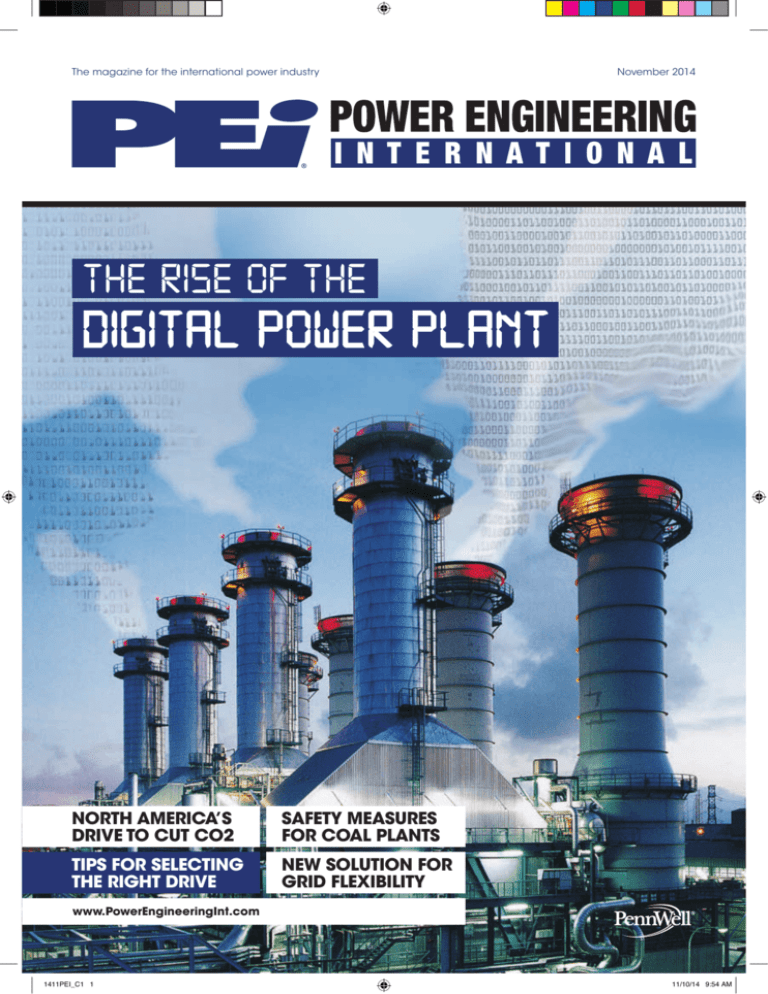

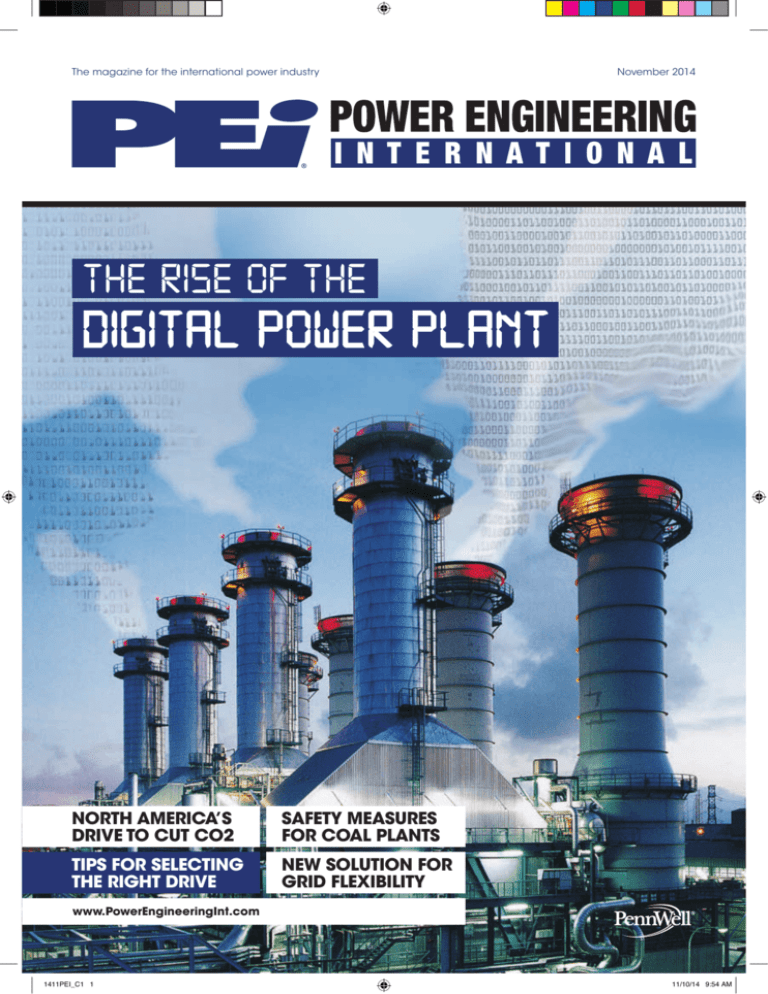

The magazine for the international power industry

NORTH AMERICA’S

DRIVE TO CUT CO2

SAFETY MEASURES

FOR COAL PLANTS

TIPS FOR SELECTING

THE RIGHT DRIVE

NEW SOLUTION FOR

GRID FLEXIBILITY

November 2014

www.PowerEngineeringInt.com

1411PEI_C1 1

11/10/14 9:54 AM

The Power of More.

