Coiling Fire Doors Full Line Specs

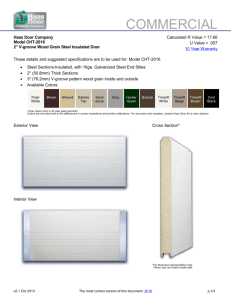

advertisement