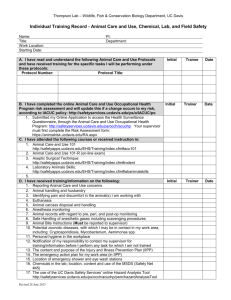

doc - UC Davis Department of Nutrition

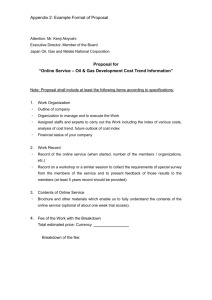

advertisement