Introducing the QSK95 Series of high-horsepower generator sets.

When it comes to power generation, more is better. More horsepower.

More performance. More reliability. But what if you could also have a

generator set that takes up less space in your facility, lowers installation

costs and reduces maintenance? At Cummins Power Generation, we

call this The Power of More — and with the QSK95 Series of generator

sets, it can be yours. Rated at up to 3,500 kW (3,750 kVA) and designed

with a smaller footprint, the QSK95 delivers the highest kilowatt per

square foot ratio in its class.

Visit our website to see how the QSK95

can give you The Power of More.

CumminsPowerOfMore.com/QSK95Series

Our energy working for you.

TM

© 2014 Cummins Power Generation Inc. All rights reserved. Cummins Power Generation and Cummins are registered trademarks of Cummins Inc. “Our energy working for you.” is a trademark of Cummins Power Generation Inc.

For more information, enter 1 at pei.hotims.com

1411PEI_C2 2

11/10/14 9:54 AM

POWER ENGINEERING INTERNATIONAL

NOVEMBER 2014/// VOLUME 22/// ISSUE 10

Contents

4

Industry Highlights

52

Diary

51

Ad Index

Canadian CCS project offers carbon-reduction breakthrough - p12

Source: SaskPower

Features

30

6

The rise of the digital power plant

Retroftting electrostatic precipitators with a high-frequency

switch mode power supply can reduce particulate emissions

and improve performance.

How real-time analysis and simulation software is bringing

operational benefts for combined-cycle plants.

12

Driving a low-carbon path for American power

36

An engineer’s guide to selecting a drive

40

Strengthening safety in mills and silos

44

Developments in power plant fre detection

The challenges and solutions involved in fre detection for

power plant operators.

A new approach to nuclear decomissioning

Meeting the challenges of decommissioning multiple nuclear

sites with a programmized approach.

Equipment selection and operating criteria are vital for

reducing fre risk in coal storage facilities.

28

Dynamic line rating: a solution for fexibility

Dynamic line rating technology can increase the capacity of

overhead transmission lines while reducing congestion.

How to fnd the optimal motor for an application while

avoiding design errors and saving money.

24

Advances in vacuum circuit-breakers

Technology advances now allow vacuum circuit-breakers to

be used in generator switching applications.

A look at North America’s new generation of low-carbon

power generation technologies.

20

A fresh perception of ESP

46

Desuperheaters rise to new challenges

How a new generation of desuperheaters is addressing

today’s 50- and 60-Hz combined-cycle power generation.

On the cover

Increasingly fast and sophisticated real-time plant analysis software is unlocking improved predictability, reliability and fexibility for combinedcycle plant - p6. Cover image credit: Siemens

Free Product Info

You can request product and service information from this issue. Simply click on the link below that will provide you access to supplier companies’ websites,

product information and more http://pei.hotims.com

If you are considering suppliers or buying products you read about in PEi, please use this service. It gives us an idea of how products are being received to help us continually

improve our editorial offering and it also lets our advertisers know that you are a PEi reader and helps them to continue supporting the free distribution of your magazine.

www.PowerEngineeringInt.com

1411PEI_1 1

Power Engineering International November 2014

1

11/10/14 9:40 AM

OCTOBER, 1947

CHUCK YEAGER

BREAKS

THE SOUND

BARRIER

For more information, enter 2 at pei.hotims.com

1411PEI_2 2

11/10/14 9:45 AM

JUNE 2014, SENTRON LD 8000 NGEO

TM

SHATTERS

THE DRAIN

INTERVAL

BARRIER

Yesterday, 8,000 hours was unthinkable.

Suddenly, anything less could be unacceptable.

New SENTRON LD 8000 Natural Gas Engine Oil (NGEO) is so advanced

it provides up to 8,000 hours between drains. Satisfy your need for proof

with our Money-Back Guarantee Trial. Visit SentronTrial.com for details.

Call 1-866-335-3369 or visit

lubricants.petro-canada.com for more information.

Petro-Canada is a Suncor Energy business

TM

Trademark of Suncor Energy Inc. Used under licence.

1411PEI_3 3

11/10/14 9:45 AM

Industry Highlights

ubsidies – can’t live with them, can’t live

S

“We are doing our utmost to be in line

without them: at least that’s how it often

with global trends and develop these lines of

seems in the power industry.

generation,” he said.

