CIV 216 exp 2Tension Test on metallic Materials

advertisement

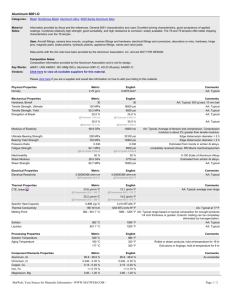

Tension Test on Metallic Materials Experiment #2 Performed: 2007.10.16 Submitted: 2007.10.23 Morgan Kelly Gilmour 1 Objective The purpose of this experiment was to obtain a stress-strain curve and determine basic mechanical properties for four metallic materials, Aluminum 2024, Aluminum 7075, and Steel 1018. Procedure Each of the three, dog-boned shaped, metallic materials, Aluminum 2024, Aluminum 7075, and Steel 7075, is measured with a caliper for thickness and width. They are individually placed in a Q-test machine and subjected to tensile load until fracture occurs, or until the machine can no longer exert force. The experimenter observes the deformation of each material, and refers to the data for stress and strain information. The experimenter then uses this data to make conclusions about the materials’ mechanical properties. Below are the three materials’ cross-sectional areas: Material = (width)(thickness) = area in^2 Width (in) Thickness (in) Area (in^2) Aluminum 2024 0.513 Aluminum 7075 0.5095 Steel 1018 0.515 0.1275 0.0654 0.1255 0.0639 0.1265 0.0651 Table 1. Materials and their areas based on width and thickness Specimens are 9 in x ½ in x ½ in The experimenter must make a stress vs. strain curve for each material. Using the force and elongation data gathered by the Q-test machine, the experimenter divides the force by the cross sectional area of the material to obtain stress (units = lb/in^2 = psi), and divides the distance the material was stretched by the initial distance (change in length / initial length) to obtain strain. The initial distance between the grips of the machine was 6.1 in. Results and Discussion Data from the Q-test machine was collected and inputted into an Excel document, producing three separate stress-strain curves for each of the materials. Samples of the stress and strain calculations, resulting graphs, and analysis of the graphs are shown below. 2 Aluminum 2024 Stress vs Strain 80000 70000 Stress (psi) 60000 50000 40000 30000 20000 10000 0 0 0.02 0.04 0.06 0.08 0.1 0.12 0.14 0.16 0.18 0.2 Strain (%) Figure 1. Aluminum 2024 Stress-strain curve. See Appendix Calculations for sample calculations. The Al 2024 stress-strain curve shows us that relatively brittle. We can see a clear elastic state, where the deformation is linear from about 0-0.02 Strain, and from 0 to about 50000 psi stress. Then the curve arcs, indicating it has entered an inelastic state, and eventually breaks off. The transition point is very obvious, indicating clearly when the material starts to fail. We observed no necking at the break point, but did observe a nearperfect 45º angle in the break point, indicating a brittle material. The break point was smooth and straight, with no material curving into another plane. These observations suggest a brittle material, but the fact that it has entered an inelastic state allows us to reject the option of it being completely brittle. This metal is slightly ductile, but relatively brittle. 3 Aluminum 7075 Stress vs. strain 90000 80000 Stress (psi) 70000 60000 50000 40000 30000 20000 10000 0 0 0.01 0.02 0.03 0.04 0.05 0.06 0.07 0.08 Strain (%) Figure 2. Aluminum 7075 Stress-strain curve The machine was unable to stretch Aluminum 7075 to a point where it broke. Therefore, the Aluminum had no break point. However, when compressed, the material buckled and bent easily. Clearly, the material is either more ductile or just stronger than Aluminum 2024, or perhaps both. Steel 1018 Stress vs. Strain 60000 Stress (psi) 50000 40000 30000 20000 10000 0 0 0.05 0.1 0.15 Strain (%) Figure 3. Steel 1018 Stress-Strain curve 4 0.2 0.25 Steel 1018 is very ductile. There