioxide emissions by one million tons each year. In the News Engineering Professor Develops Microfluidic Chips For Bitumen Gas Analysis Engineering Professor Part of Team Awarded Research Grant MIE Professors Honoured by Canadian Society for Mechanical Engineering