They often dominate debates at energy

Also speaking at Russia Day was Adnan

conferences around the world, and it was no

Amin, director of the International Renewable

different at POWER-GEN Middle East in Abu

Energy Agency

Dhabi in October.

meeting the world’s rising energy demand

“Subsidies are the biggest ailment that

afficts the Middle East power sector,” said Dr

said

that

with the current global energy mix would be

“catastrophic”.

Hisham Khatib, honorary vice-chairman of the

World Energy Council.

(IRENA), who

Mr Amin said that any move to meet

demand with fossil-fuelled technology would

Speaking at the opening ceremony of

“lock in pollution and climate change”.

POWER-GEN Middle East, Dr Khatib said that

He said what was needed was a shift to

Middle East power generation subsidies use

more renewable technologies and added

8.4 per cent of the region’s GDP and account

that this was already happening.

for half of the energy subsidies in the world.

He said the continued use of subsidies was

the key factor in the Middle East’s rocketing

“Investment in renewables is booming,”

he said. “More than 100 GW of capacity has

been added every year for the past years.”

energy demand – up to 8 per cent a year for

He said fnancing of renewable projects

the last decade, which is almost four times the

was getting cheaper because the perceived

fgure for any other country in the world.

risks associated with ‘green’ technologies were

Yet he added that “subsidies beneft the

dropping.

rich, less the poor”.

Amin added that “Russia can play a very

And while he said that there were “shy”

important role in the renewables story” and

attempts to phase out subsidies, he stressed

that the Federation has “vast potential” to

that these needed to be made a “top priority”

embrace clean technologies.

and put a price tag on this of $140 billion of

Russia plans to derive 4 per cent of its

investment in the next fve years – which rises

power from renewables by 2020, which

to $230 billion if transmission and distribution

Adnan said was “a viable target”. He added

work is included.

that if Russia – which has applied to join the

Dr Khatib was joined on the stage at the

International Renewable Energy Council – hit

opening ceremony by Russia’s deputy energy

this target, it would displace six million tonnes

minister Yury Sentyurin, who used his speech

of carbon dioxide a year.

to stress the importance of international

collaboration on energy projects.

REthinking

Energy

in

which

the

organization explores “the changes that are

becoming more dynamic yet less predictable”

transforming the way we produce and use

and that the “silver bullet” to secure energy

energy, and how they will affect governments,

supplies for countries around the world was

businesses and citizens alike”.

“politically unbiased co-operation”.

In the foreword to the report (look out for

Mr Sentyurin also later spoke at Russia Day,

our feature in next month’s PEi), Amin says that

a special event being held as part of POWER-

it is “no longer a matter of whether but of when

GEN Middle East, which returned to Abu Dhabi

a systematic switch to renewable energy

for the frst time in 12 years.

takes place – and how well we manage the

told

a

packed

audience

that

transition”.

renewables were going to play a key role in

the Russian Federation’s future energy mix.

Probably true, even if he’s talking in

decades. What is certainly true – in the Middle

He said a target had been set of having

East and every other region of the world – is his

6 GW of renewables online by 2020, which

next statement: “The power sector is changing

would account for 4 per cent of the Russian

so fast that policymakers are fnding it hard to

Federation’s energy mix.

keep up.”

4

1411PEI_4 4

Kelvin Ross, Editor, www.PowerEngineeringInt.com

IRENA has just published a new report

called

He said that “the global power markets are

He

“Power generation

subsidies account for

8.4 per cent of the

Middle East’s GDP

and make up half

of the energy subsidies

in the world.”

Power Engineering International November 2014

Follow PEi Magazine on Twitter:

@PEimagzine

Follow me: @kelvinross68

www.PowerEngineeringInt.com

11/10/14 9:45 AM

© Maksim Kabakou - Fotolia.com

WESTINGHOUSE ELECTRIC COMPANY LLC

CYBER SECURITY

WE HAVE YOUR PLANT

COVERED UNDER LOCK

AND KEYSTROKE

Reliable Solutions. Regulatory Compliant. Long-term Support.

Protect the critical digital assets of your power plant with

Westinghouse’s suite of cyber security solutions. We offer a

specialized approach and worldwide experience implementing

cyber security products and services for the operating fleet and

the next generation of new plants.

Westinghouse has the expertise and technology to meet today’s

global cyber security nuclear regulations.

From a thorough systems vulnerability assessment through

mitigation solutions and long-term maintenance, Westinghouse

has your cyber security needs covered.

To learn more about cyber security, visit us at

www.westinghousenuclear.com

Westinghouse

Electric Company

@WECNuclear

For more information, enter 3 at pei.hotims.com

1411PEI_5 5

11/10/14 9:45 AM

Intelligent analytics collect vast amounts of data

Credit: Dreamstime

Operations and maintenance

Big data unlocks

better effciency

With increasingly fast

and sophisticated

real-time plant analysis

and simulation software

comes improved

predictability, reliability

and fexibility – all of

which look certain to

bring operational benefts

for combined-cycle plant,

writes Penny Hitchin

6

1411PEI_6 6

T

oday’s rate and speed of digital

be promptly looped back into the decision

development

process.

