What is an RTD? - Texas Instruments

advertisement

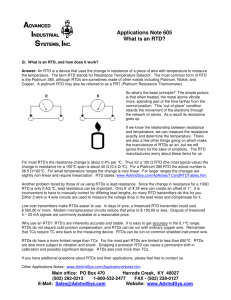

Signal Conditioning and Linearization of RTD Sensors Collin Wells Texas Instruments HPA Precision Linear Applications 9/24/11 Introduction • Primary Support – 4-20mA Loop Drivers (XTRXXX) – Gamma Buffers (BUFXXXXX) • Other Support – – – – Temperature Sensors (TMP) IR Temperature Sensors (TMP006) OPA Stability Instrument Amplifiers • Applications (Other) – Industrial – Programmable Logic Controllers (PLC) – RTD – Reference Designs Contents •RTD Overview •RTD Nonlinearity •Analog Linearization •Digital Acquisition and Linearization What is an RTD? • Resistive Temperature Detector • Sensor with a predictable resistance vs. temperature • Measure the resistance and calculate temperature based on the Resistance vs. Temperature characteristics of the RTD material RTD Resistance vs. Temperature 400 360 320 R RTD RTD (Temp) Resistance (Ohms) 280 240 PT100 200 α = 0.00385 160 120 80 40 0 200 100 0 100 200 300 400 Temperature (C) 500 600 700 800 How does an RTD work? • L = Wire Length L Resistance R Resisti vity p • A = Wire Area A • e = Electron Charge (1.6e-19 Coulombs) 1 • n = Electron Density e n • u = Electron Mobility • The product n*u decreases over temperature, therefore resistance increases over temperature (PTC) • Linear Model of Conductor Resistivity Change vs. Temperature ( t) 0 1 t t0 What is an RTD made of? • Platinum (pt) Metal • Nickel (Ni) • Copper (Cu) •Have relatively linear change in resistance over temp •Have high resistivity allowing for smaller dimensions •Either Thin-Film or Wire-Wound *Images from RDF Corp Resistivity (Ohm/CMF) Gold (Au) 13 Silver (Ag) 8.8 Copper (Cu) 9.26 Platinum (Pt) 59 Tungsten (W) 30 Nickel (Ni) 36 How Accurate is an RTD? • Absolute accuracy is “Class” dependant - defined by DIN-IEC 60751. Allows for easy interchangeability of field sensors **Temperature Range of Validity Error at 100C (C) Error over WireWound Range (C) Tolerance Class (DIN-IEC 60751) WireWound Thin-Film Tolerance Values (C) Resistance at 0C (Ohms) *AAA (1/10 DIN) 0 - +100 0 - +100 +/-(0.03 + 0.0005*t) 100 +/- 0.012 0.08 0.08 AA (1/3DIN) -50 - +250 0 - +150 +/-(0.1 + 0.0017*t) 100 +/- 0.04 0.27 0.525 A -100 - +450 -30 - +300 +/-(0.15 + 0.002*t) 100 +/- 0.06 0.35 1.05 B -196 - +600 -50 - +500 +/-(0.3 + 0.005*t) 100 +/- 0.12 0.8 3.3 C -196 - +600 -50 - +600 +/-(0.6 + 0.01*t) 100 +/- 0.24 1.6 6.6 *AAA (1/10DIN) is not included in the DIN-IEC-60751 spec but is an industry accepted tolerance class for high-performance measurements **Manufacturers may choose to guarantee operation over a wider temperature range than the DIN-IEC60751 provides • Repeatability usually very good, allows for individual sensor calibration • Long-Term Drift usually <0.1C/year, can get as low as 0.0025C/year Why use an RTD? Table Comparing Advantages and Disadvantages of Temp Sensors How to Measure an RTD Resistance? • Use a……. Current Source or Wheatstone Bridge +Vsource RA RA + - ISOURCE - VMEAS RA Vmeas Vmeas RRTD Isource RRTD Isource RRTD Vmeas Isource VMEAS + RRTD RRTD RRTD 1 Vmeas Vsource RA RRTD 2 RRT D 2 RA Vmeas RA Vsource Vsource 2 Vmeas Note on Non-Linear Output of Bridge RRTD Vmeas Vsource RA RRTD 1 2 +Vsource 100 100 - 100 + Denominator causes a non-linear output even for a linear sensor ΔRTD = 50Ohms VMEAS RTD 500.00m Voltage (V) 375.00m 250.00m 125.00m 0.00 100.00 112.50 125.00 Input resistance (ohms) 137.50 150.00 Simple Current Source / Sink Circuits +5V +5V REF200 R9 10k RTD 100 +5V R12 10k U1 OPA333 + - Q1 R4 10k + + Q2 U2 OPA333 - I_Out 100uA R8 40k +5V Rset 10k V3 2.5 U8 REF5025 R2 200k - Vout R1 INA326T1 INA326T + 10u Vdiff -49.85m GND Trim R1 + + 1u Rset 25k Vcm 2.5 +5V + V2 2.5 I_Out 100.05uA C1 100n - R2 R3 49.9 Tem p + U9 OPA340 RTD 100 R4 100 Vin 1u RTD 100 + +5V 100uA R1 10k + AM5 R3 40k I_Out 100uA RTD Types and Their Parasitic Lead Resistances RL 2-Wire RL White 3-Wire RRTD White RRTD Red Red RL RL Red RL RL RL 4-Wire White White RRTD Red RL RRTD 2-Wire with Compensating Loop Red RL RL RL Blue Blue Red RL White RL 2-Wire Measurements +Vsource A RL + - I SOURCE Isource RRTD Isource 2 RL Error Isource 2RL VMEAS RRTD RA RL - VMEAS + RRTD Vmeas RA R RL RL RRTD 2RL Vmeas Vsource RA RRTD 2.RL 1 2 2 RA RL Error Vsource RA RRTD RA 2 RL RRTD 3-Wire Measurements +Vsource ISOURCE1 RL RA VMEAS ISOURCE2 VMEAS RL + - - RRTD RL RA + RL RA RL RRTD RL Isource1 Isource2 Vmeas I RL I RRTD ( 2 I) RL + Vmeas I RL ( 2 I) RL Vmeas Vmeas + RRTD RL Vmeas Vsource RA RRTD 2 RL I I RRTD 3 I RL 3 I RL I RRTD 3 I RL 3 I RL 1 2 RL RA RRTD Error Vsource RA RRTD RA 2 RL RRTD I RRTD Error = 0 as long as Isource1 = Isource2 and RL are equal 4-Wire Measurements +Vsource RL RL RA - I RL VMEAS + VMEAS - RL RL + RRTD RA RL RRTD RA RL Vmeas RL Isource RRTD Vmeas RA Vsource RA RRT D 2 2 2 RA 6 RA RL 2 RRT D RA 4 RL 2 RRT D RL System Errors reduced to measurement circuit accuracy RL 2.0 RA 2.0 RRTD Error Vsource RA RRTD RA 4.0 RL RRTD Self-Heating Errors of RTD • Typically 2.5mW/C – 60mW/C • Set excitation level so self-heating error is <10% of the total error budget Self-Heating Error of an RTD vs. Exciation Current 10 1 Temperature (C) 0.1 Errorselfheat200n( I) Errorselfheat0( I) Errorselfheat850( I) 0.01 3 110 4 110 5 110 6 110 7 110 5 110 4 3 110 110 I Current (A) 0.01 RTD Resistance vs Temperature Callendar-Van Dusen Equations Equation Constants for 2 2 3 RTD( T) R0 1 A T B T C T ( T 100) For (T > 0) : RTD( T) R0 1 A T B T For (T < 0) : IEC 60751 PT-100 RTD (α = 0.00385) R0 100 3 A 3.908310 RTD Resistance vs. Temperature 7 400 B 5.775 10 360 12 C 4.183 10 320 RTD (T) Resistance (Ohms) 280 240 200 160 120 80 40 0 200 100 0 100 200 300 400 Temperature (C) 500 600 700 800 RTD Nonlinearity RTD Resistance vs. Temperature 400 Linear fit between the two end-points shows the Full-Scale nonlinearity 360 320 RTD( Temp) R LINFIT( Temp) Nonlinearity and Temperature Error vs. Temperature Resistance (Ohms) 280 240 200 160 120 5 50 80 4.5 40 0 200 3.5 3 30 2.5 2 20 1.5 1 10 0.5 0 200 95 10 115 220 325 430 Temperature (C) 535 640 745 0 850 Temperature Error (C) Temperature Nonlinearity (%FSR) 40 4 95 10 115 220 325 430 Temperature (C) Nonlinearity = 4.5% Temperature Error > 45C 535 640 745 850 RTD Nonlinearity 2 2 3 RTD( T) R0 1 A T B T C T ( T 100) For (T > 0) : RTD( T) R0 1 A T B T For (T < 0) : R0 100 RTDlinear ( T) R0 ( 1 A T) RTD Resistance vs. Temperature 450 3 A 3.908310 405 7 B 5.775 10 360 12 C 4.183 10 RTD( Temp) RTD linear (Temp) B and C terms are negative so 2nd and 3rd order effects decrease the sensor output over the sensor span. Resistance (Ohms) 315 270 225 180 135 90 45 0 200 95 10 115 220 325 430 Temperature (C) 535 640 745 850 Measurement Nonlinearity + RRTD VMEAS ISOURCE - Vmeas Isource RRTD RTD Sensor Output vs. Temperature (Isource = 100uA) 0.045 0.0415 0.038 V RTD (Temp) V RTD_linear (Temp) Voltage (V) 0.0345 0.031 0.0275 0.024 0.0205 0.017 0.0135 0.01 0 80 160 240 320 400 480 Temperature (C) 560 640 720 800 Correcting for Non-Linearity Sensor output