Plumbing & Heating Installation Guide

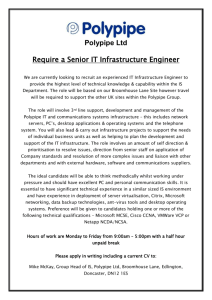

advertisement