and

rate

phenomenal,

is

The physical world is increasingly getting

mirrored in the power generation

online as objects, devices and machines

industry:

acquire

of

this

is

of

rapid

development

digital

intelligence,

while

advances in connectivity mean that objects

enabling increasingly sophisticated operation

can be wirelessly integrated into information

of combined-cycle gas turbine plant. Big data,

networks. The last few years have seen a huge

the Internet of Things, wireless mesh networks

increase in the use of wireless sensors and

and cloud computing are all making their

instruments in power plants.These observe and

mark.

monitor their environment, communicating

and

information about temperature, pressure, fow

capacity have enabled collection, analysis

and vibration from the heart of the power

and

plant back to the control centre.

storage

in

technology

more

is

Increases

information

change

of

computing

increasing

speed

volumes

of

information. New software platforms are used

Big data is generating datasets that are

to interpret data and feed back information

increasing exponentially in both complexity

enabling optimization of operations and

and volume. Analyzing, storing and applying

maintenance.As the speed and sophistication

this

of real-time analytics increase, insights can

Companies such as GE are building cloud-

Power Engineering International November 2014

data

is

a

considerable

challenge.

www.PowerEngineeringInt.com

11/10/14 9:46 AM

EXPERIENCE

MATTERS

DNV

KEMA

GARRAD HASSAN

GL RENEWABLES CERTIFICATION

DNV GL in the energy sector

For more information, enter 4 at pei.hotims.com

In DNV GL we unite the strengths of DNV, KEMA, Garrad Hassan

and . Our 2500 energy experts take a

www.dnvgl.com/energy

SAFER, SMARTER, GREENER

1411PEI_7 7

11/10/14 9:46 AM

Operations and maintenance

transforming the pattern of demand, so that

combined-cycle plants are called upon to

provide fexible peak load. For an existing

power plant operating in a deregulated

competitive market, accurate prediction of

plant capacity and fuel consumption under

expected conditions for the days ahead is

essential. Weather information (notably the

likely availability of wind, hydro and solar)

should be factored in to the equation.

In order to bid into the market, plant

operators need the ability to make accurate

predictions of future operational costs. Under

a capacity market operators will be looking

to predict how best to operate in the next two

weeks, informing their bids into the market.

Petek says: “In the past, in a regulated

market, you could look back at the price of

Going forward, plant performance and asset condition will be monitored with increasing reliability

Credit: Siemens

operation to make a price. Now the historic

price of power is less signifcant: you have to

bid into the future, looking at where the market

based services with intelligent analytics to

requirements of the tender and producing the

collect and combine vast amounts of data

most competitive tariff.

to use in industries which include power

generation.

Factors will include likely demand and

The contract is for a power and water

purchase agreement for 25 years and bidders

must

around

100

weather forecast for the next two weeks.

“Based on this predictive work, you feed in

documented

your fossil generation and look at how many

Software modelling

operating points so the government can

startups do you want to use in the next two

Ambient and load conditions signifcantly

evaluate the bid in technical terms. VTU’s Dr

weeks, what will be the cost of stop-and-go

affect gas turbine and combined cycle

Josef Petek explains why the simulation plays

generation. Does it make sense to have low-

performance, thus process simulation plays a

a vital role in putting together the bid:

load parking position? Does it make sense

key role in every large project.

submit

is going, depending on the renewables.”

“There is a very strong emphasis on the

to reduce load to a minimum because

to

documentation of the technical capability

electricity price is so low that it does not pay

simulate the thermodynamics and drive the

of the plant. You are going for a long-term

to shut down the plant and you are maybe

optimization of the power plant. Experts can

relationship

paid for quickly ramping up and producing if

compile detailed models of gas turbines and

guarantees. The government owns the gas

all major components and simulate plant

and is the sole buyer of the products, electricity

In the past, effciency was the priority for

operations under the entire range of ambient

and water, so understanding the effciency

combined-cycle plant, but on networks that

and load conditions. Linking market models

and capacity of the power plant is essential.”

give priority dispatch to renewable sources

Sophisticated

software

is

used

that

includes

performance

immediate need arises?”

incorporates fnancial and environmental

Thermal power plant generation has

it is increasingly fexibility, startup time and

information so that operational costs can be

traditionally been dictated by load demand,

low load operation. Operators will rely on

projected.

but the increasing supply of intermittent

emerging predictive software to provide the

renewable energy, notably in Europe, is

answers.

Austrian software specialist VTU Energy

is currently modelling a large combined

water and power plant for a bidder for an

IWPP (Independent Water & Power Producer)

contract in the Middle East.

The developers pull together technical

information from vendors of gas turbines,

desalination units and other components

which VTU feeds into its overall plant model for

use in the bid process.

