Table of Contents - Think St. Edward's University

advertisement

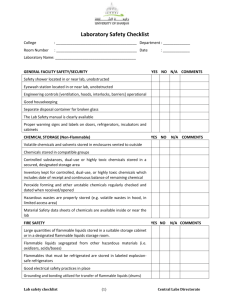

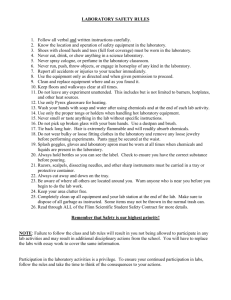

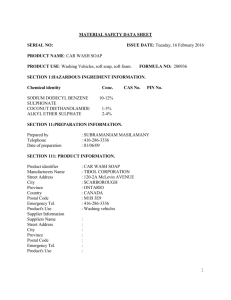

Department of Chemistry St. Edward’s University Safety Manual & Chemical Hygiene Plan 2013-2014 Introduction This Manual is concerned with the safety procedures of the chemistry laboratories. At St. Edward’s there are two types of chemistry lab courses. The 1 lower division Chemistry labs are closed courses meaning that they meet for a defined period of time on a particular day of the week. Undergraduate Research and the upper division chemistry labs are open labs meaning that they do not meet at specific times like the Organic or Introductory Chemistry labs. Ordinarily the Instrumentation lab is your first exposure to an open laboratory. To function safely in such an environment it is important that you be familiar with these safety regulations. Lab worker is identified as a student in an open lab or doing research, teaching assistant, faculty or any other person working in the labs at St. Edwards. Safety Regulations for Closed Labs 1. Closed lab have defined procedures and safety protocols. A review of safety procedures is completed in the first or second lab period including students signing a liability waiver and copy of the safety rules. In addition, key safety issues for each lab are reviewed in pre-lab lecture. The students always have trained personnel in the lab, generally an instructor and teaching assistant. The procedures have been refined to minimize hazards associated with each lab. 2. Know the location of all exits for the laboratory and the building. Each exit in the building will have a lighted exit sign. 2. Know the location and use of the safety showers, eyewashes, and first-aid kits. 3. Know where the fire extinguishers and alarm pull boxes are located and how they operate. 4. Know the location of the nearest phone that can be used in an emergency. 5. Know the potential hazards of the materials, facilities, and equipment with which you will work. If you are uncertain, ask your instructor. 6. Use the proper safety equipment for your procedure. This could include a fume hood, glove box, biosafety cabinet, shields, or other equipment. 7. Wear eye protection in the laboratory. Splash goggles are required for wet chemical work or work with dusts and powders. 8. Wear personal protective gear where laboratory or experimental conditions dictate. This could include laboratory aprons, laboratory coats, gloves, gauntlets, goggles, face shields, dust masks, respirators, and other equipment. 2 9. Wear clothes that protect the body against spills, dropped objects, and other accidental chemical contact. Shorts are discouraged. Open shoes, sandals, and bare feet are forbidden. 10. Long hair should be tied back or otherwise confined. Secure ties or other articles of clothing or jewelry that might become entangled in equipment. 11. Eating, drinking, gum chewing, tobacco chewing, or application of cosmetics should be avoided where chemicals or biological hazards will be stored or used. Food must not be kept in refrigerators or cold rooms with chemicals or other hazardous materials. 12. Do not pipette by mouth. Use only mechanical pipetting devices. 13. Wash hands carefully before leaving the laboratory. Beware of contamination on clothing, door knobs, frames, etc. Remove any protective gear (gloves, etc.) before leaving the laboratory. 14. Follow written protocols or instructions. Perform only authorized experiments. Do not create shortcuts to procedures. 15. Do not move or disturb equipment in use without consent of the instructor. 16. Do not leave equipment or reactions operating while unattended. 17. Do not work alone in the laboratory after normal working hours. 18. Do not horseplay in the laboratory. 19. Follow good housekeeping practices – clean up as you go and keep work areas, aisles, corridors, and exits uncluttered. Maintain clear accessibility to eyewash/emergency showers, fire extinguishers, and electrical panels. 20. Do not use unfamiliar equipment without instruction and permission. 21. Report all accidents and injuries immediately to your laboratory instructor. 22. Report unsafe conditions to your instructor or supervisor. 23. Ear buds to audio devices can be worn in the lab, but only one ear bud can be in at a time to ensure you are aware of your surroundings. 3 Safety Regulations for Open Labs In addition to the regulations for closed labs above, additional expectations are required for open labs. Open labs give you a great deal of flexibility since you can schedule your own work but they also impose some responsibilities. It is your responsibility to: a. Follow the established procedures and safety guidelines identified in this manual. Carefully evaluate each procedure for safety issues and hazards prior to completing the experiment. Instrumental Analysis class includes a review of these safety rules in the beginning of the semester. Other open labs and research labs should include review of safety issues associated with the labs. b. Inquire about and use personal protective equipment to protect yourself from identified hazards. c. Notify the instructor of any unsafe or potentially unsafe condition. Ask the faculty member or safety officer if you have questions about procedures to follow or safety issues. New Experimental Procedure evaluation If you are doing a procedure that is new to you either in research or in advanced lab, you should fill out the next experiment form (electronically) at the back of the manual and turn in a copy to your professor and the safety office, Dr Wharry. Safety Training for open labs including research labs and teaching assistants. Each student shall complete 4 hours of safety training in the fall with a 2 hour refresher course to be completed in the spring semester. Access to the lab will revoked if this safety training is not completed. The training will include an exam which a required grade of 80 to pass. 4 Contact Information If an accident or other emergency occurs in the lab one of your first steps should be to contact your instructor. This includes calling the instructor at home if you are working after hours or on the weekend. If you cannot reach your instructor, call another faculty member. The appropriate numbers are Chemical Safety / Chemical Hygiene Officer Dr. Donald Wharry cell 512-695-8498;512-261-5842 Faculty Dr. Henry Altmiller 1-888-999-9630 from campus phones 1-512-295-4616 Dr. Eamonn Healy 452-3634 Dr. Mary Kopecki-Fjetland 1-888-999-9781 from campus phones 1-512-295-7839 Dr. Jeff Potratz Cell 512-850-0500 Dr. Sandra Loudwig Cell: 512-289-7807 Office: 512-233-1698 If all else fails call the School Dean Dr. Patricia Baynham Office 512-233-1675 Cell 512-608-3479 If someone is hurt also contact the University Police (448-8444) and possibly EMS. 5 Housekeeping 1. Lab areas are to be kept clean and uncluttered. This is particularly important for Rm 104 which is more public. 2. Put your name or initials on any glassware that you regularly use. Also put your name or initials as well as the contents on any solutions that you prepare and store for more than 30 minutes. 3. Contaminated glassware should be cleaned daily. 4. Spills shall be cleaned up immediately from work areas and floors. 5. Doorways and walkways within the lab shall not be blocked or used for storage. 6. Access to exits, hallways, emergency equipment, and utility controls shall never be blocked. 7. Chemical containers shall be properly emptied and cleaned prior to disposal. Glass bottles will be uncapped, washed out with an appropriate solvent, triple rinsed with water and placed in the glass container for disposal. 8. Broken glassware should be cleaned of any chemical residue and disposed in broken glassware containers located in every lab not in the regular trash to avoid injury to janitorial staff. All broken glass shall be disposed in rigid, puncture-proof containers such as a cardboard box with taped seams, or a plastic bucket or metal can with a sealing lid. All broken glass disposal containers shall be clearly marked "DANGER - BROKEN GLASS" 9. Equipment and instrumentation shall be cleaned to remove spillage and contamination before repair or calibration service is requested and service personnel will be informed of any hazardous contamination prior to servicing. 9. The chemical safety officer will periodically inspect the laboratories. If you see Dr. Wharry prowling around your materials or watching you while you’re doing something with a puzzled look on his face, be very afraid. Any materials left out can be confiscated by any faculty member. Students who habitually fail to clean up after themselves can have the use of the labs and study desk severely restricted. 10. Spectrometer cells should be cleaned and returned to their storage boxes immediately after use. Solutions should not be kept in the cells and the cells should be removed from the spectrometer after use. 6 11. The chemical inventory is on every computer in the labs. When you return something be sure to put it back in its proper place. 