Heat Conduction Through Various Material in a

advertisement

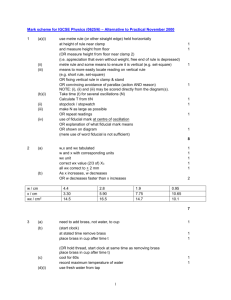

Heat Conduction Through Various Material in a Series of Bars MECH595 – Introduction to Heat Transfer Professor M. Zenouzi Prepared by: Andrew Demedeiros, Ryan Ferguson, Bradford Powers October 22, 2009 1 Abstract This laboratory explores the phenomenon of linear heat conduction in various materials. The thermal contact resistance and thermal conductivity of unknown materials are calculated using a measured temperature profile. Graphical representations are presented along with calculated figures. 2 Contents Introduction .................................................................................................................................................. 4 Theory ........................................................................................................................................................... 4 Procedure...................................................................................................................................................... 6 Results ........................................................................................................................................................... 6 Brass 1” to Brass 1” ................................................................................................................................... 7 Brass 1” to Brass 1” to Brass 1” ................................................................................................................ 8 Brass 1” to Stainless Steel 1” to Brass 1” .................................................................................................. 9 Brass 1” to Brass 0.5” to Brass 1” ........................................................................................................... 10 Brass 1” to Paper to Brass 1” .................................................................................................................. 11 Brass 1” to thermal grease to Brass 1” ................................................................................................... 12 Discussion of Results ................................................................................................................................... 13 Conclusion ................................................................................................................................................... 13 Appendix ..................................................................................................................................................... 15 Raw Thermocouple and Power Readings ............................................................................................... 15 3 Introduction This laboratory studies the phenomenon of linear thermal conduction including the effect of thermal contact resistance and thermal conductivity of materials. The Hampden Model H-6862-CDL multi-section bar module is used to study these properties. This setup is shown in Figure 1. Figure 1 ~ Hampden H-6862-CDL This device provides heat via an electric heater. The power and heat generation is monitored by a digital wattmeter and a series of thermocouples. For the study of linear heat conduction two or three sections are placed in the machine. Each piece consists of a metal sample encased in thermoplastic insulation. It should be noted that in an ideal setup, no heat would be lost through the insulation. While heat is lost to the environment on this device, this loss will be treated as negligible. Materials tested include 1” brass, ½” brass, 1” stainless steel, and paper. Additionally the effectiveness of a silicon thermal compound was evaluated. Theory In this laboratory experiment heat flux in the axial direction in a brass bar was to be calculated. To calculate the heat flux across the brass bar equation 1 was used. Eq. 1 4 Thermal resistance for the bar can be calculated by Equation 2. Eq. 2 Thermal resistances help to create a “thermal circuit”, it allows the circuit to be expressed symbolically, which becomes simpler and easier to solve. To calculate the total axial heat flux per unit area, equation 3 is used. Area is omitted. Eq. 3 Applying an energy balance to the axial heat conduction system, it is shown that all energy entering the system exits the system, resulting in zero net stored energy. Being that the bar is very well insulated radially, it is clear that all heat transferred is in the axial direction. Eq. 4 Where Ein signifies the energy applied to the system, and Eout is the energy transferred via conduction. Input heat flux into the system can be calculated by dividing the total input power by the cross sectional area of the bar, shown in equation 5. Eq. 5 Thermal conductivity, k can be calculated using the following equation and then solving for k. In order to do this though, the value of q must be known. As seen below in Equation 6. 5 Eq. 6 Procedure The procedure of this experiment is provided below. 1. Connect the thermocouples into the heater jacks on the linear panel. 2. Plug in the heater power cord into the heater socket on the linear panel. 3. Clamp the desired linear panel between the heat transfer assemblies. 4. Power the device with 120 VAC. Switch on the main AC circuit breaker. Open and run the LabView software. 5. Set desired temperature. Allow time for steady state to be reached. At this point the wattmeter and temperature reading will stabilize. 