The company uses the Ebsilon Professional

heat balance software and its own Gas

Turbine Library to build an accurate plant

simulation model. This is used to fnd a

commercial optimum while meeting the

8

1411PEI_8 8

Power Engineering International November 2014

HRSG detail from Ebsilon Professional heat balance software

Credit: VTU Energy

www.PowerEngineeringInt.com

11/10/14 9:46 AM

Operations and maintenance

Big data and cloud computing

cycle power plant. Increasing the amount

Hachenski explains GE’s approach to

Number-crunching the mounting volumes of

of data from within the power plant means

making screens intuitive and user-friendly:

data from a power plant requires additional

installing smart devices and instruments. GE

“One of the things we have done is to

processing power and broadband capacity.

has done a lot in development around smart

redesign the screen ‘look and feel’ so that

The aim is to increase effciency of both

bus technology to reduce the number of

operators can easily and quickly see how

operations and asset maintenance through

terminations required to install the technology.

the plant is running. We are trying to visually

improved

Reducing wired connections saves parts,

represent what is important to the operator.

costs and time.

We do not want to burden the operator with a

understanding

of

the

plant

processes.

Eric

Kauffman,

Software

&

Analytics

product

tonne of information or with too many alarms.”

Strategy Leader at GE, says: “We have created

manager at GE, explains: “By using smart bus

Alarms alert the operator to a change, inform

a cloud-based version of our Effciency Map

technology, we dramatically reduced the

the operator of the nature of the change,

product which brings data back centrally.

installation time by decreasing the number of

and guide the operator toward a course of

This enables us to get better data by adding

wires and terminations. For instance, we have

corrective action.

a reconciliation element that would be too

reduced 3600 terminations down to 1800, a

complex to do on-site. It also enables our

50 per cent reduction in the plant.”

engineers to provide a second set of eyes for

Mark

Hachenski,

executive

GE leverages its new GE Software business

and team of user experience experts to help

Hachenski gives an example of how

make the software and experience more user-

hardware developments go hand in hand with

friendly. The interface was tested by bringing

He cites an example of the benefts:

advances in communications technology: “In

in operators to use simulated screens while

“Calculations using plant sensors might show

addition, smart bus technology can provide

observers watched them walk through various

a curve with uncertainty rate of 1–2 per cent.

higher reliability for customers.

alarms or faults in the system.

the customer.”

By using a combination of a physics model,

“In the past we used hydraulic fuel skids

Hachenski says: “Customers tell us that

a precision test and the data reconciliation

which would only annunciate four or fve

operators make mistakes as they try to

algorithm we have been able to demonstrate

analogue diagnostics. Moving into the twenty-

manually start up systems. We are looking at

overall uncertainties of below 1 per cent.

frst century, with a smart bus electronic fuel

how to automate the process so that a startup

“This gives customers better visibility to the

skid we get 60 digital health bits to come back

screen walks them through a step-by-step

existence and location of problems in the plant

into our system. This provides better visibility of

sequence. However while some customers

– and, more importantly, where the problem

what is going on for quicker actions to resolve

want operators to follow this, others don’t want

is not. It also gives a better understanding of

problems.”

operators interfering, so the software interface

plant capability so purchasers are able to buy

However sophisticated the software and

fuel more effciently and reduce the amount

remote control systems, human operators

of safety margin that traders put into their bid.

must accommodate different operators.”

are an essential part of the system. It is not

Wireless mesh networks

some

helpful to swamp them with masses of data:

The development of low-cost, fexible wireless

deregulated US markets, an improvement of 1

it is important that the information presented

networks has opened up the potential for

per cent in accuracy can be worth over half a

by the software is relevant, accessible and

additional data collection from the heart

million dollars per year in a typical combined-

comprehensible.

of the power plant, increasing real-time

Kauffman

estimates

that,

in

Load quickly

ñ safely

www.rs-seliger.de

For more information, enter 5 at pei.hotims.com

www.PowerEngineeringInt.com

1411PEI_9 9

Power Engineering International November 2014

9

11/10/14 9:46 AM

Operations and maintenance

from the heart of the power plant. Intelligent

devices can be coupled to intelligent networks

and the information can be analyzed remotely,

locally or through a combination of both.

Having collected the data, the control

system’s software is able to analyze it against

historical

baseline

maintenance

data

or

other

for

predictive

performance

evaluation.

Williams says: “As we go forward, I think we

will see a merging of technologies so that

we can watch the plant in real time from the

distributed control system and use simulation

that is closely tracking that performance to

run ‘what-if’ scenarios that will enable us to

Human operators are still an essential part of the system

Credit: Emerson Process Management

make process adjustments for more effcient

operations. Synchronizing the simulation with

real-time plant operation will allow asset

understanding of the way that processes

control system. A wireless instrument can

managers to optimize plant performance,

and components operate. This also allows

collect

reduce environmental footprint and keep

for performance validation and improved

unavailable due to the impracticality and

maintenance practices, including predictive

expense of hardwiring in a diffcult-to-reach or

approaches.

harsh environment.

information

that

was

previously

consumable costs as low as possible.”

Going forward…

Traditional networks rely on a small number

The data can then be integrated through

Software specialists, plant manufacturers and

of wired access points or wireless hotspots

the wireless network and sent to the control

operators say they are always learning from

for communication. In a wireless mesh

system so that it can be analyzed and

the data. Going forward, better analytics, a

network, the network connection is spread

performance

high degree of physics models plus big data

out among numerous wireless mesh nodes

equipment. This leads to the best possible use

(smart transducers and devices acting as

of plant assets.”

adjustments

made

to

the

look certain to bring operational benefts.