12. No one should be in the labs after 11:00 pm either during the week or on weekends 7 CHEMICAL HYGIENE PLAN The Occupational Safety and Health Administration (OSHA), part of the Department of Labor, administers a variety of regulations. These regulatory requirements are published in and referred to as the Code of Federal Regulations (CFR). The Code of Federal Regulations is a codification of the general and permanent rules published in the Federal Register by the Executive departments and agencies of the federal government. The Code is divided into 50 titles which represent broad areas subject to federal regulation. Each title is divided into chapters with each chapter further subdivided into parts, subparts, and sections. Part 1910 of Title 29 (cited as "29 CFR 1910"), section 1450 of subpart Z, "Occupational Exposures to Hazardous Chemicals in Laboratories", referred to as the "Laboratory Standard", specifically addresses mandated regulatory requirements. Many educational institutions, colleges, universities, industry, and other organizations that use hazardous chemicals in their laboratories are now required by the Laboratory Standard to develop Chemical Hygiene Plans. The development of a detailed written chemical hygiene plan is necessary to establish continuity, to train personnel, and to help ensure that all lab workers recognize and comply with work place safety. It is extremely difficult to effectively communicate and enforce requirements without a detailed written chemical hygiene plan. An effective chemical hygiene plan necessitates that mechanisms be in place and functioning to ensure that safety policies and procedures are being adhered to, lab workers are meeting their safety responsibilities, and an effective form of monitoring and documentation is in place for confirmation purposes. It is therefore the intent of this laboratory chemical safety manual to define the guidelines for the implementation of the laboratory standard. The St Edwards University laboratory safety manual applies to all chemistry laboratories. Many laboratories use hazardous chemicals. OSHA defines a hazardous chemical as a substance for which there is statistically significant evidence, based on at least one scientific study, showing that acute or chronic harm may result from exposure to that chemical. This broad definition clearly applies to almost all of the chemicals typically used in laboratories. The purpose of the St Edwards University laboratory safety manual is to protect lab workers, while they are working in a laboratory, from harm due to potential exposure of hazardous chemicals. In addition to lab workers who ordinarily spend a large amount of time working in a laboratory space, for the purposes of this policy " lab workers " also includes office, custodial, maintenance, and repair or maintenance personnel, and others who, as part of their duties, regularly spend a significant amount of their time within a laboratory environment. All laboratories meeting the following three criteria are subject to the St Edwards University laboratory safety manual(which includes all chemistry laboratories: 1. Chemical manipulations are carried out on a laboratory scale. That is, the work with chemicals is in containers of a size that could be easily and safely manipulated by one person. 2. Multiple chemical procedures or chemicals are used. 3. Protective laboratory practices and equipment are available and in common use to minimize the potential for employee exposure to hazardous chemicals. 8 Emergency Procedures 1. PROCEDURES IN CASE OF FIRE (or EXPLOSION) 1. If the fire is small, attempt to extinguish it without endangering yourself. Get the nearest fire extinguisher and keep low with the exit to your back so you have an escape route. 2. If the fire becomes large get out and close the door! The sprinkler system and fire alarm will probably come on. a) Leave the area of immediate danger; be sure that other people are out. b) Call the instructor and Campus Police. 3. If hazardous chemicals are involved, stay away from the area and out the smoke. of 4. If Campus Police calls the fire department stand by to advise them when they arrive if chemicals are involved in the fire. 5. If the sprinkler system goes off, be prepared to clean up the mess. 2. ACCIDENT REPORTING ALL injuries shall be reported to faculty supervisor for the lab, the department chair and the Dean of Natural sciences within 48 hours. The Safety Incident reporting form documents both the nature of the incident and also all injuries resulting from the incident. The Safety Incident reporting form to be used is in Appendix A Minor injuries many times are not reported because they are perceived to be embarrassing or that "careless actions" led to the accident. However, minor injuries can sometimes lead to more serious complications that only become evident at a later time. Liability and insurance matters will be handled more effectively if initial accident documentation exists. In addition, all minor accidents should be investigated by safety officer. Taking corrective action as a result of a minor accident may keep a major incident from occurring. Without knowledge of all minor accidents, the desirable investigation is circumvented. Lab workers should understand that the purpose of reporting and documenting accidents is not to affix blame, but instead to determine the cause of the accident so that similar incidents may be prevented in the future. 9 Fire Extinguishers Everyone working in a laboratory should know the location and correct use of fire extinguishers. Fire extinguishers are designed to fight small fires. . You should remain in the area to use an extinguisher only if the fire is limited in size. It is important to use the right kind of extinguisher for the fire. Not all extinguishers can be safely used on all types of fires. The four classes of fire are identified by the following letters: A,B,C, and D: A - Ordinary combustible solids including paper, wood, coal, rubber, and textiles. B - Flammable and combustible liquids, including gasoline, diesel fuel, alcohol, motor oil, grease, and flammable solvents. C - Electrical equipment. D - Combustible or reactive metals (such as sodium and potassium), metal hydrides, or organometallics (such as alkylaluminums). The fire extinguishers in the chemistry labs are for A, B and C fires. All extinguishers operate in a similar fashion: Pull the safety pin which runs through the handle. A small, plastic band must be separated as the pin is released. Swing the nozzle or hose away from the extinguisher and direct it at base of the flames. Squeeze the handle of the extinguisher and hold down. A loud noise may be heard as the extinguishing agent is discharged. The extinguisher will "shoot" for about 20 - 30 seconds. Sweep the nozzle from side to side at the flames while extinguishing. Be sure to notify the instructor if a fire extinguisher has been discharged. 10 the 3. PROCEDURES IN CASE OF A HAZARDOUS CHEMICAL SPILL 1.Attend to any person(s) who may have been contaminated and/or injured if it is safe to reach them. Use safety showers and eyewashes as appropriate. In the case of eye contact, promptly flush eyes with water for a minimum 15minute period and seek medical attention immediately. In case of skin contact, promptly flush the affected area with water and remove any contaminated clothing or jewelry. If symptoms persist after washing, seek medical attention. 2. Notify persons in the immediate area about the spill, evacuating all nonessential personnel from the spill area and adjoining areas that may be impacted by vapors or a potential fire. 3. If the spilled material is flammable, turn off all potential ignition sources. Avoid breathing vapors of the spilled materials. Be aware that some materials either have no odors or create olfactory fatigue, so that you stop smelling the odor very quickly. 4. Leave on or establish exhaust ventilation if it is safe to do so. Close doors to slow down the spread of odors. 5. Notify Campus Police if there is an immediate threat to life or health. Notify the instructor as soon as possible. Minor Spills 1. If the spill is minor and of known limited danger, clean up immediately. 2. Cover liquid spills with compatible absorbent material. There is a container of absorbent material under the hood nearest the west door of 104. Lime should be used to neutralize spilled acids. A labeled container is also under the west hood in 104. Citric acid or any other weak solid acid can be used for bases. These are available in the stockroom. There are also containers of absorbent material and lime in 109 and in 207. 3. Powdered materials should be covered with wet paper towels (if compatible) to avoid dispersal and then picked up with a broom and dustpan. Clean spills from the outer areas first, cleaning towards the center. 4. Place the spilled material into an impervious container, seal, and notify the instructor. 5. If appropriate, wash the affected surface with soap and water. Mop up the residues and containerize for disposal. 