UCS & BTS Correlation in Limestone: A Geotechnical Study

advertisement

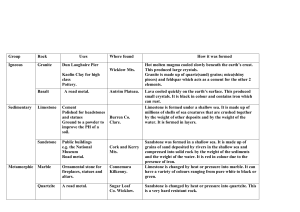

Correlation Between Unconfined Compressive Strength and Indirect Tensile Strength of Limestone Rock Samples Ramli Nazir Associate Professor (Ir. Dr), Faculty of Civil Engineering, Department of Geotechnics and Transportation, Universiti Teknologi Malaysia Ehsan Momeni PhD student in Geotechnical Engineering, Faculty of Civil Engineering, Department of Geotechnics and Transportation, Universiti Teknologi Malaysia; mehsan23@live.utm.my Danial Jahed Armaghani PhD student in Geotechnical Engineering, Faculty of Civil Engineering, Department of Geotechnics and Transportation, Universiti Teknologi Malaysia; danialarmaghani@yahoo.com Mohd For Mohd Amin Associate Professor, Faculty of Civil Engineering, Universiti Teknologi Malaysia ABSTRACT In Geotechnical Engineering, determining the Unconfined Compressive Strength (UCS) of rock is of prime importance as its role in design and analysis of geotechnical problems is crucial. Although laboratory test is the most direct way for estimating the rock compressive strength but UCS determination in the laboratory would be problematic if the rock masses are weathered mainly because obtaining proper core segments for testing purpose is difficult in this situation. Hence, the use of index testing as an alternative for predicting UCS is investigated by researchers. It is well established that indirect tensile strength or Brazilian Tensile Strength (BTS) is related to UCS. In this paper, in order to develop a new correlation between UCS and BTS, some laboratory tests on dry limestone specimens including 20 Unconfined Compression Tests (UCT) and 20 Brazilian Tests (BT) have been conducted. The paper also reviews some recent correlations between UCS and BTS as well as investigates the reliability of these correlations. Findings show the results of the experimental tests are in good agreement with previous studies. Based on the results, new strong correlation with coefficient of determination of 0.9 is introduced for predicting the UCS of limestone core samples from its BTS. A critical review on the degree of accuracy of recent correlations between UCS and BTS shows that apart from Kahraman`s correlation, other correlations either overestimate or under estimate UCS of rock samples to a significant amount. KEYWORDS: Brazilian Test, Indirect Tensile Strength, Limestone, Unconfined Compressive Strength. - 1737 - Vol. 18 [2013], Bund. I 1738 INTRODUCTION Unconfined Compressive Strength (UCS) of rock is considered as an essential parameter in analysis of geotechnical problems such as rock blasting and tunneling. Although laboratory test is the most reliable and direct method for estimating UCS, direct determination of UCS in laboratory is time-consuming and expensive. In addition, in direct method of UCS determination, having sufficient number of high quality rock samples is a prerequisite. However, it is not always possible to extract proper cores for sampling purpose in highly weathered rocks (Romana, 1999; Kahraman, 2001; Ceryan et al. 2012).Therefore, the use of various correlations for UCS prediction has been highlighted in the literatures. These correlations often relate other rock index parameters such as point load index, rebound number of Schmidt hammer, and indirect tensile strength of the rock to UCS (Cargill and Shakoor, 1999; Sharma and Singh, 2008; Nazir et al. 2013). Implementing such correlations is of interest, mainly due to the fact that rock index tests have the advantages of being relatively fast and economical. Brazilian Test (BT) is used for indirect determination of tensile strength of rock samples. It is established that Brazilian tensile strength is related to UCS. Oneof the most agreed correlation between UCS and indirect tensile strength or Brazilian Tensile Strength (BTS) of the rock is highlighted in the study by Sheorey (1997). According to his study, the compressive strength of the rock is approximately 10 times its tensile strength. Nevertheless, Sheorey`s strength ratio variation is high (Cai, 2006) and consequently cannot be generalized due to the fact that rock behavior varies from