Performance will be diagnosed in real

transmitters that function in the same way

In the past a small number of wireless

time, sustaining output and effciency, while

as a wireless router) and share the network

instruments may have been used around

asset condition will be monitored and

connection across a large area. Information

the plant. Williams says that they are being

predicted with increasing reliability.

travels wirelessly across the network from one

increasingly used for a range of performance

mesh node to the next.

testing and diagnostics functions.

The nodes are programmed with software

“Power generators started using wireless

and

smart

performance,

enabling plant to get online faster from a hot

validate

or cold start and despatch faster. Software

network, and dynamic routing means they

performance of new equipment, but are

can co-ordinate between the steam turbine

automatically choose the quickest and most

now fnding that the accuracy of wireless

and the gas turbine to reduce startup time

reliable path. If one node is inoperative, the

instrumentation is so good that it can be

by 50 per cent.

rest of the nodes can still communicate with

used it as a backup to wired devices and to

each other, directly or through one or more

verify plant performance. A wireless network

and

intermediate nodes. Wireless mesh networks

can support dozens of instruments used to

hardware, software and communications

can self-form and self-heal.

validate performance.”

yield increasing amounts of information

with

which

The rate of change looks set to continue

accelerate

as

developments

in

wireless

about conditions at the heart of the plant.

wired to a network connection, which then

instrumentation can be deployed compared

GE’s Hachenski says: “We are learning every

wirelessly shares its connection with all other

to hardwired devices means that many new

day. The amount of information we are

nodes in its vicinity.

data sets are becoming readily available.

getting that we didn’t have before gives us so

Effciency Solutions Manager Jeff Williams of

As Williams says, “It is easy to hang a wireless

much more visibility. We have only scratched

Emerson Process Management is enthusiastic

transmitter onto a piece of equipment for

the surface of fguring out how to take it to

about the potential of wireless mesh networks

temporary analysis – getting this information

the next step.”

to improve data collection from power plants.

is something which would have previously

“Wireless networks have been available

required the use of many portable instruments

Penny Hitchin is a journalist focusing on

as well as associated manpower.”

energy matters.

for a number of years,” he says, “but today we

ease

to

improve

instruments

The

networks

software

can

that tells them how to interact within the larger

Only one gateway needs to be physically

and

Sophisticated

instruments

see them with expanded functionality. Wireless

Wireless networks and sensors are being

area networks in power plants are being used

used to measure increasing amounts of

in parallel with the plant’s real-time distributed

temperature, pressure, vibration and fow data

10

1411PEI_10 10

Power Engineering International November 2014

i

Visit www.PowerEngineeringInt.com

for more information

www.PowerEngineeringInt.com

11/10/14 9:46 AM

The new WDG-V.

Impressing even the

world’s most demanding

combustion manager.

The new AMETEK Thermox WDG-V extractive combustion analyzer offers

industry-leading safety support. First in its class to be third-party certified for

SIL-2 implementation in safety-instrumented systems, the WDG-V provides

a complete solution for combustion process control and safety.

Reliable detection of low-combustion oxygen and/or high CO in a fired heater

or boiler is critical to burner management system effectiveness. The WDG-V

analyzer monitors hot, wet flue gas to minimize excess oxygen, lower

NOx emissions, and improve operating efficiency in power generation

and petrochemical refining. It can also monitor methane levels to

assure safe burner startup and shutdown.

The all-new WDG-V. Combustion management and safety capabilities

so good, they make this guy jealous. Learn more at www.ametekpi.com.

© 2013 by AMETEK Inc. All rights reserved.

For more information, enter 6 at pei.hotims.com

1411PEI_11 11

11/10/14 9:46 AM

Carbon abatement

Canada’s Boundary Dam is the frst commercial-scale post-combustion CCS process on a coal-fred power plant

Credit: Sask Power

Driving a

path for North

American power

A confuence of factors

is driving the North

American power sector

down a low-carbon

road. Responding to

customer demands,

OEMs are expanding the

capabilities and material

composition of their

products in order to meet

effciency demands and

develop a new generation

of technologies, fnds

David Appleyard

12

1411PEI_12 12

A

lthough the US lags behind

circumstances states will have until 2018 to

Europe’s

deliver their proposals.

policymakers

in

efforts to address carbon

Power plants account for roughly one

emissions from the power

third of all US greenhouse gas emissions and

sector, under the Obama

while there are limits in place for emissions of

administration the Environ-

pollutants such as arsenic, mercury, sulphur

mental Protection Agency (EPA) has moved to

dioxide, nitrogen oxides and particulates, until

tackle carbon dioxide output from electricity

recently the US has been largely resolute in its

generation.

rejection of constraints on carbon emissions.

