sample - Forecast International

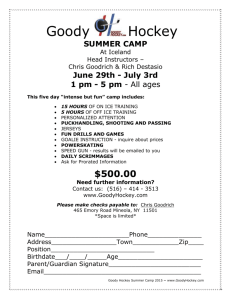

advertisement