decreases over span? Compensate by increasing excitation over span! RRTD + VMEAS ISOURCE - + I SOURCE RRTD VMEAS - I CORRECTION Icorrection = gain*Vmeas+Offset Vmeas Vmeas (Isource + I correction R RTD Isource RRTD RTD Sensor Output vs. Temperature (Isource = 100uA) 0.045 0.0415 Increasing excitation source over measurement span produces linear sensor output 0.038 V RTD (Temp) V RTD_linear (Temp) Voltage (V) 0.0345 0.031 0.0275 0.024 0.0205 0.017 0.0135 0.01 0 80 160 240 320 400 480 Temperature (C) 560 640 720 800 VRTD_linear ( T) RTDlinear ( T) Isource Correcting for Non-linearity Isource 0.0005 Isource_correction ( T) Isource VRTD( T) RTD( T) Isource VRTD_linear (T) VRTD( T) RTD( T) VRTD_correction ( T) RTDlinear ( T) Isource_correction ( T) VRTD_linear ( T) RTDlinear ( T) Isource Isource_correction ( T) Isource 0.25 VRTD_linearized ( T) Isource_correction ( T) RTD( T) Resistance vs. Temperature VRTD_linear (T) VRTD RTD( T) RTD( T) 0.225 VRTD_correction ( T) RTDlinear ( T) Isource_correction ( T) 0.2 0.175 Voltage (V) VRTD_linearized ( T) Isource_correction ( T) RTD( T) VRTD ( Temp ) 0.15 VRTD_correction ( Temp ) 0.125 VRTD_linearized ( Temp ) 0.1 0.075 0.05 0.025 0 200 100 0 100 200 300 Temp Temperature (C) 400 500 600 700 800 Analog Linearization Circuits Analog Linearization Circuits Two-Wire Single Op-Amp R2 49.13k Example Amplifiers: R3 60.43k Low-Voltage: R4 1k V1 5 R1 4.99k Vout OPA333 OPA376 + High Voltage: OPA188 OPA277 R5 105.83k RTD 100 I_Correction A voltage-controlled current source is formed from the op-amp I_RTD output through R4 into the RTD This circuit is designed for a 0-5V output for a 0-200C temperature span. Components R2, R3, R4, and R5 are adjusted to change the desired measurement temperature span and output. R2 49.13k Analog Linearization Circuits R4 1k R1 4.99k Vout V1 5 Two-Wire Single Op-Amp R3 60.43k + R5 105.83k I_Correction RTD 100 Non-linear increase in excitation current over temperature span will help correct non-linearity of RTD measurement I_RTD 50.00u 37.50u I_Correction (A)25.00u 12.50u 0.00 1.01m 1.00m I_RTD (A) 996.00u 988.00u 980.00u 0.00 50.00 100.00 Temperature (C) 150.00 200.00 75.00 R2 49.13k V1 5 Two-Wire Single Op-Amp R4 1k Vout R1 4.99k 50.00 Analog Linearization Circuits R3 60.43k + R5 105.83k I_Correction 25.00 RTD 100 This type of linearization typically provides a 20X - 40X improvement in linearity I_RTD 0.00 5.00 (V) 3.13 0.00 1.25 1.88 3.75 625.00m Voltage (V) 2.50 4.38 Without Correction 2.50 With Correction 1.88 1.25 625.00m 0.00 0.00 25.00 50.00 75.00 100.00 125.00 Temperature (C) 150.00 175.00 200.00 Analog Linearization Circuits Three-Wire Single INA V1 15 I_Bias R2 4.99k R1 4.99k +15V A voltage-controlled current source is formed from the INA output through Rlin into the RTD Example Amplifiers: Low-Voltage: I_Correction INA333 INA114 Rlin 105.83k V2 5 -15V -15V Rg Rg 801 Rz 100 V3 15 Ref Rg + + U2 INA826 High Voltage INA826 INA114 +15V RTD 100 Remote RTD RL3 1 RL2 1 I_RTD RL1 1 Vout This circuit is designed for a 0-5V output for a 0-200C temperature span. Components Rz, Rg, and Rlin are adjusted to change the desired measurement temperature span and output. V1 15 Analog Linearization Circuits I_Correction R2 105.83k V2 5 -15V V3 15 Rg RL3 1 RL2 1 RL1 1 5.00 U2 INA826 +15V I_RTD This type of linearization typically provides a 20X - 40X improvement in linearity and some lead resistance cancellation Vout Ref Rg + + RTD 175.8 Remote RTD 4.37 3.75 3.12 Voltage (V) Without Correction 2.50 With Correction 1.87 