place to place and is site specific. This paper proposes a new correlation between UCS and BTS of specific type of rock i.e limestone as the relationship between compressive and tensile strength of rock depends on rock type (Brook, 1993). PREVIOUS STUDIES Many studies have been conducted to show that UCS is related to other physical properties of the rock samples (Sheorey et al. 1984; Shakoor and Bonelli, 1991; Ulusayet al. 1994; Romana, 1999; Tugrul and Zarif, 1999; Sachpazis, 1999; Katza et al. 2000; Kahraman, 2001;Yasar and Erdogan, 2004; Chang et al. 2006; Guney et al. 2005; Tiryaki, 2006; Vasconcelos, 2008; Sharma and Sing, 2008; Kilic and Teymen, 2008; Moradian and Behnia, 2009; Diamantiset al. 2009; Ceryanet al. 2012; Kohno and Maeda, 2012; Nazir et al. 2013; Khandelwal, 2013). Kahraman et al. (2012) conducted a research on compressive and tensile strength of different type of rocks. Based on their results, they proposed a linear correlation between UCS and BT. However, the coefficient of determination, R2, of their study was almost 0.5 which is not reliable enough. Farah (2011) conducted a comprehensive study to obtain some correlations between UCS and other physical properties of weathered Ocala limestone. According to his study, indirect tensile strength i.e BTS has a better correlation with UCS than that of point load strength. In order to discover correlations between UCS and other physical properties of the rock samples, Altindag and Guney (2010) conducted a research for a wide range of strength values i.e UCS (5.7 - 464 MPa), BTS (0.5 - 30.5 MPa). They found a strong correlation between UCS and BTS of the different rock types.Tungal and Zarif (2000) conducted another study on engineering properties of limestone in Istanbul, Turkey.Their results show that there is a linear correlation between UCS and BT. The positive linear relationship between UCS and indirect tensile strength is also confirmed in the study by Gupta and Rao (1998). Din and Rafigh (1997) investigated the relationship between UCS and BTS of two different types of limestone in Pakistan. According to their findings, the UCS to BTS ratio is almost 7.5. However, Vutukuri et al. (1974) suggested that strength ratio of most rocks varies from 10 to 50. Vol. 18 [2013], Bund. I 1739 Table 1: Recent correlations between UCS and BTS References Correlation R or R2 Rock Type Kahraman et al.(2012) UCS ( R2 = 0.5 Different rock types including limestone Farah (2011) UCS ( Altindag and Guney (2010) UCS (MPa)= 12.38 * BTS1.0725 ) ) = 10.61 ∗ BTS = 5.11 ∗ BTS − 133.86 R2 = 0.68 Weathered limestone R = 0.89 Different rock types including limestone LABORATORY ROCK STRENGTH TESTS Rock strength test is to verify resistance of rock against loading. The strength test can be direct or indirect where the term direct or indirect implies mode of loading under which rock sample is subjected to. Since strength test involves destruction of sample, property being assessed is direct indication on strength and it can be considered as afundamental data for detailed design. Strength tests carried out in this study are: (1) Unconfined Compression Test (Direct strength test), and (2) Indirect tensile strength test (Brazilian test). Unconfined Uniaxial Compression Test Uniaxial Compression Test, also termed as UCT, is used for estimating the compressive strength of rock specimens under uniaxial loading. The compressive strength of rock sample is obtained through loading rock specimens under either load-controlled condition or straincontrolled condition. The latter represents loading conditions more precisely in the field and causes complete stress-strain curve (Figure 1) of sample to be obtained. Depending on monitored parameters during test, several basic engineering properties of rock can be determined from this test. Basically, UCT is used to determine ultimate uniaxial compressive strength (UCS). In fact, UCS is the peak value in curve and the corresponding axial strain, a, where peak stress occurs is termed as strain at failure (f %). Stillborg (1986) listed typical values for compressive strength (UCS) for various rocks. According to his suggestion, UCS of limestone rocks ranges from 50 MPa to 200 