N° 16745

advertisement

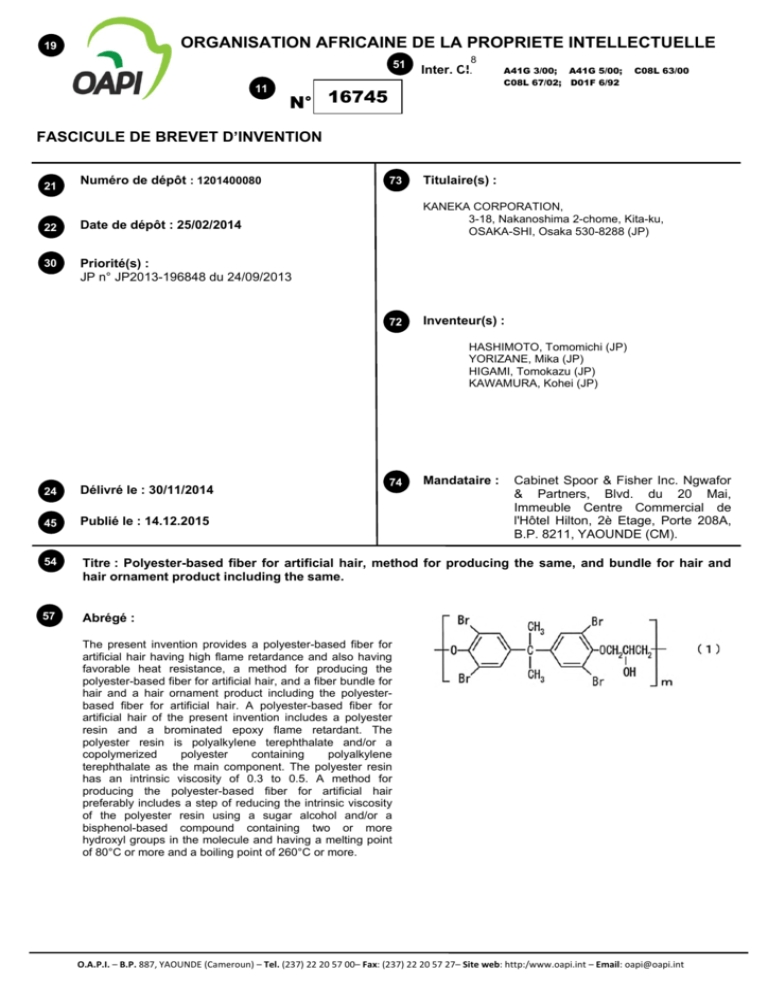

ORGANISATION AFRICAINE DE LA PROPRIETE INTELLECTUELLE 19 11 51 8 Inter. CI. N° 16745 A41G 3/00; A41G 5/00; C08L 67/02; D01F 6/92 C08L 63/00 FASCICULE DE BREVET D’INVENTION 21 Numéro de dépôt : 1201400080 22 Date de dépôt : 25/02/2014 30 Priorité(s) : JP n° JP2013-196848 du 24/09/2013 73 Titulaire(s) : KANEKA CORPORATION, 3-18, Nakanoshima 2-chome, Kita-ku, OSAKA-SHI, Osaka 530-8288 (JP) 72 Inventeur(s) : HASHIMOTO, Tomomichi (JP) YORIZANE, Mika (JP) HIGAMI, Tomokazu (JP) KAWAMURA, Kohei (JP) 74 Mandataire : Cabinet Spoor & Fisher Inc. Ngwafor & Partners, Blvd. du 20 Mai, Immeuble Centre Commercial de l'Hôtel Hilton, 2è Etage, Porte 208A, B.P. 8211, YAOUNDE (CM). 24 Délivré le : 30/11/2014 45 Publié le : 14.12.2015 54 Titre : Polyester-based fiber for artificial hair, method for producing the same, and bundle for hair and hair ornament product including the same. 57 Abrégé : The present invention provides a polyester-based fiber for artificial hair having high flame retardance and also having favorable heat resistance, a method for producing the polyester-based fiber for artificial hair, and a fiber bundle for hair and a hair ornament product including the polyesterbased fiber for artificial hair. A polyester-based fiber for artificial hair of the present invention includes a polyester resin and a brominated epoxy flame retardant. The polyester resin is polyalkylene terephthalate and/or a copolymerized polyester containing polyalkylene terephthalate as the main component. The polyester resin has an intrinsic viscosity of 0.3 to 0.5. A method for producing the polyester-based fiber for artificial hair preferably includes a step of reducing the intrinsic viscosity of the polyester resin using a sugar alcohol and/or a bisphenol-based compound containing two or more hydroxyl groups in the molecule and having a melting point of 80°C or more and a boiling point of 260°C or more. O.A.P.I. – B.P. 887, YAOUNDE (Cameroun) – Tel. (237) 22 20 57 00– Fax: (237) 22 20 57 27– Site web: http:/www.oapi.int – Email: oapi@oapi.int 16745 POLYESTER-BASED FIBER FOR ARTIFICIAL HAIR, METHOD FOR PRODUCING THE SAME, AND FIBER BUNDLE FOR HAIR AND HAIR ORNAMENT PRODUCT INCLUDING THE SAME BACKGROUND OF THE INVENTION 1. Field of the Invention The present invention relates to a polyester-based fiber for artificial hair capable of being used as an alternative to human hair, a method for producing the polyester-based fiber for artificial hair, and a fiber bundle for hair and a hair ornament product including the polyester-based fiber for artificial hair. Specifically, the present invention relates to a polyester-based fiber for artificial hair having high flame retardance and also 10 having favorable heat resistance, a method for producing the polyester-based fiber for artificial hair, and a fiber bundle for hair and a hair ornament product induding the polyester-based fiber for artificial hair. 2. Description of Related Art In hair ornament products such as a hairpiece, a hair wig, crepe hair, a hair band, and doll hair, 15 human hair has been conventionally used. However, in recent years, it is becoming difficult to obtain human hair, and the importance of fibers for artificial hair, instead of human hair, is increasing. Modacrylic fibers have often been used as fiber materials for artificial hair because of their flame retardance, but the heat resistance of the modacrylic fibers has been insufficient. Thus, it has been proposed to use polyester-based fibers containing polyethylene terephthalate as the main component, which has excellent heat resistance, as fibers 1 16745 for artificial hair. In addition, since polyester-based fibers for use as fibers for artificial hair are also required to have flame retardance for the sake of safety, various attempts have been made to impart flame retardance to the polyester-based fibers. For example, JP 200542234A, JP 2005-264397A, WO 2005/056894, and JP 2007-131982A have proposed flame retardant polyester-based fibers obtained by incorporating a brominated 5 epoxy flame retardant into a polyester-based fiber. SUMMARY OF THE INVENTION However, although the flame retardance of the flame retardant polyester-based fibers disdosed in JP 2005-42234A, JP 2005-264397A, WO 2005/056894, and JP 2007-131982A has been improved by 10 incorporating a brominated epoxy flame retardant into the fibers, the heat resistance of the fibers has been insufficient in some cases. Thus, the fibers were easily caused to shrink by heat, and there have been cases where the fibers were softened or crimped during setting with a hair iron at a high temperature. In order to solve the above-described conventional problems, the present invention provides a polyester-based fiber for artificial hair having high flame retardance and also having favorable heat resistance, 15 a method for producing the polyester-based fiber for artificial hair, and a fiber bundle for hair and a hair ornament product induding the polyester-based fiber for artificial hair. The present invention relates to a polyester-based fiber for artificial hair including a polyester resin and a brominated epoxy flame retardant, wherein the polyester resin is at least one resin selected from the group consisting of polyalkylene terephthalate and copolymerized polyesters containing polyalkylene 2 16745 terephthalate as the main component, and the polyester resin has an intrinsic viscosity of 0.3 to 0.5. In the polyester-based fiber for artificial hair, it is preferable that the brominated epoxy flame retardant has a number-average molecular weight of 1000 to 20000. Moreover, it is preferable that the polyester-based fiber for artificial hair includes 0.1 parts by weight or more and