1.25 622.27m 0.00 0.00 25.00 50.00 75.00 100.00 125.00 Temperature (C) 150.00 175.00 200.00 R1 10k -15V R6 801 R14 100 Three-Wire Single INA I_Bias R9 4.99k R7 4.99k +15V Analog Linearization Circuits XTR105 4-20mA Current Loop Output XTR105 Iref1 800u i_lin OA1 + i_rtd Q1_EXT Q1_INT R5 1k VIN+ i_jfet Iref2 800u R4 1k Rlin1 16.099k Rlin 1k OA3 R_CL 0 Rg 162.644 VIN- V_PS 24 + - + Q1 OA2 Rz 100 RTD 100 VCM i_afe Rcm 1.5k R2 25 R1 975 V_420 I_Out i_Q1 RL 250 Analog Linearization Circuits XTR105 4-20mA Current Loop Output 20.00m 18.00m 16.00m 14.00m Without Correction I_Out (A) 12.00m 10.00m With Correction 8.00m 6.00m 4.00m 0.00 25.00 50.00 75.00 100.00 Temperature (C) 125.00 150.00 175.00 200.00 Analog + Digital Linearization Circuits XTR108 4-20mA Current Loop Output Digital Acquisition Circuits and Linearization Methods Digital Acquisition Circuits ADS1118 16-bit Delta-Sigma 2-Wire Measurement with Half-Bridge +V source RA RL RRTD RL RL RRTD RA AIN0 AIN1 AIN2 AIN3 RL Digital Acquisition Circuits ADS1220 24-bit Delta-Sigma Two 3-wire RTDs R REF +V source RL RL R RTD RL RL RL R COMP R RTD RL 3-wire + Rcomp shown for AIN2/AIN3 +Vdig Digital Acquisition Circuits ADS1220 24-bit Delta-Sigma One 4-Wire RTD R REF +V source RL RL R RTD RL RL +Vdig Digital Acquisition Circuits ADS1247 24-bit Delta-Sigma Three-Wire + Rcomp Digital Acquisition Circuits ADS1247 24-bit Delta-Sigma Four-Wire Digital Linearization Methods • Three main options – Linear-Fit – Piece-wise Linear Approximations – Direct Computations RTD Sensor Output vs. Temperature (Isource = 100uA) 0.04 0.037 0.034 V RTD (Temp) Voltage (V) 0.031 0.028 0.025 0.022 0.019 0.016 0.013 0.01 0 80 160 240 320 400 480 Temperature (C) 560 640 720 800 Digital Linearization Methods Linear Fit Pro’s: Con’s: •Easiest to implement Least Accurate •Very Fast Processing Time •Fairly accurate over small temp span TLinear ( t) A RTD( t) B End-point Fit Best-Fit V Lin_Fit ( Temp) RTD Sensor Output vs. Temperature (Isource = 100uA) 0.04 0.04 0.037 0.037 0.034 0.034 0.031 0.031 0.028 V RTD( Temp) 0.025 V Lin_Fit (Temp) Voltage (V) V RTD( Temp ) Voltage (V) RTD Sensor Output vs. Temperature (Isource = 100uA) 0.028 0.025 0.022 0.022 0.019 0.019 0.016 0.016 0.013 0.013 0.01 0 80 160 240 320 400 480 Temp Temperature (C) 560 640 720 800 0.01 0 80 160 240 320 400 480 Temp Temperature (C) 560 640 720 800 Digital Linearization Methods Piece-wise Linear Fit Pro’s: Con’s: •Easy to implement •Code size required for coefficients •Fast Processing Time •Programmable accuracy TPeicewise T( n 1) ( T( n ) T( n 1) ) RT D( n) RT D( n 1) RT D RT D( n 1) RTD Sensor Output vs. Temperature (Isource = 100uA) 0.04 0.037 0.034 V RTD (Temp) V Lin_Fit (Temp) Voltage (V) 0.031 0.028 0.025 0.022 0.019 0.016 0.013 0.01 0 80 160 240 320 400 480 Temperature (C) 560 640 720 800 Digital Linearization Methods Direct Computation Pro’s: Con’s: •Almost Exact Answer, Least Error •Processor intensive •With 32-Bit Math Accuracy to +/-0.0001C •Requires Math Libraries •Negative Calculation Requires simplification or bi-sectional solving RTD Sensor Output vs. Temperature (Isource = 100uA) 0.04 Positive Temperature Direct Calculation RTD( t) A A 4B 1 R0 0.037 0.034 2 V RTD (Temp) 2B Voltage (V) TDirect( t) + 0.031 0.028 0.025 0.022 0.019 0.016 Negative Temperature Simplified Approximation 3 0.013 2 0.01 0 80 160 6 TDirect ( t) 241.96 2.2163 RTD ( t) 2.8541 10 RTD ( t) 9.9121 10 3 2 6 3 8 4 0 RTD( t) 9.9121 10 RTD( t ) 1.705210 RTD( t ) 240 320 3 400 480 560 640 8 RTD ( t) 1.7052 