MEL-TEMP® - Cole

advertisement

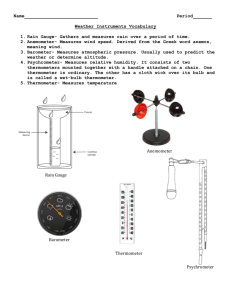

BARNSTEAD|THERMOLYNE MEL-TEMP® Capillary Melting Point Apparatus Model No. 1001 1002 1101D 1102D 1201D 1202D - 120 230 120 230 120 230 VAC VAC VAC, VAC, VAC, VAC, Digital Thermometer Mercury Thermometer Digital Thermometer Mercury Thermometer LT1187X2 • 9/25/00 1 Table of Contents Introduction..........................................................................................................................................................3 Safety Information ..............................................................................................................................................4 Alert Signals..................................................................................................................................................4 Intended Use ................................................................................................................................................4 General Usage..............................................................................................................................................4 Warnings ......................................................................................................................................................4 General Specifications ........................................................................................................................................5 Declaration of Conformity ............................................................................................................................6 Environmental Conditions ............................................................................................................................6 Installation ..........................................................................................................................................................7 Capillary Selection ........................................................................................................................................7 Operation ............................................................................................................................................................8 General Maintenance ..........................................................................................................................................9 General Cleaning Instructions ......................................................................................................................9 Glass Thermometers ....................................................................................................................................9 Separated Thermometer Mercury Thread ....................................................................................................9 Thermometer Verification............................................................................................................................10 Removing Stuck Thermometer from MEL-TEMP Unit................................................................................10 Lamp Replacement ....................................................................................................................................11 Replacing Fuses ........................................................................................................................................11 Replacement Parts............................................................................................................................................12 Ordering Procedures ........................................................................................................................................13 One Year Limited Warranty ..............................................................................................................................14 2 Introduction MEL-TEMP provides precise melting points up to 500°C. Castings conduct and radiate heat uniformity to capillaries and thermometer. This patented technology completely eliminates the mess and hazards of conventional oil bath designs. Sample observation is enhanced by an integrated light and precision 6X lens. MEL-TEMP is engineered to withstand years of heavy use.The housing is made of extruded aluminum. Durable, top quality components are mounted on a 1/8” thick aluminum panel. MEL-TEMP accepts up up three capillaries. Samples are illuminated and clearly visible through the precision 6-power lens. Each capillary is heated on three sides and the block is made from a highly conductive alloy to prevent hot spots. 