less than 5 parts by weight of a 5 viscosity-reducing agent with respect to 100 parts by weight of the polyester resin, the viscosity-reducing agent being a sugar alcohol and/or a bisphenol-based compound containing two or more hydroxyl groups in the molecule and having a melting point of 80°C or more and a boiling point of 260°C or more. The present invention also relates to a method for producing the polyester-based fiber for artificial hair, the method induding a step of reducing the intrinsic viscosity of a polyester resin using a viscosity-reducing 10 agent, the viscosity-reducing agent being a sugar alcohol and/or a bisphenol-based compound containing two or more hydroxyl groups in the molecule and having a melting point of 80°C or more and a boiling point of 260°C or more. The present invention also relates to a fiber bundle for hair including the polyester-based fiber for artificial hair and at least one fiber selected from the group consisting of human hair, animal hair, polyvinyl 15 chloride-based fibers, modacrylic fibers, polyamide-based fibers, polyolefin-based fibers, regenerated protein fibers, and other polyester-based fibers, The present invention also relates to a hair ornament product including the polyester-based fiber for artificial hair. The hair ornament product may further include at least one fiber selected from the group consisting 3 _—- 16745 of human hair, animal hair, polyvinyl chloride-based fibers, modacrylic fibers, polyamide-based fibers, polyolefin-based fibers, regenerated protein fibers, and other polyester-based fibers. According to the present invention, in the polyester-based fiber for artificial hair including the polyester resin and the brominated epoxy flame retardant, the intrinsic viscosity of the polyester resin is set to a range of 5 0.3 to 0.5. Thus, the present invention provides a polyester-based fiber for artificial hair, a fiber bundle for hair, and a hair ornament product that have high flame retardance and also have favorable heat resistance. DETAILED DESCRIPTION OF THE INVENTION The inventors of the present invention have conducted numerous studies to solve the above 10 problems and found that when, in a polyester-based fiber for artificial hair including a polyester resin and a bronninated epoxy flame retardant, the intrinsic viscosity (IV) of the polyester resin is set within a range of 0.3 to 0.5, heat resistance is improved while high flame retardance is maintained. Thus, the present invention was accomplished. Moreover, the inventors of the present invention found that using a brominated epoxy flame retardant having a low number-average molecular weight, in particular, a brominated epoxy flame retardant 15 having a number-average molecular weight of 1000 to 20000, in addition to setting the intrinsic viscosity of the polyester resin within a range of 0.3 to 0.5 improves color development while maintaining high flame retardance and heat resistance. Furthermore, the inventors of the present invention found that a sugar alcohol and/or a bisphenol-based compound containing two or more hydroxyl groups in the molecule and having a melting point of 80°C or more and a boiling point of 260°C or more serves as a viscosity-reducing 4 16745 agent and has an effect of reducing the intrinsic viscosity of the polyester resin. When a polyester resin having an intrinsic viscosity of more than 0.5 is used as a raw material polyester resin, and an adjustment is made so that the intrinsic viscosity of the polyester resin after being processed into fiber is within a range of 0.3 to 0.5 by reducing the intrinsic viscosity of the raw material polyester resin by using a sugar alcohol and/or a 5 bisphenol-based compound containing two or more hydroxyl groups in the molecule and having a melting point of 80°C or more and a boiling point of 260°C or more, in particular, by incorporating 0.1 parts by weight or more and less than 5 parts by weight of the sugar alcohol and/or the bisphenol-based compound containing two or more hydroxyl groups in the molecule and having a melting point of 80°C or more and a boiling point of 260°C or more with respect to 100 parts by weight of the polyester resin, a polyester-based fiber for artificial 10 hair having good spinning properties and excellent flame retardance, heat resistance, and color development can be produced. The polyester-based fiber for artificial hair of the present invention is composed of a polyester resin composition including a polyester resin, a brominated epoxy flame retardant, and the like. The polyester resin is at least one resin selected from the group consisting of polyalkylene 15 terephthalate and copolymerized polyesters containing polyalkylene terephthalate as the main component. The polyalkylene terephthalate is not particularly limited and may be, for example, polyethylene terephthalate, polypropylene terephthalate, polybutyiene terephthalate, or polycyclohexane dimethylene terephthalate. The copolymerized polyesters containing polyalkylene terephthalate as the main component are not particularly limited and may be, for example, copolymerized polyesters containing polyalkylene terephthalate such as 20 polyethylene terephthalate, polypropylene terephthalate, polybutylene terephthalate, or polycyclohexane 5 16745 dimethylene terephthalate as the main component and other copolymerizable components. In the present invention, the term "main component" means a component that is contained in an amount of 80 mol°/0 or more. Thus, the "copolymerized polyesters containing polyalkylene terephthalate as the main component" refers to the copolymerized polyesters containing 80 mol% or more of polyalkylene terephthalate. 