6. Repeat for each desired material, replacing the panels and allowing for steady state to be reached. Results The results for the tested samples are provided below. The data for each sample is provided in its own section. Detailed temperature records are provided in the appendix at the end of this report. The heat transfer rate per area was calculated using Fourier’s law: q' ' x = K ∆T L Where k is the thermal conductivity The contact resistances are calculated using the following formula: Rt'',c = T A − TB q' ' x 6 Brass 1” to Brass 1” ΔT L Kbook A q'' q Rc ktotal 100 90 80 70 Temp ˚C 60 50 40 30 20 10 0 0 0.02 0.04 0.06 0.08 0.1 0.12 Thermocouple location 7 0.14 67.78 0.127 109 0.000506 58171.4 29.47 0.000935 244.69 ˚C m W/m·K m2 W/m2 W K·m2/W W/m·K Brass 1” to Brass 1” to Brass 1” ΔT L Kbook A q'' q Rc ktotal 100 90 80 70 Temp ˚C 60 50 40 30 20 10 0 0 0.02 0.04 0.06 0.08 0.1 0.12 Thermocouple location (m) 8 0.14 127 0.1778 109 0.000506 77857.1 39.45 0.000813 328 ˚C m W/m·K m2 W/m2 W K·m2/W W/m·K Brass 1” to Stainless Steel 1” to Brass 1” ΔT L Kbook A q'' q Rc k ktotal 100 90 80 70 Temp ˚C 60 50 40 30 20 10 0 0 0.02 0.04 0.06 0.08 0.1 0.12 0.14 0.16 Thermocouple location (m) 9 0.18 0.2 123 0.178 109 0.000506 75320.2 38.16 0.000796 17.55 332 ˚C m W/m·K M2 W/m2 W K·m2/W W/m·K W/m·k Brass 1” to Brass 0.5” to Brass 1” ΔT L Kbook A q'' q Rc k ktotal 100 90 80 70 Temp ˚C 60 50 40 30 20 10 0 0 0.02 0.04 0.06 0.08 0.1 0.12 0.14 Thermocouple location (m) 10 0.16 0.18 0.2 189 0.178 109 0.000506707 115735.9551 58.64427403 0.00048482 137.93 476 ˚C m W/m·k m2 W/m2 W K·m2/W W/m·k W/m·k Brass 1” to Paper to Brass 1” ΔT L Kbook A q'' q Rc ktotal 90 80 70 Temp ˚C 60 50 40 30 20 10 0 0 0.02 0.04 0.06 0.08 0.1 Thermocouple location (m) 11 0.12 0.14 100 0.127 109 0.000506 85826.7 43.489 0.000472 378 ˚C m W/m·K m2 W/m2 W K·m2/W W/m·K Brass 1” to thermal grease to Brass 1” ΔT L Kbook A q'' q Rc ktotal 90 80 70 Temp ˚C 60 50 40 30 20 10 0 0 0.02 0.04 0.06 0.08 0.1 Thermocouple location (m) 12 0.12 0.14 87 0.127 109 0.000506 74669.2 37.835 0.000252 611 ˚C m W/m·K M2 W/m2 W K·m2/w W/m·K Discussion of Results The data displayed on the pages above show the linear temperature distribution for each combination of material. The tables to the right of the graphs display the calculated results for each material. The 1” brass to 1” brass setup resulted in a thermal conductivity value of 244.69 W/m·K. The 1” brass section had a calculated thermal conductivity of 328 W/m·K and the ½” insert had a value of 476 328 W/m·K. This is an average value of 350 W/m·K. This compares to a book value of 110 W/m·K for cartridge brass (70% Cu, 30% Zn). For the sample in which the brass sections where connected through paper the calculated k value for the system was 378 W/m·K. Since the paper was thin, it was difficult to obtain a thermal conductivity value for just the paper with the laboratory equipment. Although paper would generally be considered an insulator, the extremely thin nature of the paper compared to the brass bars would make this property subtle. For the brass enhanced with the thermal grease the overall system thermal conductivity was calculated to be 611 W/m·K. This is significantly greater than the value calculated for the brass bars alone. This shows that the thermal paste is enhancing the ability of the brass to transfer heat. Finally the 1” stainless steel segment resulted in a combined system thermal conductivity of 332 W/m·K. The book value conductivity for stainless steel is 480 W/m·K. Conclusion The data and results calculated from this experiment where somewhat mixed. Many of the calculated thermal conductivity values for the materials were either too high or low considering the 13 generally accepted book values. There are several situations that could have brought about this lack of accuracy. First it is possible that not sufficient time was taken between changing materials and taking measurements. Given that the results were supposed to be taken at near steady-state conditions a delay of at least five time constants should have been taken between changing materials and taking temperature measurements. This most likely explains the large difference between temperatures in the two bars (especially in the 1” brass to 1” brass example). It is also possible that the instruments and thermocouples where configured incorrectly. This would have also disrupted the results. Although the detailed calculation are questionable the generally trend of the heat flow is obvious. In all examples it is clear that the temperature distribution is transitioning from high to low in the direction of heat flow. 14 Appendix Raw Thermocouple and Power Readings 1” Brass- 1” Brass Left Bar Right bar Water in Water out Heater Temp Thermocouple Temp ˚F Temp ˚c 0 201 93.8889 0.0254 190 87.7778 0.0508 185 85 0.051 87 30.5556 0.1016 82 27.7778 0.127 79 26.1111 76 24.4444 76 24.4444 296 146.667 1” Brass – 1” Stainless – 1” Brass Left Bar Right bar Water in Water out Heater Temp 1” Brass- 1” Brass - 1” Brass Thermocouple Left Bar 0 0.0254 0.0508 0.0762 0.1016 0.127 Center Bar Water in Water out Heater Temp - Temp ˚F Temp ˚c 203 95 196 91.1111 190 87.7778 89 31.6667 86 30 85 29.4444 74 23.3333 74 23.3333 296 146.667 1” Brass – 0.5” Brass – 1” Brass Thermocouple Temp ˚F Temp ˚c 0 193 89.44 0.0254 184 84.44 0.0508 178 81.11 0.127 70 21.11 0.1524 70 21.11 0.1778 70 21.11 74 23.33 74 23.33 268 131.1 Thermocouple Left Bar Right bar 15 0 0.0254 0.0508 0.127 0.1524 0.1778 Temp ˚F Temp ˚c 189 87.2222 180 82.2222 179 81.6667 78 25.5556 77 25 75 23.8889 1” Brass – Paper – 1” Brass Thermocouple Left Bar Right bar 0 0.0254 0.0508 0.127 0.1524 0.1778 1” Brass – Thermal Grease – 1” Brass Temp ˚F Temp ˚c 189 87.2222 180 82.2222 179 81.6667 78 25.5556 77 25 75 23.8889 Left Bar Right bar Water in Water out Heater Temp 16 Thermocouple Temp ˚F Temp ˚c 0 183 83.88889 0.0254 169 76.11111 0.0508 154 67.77778 0.051 120 48.88889 0.1016 107 41.66667 0.127 96 35.55556 74 23.33333 74 23.33333 269 131.6667