11 III: Laboratory Safety Equipment 1. CHEMICAL FUME HOODS Chemical fume hoods are an effective means of controlling exposure to toxic substances. A chemical fume hood is an enclosure which is vented directly to the outdoors. It is designed to efficiently remove hazardous fumes, gases, and vapors. The correct type of hood to be used depends on the materials involved. The hoods in the science building have a flow gauge which indicates proper operation. If the indicator light is green and it indicates “FLO” with the sash closed, it is operating properly and ready for use. The flow rate will be indicated once you open the sash. If the gauge indicates that there is no flow, the hood cannot be used. When the exhaust first goes off an alarm will sound. You can turn off the alarm by pressing the proper button but notify a faculty member as soon as possible. Use the chemical fume hood with the horizontal sash in place to serve as a physical barrier between your face and the hood contents. Do not store your supplies in the hoods, they are not storage cabinets. Proper Hood Operation Do not place equipment or chemicals close to the slot openings in the baffles at the rear of the hood, or close to the front edge of the hood. Clutter in the hood disrupts the air flow, reducing its capture efficiency. Keep the sash glass clean. Never obstruct your view with paper, notices, decals, or other items on the sash. Avoid sudden movements while working in the hood. Walking briskly past the hood can disrupt air currents and pull vapors out of the hood. Keep your head outside of the fume hood, but set equipment and perform tasks as far back in the hood as possible. Perchloric acid can leave explosive residues in a fume hood, duct system, or on a hood fan. Perchloric acid can also form explosive mixtures with organic compounds. For this reason, the use ofperchloric acid in fume hoods must be carefully evaluated prior to use. When you are through using the hood make sure that you close the sash. 12 2. GLOVE BOXES When highly toxic substances must be contained, or reactive substances must be handled in an inert or dry atmosphere, it may be necessary to use a completely enclosed glove box unit. Your instructor will show you how to work with this equipment. 3: LAMINAR FLOW HOODS The labs in 104 and 107 are also equipped with laminar flow hoods. These are designed for biochemical work. The instructions for their use are given above the sash. If you need to use these hoods, your instructor will give you directions. They are equipped with an ultraviolet lamp. The lamp will not go on unless the sash is lowered. The laminar flow hoods cannot be used in place of a fume hood. 4. EMERGENCY SHOWERS AND EYEWASH STATIONS Combination eyewash/showers are available for use by all. In the event of contact with a chemical or substance, immediately irrigate the eyes and/or other parts of the body for 15 minutes. Clothing that has been in contact with injurious substances should be removed. Eyewashes should be inspected every month during the semester. Be sure and check the eyewashes in the lab which you are working as research or teaching assistant every month. IV: Handling Chemicals 1. SAFE HANDLING RECOMMENDATIONS Before beginning to use any chemical, each user must be familiar with the characteristics associated with the particular chemical. Material Safety Data Sheets (MSDSs) are a good source of information. These are available on the desktop of the computers in all chemistry labs. Hard copies are available in the storeroom and in 109 and 209 for chemicals in that respective lab. Many web sites can be accessed by simply entering MSDS into Goggle. Some examples are: Oxford University: http://physchem.ox.ac.uk:80/MSDS/ Cornell: http://msds.ehs.cornell.edu/msdssrch.asp Vermont MSDS: http://hazard.com/msds/index.php Sigma-Aldrich is a good site and registration is free. http://www.sigmaaldrich.com/united-states.html 13 The type of information that you should be concerned with is as follows. 1. Quantity of chemical that is toxic or hazardous: a. Know the amount of exposure considered to be safe. b. Know the lethal dose of any very toxic chemical. 2. Route of exposure of the chemical: a. absorption through the skin or eye b. ingestion c. inhalation d. injection 3. Type of hazard (many chemicals are dangerous in more than one way): a. corrosive b. explosive c. flammable d. irritant e. reactive f. sensitizer g. toxic 4. Mode of action: a. acute toxicity b. chronic toxicity (numerous smaller exposures cause damage) c. carcinogen (can cause cancer) d. mutagen (can cause permanent mutation) e. teratogen (can cause abnormalities during prenatal development) 5. Symptoms and target organs of over-exposure: Each chemical or group of chemicals has identifiable symptoms on a particular organ(s) that can be associated with overexposure to that chemical. 6. Physical characteristics of the chemical: a. aerosol (airborne dusts or mists) b. cryogen c. dusts or particles (can become airborne and inhaled) d. gas e. liquid f. solid 14 g. vapor density (heavy vapors will fall to the floor and may stay in pockets) h. vapor pressure (fast evaporation can increase exposure) i. flammability 7. Chemical compatibility (mixing some chemicals can cause explosion, release of toxic gases, or cause a fire). 8. Standard operating procedures should be developed before starting any work with hazardous chemicals. Recommended work practices include such points as: a. restrict the amount of chemicals ordered, kept on hand, and used b. substitute less hazardous chemicals whenever possible c. use a fume hood or other containment device where feasible d. do not work alone when handling hazardous materials e. keep work area clean f. wear eye protection h. wear the proper type of gloves as necessary i. wash hands frequently and before eating, drinking, or applying cosmetics or taking medications j. label all containers k. keep containers closed except when in use l. segregate chemicals in storage to keep incompatibles separated m. do not taste chemicals n. do not mouth pipette o. avoid smelling chemicals p. know the locations of fire extinguishers, eye washes, and emergency showers q. do not smoke, eat, drink, apply cosmetics, take oral medications, or chew gum or tobacco while using chemicals 9. Chemical fume hoods are the primary defense against inhaling hazardous materials in the laboratory. Operations should be performed as far into the hood as possible; the air slots at the back of the hood must not be blocked. Hoods must be operated with the sash(es) in place. Make sure the hood's work surface is uncluttered and that it is working properly. 10. The following types of personnal protection are recommended a. Eye protection, if faithfully and properly worn, will eliminate nearly all eye injuries. Contact lens users should be especially aware of the need for eye protection and the importance of immediately removing lenses in case chemicals do get in their eyes. Lenses will interfere with flushing the eyes. 15 b. Glove type must be chosen for the specific task and chemical. Even with the correct gloves, protection may not be complete; therefore, gloves should be changed frequently and after obvious exposure. c. Foot protection must be used when the situation warrants. Full foot coverage must be worn when working with corrosive chemicals. Students entering laboratories should wear closed-toed shoes. d. Aprons and laboratory coats may be worn to protect clothing and when using corrosive or toxic chemicals. 11. All students should know how to handle compressed gas cylinders, how to attach a gas regulator and how to read the gauges. Remember that if these are not properly handled and if they should break it will be like a bomb. 2. CHEMICAL STORAGE Many laboratory accidents are due to improper storage practices and both city and state fire code regulations require certain minimum storage practices. Although instituting a sound storage protocol requires an investment of time, it pays off in the long run. For safe storage of laboratory chemicals, four major principles apply: 1. Maintain control of the inventory 2. Label containers 3. Segregate chemicals by compatibility 4. Provide adequate storage space and appropriate containers An updated inventory is on every computer in all the chemistry labs and a hard copy is in JBWN 104. This inventory is updated every spring, but you should check on the shelves to ensure availability. If you use the last of something, let Dr. Wharry or your advisor know so it can be replaced. Maintain control of the inventory: keep the minimum amount on hand purchase limited quantities inspect storage locations regularly and properly dispose of outdated chemicals Label containers: Label transfer containers. Include: 16 chemical name physical and health hazards storage class (this can be color-coded to make storage decisions easier) name expiration date (this is especially important for peroxidizable chemicals) Segregate incompatible chemicals from one another: At St. Edward’s we use the following storage code. RED: Flamable. Should be stored in special cabinets. Blue: Health Hazzard. Toxic if inhaled, ingested, or absorbed through skin. Yellow: Reactive and oxidizing agents. May react violently with water, or other substances. air, White: Corrosive. May harm skin, eyes, mucous membranes Gray: General Chemical Storage. Presents no more than moderate hazard in any of the above catagories. The chemicals are alphabetized within each category ignoring any numbers or prefixs; i.e. p, m, dl, Put the chemicals back where you got them so they can be found by others Initially assign each chemical to broad classes, for example: flammable, water reactive, oxidizer, acids, bases, highly toxic. This information is usually available on the bottle or from catalogs. Fisher, for example, lists the storage code for every chemical it sells. Aldrich does not. 3. Hazardous Waste Chemical Disposal Chemicals cannot routinely be disposed in the sinks in the labs. Your instructor will provide guidance on handling chemicals during lab. St Edwards is allowed to dispose of 5 lbs/week hazardous waste in the sink primarily to accommodate residual acetone and ethanol used to rinse glassware. Containers are provided in all the labs for the waste chemicals generated in that laboratory. These containers should have a Satellite Accumulation Area (SAA) label on the container with actual chemical name written out on the the label, no chemical symbols. A list of hazardous waste characterization of laboratory waste