5 Examples of the other oopolymerizable components indude the following: polycarboxylic adds such as isophthalic acid, orthophthalic acid, naphthalenedicarboxylic add, paraphenylenedicarboxylic acid, trimellitic acid, pyromellitic add, succinic add, glutaric add, adipic add, suberic add, azelaic acid, sebacic add, and dodecanedioic add, and their derivatives; dicarboxylic adds including a sulfonic add salt such as 5-sodiumsulfoisophthalic add and dihydroxyethyl 5-sodiumsulfoisophthalate, and their derivatives; 10 1,2-propanediol; 1,3-propanediol; 1,4-butanediol; 1,6-hexanediol; neopentyl glycol; 1,4-cyclohexanedimethanol; diethylene glycol; polyethylene glycol; trimethylolpropane; pentaerythritol; 4-hydroxybenzoic acid; and c-caprolactone. Specific examples of the copolymerized polyesters containing polyalkylene terephthalate as the main component include copolymerized polyesters obtained by copolymerization of polyethylene terephthalate as 15 the main component with one compound selected from the group consisting of ethylene glycol ether of bisphenol A, 1,4-cyclohexanedimethanol, isophthalic acid, and dihydroxyethyl 5-sodiumsulfoisophthalate. The polyalkylene terephthalate and/or the copolymerized polyesters containing polyalkylene terephthalate as the main component may be used alone or in a combination of two or more. In particular, it is preferable that polyethylene terephthalate, polypropylene terephthalate, polybutylene terephthalate, a 20 copolymerized polyester obtained by copolymerization of polyethylene terephthalate as the main component 0 16745 with ethylene glycol ether of bisphenol A, a copolymerized polyester obtained by copolymerization of polyethylene terephthalate as the main component with 1,4-cyclohexanedimethanol, a copolymerized polyester obtained by copolymerization of polyethylene terephthalate as the main component with isophthalic add, and a copolymerized polyester obtained by copolymerization of polyethylene terephthalate as the main 5 component with dihydroxyethyl 5-sodiumsulfoisophthalate are used alone or in a combination of two or more. In the polyester-based fiber for artificial hair, the intrinsic viscosity of the polyester resin, that is, the intrinsic viscosity of the polyester resin after being processed into fiber is 0.3 to 0.5, preferably 0.35 to 0.5, and more preferably 0.4 to 0.5. When the polyester resin in the polyester-based fiber for artificial hair has an intrinsic viscosity of 0.3 or more, the polyester-based fiber for artificial hair has excellent flame retardance and 10 does not drip during a combustion test. In addition, the polyester-based fiber for artificial hair also has excellent heat resistance and is not softened during setting with a hair iron at a high temperature. When the polyester resin in the polyester-based fiber for artificial hair has an intrinsic viscosity of 0.5 or less, the polyester-based fiber for artificial hair has excellent heat resistance and is not easily caused to shrink by heat. Thus, the fiber is not likely to be crimped during setting with a hair iron at a high temperature. 15 In the present invention, the intrinsic viscosity of the polyester resin that is used as the raw material (before being processed into fiber) may be selected as appropriate so that the polyester resin in the fiber (after being processed into fiber) has an intrinsic viscosity of 0.3 to 0.5, and is not particularly limited. As will be described later, in the case where a viscosity-reducing agent is used to reduce the intrinsic viscosity of the polyester resin, the intrinsic viscosity of the polyester resin before being processed into fiber is preferably 0.4 or 20 more, more preferably 0.5 or more, and even more preferably 0.6 or more. 7 16745 Although there is no particular limitation to the brominated epoxy flame retardant, for example, it is possible to use as a raw material a brominated epoxy flame retardant having an epoxy group, tribromophenol, tetrabromobisphenol A, or the like at the end of the molecule. Specifically, the brominated epoxy flame retardant may be a compound induding a structural formula 5 represented by general formula (1) below in the molecule. Chemical Formula 1 - (1) OCH 2CHCF1 2 01-1 rr In general formula (1) above, m is 1 to 1000. The brominated epoxy flame retardant preferably has a number-average molecular weight of 1000 10 to 20000, more preferably 2000 to 15000, and even more preferably 2000 to 10000. When the brominated epoxy flame retardant has a number-average molecular weight within the above-described range, the brominated epoxy flame retardant is easily dispersed in the polyester resin, resulting in favorable color development and also excellent spinning stability. From the standpoint of preventing fiber fusion, it is preferable that the brominated epoxy flame 15 retardant has tribromophenol and/or tetrabromobisphenol A, more preferably tetrabromobisphenol A, at the end of the molecule. When a brominated epoxy flame retardant having a low number-average molecular weight has an epoxy group at the end of the molecule, the reactivity with the polyester resin is excessively high. 8 16745 Thus, a gel is generated during melt kneading and/or melt spinning, and there is a risk that fiber fusion may occur. In contrast, when a brominated epoxy flame retardant having a low number-average molecular weight has tribromophenol and/or tetrabromobisphenol A at the end of the molecule, the reactivity with the polyester resin is not high. Thus, generation of the gel during melt kneading and/or melt spinning is suppressed, and 5 fiber fusion is unlikely to occur. In the present invention, a brominated epoxy flame retardant having the above-described structure at the end of the molecule is used as the raw material. However, there is no particular limitation to the structure of the brominated