3 Safety Information Intended Use Alert Signals Warning Warnings alert you to a possibility of personal injury. Caution Cautions alert you to a possibility of damage to the equipment. Note Notes alert you to pertinent facts and conditions. Hot Surface Hot surfaces alert you to a possibility of personal injury if you come in contact with a surface during use or for a period of time after use. Your Capillary Melting Point Apparatus has been designed with function, reliability and safety in mind. It is your responsibility to install it in conformance with local electrical codes. For safe operation, please pay attention to the alert signals throughout the manual. General Usage Do not use this product for anything other than its intended usage. Warnings To avoid personal injury: 1. Refer servicing to qualified personnel. 2. Do not use in the presence of flammable or combustible materials; fire or explosion may result. This device contains components which may ignite such materials. 3. Thermometer must be rated with a range high enough to cover the specifications of this product. Improperly rated thermometers may burst if used above rated temperature. To avoid electrical shock: 1. Do not allow unit to become wet. 4 2. Use a properly grounded electrical outlet of correct voltage and current handling capacity. 3. If power cord becomes damaged, replace immediately. 4. Disconnect from power supply before servicing. General Specifications Temperature range: Heating rate control: Ambient to 500°C Continuously adjustable with built-in variable transformer Temperature resolution: 0.1°C with low mass thermocouple and precision digital thermometer One-half the smallest graduation with glass thermometer Reproducibility: 1°C Absolute accuracy of melting point: determined by thermometer Melting point capillaries: accepts 1 to 3 capillaries simultaneously, 1.5-1.75mm outside diameter. Thermometer well: 6.75mm inside diameter, 76 mm deep Heat-up time, full power: 25°C-400°C in 5 minutes 400°C-500°C in 4 minutes Cool-down time, unassisted: 500°C-400°C in 2 minutes 400°C-300°C in 2 minutes 300°C-200°C in 5 minutes 200°C-100°C in 7 minutes Dimensions: 14L x11.7W x23H (cm) Shipping Weight: 2.3kg Power requirements: 200 watts,120 VAC or 200 watts, 230 VAC 5 GENERAL SPECIFICATIONS Declaration of Conformity Barnstead|Thermolyne hereby declares under its sole responsibility that this product conforms with the technical requirements of the following standards (230 volt models only): EMC: EN 61000-3-2 EN 61000-3-3 EN 61326-1 Limits for Harmonic Current Emissions Limits for Voltage Fluctuations and Flicker Electrical Equipment for Measurement, Control, and Laboratory Use; Part I: General Requirements Safety: EN 61010-1 Safety Requirements for Electrical Equipment for Measurement, Control and Laboratory Use; Part I: General Requirements Part II: Particular Requirements for Laboratory Equipment for the Heating of Materials EN 61010-2-010 per the provisions of the Low Voltage Directive 73/23/EEC, as amended by 93/68/EEC. The authorized representative located within the European Community is: Electrothermal Engineering, Ltd. 419 Sutton Road Southend On Sea Essex SS2 5PH United Kingdom Copies of the Declaration of Conformity are available upon request. Environmental Conditions Operating: Storage: 6 17°C - 27°C; 20% - 80% relative humidity, non-condensing. Installation Category II (over-voltage) in accordance with IEC 664. Pollution Degree 2 in accordance with IEC 664. Altitude limit: 2000 meters. -25°C - 65°C; 20% to 80% relative humidity. Installation Plug MEL-TEMP into a grounded wall receptacle using the supplied power cord. The voltage and power required for your MEL-TEMP is marked on the label at the rear of the unit. Note Replacement capillaries may be purchased directly from Barnstead|Thermolyne. See “Replacement Parts” list. Capillary Selection Your MEL-TEMP includes a vial of Barnstead|Thermolyne’s precision melting point capillaries. They were specifically developed to fit the MEL-TEMP and will provide the most uniform and repeatable results. Never force a capillary into the MEL-TEMP. 7 Operation Note If your MEl-TEMP was purchased with our thermocouple kit for use with a digital thermometer, please follow the kit’s instruction sheet. Note Your MEL-TEMP may produce smoke the first time it is heated. The smoke is caused by residual machining oils that have impregnated the metal casing assembly. Once the oils burn away, the smoke will permanently cease. 