is 17 included in Appendix B and is updated if new waste is generated. All waste generated should be stored in the area of generation until waste disposal is arranged. There is not a central hazardous storage waste site. An inventory of hazardous waste accumulated will be completed by the safety officer every month during the semester to ensure we maintain our small quantity generator status since we generally have a waste disposal with a regulated waste disposal company once a year and the inventory documents generation volumes not the waste manifest. Copies of this inventory are shared with the Chemistry Department Chair, Dean of Natural Sciences, Natural sciences office staff for filing and the Physical plant assistant director. The limits of hazardous waste generation to maintain small quantity generator is 220 lbs of hazardous waste and 2.2 lbs of acutely hazardous waste (class P). If you are doing an experiment that will generate more than this amount contact the Chemistry Department Chair, Safety Officer and Dean of Natural sciences prior to performing the experiment. General Storage of Chemicals by Class (Examples): A: Flammables and Combustible Chemicals Flammables are chemicals that have a flash point less than 100°F. Combustible chemicals have flash points that are100-200°F. If stored or used improperly, flammables and combustibles can be a fire hazard. Examples: benzene alcohols hydrogen sulfide acetone ethers organic acids (i.e., glacial acetic acid) Regulations limit stored flammables to 60 gallons per fire space. A fire space is an area that is enclosed by fire-rated walls and doors. A laboratory often qualifies as a fire space. Quantities of greater than 10 gallons must be stored in a flammable storage cabinet. Another alternative for storing more than 10 gallons of flammables per fire area is to use safety cans. Up to 25 additional gallons of flammables can be stored in safety cans. Segregate flammables from oxidizing acids and oxidizers. Keep flammables away from ignition sources. Water-reactive Chemicals 18 Water reactive materials react with water, moisture, or water solutions to produce heat or flammable gases. Examples: sodium (elemental) potassium (elemental) calcium carbide phosphorous pentachloride Store water reactives away from any sources of water or moisture. Oxidizers Oxidizers react vigorously with reducing materials. The reaction can lead to fires or explosions. Examples: halogens ammonium persulfate hydrogen peroxide sodium dichromate potassium permanganate perchloric acid Keep oxidizers away from flammables, combustibles (such as paper, wood) and other reducing agents. Reducing Materials Reducing materials react vigorously with oxidizers. The reaction can lead to fires or explosion. Examples: ammonia carbon metals metal hydrides most organics phosphorus silicon sulfur Store reducing materials away from oxidizers. B: Acids and Bases 19 Acids Acids require special storage because they are corrosive and some are oxidizers. There are two main groups of acids, organic acids, and inorganic (mineral) acids. Some inorganic acids are oxidizers and will react with organics. Therefore, as a rule of thumb, inorganic acids should be stored separately from organic acids. Examples of inorganic acids: Oxidizers perchloric acid chromic acid sulfuric acid nitric acid Non-oxidizers hydrochloric acid hydrofluoric acid phosphoric acid Examples of organic acids: acetic acid formic acid butyric acid propionic acid picric acid acrylic acid Segregate acids from bases and active metals such as potassium and magnesium. Segregate acids from chemicals that could generate toxic gases upon contact such as sodium cyanide. Segregate oxidizing inorganic acids from organic acids, flammable and combustible materials. Most mineral acids can be stored together except perchloric acid (see below). Organic acids (e.g. glacial acetic acid) are combustible and should be stored separately or with flammables rather than with inorganic acids. Several inorganic acids are oxidizers and therefore, incompatible with organics. Perchloric acid and picric acid require special handling. 20 Picric acid is reactive with metals or metal salts and explosive when dry. Picric acid must contain at least 10% water to inhibit explosion. Store picric acid in a cool, dry, non-ventilated area away from incompatibles or ignition sources. Perchloric acid is also potentially explosive and should be stored itself. by Bases Bases are corrosive and react violently with acids Examples: ammonium hydroxide sodium hydroxide calcium hydroxide organic amines Segregate bases from acids. Highly Toxic Chemicals Highly toxic chemicals should be stored according to the hazards of the chemical. Poison gases should be stored in a chemical fume hood or ventilated cabinet with alarm. Examples: phosgene arsine phosphine osmium tetroxide dimethyl sulfate toluene-2,4-diisocyanate Store highly toxic chemicals (non-gases) in secondary containers and in a wellventilated area. Containers should be closed with tape or sealant. We do not ordinarily stock such chemicals. C: Refrigerators When searching for an item in a refrigerator used for chemical storage, be careful not to inhale vapors that may have built up in the cabinet. 21 All chemicals, including those stored in refrigerators and freezers, should be sealed and labeled with the name of the material, the date it was placed in storage, and the name of the person storing it there. Refrigerators and freezers should be cleaned on a regular schedule, and old chemicals should be properly discarded. DO NOT store food in any refrigerator used to store chemicals. D. FLAMMABLE STORAGE Flammable storage cabinets are available in the stockroom and should be used to store flammable and combustible liquids. Flammable storage cabinets are designed to protect the contents from external fires. For this reason, the door(s) must be kept closed except when removing or replacing the cabinet's contents. The interior of the cabinet is capable of withstanding the effects of vapors from solvents, but not of other materials, such as corrosives. These materials are incompatible with most flammables. Only flammable materials should be kept in flammable storage cabinets. Additionally, flammable storage cabinets are designed with a lip to contain a two-inch depth of a spilled liquid. Two of the flammable storage cabinets are connected to the exhaust system E. CHEMICAL HAZARDS This section contains descriptions of the general categories of chemical hazards and the safety principles associated with each. This section does not contain advice for handling specific chemicals. Safe work in a chemical laboratory requires very detailed knowledge of the nature, potential, and compatibilities of each substance used. Anyone planning an experiment or procedure should review the Material Safety Data Sheet (MSDS) for each chemical used. The following categories provide a structure for thinking about and planning protection against common chemical hazards. In actual practice, such hazards do not group themselves in neat categories, but usually occur in combination or sequence. The categories and concepts are provided as an aid to awareness, and as encouragement for consistent safe planning and practice. 1. Fire Hazard Flammability is one of the most common chemical hazards. To handle a flammable substance safely, you must know its flammability characteristics: flash point, upper and lower limits of flammability, and ignition requirements. This information appears on each MSDS. 22 a. Flash Point For a liquid, the flash point is the lowest temperature at which the liquid gives off enough vapor to form an ignitable mixture with air and produce a flame when a source of ignition is present. Many common laboratory solvents and chemicals have flash points lower than room temperature. b. Ignition Temperature The ignition (or autoignition) temperature of a substance, solid, liquid, or gas, is the minimum temperature required to initiate self-sustained combustion. Some ignition temperatures can be quite low. c. Autoignition Autoignition or spontaneous combustion occurs when a substance reaches its ignition temperature without the application of external heat. This characteristic is particularly important to keep in mind in the storage and disposal of chemicals. d. Limits of Flammability Each flammable gas and liquid (as a vapor) has a limited range of flammable concentration in mixtures with air. The lower flammable limit (or lower explosive limit) is the minimum concentration below which a flame is not propagated when an ignition source is present - such a mixture would be too lean to burn. The upper flammable limit (or upper explosive limit) is the maximum concentration of vapor in air above which a flame is not propagated -- such a mixture is too rich. The flammable range (or explosive range) lies in between the two limits. Listed measurements of all these characteristics: flash points, ignition temperatures, limits of flammability, are derived through tests conducted under uniform and standard conditions that may be very different from actual practice. For example, concentrations of vapor in air in a laboratory are rarely uniform, and point concentrations can be quite high. It is good practice to set maximum allowable concentrations at 20 percent of the listed lower limit of flammability within closed systems. Generally, this 20 percent limitation is well above the maximum concentration considered to be safe for health considerations. e. Precautions with Flammable Liquids Flammable liquids do not burn; their