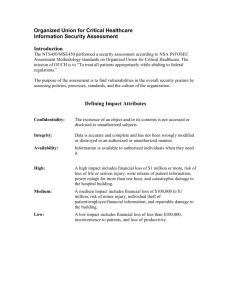

criticality safety in the handling of fissile material

advertisement