epoxy flame retardant after melt kneading and/or melt spinning. For example, the end of the molecule of the brominated epoxy flame retardant may be replaced by an epoxy group, a hydroxyl group, 10 a phosphoric acid group, or a phosphonic acid group. Alternatively, the end of the molecule of the bronninated epoxy flame retardant may be bound to the polyester resin through an ester group. The brominated epoxy flame retardants may be used alone or in a combination of two or more. Preferably, the polyester-based fiber for artificial hair indudes 5 to 40 parts by weight of the brominated epoxy flame retardant with respect to 100 parts by weight of the polyester resin. More preferably, 15 the polyester-based fiber for artificial hair indudes 5 to 30 parts by weight and even more preferably 6 to 25 parts by weight of the brominated epoxy flame retardant with respect to 100 parts by weight of the polyester resin. When the content of the brominated epoxy flame retardant is within the above-described range, the polyester-based fiber for artificial hair has excellent flame retardance, color development, and spinning properties. 9 16745 Preferably, the polyester-based fiber for artificial hair indudes 0.1 parts by weight or more and less than 5 parts by weight of a viscosity-reducing agent with respect to 100 parts by weight of the polyester resin. More preferably, the polyester-based fiber for artificial hair includes 0.2 to 4 parts by weight, even more preferably 0.4 to 3 parts by weight, and particularly preferably 0.8 to 3 parts by weight of the viscosity-reducing agent with respect to 100 parts by weight of the polyester resin. The viscosity-reducing agent is a sugar alcohol and/or a bisphenol-based compound containing two or more hydroxyl groups in the molecule and having a melting point of 80°C or more and a boiling point of 260°C or more. In the present invention, the sugar alcohol and/or the bisphenol-based compound containing two or more hydroxyl groups in the molecule and having a melting point of 80°C or more and a boiling point of 10 260°C or more has an effect of reducing the intrinsic viscosity of the polyester resin, and improves the heat resistance and color development of the polyester-based fiber for artificial hair by reducing the intrinsic viscosity of the polyester resin. When two or more hydroxyl groups are present in the molecule, the sugar alcohol and/or the bisphenol-based compound has good reactivity with the polyester resin and easily reduces the intrinsic viscosity of the polyester resin. Moreover, when the melting point is 80°C or more, the sugar alcohol 15 and/or the bisphenol-based compound does not decompose during steps such as melt kneading or melt spinning of the polyester resin composition, and can exert the function of a viscosity-reducing agent. Furthermore, when the boiling point is 260°C or more, the sugar alcohol and/or the bisphenol-based compound does not function as a plasticizer and functions as a viscosity-reducing agent, and thus the heat resistance of the polyester-based fiber for artificial hair is not reduced. 20 The sugar alcohol that is used as the viscosity-reducing agent may be any sugar alcohol containing 10 16745 two or more hydroxyl groups in the molecule and having a melting point of 80°C or more and a boiling point of 260°C or more, and is not particularly limited. Examples thereof include erythritol, pentaerythritol, and sorbitol. More preferably, the sugar alcohol that is used as the viscosity-reducing agent has a melting point of 120°C or more. Also, it is more preferable that the sugar alcohol that is used as the viscosity-reducing agent has a 5 boiling point of 270°C or more. The bisphenol-based compound that is used as the viscosity-reducing agent may be any bisphenol-based compound containing two or more hydroxyl groups in the molecule and having a melting point of 80°C or more and a boiling point of 260°C or more, and is not particularly limited. Examples thereof include tetrabromobisphenol A and tetrabromobisphenol S. More preferably, the bisphenol-based compound 10 that is used as the viscosity-reducing agent has a melting point of 120°C or more. Also, it is more preferable that the bisphenol-based compound that is used as the viscosity-reducing agent has a boiling point of 270°C or more. With regard to the viscosity-reducing agent, a single compound may be used alone, or two or more compounds may be used in combination. 15 The sugar alcohols and the bisphenol-based compounds that are used as the viscosity-reducing agent may be present in a state in which they are bound to the polyester resin through an ester bond in the polyester-based fiber for artificial hair. The polyester-based fiber for artificial hair may contain various kinds of additives such as a flame retardant other than the brominated epoxy flame retardant, a flame retardant auxiliary, a stabilizer, a fluorescent 11 16745 agent, an antioxidant, and an antistatic agent as needed without impeding the effects of the present invention. The polyester-based fiber for artificial hair of the present invention can be obtained by, for example, melt spinning a polyester resin composition containing a polyester resin and a brominated epoxy flame retardant by an ordinary melt spinning method. The polyester resin composition can be obtained by dry 5 blending each of the above-described components such as the polyester resin, the brominated epoxy flame retardant, and the viscosity-reducing agent, and melt kneading the mixture using various general kneading machines. Examples of the kneading machines include a single-screw extruder, a twin-screw extruder, a roll, a Banbury mixer, and a kneader. In particular, the twin-screw extruder is preferred in terms of the adjustment of the