vapors do. For a fire to occur, there must be 23 1) a concentration of vapor between the lower and upper flammable limits 2) an oxidizing atmosphere, usually air 3) a source of ignition. It is unlikely that air can be excluded. However we can try to control vapor levels and igmition sources. Use careful handling, fume hoods to reduce the likelihood of a spill or other condition that could lead to high vapor levels. Also ensure that open flames are not used nearby where flammable vapors are present. Ventilation is very important. A fume hood should be used when flammable liquids are used. Ignition sources include electrical equipment, open flames, static electricity, and hot surfaces. Others working in the laboratory should be informed of the presence of flammable substances so that ignition sources can be eliminated. Remember that most flammable vapors are heavier than air, and will spread out horizontally for considerable distances until an ignition source is contacted. Flammable liquids should be handled only in areas free of ignition sources. Heating should be limited to water and oil baths, heating mantles, heating tapes, and sand baths. Static-generated sparks can be sudden ignition sources. When transferring flammable liquids in metal equipment, take care that metal lines and vessels are bonded together and grounded to a common ground. f. Precautions with Flammable Gases Leakage of compressed or liquefied gases can quickly produce a flammable or explosive atmosphere in the laboratory. 2. Explosion Hazard Ignition of flammable vapors or gases can occur with such speed that an explosion results. There are other substances that are explosive in response to heat, mechanical shock, or contact with a catalyst. With some substances, very tiny amounts of impurity are sufficient to begin a reaction that quickly becomes explosive. a. Precautions - Acquire a Material Safety Data Sheet (MSDS) for each chemical being used. It is crucial to know a chemical’s potential, including its compatibility’s with other substances. Be alert to any unusual change in the appearance of a reaction mixture. Rapid unexpected temperature rise or fuming are signals of imminent decomposition and emergency measures need to be taken immediately, such as removing the heat source, quickly applying a cooling bath, or leaving the room. 24 Explosive compounds should be protected from the conditions to which they are sensitive (mechanical shock, heat, light, etc.). Check the MSDS to see what those conditions are. Such substances should be brought to the laboratory only as required, and only in the smallest quantities absolutely necessary. Reactions involving or producing explosives should be designed on as small a scale as possible, and should be done behind a suitable blast shield. Special care should be taken that equipment is maintained (for example, that oil is routinely changed in vacuum pumps) and that heating methods used do not cause, or increase the potential for ignition. Other laboratory workers must be notified when an explosive hazard is present, through direct announcement and conspicuous warning signs. Highly exothermic, potentially explosive reactions, or sudden polymerizations must never be left unattended. b. Personal Protection - All explosive substances should be handled in a hood with the sash down far enough to protect your face and upper torso. These substances should be used only with the close supervision of a faculty member. 3. Toxicity Toxicity is the potential of a substance to cause injury by direct chemical action with the body tissues. Whether the effect is acute or chronic, the only way to avoid such injury is to prevent or greatly minimize contact between toxic chemicals and body tissues. a. Exposure Limits - The dose, or amount of chemical, and the part of the body exposed, determines the body's response. In the workplace, there are certain guidelines or regulations that limit your exposure to hazardous substances. These guidelines, which are set by various regulatory or professional organizations, are referred to as "workplace exposure limits. i) A workplace exposure limit is the airborne concentration of a material below which most persons can be exposed for long periods of time without adverse effect. These limits are based on an 8-hour-weighted average (TWA) over a working lifetime. Workplace exposure limits may be expressed as Threshold Limit Values (TLV) or Permissible Exposure Limits (PEL). A Permissible Exposure Limit is a legal limit and a TLV is a guideline. ii) Time-Weighted Average (TWA) is the average concentration of a substance integrated over a period of time (e.g., a normal 8- hour). 25 iii) A Short-Term Exposure Limit (STEL) is the maximum concentration limit for a continuous exposure period(usually no more than 15 minutes), provided that the daily TWA is not exceeded. Because workplace exposure limits are generally expressed as average concentrations, excursions above these values are permitted. The exposure levels during such excursions must be below the STEL. However, there are certain levels which must never be exceeded even instantaneously. These are known as the ceiling levels for a TLV or TLV-C. All these levels, though often based on data from animal research, refer to the exposure and resistance of a healthy adult. These levels do not necessarily apply to pregnant women, their unborn fetuses, or adults who are ill or under special stress. In such situations, the individual and his or her instructor must carefully consider all pertinent information. b. Acute Toxicity - Acute toxic effects are usually produced by a single large dose received in a short period of time. Damage is immediate, and may be partially or totally reversible. Acute toxic effects include: Simple asphyxiation: the body does not receive enough oxygen (for example, when gaseous nitrogen has displaced the air in a room). Chemical asphyxiation: the body is prevented from using oxygen (for example, when carbon monoxide instead of oxygen is absorbed in the blood). Anesthetic: causes dizziness, drowsiness, headaches, and coma (for example, by the vapors of many organic solvents). Neurotoxic: the brain's control of the nervous system is slowed down or changed (for example, by concentrations of lead and mercury). Corrosive: body tissue is directly damaged by reaction with chemicals (for example, by strong acids or bases). Allergic: repeated exposure to a chemical produces sensitizing, until there is an allergic reaction at the contact site (usually skin). Irritant: a chemical that causes a reversible inflammatory effect by chemical action at the site of contact. c. Chronic Toxicity - Chronic toxicity refers to adverse or injurious effects that usually result from prolonged exposure to a substance, often at low dose levels. Damage may not appear for many years, and is often irreversible. As a result, this class of hazard is both very difficult and very important to guard against. Types of chronic toxic effects include: 26 Carcinogenicity: produces cancer (for example, acrylonitrile, asbestos, benzene, and vinyl chloride are known to produce cancer in humans). Mutagenicity: alters cell genes; subsequent generations show genetic damage. Teratogenicity: harms developing fetus. Reproductive toxicity: interferes with the reproductive system in women. men or Specific organ toxicity: damages specific organs (for example, carbon tetrachloride can cause liver damage d. Precautions The precautions to take against contact with toxic substances are repeated many times throughout this manual. With chemicals of low acute toxicity, it may be tempting to be less rigorous; yet it is precisely those chemicals that most require continual caution - safety must become a habit. Everyone must protect his or her body against all forms of chemical contact absorption, inhalation, ingestion, and injection. Never eat, drink or smoke in the laboratory; wear the appropriate protective gear, and always remove it before leaving the laboratory. Remember that the chemicals taken home on your clothes will have a more powerful effect on growing children and elderly people than on most adults. 4. Corrosivity Corrosiveness is a form of acute toxicity unique and hazardous enough to merit separate discussion. Corrosive chemicals include strong acids and bases, as well as oxidizing and dehydrating agents. When they come in contact with the skin, eyes, or respiratory tract they react with those tissues and cause local injury. a. Liquid Corrosives A liquid corrosive will act on the skin either rapidly or slowly, depending on concentration and length of contact. These chemicals react directly with the skin - dissolving or abstracting from it some essential components, denaturing the proteins of the skin, or disrupting the skin cells. Inorganic acids, organic acids, and bases are among typical liquid corrosives. When handling liquid corrosives, contact must be scrupulously avoided. Wear goggles, rubber or suitable synthetic gloves, and a face shield. Since many 27 liquid corrosives also release irritating vapors, procedures using these materials may need to be performed in a fume hood. b. Solid Corrosives Solid corrosives interact with the skin when dissolved by surface moisture. Damage then occurs both from the corrosive action and from the heat of solution. Because they are solid, these chemicals are relatively easy to remove; but because they may not react immediately and may not be painful at first (as with the caustic alkalis), they could cause substantial damage before being detected. Solid corrosives are most