In June the EPA issued a proposal for a

However, in June 2013 President Obama

so-called Clean Power Plan, under which

issued a presidential memorandum directing

guidelines will be set for states in order to

the EPA to complete greenhouse standards

address greenhouse gas emissions from

for the power sector under the auspices of the

existing fossil fuel-fred generation assets.

Clean Air Act.

Refecting that different states have different

As a result, by the time the proposed plan is

mixes of sources and opportunities, the EPA

fully implemented in 2030, the EPA aims to cut

plans to deliver state-specifc, rate-based

carbon emissions from the power sector by

goals for CO2 emissions from the power sector.

30 per cent below 2005 levels nationwide, as

Currently under consultation, a fnal ruling

well as cut particulates, nitrogen oxides and

on the plan is due in June 2015. States are now

sulphur dioxide by more than 25 per cent as a

attempting to identify a path forward using

coincidental beneft.

either current or new electricity production

This, says the EPA, will avoid up to 6600

and pollution control policies to meet the

premature deaths annually and provide up

proposed programme’s goals. These plans

to $93 billion in climate and public health

are due in June 2016, though under some

benefts. Simultaneously, the agency expects

Power Engineering International November 2014

www.PowerEngineeringInt.com

11/10/14 9:46 AM

For more information, enter 7 at pei.hotims.com

1411PEI_13 13

11/10/14 9:46 AM

Carbon abatement

the measures to reduce electricity costs by

effect of such a rule would be to stop the

forces. The dynamism of the US oil and gas

roughly 8 per cent through increasing energy

construction

industry has created a great reduction

effciency.

generation capacity in the US.”

of

any

future

coal-fuelled

in power generation from coal, and the

Ravi Krishnan, founder of global marketing

This is a point echoed by Krishnan, who

generation mix has seen the biggest beneft

and strategy consultancy frm Krishnan &

says: “The US is moving away from coal and

in terms of carbon footprint and that’s driven

Associates, highlights the policy context for the

it is unlikely that any new supercritical or ultra-

just by economic forces.” As a recent example,

US, but also the challenging market structures

supercritical power plant will be built in the

Nolen cites the hub pricing for gas outside

which have existed to date, saying: “The US

future.”

New York City, where the natural gas price

market was obviously expecting some future

went to $1.70 per million BTU. “There is no way

CO2 emission norms for power plants. However,

Building on market trends

coal can compete with that; it’s due to this

there were no monetization mechanisms

The EPA’s guidelines for existing facilities build

tremendous amount of supply that’s driven

such as a national cap-and-trade system,

on trends already underway in the power

that change,” he says.

penalties, tax credits or subsidies for power

sector that are resulting in a cut in carbon

producers to avail themselves of. Therefore,

intensity, both from existing power plants and

Carbon capture and storage

unlike Europe, there are fewer pre-combustion,

across the evolving generation portfolio as a

Don Ryan, who manages the advanced

post-combustion or advanced combustion

whole.

technology group at Babcock & Wilcox

technologies being demonstrated in the USA.”

As part of the proposed measures, the EPA

Power Generation Group, explains that setting

Certainly, the nation appears to be

offered four ‘building blocks’ that it believes are

carbon emission limits for coal-fred plants

making up for lost time. Measures to address

central to state measures to achieve portfolio-

only marginally above the demonstrated

emissions from existing generating facilities

level reductions in carbon intensity. The EPA

emissions from a gas turbine combined-

follow proposals announced in September

identifes measures to make existing fossil-

cycle plant makes carbon capture and

2013 that set emissions standards for new-

fuelled plants more effcient and suggests

storage a mandatory element for new coal-

build projects, a plan also developed under

despatching lower-emission sources, such as

fred capacity in the US. “Where we see the

Obama’s Climate Action Plan.

natural gas, more often.

regulations for new units is that, even with the

Under this proposal, new large natural

In particular, the emergence of cheap

best-available, highest-effciency boiler and

gas-fred turbines are limited to 1000 pounds

and abundant shale gas has seen the

steam turbine technology, you would need

of CO2 per MWh (about 450 kg/MWh), while

marginal cost of coal-fred capacity become

partial carbon capture to get to the EPA limits,”

new coal-fred units would need to meet a limit

increasingly uncompetitive.

he says.

of 1100 lb/MWh.

Scott Nolen, Global Technical Solutions

The best coal-fred technology on the

However, the American Coal Council

Leader at GE Power & Water’s Distributed

market right now features ultra-supercritical

(ACC) said the EPA’s revised carbon pollution

Power business, highlights the impact of shale

steam

standard for new power plants sets an

gas on cutting US carbon emissions:“The most

3700–4000 psi range and steam temperatures

emissions limit for coal “that cannot be met

remarkable thing is the transformation of the

of 1110–1130oF. However, as Ryan explains:

given current technology. Thus, the practical

generation mix in the US driven by economic

“That doesn’t get you down to the CO2

conditions

with

pressures

in

the

The Petra Nova Carbon Capture Project is expected to capture 90 per cent of the CO2 in the processed fue gas from an existing unit

Credit: NRG

14

1411PEI_14 14

Power Engineering International November 2014

www.PowerEngineeringInt.com

11/10/14 9:46 AM

For more information, enter 8 at pei.hotims.com

1411PEI_15 15

11/10/14 9:46 AM

Carbon abatement

emission level of a gas turbine combined

cycle without the addition of carbon capture

to a coal-fred boiler.”