degree of kneading and the ease of operation. Melt kneading is preferably performed at a temperature 10 of not lower than the melting point of the polyester resin, for example, at a temperature of 250 to 280°C, although there is no limitation thereto. Preferably, the polyester resin composition includes 5 to 40 parts by weight of the brominated epoxy flame retardant with respect to 100 parts by weight of the polyester resin. More preferably, the polyester resin composition includes 5 to 30 parts by weight and even more preferably 6 to 25 parts by weight of the 15 brominated epoxy flame retardant with respect to 100 parts by weight of the polyester resin. In addition, the polyester resin composition preferably includes 0.1 parts by weight or more and less than 5 parts by weight, more preferably 0.2 to 4 parts by weight, even more preferably 0.4 to 3 parts by weight, and particularly preferably 0.8 to 3 parts by weight of the viscosity-reducing agent with respect to 100 parts by weight of the polyester resin. 90 The polyester-based fiber for artificial hair is preferably produced by melt kneading the polyester resin 12 16745 composition including the polyester resin, the brominated epoxy flame retardant, and the viscosity-reducing agent and melt spinning the melt-kneaded polyester resin composition. When a polyester resin having an intrinsic viscosity of more than 0.5 is used as a raw material polyester resin, and an adjustment is made by reducing this intrinsic viscosity using a sugar alcohol and/or a bisphenol-based compound containing two or 0 more hydroxyl groups in the molecule and having a melting point of 80°C or more and a boiling point of 260°C or more so that the polyester resin after being processed into fiber has an intrinsic viscosity within a range of 0.3 to 0.5, a polyester-based fiber for artificial hair having good spinning properties and exhibiting excellent flame retardance, heat resistance, and color development can be produced. When the polyester resin composition indudes the sugar alcohol and/or the bisphenol-based compound containing two or more 10 hydroxyl groups in the molecule and having a melting point of 80°C or more and a boiling point of 260°C or more (viscosity-reducing agent), the viscosity-reducing agent reduces the intrinsic viscosity of the polyester resin during melt kneading and/or melt spinning. In the case where the polyester-based fiber for artificial hair of the present invention is produced by melt spinning by performing an ordinary melt spinning method, for example, the polyester resin composition is 15 melt spun into yams while the temperatures of an extruder, a gear pump, a spinneret, and the like are set to 250 to 310°C. Then, the obtained yams are cooled to a temperature of not more than the glass transition point of the polyester resin, and wound up at a speed of 50 to 5000 m/min, and thus spun yams (undrawn yams) are obtained. Moreover, the spun yams may also be cooled in a water bath containing cooling water so as to control the fineness. The temperature and amount of the cooling air applied, the temperature of the 20 cooling water bath, the cooling time, and the winding speed can be adjusted appropriately in accordance with 13 16745 the extrusion rate of the polymer and the number of holes of the spinneret. In the present invention, it is preferable that the obtained spun yams (undrawn yams) are hot drawn. The drawing may be performed by either a two-step method or a direct drawing method. In the two-step method, the spun yams are once wound, and then drawn. In the direct drawing method, the spun yams are 5 drawn continuously without winding. The hot drawing may be performed by a single-stage drawing method or a multi-stage drawing method that includes two or more stages. The heating means for the hot drawing may be a heating roller, a heat plate, a steam jet apparatus, or a hot water bath, and they can be used in combination as desired. It is preferable that the polyester-based fiber for artificial hair of the present invention is a fiber like 10 non-crimped raw silk. In addition, the polyester-based fiber for artificial hair preferably has a fineness of 10 to 100 dtex, more preferably 20 to 90 dtex, and even more preferably 35 to 80 dtex because the fineness within the above-describe range is suitable for artificial hair. The polyester-based fiber for artificial hair of the present invention has favorable flame retardance and heat resistance. 15 The flame retardance of the polyester-based fiber for artificial hair can be determined based on the LOI value and whether or not dripping occurs during a combustion test. Measurement of the LOI value and the combustion test can be performed in the manners that will be described later. In light of the excellent flame retardance of the polyester-based fiber for artificial hair, it is preferable that the LOI value is 23 or more and no dripping occurs in the combustion test, and it is more preferable that the LOI value is 25 or more and no 14 16745 dripping occurs in the combustion test. The heat resistance of the polyester-based fiber for artificial hair can be determined based on the heat shrinkage percentage at 220°C that is measured with a TMA (thermal strain and stress measuring apparatus) and whether or not the fiber is softened and/or crimped by application of heat with a hair iron at 5 220°C. Measurement of the heat shrinkage percentage at 220°C with a TMA and application of heat with a hair iron at 220°C can be conducted in the manners that will be described later. It is preferable that the heat shrinkage percentage at 220°C of the polyester-based fiber for artificial hair that is measured with a TMA is less than 5% in light of excellent heat resistance. Moreover, it is preferable that