commonly dangerous in a finely divided state. Dust control and good exhaust ventilation are essential. The use of goggles, gloves, and other protective clothing is critical. In case of chemical contact, care must be taken during the emergency shower irrigation to remove all particles of solid matter that might be lodged in the skin or clothes. c. Gaseous Corrosives Gaseous corrosives pose the most serious health hazard because of possible damage to the lungs, including spasm, edema, pneumonia, and even death. Different corrosive gases affect different parts of the lung (for example, ammonia affects the upper respiratory tract, while phosgene affects the lung, causing pulmonary edema), but all are to be avoided. It is crucial that corrosive gases not be inhaled. These substances must be used in a chemical fume hood or other approved capture device. Skin and eyes must also be protected, as gases contact all exposed parts of the body. 5. Impurities and Combinations MSDSs contain information on pure chemicals, known mixtures, and proprietary materials -- unfortunately there are no such sheets for other materials found in the laboratory, including solutions, mixtures of unknown or uncertain composition, and byproducts of reactions, all common in the laboratory. Impurities, synergistic effects, formation of unexpected products and byproducts, insufficiently clean equipment, and the combination of vapors from your experiment with that of your neighbor's can all produce sudden and unanticipated hazards. There is no absolute protection against all contingencies, but it helps to wear protective gear, to clean equipment scrupulously, to be aware of experiments in progress in nearby areas, and to be completely familiar with emergency procedures. 28 Procedures for Working with Liquid Nitrogen Liquid nitrogen is frequently used in chemical research laboratories for the purpose of cooling. Liquid nitrogen is a valuable coolant because of its low boiling point (bp -196 °C), inexpensive price, and low toxicity. In comparison to liquid air, which was previously used as a popular coolant, liquid nitrogen has the advantage that it does not support combustion. Handling Liquid Nitrogen: Personal Protection Cryogenic liquids such as liquid nitrogen can cause very severe burns upon eye or skin contact. Splashes are common when handling liquid nitrogen, and safety goggles must therefore be worn at all times when working with this material. In addition, protective gloves that can easily be removed in the event of a spill should be worn when handling liquid nitrogen (alternatively, potholders may sometimes be more convenient for handling small containers of cryogenic materials). Particular care must be taken to prevent uninsulated vessels containing liquid nitrogen from coming into contact with unprotected parts of the body, since extremely cold materials can become firmly bonded to the skin such that separation is not possible without serious injury. Contact of the skin with liquid nitrogen can cause severe cryogenic burns; the tissue damage that results is similar to that caused by frostbite or thermal burns. Since small amounts of liquid nitrogen quickly evaporate from the surface of exposed skin, some inexperienced workers may mistakenly underestimate the risk of cryogenic burns when working with this material. In fact, it is not unusual for spills and splashes of liquid nitrogen to become trapped under rings, bracelets, watchbands, or inside gloves, and this can result in serious and painful burns. Containers for Liquid Nitrogen The properties of some materials (including metals) change drastically when exposed to cryogenic liquids such as liquid nitrogen. Containers for such liquids must therefore be selected carefully to ensure that they can withstand the temperatures and pressures they may be exposed to. Liquid nitrogen is commonly stored in Dewar flasks which should be taped to minimize the hazard in the event of an implosion. Cold Traps Cooled with Liquid Nitrogen A common use of liquid nitrogen is as a coolant for traps incorporated in vacuum lines. Extreme care must be employed when using liquid nitrogen as a cold trap coolant. Systems including liquid nitrogen traps must never be opened to the atmosphere until the trap is removed from the coolant. Oxygen has a 29 higher boiling point (-183 °C) than nitrogen (-196 °C), and will condense out of the atmosphere and collect in a liquid-nitrogen cooled vessel open to the air. Liquid oxygen forms highly explosive mixtures with many organic materials. If you suspect liquid oxygen has condensed in a cold trap, then shield the trap (with an explosion shield, closed hood window, etc.), post a sign indicating the danger, and allow the trap (vented to the atmosphere) to slowly warm to room temperature. Liquid Nitrogen and Condensed Argon Argon, a gas commonly employed as an "inert atmosphere" for chemical reactions, distillations, and other laboratory operations, also has a boiling point (-186 °C) which is higher than that of nitrogen. Consequently, liquid argon will condense in a reaction vessel under an argon atmosphere which is cooled with liquid nitrogen. This creates an extremely hazardous situation, since if the vessel is then removed from the coolant, the liquid argon will instantly vaporize, expanding in volume by a factor of 847! Even if the vessel is vented (e.g. to an inert gas line), an explosion is very likely due to the rapid increase in pressure in the vessel. Consequently, never cool an apparatus that is under an argon atmosphere using liquid nitrogen. NFPA 704 WARNING MARKING REGULATIONS 30 NFPA 704 WARNING MARKING REGULATIONS Many fire agencies require NFPA 704 Placards. Check with your local agency to determine their requirements. The following is intended to help you provide proper placards when required by your local agency. The diamond shaped diagram gives at a glance a general idea of the inherent hazards and the order of severity of these hazards under emergency conditions such as spills, leaks and fires. The diagram identifies the "Health", "Flammability", and "Reactivity" hazards of materials and indicates the order of severity of each hazard by the use of numerical gradings, from four (4), indicating severe hazard or extreme danger, to blank, indicating no required warning. In the diamond-shaped diagram, the "health" hazard is identified at the left with a blue background, "Flammability" at the top with a red background and "Reactivity" at the right with a yellow background. The bottom space is used t identify special hazards important to emergency response personnel and has a white background. Additional special hazards are listed in rectangular white boxes below the placard. DETERMINING WARNING SYSTEM PLACARDING REQUIREMENTS FIRST Determine the warning system category numbers for each material stored or used at the facility. The placard warning system number for each hazard category will be selected according to the following criteria: HEALTH 4. ±3. ±2. ±1. FLAMMABILITY ±4. Materials that have an inhalation Threshold Limit Value (TLV) or Permissible Exposure Limit (PEL) of less than 100 parts per million (PPM) and on skin contact can be absorbed through the skin to create a poisonous effect on the body. All other materials that have an inhalation TLV or PEL of less then 100 ppm and may on skin contact create an irritating or burning effect on the exposed skin. Materials that have an inhalation TLV or PEL from 100 to 1000 ppm and may on skin contact create an irritating effect on the exposed skin. Materials that have an inhalation TLV or PEL over 1000 but under 5000 ppm. All flammable gases and liquids with a flash 31 point below -45oF. ±3. ±2. ±1. REACTIVITY ±4. ±3. ±2. ±1. All flammable gases or liquids with flash points from -45oF to 100oF. All combustible liquids or solids with flash points from 101oF to 140oF. All combustible liquids with flash points from 141oF to 300oF. Materials readily capable of detonation or explosive reaction at normal temperatures and pressures. Includes materials that are very sensitive to heat, shock or light. Materials which when heated and under confinement are capable of detonation and which may react violently with water. A -W- should appear as a special hazard if an explosive reaction with water can be expected. Materials which will undergo a violent chemical change at elevated temperatures and pressures but do not detonate. A -W- should appear as a special hazard if contact with water may cause a violent reaction or may cause potentially explosive mixtures to be formed. Materials which are normally stable, but may become unstable in combination with other materials or at elevated temperatures and pressures. A -W- should appear as a special hazard if a vigorous but not violent reaction with water may take place. SPECIAL HAZARDS Special hazard symbols such as -W- (water reactive), OXY (oxidizing material), CRY (cryogenci material), COR (corrosive material), POI (poisonous material) or the radiation warning symbol will be added to the white bottom section of the placard when available information indicates that one of these special hazards exist. When multiple special hazards exist, white panels will be added below the placard to list the additional special hazards that apply. SECOND Determine the need for facility placards by comparing the total amount of 32 material with the same hazard category number to the amount requiring placarding as specified in the following table for each hazard category number. Facility and building placards identify the highest hazard rating in