MPa. Nevertheless, if UCT is conducted with measurement on axial strain (a) and horizontal strain (r) through installing a pair of strain gauges, besides UCS, several important parameters pertaining to rock deformation such as strain at failure (f), Young’s modulus (E) and Poisson’s ratio (), can be obtained (See Figure 1). a 120 c = 104 MPa 80 Slope = c/2 40 Slope = Et, Eav -0.2 -0.1 r (%) 0 0.1 0.2 0.3 a (%) Figure 1: Schematic figure of stress-strain curve Vol. 18 [2013], Bund. I 1740 Indirect Tensile Strength Tensile strength test is to verify tensile strength of rock samples or its resistance against fracturing. Direct tensile test on rock sample is relatively difficult to undertake and Brazilian test offers an indirect method to measure tensile strength. The term ‘indirect tensile’ implies that load is applied under compression. Figure 2 shows typical mode of failure associated with tensile stress. Typical values for Brazilian tests or indirect tensile strength for various rocksare listed in the study by Stillborg (1986). According to his work,BTS of limestone ranges from 5 MPa to 20MPa. Figure 2: Mode of failure of rock samples in Brazilian test TEST PROCEDURE 40 laboratory strength tests on dry limestone core samples including 20 unconfined compression tests and 20 Brazilian Tensile Strength (BTS) tests were conducted in Geotechnical Laboratory of University Teknologi Malaysia according to the procedure suggested by International Society of Rock Mechanic (ISRM, 1981). More illustration regarding tests procedures are given in the following paragraphs. Uniaxial compression test The uniaxial compression tests were conducted on Tinius Olsen (USA) Universal Testing Machine (UTM). This machine with 3000 kN capacity can apply compressive load at constant strain rate on the specimen. In this study, all compression tests were conducted at strain rate equals to 0.5mm/mm/s. TML 500 kN load cell (see Figure 3) and a pair of strain gauges were used to measure applied load and deformation during the test. In order to record data, both load cell and strain gauges were wired to a data logging system. The stress-strain data was continuously logged into a computer and the stress at failure was considered as the UCS of limestone specimens. Vol. 18 [2013], Bund. I 1741 Figure 3: 500 kN TML load cell and installed strain gauges Brazilian Test Th test was conducted using Brazilian test apparatus (MATEST of Italy) which is equipped with digital display unit for displaying maximum load (see Figure. 4). Sample is placed on specially fabricated steel cradle (Figure 5), and then mounted in between the loading platens. This cradle ensures load acts tangentially on the disc-shaped sample and consequently induces tensile fracture along its vertical diameter. Sample thickness (t) and diameter (D) were recorded, and load was applied until sample fails under maximum compressive load (in kN). Having the sample dimension and maximum tensile load at failure (F), the Brazilian Tensile Strength (BTS) is obtained by using the following equation given by Gokhale (1960). = Figure 4: Brazilian test apparatus 2 Figure 5: Cradle for disc sample Vol. 18 [2013], Bund. I 1742 Result and Discussion The unconfined compression and Brazilian tests results are tabulated in Table 2. Previous literatures show that results are in acceptable ranges. (Stillborg ,1986; Matsui and Shimada, 1993; Reddish and Yassar, 1996; Din and Rafiq, 1997; Farah, 2011; Kahraman, 2012). As shown in the Table 2, the UCS of limestone core samples ranges between 21.18 to 100 MPa while BTS ranges between 3.02 to 14.2 MPa. In Table 2, apart from determined UCS and BTS in laboratory, UCS is predicted by using recent correlations given in Table 1for further reliability analysis. Figure 6 depicts the determined UCS versus obtained BTS in laboratory. As shown in this figure, there is a strong correlation with high reliability between UCS and BTS. The new proposed correlation for prediction of UCS is given in the following equation. The proposed relationship between UCS and BTS is close to suggested ratio of compressive strength to tensile strength given by Sheorey (1997) and Kahraman et al., (2012). In addition, the coefficient of determination of developed correlation is 0.9 which is relatively higher than previous suggested correlations. Apart from that,new correlation has the advantage of being developed for specific type of rock which is limestone. ( ) = 9.25 . Table 2: Laboratory tests results and Predicted UCS \ Predicted UCS (MPa) Predicted UCS (MPa) Predicted UCS (MPa) Kahraman et al.