the fiber is not crimped, more preferably the fiber is not softened, by application of heat with a hair iron at 220°C. It is particularly preferable 10 that the heat shrinkage percentage at 220°C that is measured with a TMA is less than 5%, and application of heat with a hair iron at 220°C does not cause any change in the external appearance and texture of the fiber. The excellent heat resistance enables curl setting and the like to be preferably performed wfth a heat instrument for beauty treatment, such as a hair iron, at 180 to 240°C. The polyester-based fiber for artificial hair (multifilament) has little fiber fusion. For example, in the 15 case where fiber fusion is evaluated in the manner that will be described later, the number of fused fibers is preferably less than 50 and more preferably less than 10. In the case where the polyester-based fiber for artificial hair of the present invention is spun-dyed, the fiber can be used as it is. However, in the case where the fiber is not spun-dyed, the fiber can be dyed under the same condition as that of ordinary polyester-based fibers. As a pigment, a dye, an auxiliary, and the like 20 to be used for dyeing, those having weather resistance and flame retardance are preferable. 15 16745 The polyester-based fiber for artificial hair of the present invention can be directly used alone as artificial hair. Alternatively, the polyester-based fiber for artificial hair of the present invention can be used as a fiber bundle for hair by mixing the polyester-based fiber for artificial hair with at least one fiber selected from the group consisting of human hair, animal hair, polyvinyl chloride-based fibers, modacrylic fibers, 5 polyamide-based fibers, polyolefin-based fibers, regenerated protein fibers, and other polyester-based fibers. The above-described fibers can be mixed as long as the fiber bundle for hair can retain excellent flame retardance and heat resistance. A hair ornament product that is formed using the polyester-based fiber for artificial hair of the present invention has excellent flame retardance and heat resistance. Examples of the hair ornament product include, 10 but not limited to, hair wigs, hairpieces, weavings, hair extensions, braided hair, hair accessories, and doll hair. The hair ornament product may be formed only of the polyester-based fiber for artificial hair of the present invention. The hair ornament product may also be formed by combining the polyester-based fiber for artificial hair with at least one fiber selected from the group consisting of human hair, animal hair, polyvinyl chloride-based fibers, modacrylic fibers, polyamide-based fibers, polyolefin-based fibers, regenerated protein 15 fibers, and other polyester-based fibers. Examples Hereinafter, the present invention will be described in more detail based on examples. However, the present invention is not limited to the examples. 10 16745 The following compounds were used in the examples and comparative examples. Polyethylene terephthalate 1 (hereinafter also referred to as "PET1"): product name "RT523" manufactured by Nippon Unipet Co., Ltd., IV = 0.70 Polyethylene terephthalate 2 (hereinafter also referred to as "PET2"): product name "regenerated 5 PET' manufactured by Nihon MTC Co., Ltd., IV = 0.47 Brominated epoxy flame retardant 1 (hereinafter also referred to as "flame retardant 1"): product name "SRT-20000" manufactured by Sakamoto Yakuhin Kogyo Co., Ltd., number-average molecular weight: 40000, an epoxy-terminated brominated epoxy flame retardant Brominated epoxy flame retardant 2 (hereinafter also referred to as "flame retardant 2"): product 10 name "SRT-2000" manufactured by Sakamoto Yakuhin Kogyo Co., Ltd., number-average molecular weight: 4000, an epoxy-terminated brominated epoxy flame retardant Brominated epoxy flame retardant 3 (hereinafter also referred to as "flame retardant 3"): product name "SRI-1540" manufactured by Sakamoto Yakuhin Kogyo Co., Ltd., number-average molecular weight: 3000, a tribromophenol end-capped brominated epoxy flame retardant 15 Viscosity-reducing agent 1: pentaerythritol (manufactured by Wako Pure Chemical Industries, Ltd., number of hydroxyl groups: 4, melting point: 261°C, boiling point: 276°C) Viscosity-reducing agent 2: tetrabromobisphenol S (product name "S-400" manufactured by Manac Incorporated., number of hydroxyl groups: 2, melting point: 300°C, boiling point: 320°C) 17 16745 (Examples 1 to 6 and Comparative Examples 1 to 3) The above described PET1 or PET2 was dried to a moisture content of 100 ppm or less, and then was dry blended with the above described other compounds in blending ratios shown in Table 1 below. Each 5 of the obtained polyester resin compositions was supplied to a twin-screw extruder, melt kneaded at 280°C, and pelletized. The pellets were dried to a moisture content of 100 ppm or less. Next, the dried pellets were supplied to a melt spinning machine, and a molten polymer was extruded at 280°C through a spinneret with nozzle holes having a nozzle diameter of 0.5 mm and a circular cross-section. The extruded polyrner was cooled to a temperature of not more than the glass transition temperature of the polyester resin, and wound up 10 at a speed of 60 to 150 m/min to obtain spun yams. The obtained spun yams were drawn to 3 times the original length at 80°C and heat-treated using a heat roller heated to 200°C. Thus, a polyester-based fiber (multifilament) having a single fiber fineness of about 60 dtex was obtained. It should be noted that in Examples 1 to 4, the intrinsic viscosity of the polyester resin was reduced by the viscosity-reducing agent (sugar alcohol or tetrabromobisphenol S) during melt kneading and/or melt spinning of the polyester resin 15 composition. The intrinsic