was necking, observable plastic deformation, and a rough break at the break point. It also took a considerable amount of strain to reach its break point, and though it has a clear transition between elastic and inelastic regions, the prominent arc in the inelastic region suggests ductility. Below are the results we gather from the graphs. For explanations as to how to derive these numbers, and for sample calculations, see Appendix Calculations. E (psi) experimental E (psi) accepted E % error Yield Strength (psi) experimental Yield Strength (psi) accepted Yield Strength % error Tensile Strength (psi) experimental Tensile Strength (psi) accepted Tensile Strength % error Rupture Strain (%) experimental Rupture Strain (%) accepted Rupture Strain % error Aluminum 2024 2,500,000 10,587,754.871 -76.39% 53000 470004 12.76% 68000 680007 0% 0.17 0.1810 -5.56% Aluminum 7075 3,000,000 10,732,792.592 -72.04% 72000 716305 .52% Steel 1018 2,400,000 30,457,7703 -92.1% 38000 559706 -32.1% 80000 830008 -3.6% X .1111 X 49000 725009 -32.2% 0.225 0.1812 25% Table 2. The values of E, Yield Strength, Tensile Strength, and Rupture strain for each of the three metals. We see from these graphs and their analyses that Steel is far more ductile than either Aluminum sample. We see that its tensile strength is in between the two other values, but that its yield strength was much lower than Al 2024 and Al 7075’s values were. This is not necessarily always the case, as we saw from the accepted values. Generally, Young’s Modulus Al 2024. http://edboyden.org/constants.html. Young’s Modulus Al 7075. http://www.freepatentsonline.com/5047092.html. 3 Young’s Modulus Steel 1018. http://en.wikipedia.org/wiki/Carbon_steel 4 Yield Strength Al 2024. http://asm.matweb.com/search/SpecificMaterial.asp?bassnum=MA2024T4. 5 Yield Strength Al 7075. http://www.springerlink.com/index/E3Q808137N237R1X.pdf. 6 Yield Strength Steel 1018. http://www.efunda.com/Materials/alloys/carbon_steels/show_carbon.cfm?ID=AISI_1018&prop=all&Page _Title=AISI%201018. 7 Tensile Strength Al 2024. http://asm.matweb.com/search/SpecificMaterial.asp?bassnum=MA2024T4. 8 Tensile Strength Al 7075. http://www.finishing.com/70/11.shtml. 9 Tensile Strength Steel 1018. . http://en.wikipedia.org/wiki/Carbon_steel. 10 Rupture Strain Al 2024. http://www.matweb.com/search/SpecificMaterial.asp?bassnum=MA2024AT3. 11 Rupture Strain Al 7075. http://www.matweb.com/search/SpecificMaterial.asp?bassnum=MA7075T6. 12 Rupture Strain Steel 1018. http://www.matweb.com/search/SpecificMaterial.asp?bassnum=M1018E. 1 2 5 Aluminum 2024 has the lowest yield strength. In our test, our samples could have been flawed, causing a lower yield stress than normal. The Aluminum 7075 could not be broken in the machine, proving that it is stronger than Aluminum 2024. The buckling that occurred when it was compressed does not mean that it would fail differently than 2024 or Steel, because these samples would have buckled had we compressed them, as well. Clearly, Aluminum 7075 was more resistant to failure than Aluminum 2024, proving it to be the stronger aluminum of the two. Steel weighs much more than Aluminum, making it a cumbersome material, and perhaps not as good to build with than Aluminum 7075. Aluminum 7075, all in all, is the best of the three materials. There is significant error involved in all three of the Young’s Modulus values. This can be attributed to the fact that this report was written with the incorrect data. Because the data was incorrect, we can also suspect that the unusually high error for Steel 1018’s numbers was due to this data problem. However, there might also have been material flaws that caused the Steel to break more easily, and this source of error might have also caused the small but