(2012) Altindag and Guney (2010) Farah (2011) 82.55 111.11 38.83 52.67 69.39 92.23 32.50 3.02 21.18 32.04 40.27 14.51 Limestone 5.93 61.61 62.92 83.04 29.38 5 Limestone 5.78 51.73 61.33 80.79 28.61 6 Limestone 3.22 27.29 34.16 43.14 15.53 7 Limestone 4.98 52.20 52.84 68.86 24.52 8 Limestone 8.83 78.09 93.69 127.27 44.20 9 Limestone 6.90 53.14 73.21 97.69 34.34 10 Limestone 8.28 60.20 87.85 118.79 41.39 11 Limestone 10.36 83.26 109.92 151.06 52.02 12 Limestone 7.41 76.67 78.62 105.46 36.94 13 Limestone 7.29 58.5 77.35 103.62 36.33 No Sample Type Determined BTS (MPa) Determined UCS (MPa) 1 Limestone 7.78 70.56 2 Limestone 6.54 3 Limestone 4 14 Limestone 11.09 85.62 117.66 162.51 55.75 15 Limestone 6.2 54.6 65.78 87.10 30.76 16 Limestone 14.2 100.7 150.66 211.84 71.64 17 Limestone 5.4 42.3 57.29 75.11 26.67 18 Limestone 6.1 51.7 64.72 85.60 30.25 19 Limestone 7.5 60.4 79.58 106.83 37.40 20 Limestone 6.3 50.3 66.84 88.61 31.27 Vol. 18 [2013], Bund. I 1743 Figure 6: Proposed correlation between unconfined compressive strength and Brazilian tensile strength The reliability and degree of accuracy of recent correlations for UCS prediction using BTS is shown schematically in Figure 7. A critical review on the correlations shows that Kahraman`s correlation (2012) can predicts UCS much better than correlation proposed by Farah (2011) and Altindag and Guney (2010). In fact, in comparison to the observed UCS, Kahraman`s correlation overestimate UCS by a factor almost equals to 1.27 while predicted UCS using Altindag and Guney`s is 1.7 times bigger than the laboratory measurements. On the other hand, Farah`s correlation underestimates UCS by 60%. Figure 7: Reliability of recent UCS-BTS correlations based on observed laboratory results Vol. 18 [2013], Bund. I 1744 CONCLUSIONS Based on the findings, the following conclusions can be drawn: 1) A number of 40 laboratory tests including 20 unconfined compressive tests and 20 indirect tensile strength (Brazilian tensile strength) tests on dry limestone specimen were conducted. The laboratory measurements showed that obtained UCS and BTS were in good agreement with previous studies. 2) From the laboratory results, a new correlation with high reliability and degree of accuracy i.e R=0.9 was proposed for predicting UCS of limestone specimens from its BTS results. 3) Through a critical review on some recent correlations for UCS prediction, it was observed that the correlation suggested by Kahraman (2012) can predict UCS much better that other proposed correlation. However, Kahraman`s correlation which is very close to well established correlation suggested by Sheorey (1997) overestimated the dry UCS of limestone core samples by a factor of 1.27. ACKNOWLEDGEMENTS The second and third authors would like to thank University Teknologi Malaysia for its financial support via allocating International Doctoral Fellowship. REFERENCES 1. Altindag, R., and Guney, A. (2010) Predicting the Relationships between Brittleness and Mechanical Properties (UCS, TS and SH) of Rocks. Scientific Research and Essays Vol. 5(16), pp. 2107 – 2118. 2. Brook, N. (1993) The Measurement and Estimation of Basic Rock Strength. In comprehensive rock engineering, 3: 41-66. 3. Cai, M. (2009), A Simple Method to Estimate Tensile Strength and Hoek-Brown strength Parameter mi of Brittle Rocks. Proceedings of the 3rd CANUS Rock Mechanics Symposium, Toronto. 4. Cargill J.S., and Shakoor A. (1990) Evaluation of Empirical Methods for Measuring the Uniaxial Compressive Strength of Rock. Int J Rock Mech Min Sci & Geomech Abstr 27:495-503. 5. Ceryan N, Okkan U, Kesimal, A (2012) Prediction of Unconfined Compressive Strength of Carbonate Rocks using Artificial Neural Networks. Environ Earth Sci. DOI 10.1007/s12665-012-1783-z. 6. Chang C, Zoback MD, Khaksar A (2006) Empirical Relations between Rock Strength and Physical Properties in Sedimentary Rocks. J Petrol SciEng 51. 