10 Temperature (C) 720 800 RTD ( t Digital Linearization Methods Direct Computation Bi-Section Method for Negative Temperatures RTDError 100 TBisection - Res 60.256 Tlow 250 Thigh 50 RTDTemp 0 99.999 while ( RTDError 0.0001) Tmid ( Tlow Thigh ) 2 Rcal 100 1 A Tmid B Tmid ( Tmid 100) C Tmid 2 Rcal 100 1 A Tmid B Tmid Rcal 0 if Rcal 0 RTDError Res Rcal Tlow Tmid if RTDError 0 Thigh Tmid if RTDError 0 RTDTemp Tmid return RTDTemp TBisection 99.999 - 2 if Tmid 0 3 if Tmid 0 Questions/Comments? Thank you!! Special Thanks to: Art Kay Bruce Trump PA Apps Team Mike Beckman Omega Sensors RDF Corp IMPORTANT NOTICE FOR TI REFERENCE DESIGNS Texas Instruments Incorporated ("TI") reference designs are solely intended to assist designers (“Buyers”) who are developing systems that incorporate TI semiconductor products (also referred to herein as “components”). Buyer understands and agrees that Buyer remains responsible for using its independent analysis, evaluation and judgment in designing Buyer’s systems and products. TI reference designs have been created using standard laboratory conditions and engineering practices. TI has not conducted any testing other than that specifically described in the published documentation for a particular reference design. TI may make corrections, enhancements, improvements and other changes to its reference designs. Buyers are authorized to use TI reference designs with the TI component(s) identified in each particular reference design and to modify the reference design in the development of their end products. HOWEVER, NO OTHER LICENSE, EXPRESS OR IMPLIED, BY ESTOPPEL OR OTHERWISE TO ANY OTHER TI INTELLECTUAL PROPERTY RIGHT, AND NO LICENSE TO ANY THIRD PARTY TECHNOLOGY OR INTELLECTUAL PROPERTY RIGHT, IS GRANTED HEREIN, including but not limited to any patent right, copyright, mask work right, or other intellectual property right relating to any combination, machine, or process in which TI components or services are used. Information published by TI regarding third-party products or services does not constitute a license to use such products or services, or a warranty or endorsement thereof. Use of such information may require a license from a third party under the patents or other intellectual property of the third party, or a license from TI under the patents or other intellectual property of TI. TI REFERENCE DESIGNS ARE PROVIDED "AS IS". TI MAKES NO WARRANTIES OR REPRESENTATIONS WITH REGARD TO THE REFERENCE DESIGNS OR USE OF THE REFERENCE DESIGNS, EXPRESS, IMPLIED OR STATUTORY, INCLUDING ACCURACY OR COMPLETENESS. TI DISCLAIMS ANY WARRANTY OF TITLE AND ANY IMPLIED WARRANTIES OF MERCHANTABILITY, FITNESS FOR A PARTICULAR PURPOSE, QUIET ENJOYMENT, QUIET POSSESSION, AND NON-INFRINGEMENT OF ANY THIRD PARTY INTELLECTUAL PROPERTY RIGHTS WITH REGARD TO TI REFERENCE DESIGNS OR USE THEREOF. TI SHALL NOT BE LIABLE FOR AND SHALL NOT DEFEND OR INDEMNIFY BUYERS AGAINST ANY THIRD PARTY INFRINGEMENT CLAIM THAT RELATES TO OR IS BASED ON A COMBINATION OF COMPONENTS PROVIDED IN A TI REFERENCE DESIGN. IN NO EVENT SHALL TI BE LIABLE FOR ANY ACTUAL, SPECIAL, INCIDENTAL, CONSEQUENTIAL OR INDIRECT DAMAGES, HOWEVER CAUSED, ON ANY THEORY OF LIABILITY AND WHETHER OR NOT TI HAS BEEN ADVISED OF THE POSSIBILITY OF SUCH DAMAGES, ARISING IN ANY WAY OUT OF TI REFERENCE DESIGNS OR BUYER’S USE OF TI REFERENCE DESIGNS. TI reserves the right to make corrections, enhancements, improvements and other changes to its semiconductor products and services per JESD46, latest issue, and