each category based on the combined materials in a category rating exceeding threshold quantities. After the health category number for the facility is determined, use the same process to determine the flammability and reactivity categories. If none of the numbering requirements for a category are met, the category is left without a number and only the background hazard category color shows. ± Hazard Category Rating Number ±HEALTH ±4 ±3 ±2 ±1 ±FLAMMABILITY ±4 Amount requiring outside placarding on a building or area within a facility More than 100 lbs, or 10 gals. or 50 cu. ft. (aggregate totals or weight or volume) More than 100 lbs., or 10 gals. or 50 cu. ft. (aggregate totals of weight or volume) More than 500 lbs. , or 55 gals. or 1000 cu. ft. (aggregate totals of weight or volume) More than 1000 lbs., or 110 gals. or 2000 cu. ft. (aggregate totals of weight or volume) More than 500 lbs., 55 gals. or 1000 cu. ft. (aggregate totals of weight or volume) More than 500 lbs., or 55 gals. or 1000 cu. ft. (aggregate volume of weight or volume) More than 1000 lbs., or 110 gals. or 2000 cu. ft. (aggregate weight or volume) ±3 ±2 33 More than 2000 lbs., or 220 gals. or 4000 cu. ft. (aggregate totals of weight or volume) More than 100 lbs., or 10 gals. or 50 cu. ft. (aggregate totals or weight or volume) More than 100 lbs., 10 gals. or 50 cu. ft. (aggregate totals of weight or volume) More than 500 lbs., or 55 gals. or 1000 cu. ft. (aggregate totals of weight or volume) More than 500 lbs., or 55 gals. or 1000 cu. ft. (aggregate totals of weight or volume) ±1 ± REACTIVITY ±4 ±3 ±2 ±1 THIRD Determine the need to placard subdivisions or rooms within the facility by comparing the amounts of materials that are used or stored in that area with the amounts requiring placarding for each hazard category number. Subdivision, area or room placards are determined in the same way that the facility placarding was determined. Subdivisions or rooms of buildings or areas will be placards to indicate the greatest possible hazards within those subdivisions. Placards will be required when the following amounts of materials are stored or used in a subdivision. ± Hazard Category Rating Number ±HEALTH ±4 ±3 ±2 ±1 34 Amount requiring outside placarding on a building or area within a facility Any amount Any amount More than 100 lbs., or 10 gals. or 50 cu. ft. (aggregate totals of weight or volume) More than 500 lbs., or 55 gals. or 1000 cu. ft. (aggregate totals of weight or volume) ±FLAMMABILITY More than 100 lbs., or 10 gals. or 50 cu. ft. (aggregate totals of weight or volume) More than 100 lbs., or 10 gals. or 50 cu. ft. (aggregate totals of weight or volume) More than 500 lbs., 55 gals. or 1000 cu. ft. (aggregate totals of weight or volume) More than 1000 lbs., or 110 gals. or 2000 cu. ft. (aggregate totals of weight or volume) ±4 ±3 ±2 ±1 REACTIV ITY 4 3 2 1 Any amount Any amount Any amount Any amount PLACARDING SIZE REQUIREMENTS AND PLACEMENT The required measurements for facility placards are 2' by 2' with each category diamond 1' by 1'. Each category diamond on the placard must have the proper background color. The numbers are to be 8" in height with 3/4" stoke and the number is to be centered within its one square foot diamond. The numbers may be either white or black proving sufficient contrast is made against the background color in each category. Placards for building or area subdivisions must be no smaller than 8" by 8" with the same category diamond color requirements. Numbers should be contrasting white or black and be of an appropriate size to be easily read within each category diamond. Placards shall be affixed to buildings or areas within the facility on each side where entry can be made at an appropriate height to be easily seen upon approaching. A placard must be placed at the property line on a facility gate or post if a placarded building or area within a facility cannot be easily seen when approaching the property. Placards that are placed to identify the hazards in 35 area subdivisions due to storage or process shall be affixed next to access points into the subdivisions. These placards must be visible when doors into subdivisions are open or closed. 36 Appendix A Safety Incident Form Safety Incident Report Form Natural Sciences Date & Time ___________________ Class _________________ Faculty _________________ Name of Student or Students involved ___________________________ Short Description of Chemicals or Hazards involved in incident Action taken to handle short term exposure Recommended Action to avoid Incident in Future activities Signature Person filling out form __________________ Signature Student or staff involved __________________ 37 Appendix B Hazardous Waste Characterization – JBWN Chemistry Updated – May 2, 2013 Gen Chem labs, 205/209 0.1 % Fe(Iron), Cr(Chromium), Hg(Mercury), Sn(Tin) - 5% sulfuric and phosphoric acids Waste from titration of ferrous ion, contains 0.1 % Fe(Iron), Cr(Chromium), Hg(Mercury), Sn(Tin) - 5% sulfuric and phosphoric acids 0.2 % Cr( Chromium) Waste from iron ore titration, standard chromium solution produced from sodium dichromate. Contains chromium ~0.2 wt% in water 0.5% Ag, silver and Cu, copper Waste from precipitation titration of chloride with silver nitrate. Silver is present as AgCl in solid phase with indicator, 2,7-dichlorofluorscien. The solution is allowed to settle to separate solid and aqueous phase is poured off since all of the silver has separated. Alternate source is collection of copper from miscellaneous expts and from a UV/Vis experiment using copper in solution. Copper concentration is <1 g/liter in ammonium solution. Other waste from general and analytical chemistry labs. All other experiments in these labs involve dilute acids and bases which are neutralized before disposal or contain only common household chemicals; i.e. citric acid, iron supplements. All other experiments contain less than 1-2 lbs of total waste for entire lab in one week. Organic labs, 109 In general, all waste is collected in waste containers. Acetone is captured after washing glassware with plastic beakers that are transferred at end of lab to a waste container for recycle of the acetone. Only non-hazardous materials are discharged in the sinks such as max of 5 liters per week of acetone and ethanol from rinsing glassware (actual is probably more like 1 liter per week). Acetone, toluene, heptane, cyclohexane, acetonitrile Miscelleanous solvent waste from organic lab. Contains mixture of primarily toluene, heptanes, cyclohexane and acetone ~10-40% of each. Contains less than 20% acetonitrile. Hazard is flammability, flash point expected to be < 140 F cyclohexane, pentenes 38 Primarily mixed pentenes, 40-90% with remainder cyclohexane. Flash point <140 F. chlorinated hydrocarbons, carbon dichloride, chloroform Miscellaneous solvent waste from organic and undergraduate lab. Primarily deutrochloroform and dichloromethane 30-80% . Also contains acetone from cleaning of NMR tubes ~10-20%. May also contain ~10-20% chloroform and carbon tetrachloride. Hazard is chlorinated hydrocarbons. Cyclohexanol, cyclohexanone, acetic acid, ethanol, bleach Waste from oxidation of cyclohexanol in organic lab. Contains cyclohexanol, cyclohexanone, acetic acid 5- 30%. Water is primary remaining component with small quantities of bleach and sodium thiosulfate. May also contain acetone and cyclododecanol/cyclodedecanone. Heptane, methyl benzoate, toluene, esters Waste from general lab operations contains heptanes and toluene 20-50% with small amounts of methyl benzoate from Grignard experiment. Also contains short chain esters of acetic acid, butyric and isobutyric acid with butanol and iso-butanol. Dimethyl formamide, Pyridine Waste from research experiments contains 30-60% Dimethyl formamide, Pyridine. Hazard is dimethylforamide and pyridine content. Methyl t-butyl ether, May be recycled Waste from experiments utilizing Methyl t-butyl ether, 70-90%. May be contaminated with other organics at less than 3%. Hazard is flash point <140 F. Benzene, acetonitrile Waste from experiment is undergraduate lab utilizing benzene 5-20%. Primary solvent is cyclohexane with small amounts of acetonitrile,< 5%. Amine waste Waste from organic lab experiment contains primarily triethyl amine with smaller amounts of other amines. Acetone and ethanol still bottoms, primarily water Residual water from recovery of acetone for reuse. May still contain acetone ~10-20% and small amounts of miscellaneous organic compounds, <5%. Ethanol Waste/ Ethanol, Copper, acetic acid Primarily Ethanol/Methanol with 4-10% butanol and with small amounts of water. Also contains small amounts of benzil and ethyl/butyl esters of butyric and acetic acid. Primary hazard is flashpoint. May contain 50 mg/L Copper. 