8 1. Place the thermometer in its well. 2. Turn the power switch ON and set the power level to obtain the desired heating rate at the anticipated melting range. Use the heating rate of six degrees per minute or less at the melting range. • Observe samples with the eye about 6” from the lens. • For the most accurate results, use 3-4 mm columns of thoroughly dried, finely powdered, densely packed samples. General Maintenance Cleaning Instructions Wipe exterior surfaces with lightly dampened cloth containing a mild soap solution. Glass Thermometers We distribute two glass thermometers which are manufactured expressly for us to our specifications. They are intended primarily for use with MEl-TEMP Capillary Melting Point Apparatus which has a 6.75 mm diameter thermometer well.The 0°-400°C thermometer is calibrated for 76mm immersion and is 400 mm long. It is mercury filled, has a white back and is divided in 1° graduations. The 90500°C thermometer is also calibrated for 76 mm immersion and is 400 mm long. It is fabricated of hard glass, has a white back, is mercury filled under nitrogen pressure and is divided in 1° graduations. Separated Thermometer Mercury Thread Vibration or shock during shipment occasionally causes a separation or breaking of the mercury thread in the thermometer stem. Please do not return a thermometer with a separated mercury thread as it can be reunited easily in the following way. 1. Dip the thermometer bulb into a few ml of an acetone/dry ice mixture until the mercury threads shrink entirely into thermometer bulb. Immediately remove the bulb from the cold mixture and tap it gently to free entrained gas bubbles. Then let the thermometer warm up to room temperature. 9 GENERAL MAINTENANCE Thermometer Verification Note A set of 26 melting point standards and a precision digital thermometer with thermocouple is available. See “Replacement Parts” list. Note A precision digital thermomether and thermocouple may be purchased directly from B|T. See “Replacement Parts” list. Periodic verification is important because of hysteresis can occur when a thermometer is cycled through a large temperature range. Thermometers can be verified using samples of accurately known melting range. Alternatively, insert a fine iron-costantan thermocouple into a 3-5 mm column of magnesia or alumina in a melting point capillary. Then raise the temperature of the MEL-TEMP at a controlled rate and use the thermocouple readings to determine the thermometer corrections at appropriate temperature intervals. Removing Broken Capillaries Broken capillaries are removed from the instrument in the following manner: 1. Switch off the main power switch and unplug the power cord from the wall. Allow the unit to cool. 2. Remove the screws at the right and left side of the unit and lift off the housing cover. 3. Remove the lens with an ordinary pair of internal, snap-ring pliers. Pliers with a 0.038 inch straight tim work nicely. 4. With the lens removed, hold the unit upside down and shke the capillary fragments into a suitable waste container. 5. Replace the lens (flat side in), snap right, housing cover and screws. You may separate the aluminum branched tube (the cast metal part that holds the lens) from the heat block. The socket head screws can be removed with a 5/64” ball-driver. 10 GENERAL MAINTENANCE Lamp Replacement Note Replacement lamps are available. See “Replacement Parts” list. Note Replacement fuses are available. See “Replacement Parts” list. 1. Switch off the main power switch and unplug the power cord from the wall. Allow unit to cool. 2. Remove the screws at the right and left side of the unit and lift off the housing cover. 3. The light shield is held in place with a multipronged retaining spring. To remove the light shield, pull straight up with moderate force. If necessary, rock the light shield back and forth slightly while pulling. 4. To remove the burned out bulb, gently push it towards the socket and rotate it approximately 30 degrees counter-clockwise. 5. Replace the lamp with a new one and reinstall the light shield, housing cover and screws. Replacing Fuses 1. Unplug your MEL-TEMP before replacing fuses. 2. MEL-TEMP has two fuses located in the power entry module (the same part that the power cord plugs into). To replace these fuses, remove the fuse drawer by squeezing the tabs with your fingertips in the direction indicated by the arrows on the drawer. 3. Substitute new fuses for the blown fuses in the drawer, then push the drawer back into the power entry module. Both sides of the drawer should click into position. 