acceptable error found in most of the other numbers. There was no rupture strain for Al 7075 because it was so strong that the machine was unable to break it. The machine ceased the tensile load before the Al 7075 broke, leaving us with no rupture strain value. However, we know that the rupture strain was supposed to be at .11, which is curiously lower than the other two materials’ numbers. Conclusion After careful analysis of the Young’s Modulus, Tensile Strength, Yield Strength, and Rupture Strength of Aluminum 2024, Aluminum 7075, and Steel 1018 under tension, we can conclude that Aluminum 7075 is the superior material because of its light weight, large tensile strength and yield strength, and superior strength to the other two materials. Aluminum 7075 was the only material that did not fracture in the machine, and although Steel is more ductile than Aluminum 7075, Steel did fracture under less stress. 6 Appendix References Conversion Factors, Material Properties, and Physical Constants. 2007. http://edboyden.org/constants.html. Visited 2007.10.20 Young’s Modulus Al 7075. 2007. http://www.freepatentsonline.com/5047092.html. Visited 2007.10.20 2 3 Carbon Steel. 2007. http://en.wikipedia.org/wiki/Carbon_steel. Visited 2007.10.20 4 ASM Aerospace Specification Metals. 2007. http://asm.matweb.com/search/SpecificMaterial.asp?bassnum=MA2024T4. Visited 2007.10.20 5 The Effect of Joint Design on Mechanical Properties of AL7075. 2005. http://www.springerlink.com/index/E3Q808137N237R1X.pdf. Visited 2007.10.20 6 AISI 1018. 2007. http://www.efunda.com/Materials/alloys/carbon_steels/show_carbon.cfm?ID=AISI_1018 &prop=all&Page_Title=AISI%201018. Visited 2007.10.20 7 ASM Aerospace Specification Metals. 2007. http://asm.matweb.com/search/SpecificMaterial.asp?bassnum=MA2024T4. Visited 2007.10.20 8 Seeking Suppliers of Alloys for Air Force. 2007. http://www.finishing.com/70/11.shtml. Visited 2007.10.20 9 Carbon Steel. 2007. http://en.wikipedia.org/wiki/Carbon_steel. Visited 2007.10.20 10 Al 2024, 2007. http://www.matweb.com/search/SpecificMaterial.asp?bassnum=MA2024AT3. Visited 2007.10.20 11 Al 7075, 2007. http://www.matweb.com/search/SpecificMaterial.asp?bassnum=MA7075T6. Visited 2007.10.20 12 Steel 1018, 2007. http://www.matweb.com/search/SpecificMaterial.asp?bassnum=M1018E. Visited 2007.10.20 7 Sample Calculations Stress Sample Calculation: Force = 4271.415 lbs Cross sectional area of Nylon = .0654 in^2 4271.415 / .0654 = 65312.16 psi = stress Strain Sample Calculation: Distance = 1.053 in Initial grip separation = 6.1 in 1.053 in / 6.1 in = 0.172623 = strain Aluminum 2024 Stress vs Strain 80000 70000 Stress (psi) 60000 50000 40000 30000 20000 10000 0 0 0.02 0.04 0.06 0.08 0.1 0.12 0.14 0.16 0.18 0.2 Strain (%) We find by looking at the graph that Al 2024’s Young’s Modulus, E, is equal to the slope of the elastic region, 2,500,000 psi. E = delta y / delta x = [(50000) psi]/[(.02-0)] = 2500000 psi 8 The internet suggests that Young’s Modulus should be about 7.310E+10 Pa, which translates to 10,587,754.87 psi.13 The error is extremely large, and the procedure for calculating percent error is below: [(experimental – accepted value) / (accepted value)] *100 = percent error The tensile strength is calculated by observing where the stress-strain curve reaches its peak. In Al 2024’s graph, we see that the tensile strength is about 68000 psi. The yield strength is calculated by following the slope of the elastic region of the stressstrain curve after observing an offset strain of .2%. We can estimate this to be about 53000 psi after looking at the graph. Finally, the rupture strain is the last point on the graph. We estimate this point to be at about .17%. 13 Young’s Modulus for Al 2024. http://edboyden.org/constants.html. 9