to discontinue any product or service per JESD48, latest issue. Buyers should obtain the latest relevant information before placing orders and should verify that such information is current and complete. All semiconductor products are sold subject to TI’s terms and conditions of sale supplied at the time of order acknowledgment. TI warrants performance of its components to the specifications applicable at the time of sale, in accordance with the warranty in TI’s terms and conditions of sale of semiconductor products. Testing and other quality control techniques for TI components are used to the extent TI deems necessary to support this warranty. Except where mandated by applicable law, testing of all parameters of each component is not necessarily performed. TI assumes no liability for applications assistance or the design of Buyers’ products. Buyers are responsible for their products and applications using TI components. To minimize the risks associated with Buyers’ products and applications, Buyers should provide adequate design and operating safeguards. Reproduction of significant portions of TI information in TI data books, data sheets or reference designs is permissible only if reproduction is without alteration and is accompanied by all associated warranties, conditions, limitations, and notices. TI is not responsible or liable for such altered documentation. Information of third parties may be subject to additional restrictions. Buyer acknowledges and agrees that it is solely responsible for compliance with all legal, regulatory and safety-related requirements concerning its products, and any use of TI components in its applications, notwithstanding any applications-related information or support that may be provided by TI. Buyer represents and agrees that it has all the necessary expertise to create and implement safeguards that anticipate dangerous failures, monitor failures and their consequences, lessen the likelihood of dangerous failures and take appropriate remedial actions. Buyer will fully indemnify TI and its representatives against any damages arising out of the use of any TI components in Buyer’s safety-critical applications. In some cases, TI components may be promoted specifically to facilitate safety-related applications. With such components, TI’s goal is to help enable customers to design and create their own end-product solutions that meet applicable functional safety standards and requirements. Nonetheless, such components are subject to these terms. No TI components are authorized for use in FDA Class III (or similar life-critical medical equipment) unless authorized officers of the parties have executed an agreement specifically governing such use. Only those TI components that TI has specifically designated as military grade or “enhanced plastic” are designed and intended for use in military/aerospace applications or environments. Buyer acknowledges and agrees that any military or aerospace use of TI components that have not been so designated is solely at Buyer's risk, and Buyer is solely responsible for compliance with all legal and regulatory requirements in connection with such use. TI has specifically designated certain components as meeting ISO/TS16949 requirements, mainly for automotive use. In any case of use of non-designated products, TI will not be responsible for any failure to meet ISO/TS16949. Mailing Address: Texas Instruments, Post Office Box 655303, Dallas, Texas 75265 Copyright © 2014, Texas Instruments Incorporated