11 Replacement Parts Part No. 1015 1003 1004 1005 1006 1007 1008 LMX21 LMX20 AY1150X1 CRX96 CRX70 EL1187X1 EL1187X2 WDX2 5120-0025 5120-0016 12 Description Student Digital Thermometer Capillaries, vial of 100 Mercury Thermometer, 0-400°C, 1° gradations Mercury Thermometer, 100-500°C, 1° gradations Precision Digital Thermometer, requires part no. 1007 Low Mass Thermocouple for MEL-TEMP, requires part no. 1006 Melting Point Standards, set of 26 standards; melting ranges 50 to 300°C at roughly 10°C increments, each standard weighs 250 to 1000mg Replacement Bulb, 115V Replacement Bulb, 230V Heat Casting Power Cord, 115V Power Cord, 230V Heating Element, 115V Heating Element, 230V Window Glass Fuse, 2 amp, 115V Fuse, 1 amp, 230V Ordering Procedures Please refer to the Specification Plate for the complete model number, serial number, and series number when requesting service, replacement parts or in any correspondence concerning this unit. All parts listed herein may be ordered from the Barnstead|Thermolyne dealer from whom you purchased this unit or can be obtained promptly from the factory. When service or replacement parts are needed we ask that you check first with your dealer. If the dealer cannot handle your request, then contact our Customer Service Department at 319-556-2241 or 800-553-0039. Prior to returning any materials to Barnstead|Thermolyne Corp., please contact our Customer Service Department for a “Return Goods Authorization” number (RGA). Material Returned without an RGA number will be returned. 13 One Year Limited Warranty BARNSTEAD|THERMOLYNE CORPORATION (“BARNSTEAD”) warrants that if a product manufactured by Barnstead shall be free of defects in materials and workmanship for one (1) year from the first to occur of (i) the date the product is sold by BARNSTEAD or (ii) the date the product is purchased by the original retail customer (the “Commencement Date”). Except as expressly stated above, BARNSTEAD MAKES NO OTHER WARRANTY, EXPRESSED OR IMPLIED, WITH RESPECT TO THE PRODUCTS AND EXPRESSLY DISCLAIMS ANY AND ALL WARRANTIES, INCLUDING BUT NOT LIMITED TO, WARRANTIES OF DESIGN, MERCHANT ABILITY AND FITNESS FOR A PARTICULAR PURPOSE. An authorized representative of BARNSTEAD must perform all warranty inspections. In the event of a defect covered by BARNSTEAD’s warranty, BARNSTEAD shall, as its sole obligation and exclusive remedy, provide free replacement parts to remedy the defective product. In addition, for products sold by BARNSTEAD within the continental United States or Canada, BARNSTEAD shall provide provide free labor to repair the products with the replacement parts, but only for a period of ninety (90) days from the Commencement Date. BARNSTEAD’s warranty provided hereunder shall be null and void and without further force or effect if there is any (i) repair made to the product by a party other than BARNSTEAD or its duly authorized service representative, (ii) misuse (including use inconsistent with written operating instructions for the product), mishandling, contamination, overheating, modification or alteration of the product by any customer or third party or (iii) use of replacement parts that are obtained from a party who is not an authorized dealer of BARNSTEAD. Heating elements, because of their susceptibility to overheating and contamination, must be returned to the BARNSTEAD factory and if, upon inspection, it is concluded that failure is due to factors other than excessive high temperature or contamination, BARNSTEAD will provide warranty replacement. As a condition to the return of any product, or any constituent part thereof, to BARNSTEAD’s factory, it shall be sent prepaid and a prior written authorization from BARNSTEAD assigning a Return Goods Number to the product or part shall be obtained. IN NO EVENT SHALL BARNSTEAD BE LIABLE TO ANY PARTY FOR ANY DIRECT, INDIRECT, SPECIAL, INCIDENTAL, OR CONSEQUENTIAL DAMAGES, OR FOR ANY DAMAGES RESULTING FROM LOSS OF USE OR PROFITS, ANTICIPATED OR OTHERWISE, ARISING OUT OF OR IN CONNECTION WITH THE SALE, USE OR PERFORMANCE OF ANY PRODUCTS, WHETHER SUCH CLAIM IS BASED ON CONTRACT, TORT (INCLUDING NEGLIGENCE), ANY THEORY OF STRICT LIABILITY OR REGULATORY ACTION. The name of the authorized Barnstead|Thermolyne dealer nearest you may be obtained by calling 1-800-4466060 (319-556-2241) or writing to: Barnstead|Thermolyne P.O. Box 797 2555 Kerper Boulevard Dubuque, IA 52004-0797 USA FAX: (319) 589-0516 E-MAIL ADDRESS: mkt@barnstead.com 14 15 Barnstead|Thermolyne A Sybron Laboratory Products Company 2555 Kerper Boulevard P.O. Box 797 Dubuque, IA 52004-0797 Phone: 319-556-2241, 800-553-0039 Fax: 319-589-0516 E-mail Address: mkt@barnstead.com 16