Inst_Amp_Samp_Hold

advertisement

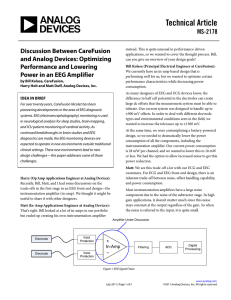

Instrumentation Amp & Sample and Hold, or, What goes between the sensor and the rest of the instrumentation system? Instrumentation Amplifier Sensors that have an analogue (continuous) output come with many varied electrical characteristics, we normally want to process the output in a measurement system. The sensors connection into the system may be single ended as in diagram 1 below; here one sensor connection is connected to the system common/0v/ground: or, it may be double ended as in the Bridge circuit shown in 2 below. In either case the signal going into the system will be the useful sensor output plus unwanted noise. The system should not load the sensor or the wanted signal will be distorted. The first stage of the instrumentation or measurement system needs to match the sensor output to the rest of the system and act as a buffer between the measurement system and the outside world, drawing as little current as possible and minimising distortion and noise. It would be useful to have a first stage that could be used with many different sensors and in many different applications without much modification. The instrumentation amplifier fills this need. An instrumentation amplifier is a development of the Operational Amplifier, see diagram below, (you may be familiar with this device). We’ll assume we have an idea Op Amp (this is, of course, unachievable but real ones come very close), it will have the following main characteristics: Input impedance: infinity (so as not to load the sensor) Output impedance: zero (so as to be able to connect to any following circuits) Gain: infinity (so we can reduce it to the value we need with a few resistors) Frequency response: infinity (so we can send very fast signals through without distortion) Real Op Amps easily achieve: Rin: 109Ω Rout:<10Ω Gain 500k Frequency response 100Mhz Op Amps usually require both a positive and negative power supply typically: ±9 to 15 volts, though single supply Op Amps and ones that work from much lower supply voltages are not uncommon. Practical Op Amp circuits for our two sensor system cases above are: In both cases the Gain (to a good approximation) by the ratio of R2/R1. [Look-up the derivation and a more precise formula in any suitable text.] There is one characteristic of Op Amps that is vital to its use as a sensor buffer and amplifier, any signal that is present at both inputs is cancelled out, so much of the noise picked up by the sensor and its connections cancels, particularly with the bridge type configuration 2. The Op Amp characteristic that quantifies this rejection is called the Common Mode Rejection Ratio CMRR it is shown on the data sheet, a typical value would be -90dB (i.e. in the output the signal is 30,000 times bigger than the common mode). CMRR is frequency dependant; generally it’s not as good at higher frequencies. The single Op Amp circuit above is not suitable for all applications because the gain setting resistors, particularly those connected to the positive input are still loading the sensor circuit. The circuit below avoids this problem. Each input id buffered by an additional Op Amp with its –ve input directly connected to the output. In this configuration the gain is 1 and there is no loading on Vin except the Op Amp input itself. This is called a unity gain buffer, its input impedance is very high (typically ≥ 109Ω). To change the gain of this circuit both R1/R2 pairs have to be adjusted and to preserve the high specification they really should be matched. This is inconvenient, so a further modification is made, as shown below. The gain stage is shifted to the input pair of Op Amps, and the R1s combined into a single resistor Rgain. Now to adjust the gain only one resistor is changed. The second stage now has unity gain with all four resistors the same value, R, and the final instrumentation amplifier circuit is: This arrangement preserves the very good CMMR of the unity gain buffered version. We can easily build such a circuit from ordinary Op Amps and obtain a very good performance, however, IC manufacturers make Instrumentation Amplifiers as single circuits, and these have superior characteristics as the resistors are accurately matched. Additionally, zero offset is also more easily adjusted. For background on non-ideal behaviour of OP Amps and the development the instrumentation amp see: http://www.mines.edu/Academic/courses/physics/phgn217/lab8/lect13/ A typical Instrumentation Amp is AD620 from Analog Devices. Single resistor sets gain between 1 and 10,000. Wide power supply range: ±2.3 to ±18 volts, Low power: 1.3mA max supply current. High bandwidth: 120kHz, fast settling. Low Noise. CMRR 100dB min. Input current 1nA max. 8 pin package. Data sheet: http://www.analog.com/static/imported-files/data_sheets/AD620.pdf Sample and Hold Measurement system often can’t keep pace with changing input signal particularly where a conversion into a digital signal is being made. Instead of continuously tracking the analogue signal it is sampled at a specified time interval, the sampled value being held until the next sample is taken. In this way the following circuit has time to complete its processing. A circuit that performs this task is called a Sample and Hold. The simple capacitor and switch illustrates the principle; close the switch to sample, open it to hold. We could build an Op Amp circuit with FET switches and a storage capacitor, but again the IC manufacturers have produced sample and hold devices with superior specification. A typical device is the National Semiconductor LM398, an 8 pin IC that uses a single external capacitor, 1-100nF, to hold for 1-1000 µs, sampling being controlled by a standard logic signal. It operates from a wide range of power supplies, is low noise, fast capture, and has a unity gain accurate to 0.002%