39 Palladium containing waste Contains less than 0.1% Palladium in toluene, ethyl acetate with triphenyl phosphine present @1-3% Undergraduate research, 104 cyclohexane and carbon tetrachloride Waste from IR experiments using cyclohexane and carbon tetrachloride as solvent. Composition 10-99% these solvents with small amounts <0.1% organic alcohols, diols and amines. Cyclohexane, benzene, acetonitrile Waste from experiment is undergraduate lab utilizing benzene 5-20%. Primary solvent is cyclohexane with small amounts of acetonitrile,< 5%. HPLC Methanol, acetonitrile, water Waste from HPLC contains primarily methanol, 20-50% and small quantities of acetonitrile, ~10-20%. Remainder is water buffered at pH ~3.0. Primarily hazard is flash point < 140 F and low pH. Cobalt chloride, ethylene diamine, triethyleneamine, Chromium, Nickel Waste from inorganic synthesis experiments – contains Cobalt chloride, ethylene diamine, triethyleneamine, Chromium, Nickel. Metals present ~1-10% in water with 10-20% ethylene diamineas chelating agent. pH = 5-8 AA waste lead, Zinc, copper, chromium dilute in water <10 ppm Primarily water containing low levels (10-50 ppm) of zinc, lead, copper, chromium, manganese, selenium. Water has initial pH of ~1-3 treated with Ca(OH)2 to neutralize acid and precipitate metals. Final pH = 10-12 Nickel, Cobalt, Chromium, Mixed metals aqueous Waste from inorganic synthesis experiments – contains Nickel, Cobalt, Chromium, Mixed metals aqueous. pH = 8-10 Manganese, Copper, cobalt, nickel Waste from inorganic synthesis experiments – contains Manganese, Copper, cobalt, nickel in an aqueous solution, pH = 8-10 Antimony waste Waste from inorganic synthesis experiments – contains pH = 1-2. Contains < 2% antimony, mixture of solids and liquids in aqueous medium. Halogenation waste – Combine with halogenated waste container Dichloromethane and bromo-alkanes 40 Solid Organic waste Contains miscellaneous organic solids, benzoic acid, fluorene, fluorenone, tetraphenyl cyclopentanone. Used Pump Oil Pump oil from changing oil in vacuum pumps. May contain low levels of volatiles <0.1%. It has not been certified or tested for flammability, but based on likely composition it does not contain flammables in the vapor head space. 41 New Experiment Form Recognize chemical hazards What chemicals are being used or generated during the experiment. Include summary of key MSDS information on hazards. List all chemicals. Recognize physical hazards What new equipment will be used and what hazards are associated with their use? Assess potential for exposure to these hazards Based on above information summarize key hazards. Minimize exposures to hazards Outline your plan to minimize exposures. Prepare for emergencies What is worst case scenario of you experiment and what would you do? 42 Laboratory Inspections Humans are creatures of habit. In many labs some conditions and procedures may exist that have existed for years (without incident) but still represent unsafe conditions that pose unnecessary risk. It is often hardest to see unsafe conditions that have become "familiar" to you. Furthermore, when entering a new lab with many preexisting conditions, procedures, and people, it is easy to get trained to function in an environment and manner that had been considered "safe" for years, even though it never was "safe” or that changing rules and norms made "unsafe" today. Stephen Jay Gould's quote reminds us that is often hardest to clearly and objectively see those things that are familiar, and perhaps important to us. The thoughtful scientist enters a new lab with new eyes and asks questions. The safety inspection: described below provides a framework to review labs that are either new to you, or very familiar to you. How Do I Conduct An Inspection of My Laboratory? We have provided a checklist of things to look for, but the key is to keep your eyes open to detect uncontrolled hazards. It is easiest to divide your inspection into the broad areas below and then get more detailed with specifics of each of these areas: • • • • • • • Housekeeping Equipment Chemical storage and chemical waste Facility integrity Personal protective equipment Safety information Procedures Rather than trying to be comprehensive for each area, it is probably better to focus on one or two and just hit the highlights of the others. Change the focus points on the next inspections. Remember that your purpose is to make your lab safer by finding and "fixing" previously unrecognized hazard so that they are managed. If possible correct a safety hazard when found, don’t just mark it on a checklist to be fixed. Also, remember that the checklist is for you and your lab mates, but with all lab notes it is prudent to keep this as a reminder of when and what you did on your last self-inspections. What Do I Look For? Housekeeping is a principal cause of incidents. Labs can become cluttered and takes initiative to keep them clean and neat. • Look at exits to ensure they are clear. • Examine your emergency equipment to make sure it is not blocked or hindered by clutter. • Check for cables, cords, bottles, cans, boxes, books, and other materials that can be trip hazard • Look at benchtops, hoods, sinks, and refrigerators to ensure that they are clean and neat. Equipment can be hazardous if not properly maintained. 43 • Look at your chemical hood. Make sure it is working, ensure its vents are not blocked equipment or bottles, and check the date for its last certification (annual requirement). • Check your fire extinguisher for its required yearly inspection tag. Make sure your eyewash station is working and free of obstruction. While you will not be able to check your safety shower, least make sure that it is accessible. • Examine the spill kit to be sure it is fully stocked. • Look for unguarded electrical contacts or moving parts on equipment or instrumentation; especially evaluate "homemade" apparatus for safety issues. • Check for unguarded vacuum pumps with pulleys. • Look at equipment that emits gases, vapors, or aerosols and ensure that they are properly exhausted. • Examine apparatus under negative or positive pressure to ensure it is guarded or wrapped to protect against implosions or explosions. • Check for radiation sources, such as lasers, to ensure they are fully guarded. • Look at your refrigerator and if it is used for storing flammables or combustibles, ensure that it is explosion-proof or safe for flammables. Chemical Storage and Chemical Waste can be contributing factors for incidents. Often chemicals that are not returned to storage can lead to hazardous situations. • Check to ensure that your chemicals are properly stored in compatible groups. • Look for time-sensitive chemicals and ensure they are disposed of at needed times. • Check on high shelves to ensure that chemicals or heavy objects are not stored there—don't store chemicals higher than 5 feet off the floor. • Examine gas cylinders to make sure they are strapped or secured. • Check chemical waste to make sure that it is labeled properly (see Sections 5.1.1 and 5.2.1). Facility Integrity can contribute to incidents. • Look for damaged floors or ceiling tiles. • Check plumbing to ensure there are no obvious leaks. • Check lighting to ensure burned out fixtures are replaced. • Check electrical receptacles to ensure they are in good condition. • Check exit signs and door closers to ensure they are in working order. • Check locks on doors and secure chemical storage to ensure they are working properly. 44 Personal Protective Equipment is an essential part of your protection against hazards. • Ensure that you and others in your lab have and use eye protection. • Ensure that appropriately selected gloves are available and used in procedures. Safety Information is essential to recognize chemical hazards. • Look for posted emergency contact information and ensure it is up to date. • Look for safety warning signs and ensure they are up to date and accurate— note that signs are not for you but for others who are not familiar with your lab. • Check the MSDSs for chemicals that you are using—briefly review them if you have not done so recently. • Examine your chemical inventory to ensure it is up to date for use by emergency personnel. • Look for your lab's Chemical Hygiene Plan. Procedures are the most likely area where incidents will ccur. • Examine your procedures for hazards and ensure that you have taken steps to minimize these hazards. • Look for emergency equipment that you might need for these procedures. • Check for all of your emergency equipment and know its location—fire extinguisher, fire alarm. eyewash, safety shower, fire blanket, and spill kit. 45 Checklist for Inspecting Your Laboratory Your name_________________ Date _ / _ / _ Lab Room Number/Building ______________ Check mark assumes that you have made the necessary corrections Floors clean, dry No bottle, cans, boxes Housekeeping on floor Exits clear/unobstructed Refrigerators clean/neat No cables/cords on floor Sinks clean/neat Benchtops clean/neat Hood vents Hoods clean/neat unobstructed Equipment Hood window clear Chemical hood working Fire extinguishers Hood doors in place unobstructed Hood certified ( / / ) Eyewashes working Extinguisher certified ( / / ) Safety shower Eyewashes unobstructed unobstructed Shower certified ( / _ / ) Spill kit fully stocked No open electrical contacts □ □ □ □ □ □ □ □ □ □ □ Chemical Storage and Chemical Waste Chemicals returned to storage Time-sensitive chemicals removed No heavy objects/ high shelves Chemical waste labeled Chemicals in inventory □ □ □ □ □ Facility Integrity Floors clear/undamaged Ceiling tiles—no sign of leaks Lighting functions properly Electrical receptacles Door closers operating □ □ □ □ □ Personal Protective Equipment Eye protection available/worn Gloves are properly selected Safety Information Emergency contact information MSDSs chemicals being used Chemical inventory up to date Procedures Procedure hazards identified Emergency equipment Fire extinguisher location □ □ □ □ □ □ □ □ Chemicals in compatible groups No chemicals on high shelves Gas cylinders secured Chemicals dated at receipt Gloves available Hazard signs posted MSDSs reviewed CHP available Procedure hazards minimized Emergency materials available Eyewash/shower location known Spill kit location known 46 □ □ □ □ □ □ □ □ □ □ □ □ □ □ □ □ □ □ □ □ □ □ □ □ 47