viscosity of the polyester resins (IV of the polyester resins after being processed into fiber) of the polyester-based fibers obtained in Examples 1 to 6 and Comparative Examples 1 to 3 was measured in the following manner. The results are shown in Table 1 below. Also, the heat resistance, flame retardance, color development, and fiber fusion of the polyester-based fibers obtained in Examples 1 to 6 and 90 Comparative Examples 1 to 3 were measured and evaluated in the following manners. The results are 18 - 16745 shown in Table 1. (IV of Polyester Resin after Being Processed into Fiber) A polyester-based fiber was dissolved in a mixed solvent of phenolitetrachloroethane with a weight 5 ratio of 1/1 so that the concentration was 0.25 g/dL, and the IV of the polyester resin in the fiber was measured at 25°C. (Heat Resistance) Heat resistance was determined by the following four criteria based on the shrinkage percentages at 10 220°C of the fiber that was measured with a TMA and the texture and external appearance after an end (length: 3 cm) of filaments (total fineness: 150000 dtex, length: 50 cm) was heated for 3 seconds with a hair iron at 220°C. A: The shrinkage percentage of the fiber is less than 5%, and both the external appearance and the texture of the fiber remain unchanged after heating with the hair iron when compared with those before 15 heating. B:The shrinkage percentage of the fiber is less than 5%, but the fiber is softened, and the texture is slightly hard. C: The shrinkage percentage of the fiber is 5% or more, a small amount of crimp is observed in the 19 16745 fiber, and the texture tends to be rough. D: The shrinkage percentage of the fiber is 5% or more, distinct crimps are observed in the fiber, and the texture is significantly rough. 5 <Measurement of Fiber Shrinkage Percentage at 220°C with TMA> Filaments (length: 2 cm, ten single yams) were used. The shrinkage percentages at 220°C of the fibers were measured with a TMA (thermal stress and strain measuring apparatus, trade name 'TMA/SS150C" manufactured by Seiko Instruments Inc., working gas: nitrogen, gas flow rate: 30 Um in, rate of temperature increase: 20°C/min, load: 18 mN). The fiber shrinkage percentage is given by an equation 10 below fiber shrinkage percentage (%) = 100-[(100xY)/X] where X is an initial sample length, and Y is a sample length at 220°C. (Flame Retardance) 15 Flame retardance was determined by the following four criteria based on the LOI value and whether or not dripping occurred in a combustion test. A: Dripping does not occur, and the LOI value is 25 or more. B: Dripping does not occur, and the LOI value is 23 or more and less than 25. 20 ----___ .--------- — 16745 C: Dripping occurs, and the LOI value is 23 or more. D: Regardless of whether or not dripping occurs, the LOI value is less than 23. <Measurement of LOI Value> 5 The LOI value was measured conforming to a method specified in JIS L 1091 E (oxygen index test). Specifically, filaments (length: 16 cm, weight: 0.25 g) were lightly tied together at both ends with a double-sided adhesive tape, inserted in a twisting device, and twisted. After the filaments were sufficiently twisted, the filaments were folded in half at the middle and twisted together. The resultant filaments were fastened at both ends with a Cellophane (registered trademark) tape so that the overall length became 7 cm. The thus 10 obtained sample was pre-dried at 105°C for 60 minutes and further dried in a desiccator for at least 30 minutes. The dried sample was adjusted to a certain oxygen concentration. After 40 seconds, the top of the sample was ignited by an igniter with the igniter flame restricted to 8 to 12 mm. The igniter was removed after the sample ignited. The oxygen concentration at which 5 cm or more of the sample burned or the sample continued burning for at least 3 minutes was obtained. The test was repeated three times under the same 15 conditions. Thus, the limiting oxygen index (L01) was obtained. <Combustion Test> First, 0.7 g of filaments that were cut to a length of 150 mm was tied into a bundle. One end of the bundle was damped and fixed to a stand so that the effective length was 120 mm, and the bundle was 21 16745 suspended vertically. Aflame of 20 mm was applied to the fixed filaments bundle for 3 seconds to cause the filaments bundle to bum, and whether or not dripping occurred was observed. (Color Development) A tow filament having a length of 30 cm and a total fineness of 100000 dtex was visually observed in 5 the sunlight, and color development was evaluated by the following four criteria by comparison with the external appearance of human hair. A: The hue of the fiber is dear and similar to that of human hair. B: The fiber is somewhat cloudy, and its color is slightly less dear in comparison with the external 10 appearance of human hair. C: The fiber is cloudy, and its color is less clear in comparison with the external appearance of human hair. D: The fiber is strongly cloudy, and its color is distinctly less dear in comparison with the external appearance of human hair. 15 (Fiber Fusion) Twenty fiber bundles (length: 50 cm, weight: 136 g) were combed at least 30 times by running a comb made of a polyacetal resin (trade name "NEW DELRIN COMB No. 826" manufactured by Uehara Cell) 22 16745 from a point 3 cm below the top of the fiber bundles down through it at a speed of 0.3 m/s. Fiber fusion was determined as follows based on the number of fused fibers that were caught in the comb. A: The number of fused fibers is less than 10. B:The number of fused fibers is 10 or more and less than 50. 