7. Diamantis K, Gartzos E, Migiros G (2009) Study on Uniaxial Compressive Strength, Point Load Strength Index, Dynamic and Physical Properties of Serpentinites from Central Greece: test results and empirical relations. Eng Geol 108:199–207. Vol. 18 [2013], Bund. I 1745 8. Din, F., and Rafiq, M. (1997) Correlation between Compressive Strength and Tensile Strength/ Index Strength of Some Rocks of North- west Frontier Province (Limestone and Granite). Geological Bulletin, University of Peshawar, 30, 183. 9. Farah, R. (2011) Correlations Between Index Properties and Unconfined Compressive Strength of Weathered Ocala Limestone. UNF Theses and Dissertations. Paper 142. 10. Gokhale K. V. J. K. (1960) Experiments in Engineering Geology, Tata McGrawHill,New Deh Ii, 23-32,47-49. 11. ISRM. (1981)Rock Characterization Testing and Monitoring, ISRM suggested methods. Commission on testing methods. International Society for Rock mechanic. Oxford: Pergamon press Ltd. 12. Kahraman S. (2001) Evaluation of Simple Methods for Assessing the Uniaxial Compressive Strength of Rock. Int J Rock MechMin Sci 38:981–994. 13. Kahraman, S., Fener, M., & Kozman, E. (2012) Predicting the Compressive and Tensile Strength of Rocks from Indentation Hardness Index. Journal of the Southern African Institute of Mining and Metallurgy, 112(5), 331-339. 14. Khandelwal, M. (2013) Correlating P-wave Velocity with the Physico-Mechanical Properties of Different Rocks. Pure Appl. Geophys. 170, 507–514. 15. Kohno, M. and Maeda, H. (2012) Relationship between point load strength index and uniaxial compressive strength of hydrothermally altered soft rocks. International Journal of Rock Mechanics & Mining Sciences. 50, 147-157. 16. Moradian Z, Behnia M. (2009) Predicting the Uniaxial Compressive Strength and Static Young’s modulus of Intact Sedimentary Rocks using the Ultrasonic Test. Int J Geomech:14–19. 17. Nazir, R., Momeni, E., Jahed Armaghani, D and Mohd For, M (2013) Prediction of Unconfined Compressive Strength of Limestone Rock Samples Using L-Type Schmidt Hammer. Electronic Journal of Geotechnical Engineering. 18 bound I. 18. Reddish DJ, Yasar E (1996) A New Portable Rock Strength Index Test Based on Specific Energy of Drilling, Int. J. Rock. Mech. Min. Sci. Geomech. Abstr., 33(5): 543-548. 19. Romana, M. (1999) Correlation between Unconfined Compressive and Point-Load (Miller tests) Strengths for Different Rock Classes. In: 9th ISRM Congress, 1. Balkema, Paris, pp 673–676. 20. Sachpazis, C.I. (1990) Correlating Schmidt Hardness with Compressive Strength and Young’s Modulus of Carbonate Rocks. Bull. Int. Assoc. Eng. Geol. 42, 75– 83. 21. Shakoor A.,and Bonelli R. (1991) Relationship between Petrographic Characteristics, engineering index properties and mechanicalproperties of selected sandstones. Bull AssocEngGeol 28:55–71. 22. Sharma P.K., Singh T.N. (2008) A Correlation between P-wave Velocity, Impact Strength Index, Slake Durability Index and Uniaxial Compressive Strength. Bull Eng Geol Environ67:17–22. 23. Sheorey, P. R. (1997) Empirical Rock Failure Criteria. Rotterdam: A.A. Balkema, 176p. 24. Stillborg, B. (1986) Professional Users Handbook for Rock Bolting. Germany. Transtech publication. 144 pp. 25. Tiryaki B (2006) Evaluation of the Indirect Measures of Rock Brittleness and Fracture Toughness in Rock Cutting, J. S. Afr. Inst. Min. Metall.,106: 1-18. Vol. 18 [2013], Bund. I 1746 26. Tugrul, A., and Zarif, I. H.(1999) Correlation of Mineralogical and Textural Characteristics with Engineering Properties of Selected Granitic Rocks from Turkey. Eng. Geol. 51, 303–317. 27. Ulusay R, Tureli K, and Ider M. H. (1994) Prediction of Engineering Properties of a selected Litharenite Sandstone from its Petrographic Characteristics using Correlation and Multivariate Statistical Techniques. Eng Geol 38(2):135–157. 28. Vasconcelos G., Lourenco P.B., Alves C.S.A., and Pamplona J. (2008) Ultrasonic Evaluation of the Physical and Mechanical Properties of Granites. Ultrasonic’s 48:453– 466. 29. Yasar, E., and Erdogan, Y.(2004) Estimation of Rock Physiomechanical Properties using Hardness Methods. Eng. Geol. 71, 281– 288. © 2013, EJGE