5 C: The number of fused fibers is 50 or more and less than 100. D: The number of fused fibers is 100 or more. Table 1 Ex. 1 Ex. 2 Ex. 3 Ex. 4 100 100 100 100 Ex. 5 Ex. 6 Corn. Corn. Corn. Ex. 1 Ex. 2 Ex. 3 100 100 100 20 20 PET1 (parts by weight) PET 2 100 100 (parts by weight) Flame retardant 1 20 20 (parts by weight) Flame retardant 2 20 (parts by weight) Flame retardant 3 20 20 20 (parts by weight) Viscosity-reducing agent 1 3 3 5 3 (parts by weight) 23 16745 Viscosity-reducing agent 2 3 (parts by weight) IV of polyester 0.40 0.45 0.40 0.40 0.38 0.47 0.62 0.28 0.65 2 2 2 2 2 3 9 1 11 Heat resistance A A A A A A D B D LOI value 26 26 26 26 26 26 27 24 21 Does Does Does Does Does Does Does not not not not not not not Occurs Occurs occur occur occur OCCUr OCCUr OCCUr OCCUr Flame retardance A A A A A A A C D Color development A A A B B C A C A 8 7 31 2 9 3 5 22 0 A A B A A A A B A resin after being processed into fiber Fiber shrinkage percentage (°/0) Dripping Number of fused fibers Fiber fusion As can be seen from the results shown in Table 1 above, the polyester-based fibers of Examples 1 to 6, in each of which the polyester resin (after being processed into fiber) had an IV within a range of 0.3 to 0.5, had favorable flame retardance and heat resistance. As can be seen from comparisons of Examples 1 to 3 5 with Example 4 and a comparison between Examples 5 and 6, in the cases where a brominated epoxy flame retardant having a number-average molecular weight within a range of 1000 to 20000 was used, the color development was improved. As can be seen from comparisons of Examples 1 to 3 with Example 5 and a 24 16745 comparison between Examples 4 and 6, the polyester-based fibers obtained by reducing the IV of the polyester resin before being processed into fiber using a sugar alcohol and/or a bisphenol-based compound containing two or more hydroxyl groups in the molecule and having a melting point of 80°C or more and a boiling point of 260°C or more as the viscosity-reducing agent to adjust the IV of the polyester resin after being 5 processed into fiber to a range of 0.3 to 0.5 exhibited superior color development. As can be seen from comparisons of Examples 1 and 2 with Example 3, in the cases where a brominated epoxy flame retardant having a low number-average molecular weight of 1000 to 20000 was used, fiber fusion in the case where the brominated epoxy flame retardant had tetrabromobisphenol A at the end of the molecule was less than that in the case where the brominated epoxy flame retardant had an epoxy group at the end of the molecule. 10 On the other hand, the polyester-based fibers of Comparative Examples 1 and 3, in each of which the polyester resin after being processed into fiber had an IV of more than 0.5, had poor heat resistance. Moreover, the polyester-based fiber of Comparative Example 3, which did not contain a brominated epoxy flame retardant, also had poor flame retardance. The polyester-based fiber of Comparative Example 2, in which the polyester resin after being processed into fiber had an IV of less than 0.3, was inferior to the 15 polyester-based fibers of the examples in both the flame retardance and the heat resistance. The invention may be embodied in other forms without departing from the spirit or essential characteristics thereof, The embodiments disclosed in this application are to be considered in all respects as illustrative and not limiting. The scope of the invention is indicated by the appended claims rather than by the foregoing description, and all changes which come within the meaning and range of equivalency of the claims 20 are intended to be embraced therein. 16745 WHAT IS CLAIMED IS: 1. A polyester-based fiber for artificial hair comprising a polyester resin and a brominated epoxy flame retardant, wherein the polyester resin is polyalkylene terephthalate and/or a copolymerized polyester containing 5 polyalkylene terephthalate as a main component, and the polyester resin has an intrinsic viscosity of 0.3 to 0.5. 2. 10 The polyester-based fiber for artificial hair according to claim 1, wherein the brominated epoxy flame retardant has a number-average molecular weight of 1000 to 20000. 3. The polyester-based fiber for artificial hair according to daim 1 or 2, comprising 0.1 parts by weight or more and less than 5 parts by weight of a viscosity-reducing agent with respect to 100 parts by weight of the polyester resin, the viscosity-reducing agent being a sugar alcohol and/or a bisphenol-based compound 15 containing two or more hydroxyl groups in a molecule and having a melting point of 80°C or more and a boiling point of 260°C or more. A method for producing the polyester-based fiber for artificial hair according to any one of daims 1 to 26 _s7) 16745 3, the method comprising: a step of reducing an intrinsic viscosity of a polyester resin using a viscosity-reducing agent, the viscosity-reducing agent being a sugar alcohol and/or a bisphenol-based compound containing two or more hydroxyl groups in a molecule and having a melting point of 80°C or more and a boiling point of 260°C or Ti more. 5. A fiber bundle for hair comprising: the polyester-based fiber for artificial hair according any one of daims 1 to 3, and at least one fiber selected from the group consisting of human hair, animal hair, polyvinyl chloride-based fibers, modacrylic fibers, 10 polyamide-based fibers, polyolefin-based fibers, regenerated protein fibers, and other polyester-based fibers. 6. A hair ornament product comprising the polyester-based fiber for artificial hair according to any one of claims 1 to 3. 15 7. The hair ornament product according to daim 6, further comprising at least one fiber selected from the group consisting of human hair, animal hair, polyvinyl chloride-based fibers, modacrylic fibers, polyamide-based fibers, polyolefin-based fibers, regenerated protein fibers, and other polyester-based fibers. 27