As a result, North America has seen some

recent advances in CCS technology. Indeed,

NRG’s carbon capture business recently broke

ground on a 240 MW project at Unit 8 of the

610 MW WA Parish power plant in Fort Bend

County, southwest of Houston, Texas.

The WA Parish Petra Nova Carbon Capture

Project is a commercial-scale system that

is expected to capture 90 per cent of the

carbon dioxide in the processed fue gas from

an existing unit. When complete in 2016, the

project is expected to be the world’s largest

post-combustion

carbon

capture

facility

installed at an existing coal plant.

In October, NRG announced that the

majority of the excavation needed to begin

building was complete, allowing drilling of the

approximately 800 piles that will serve as the

plant’s foundation to begin. NRG has formed

a 50/50 joint venture with JX Nippon Oil & Gas

Exploration Corp to build and operate the

Petra Nova Carbon Capture Project.

The

captured

CO2

will

increase

oil

production at the West Ranch oilfeld some

130 km away, jointly owned by Petra Nova and

Hilcorp Energy Co. Enhanced Oil Recovery

Gas-fred generation and fexible reciprocating engines are increasingly economically attractive

Credit: GE

(EOR) is expected to boost oil production

at the feld from around 500 barrels per

day (bpd) to approximately 15,000 bpd.

up to one million tonnes of carbon dioxide

This is a point echoed by B&W’s Ryan, who

A US Department of Energy grant of up to

annually. The captured CO2 will be used for

notes that the FutureGen research project on

$167 million has been awarded to the

EOR. Babcock & Wilcox Canada was engineer,

oxy-fred combustion, being developed in the

$1 billion project as part of the Clean Coal

manufacturer and constructor of the critical

US state of Illinois, has been delayed by the

Power Initiative (CCPI) programme while

components to retroft the boiler under a

challenges of raising commercial fnance.

additional funding will come from loans of

$107 million contract.

The project’s total capital cost (planning,

$250 million and equity contributions from

Saskatchewan

design and construction) is approximately

invested C$240 million in the demonstration

$1.65 billion, of which DOE will contribute

The project will be constructed under a fxed-

project. Canadian economy minister Bill Boyd

$1 billion and the private sector will contribute

price contract by a consortium composed of

noted: “This project is important because

the remainder.

Mitsubishi Heavy Industries Americas and The

it is applicable to about 95 per cent of the

Says Ryan: “There’s a piece of the funding

Industrial Company using the KM-CDR Process

world’s coal plants.” Likewise Luke Warren,

that the equipment suppliers are putting into

jointly developed by MHI and Kansai Electric

chief executive of the Carbon Capture and

it, the US DOE are putting into it and there’s a

Power Co.

Storage Association, commented: “It is hoped

piece that we needed to go out to commercial

that Boundary Dam will form part of a much-

fnancial institutions. It’s been delayed due to

needed commercial proof point that the

working out the terms with the commercial

economics make sense.”

fnancing institutions to get the last piece of

both NRG and JX Nippon.

October also saw the offcial inauguration

of

SaskPower’s

Boundary

Dam

project,

claimed as the world’s frst post-combustion

The

commercial-scale CCS process on a coalfred power plant.

government

of

However,the economics of CCS technology

funding.”

are still tenuous, as Krishnan explains: “Future

The FutureGen Industrial Alliance was

Saskatchewan,

development of CCS technology will depend

formed to partner with the DOE on the

Canada, the C$1.4 billion ($1.25 billion)

on its cost, CO2 transport and storage

FutureGen 2.0 project to retroft an existing

rebuild project at Unit 3 of the 824 MW coal-

mechanisms, natural gas prices, regulatory

plant. Construction was due to begin on both

fred power plant generates 110 MW. CCS will

factors and the monetization of CO2 emissions.

the plant and the CO2 pipeline and storage

reduce carbon emissions by 90 pe cent and,

Presently the CAPEX of CCS projects and

facility in 2014, with commercial operations

when fully optimized, the process will capture

technology solutions is extremely high.”

originally scheduled for autumn 2017.

Located

16

1411PEI_16 16

in

Estevan,

Power Engineering International November 2014

www.PowerEngineeringInt.com

11/10/14 9:46 AM

AvantGuard

Redefining

anti-corrosion

®

Hempel introduces AvantGuard®, a new

innovative anti-corrosion technology, based on

activated zinc and locked into our new range of

high performance protective coatings.

AvantGuard® reduces the effects of corrosion

and offers advanced protection. This increased

durability has been proven in extensive tests.

Redefining protection with reduced rust creep

and enhanced corrosion protection

Redefining durability with improved

mechanical strength

Redefining productivity with greater working

tolerances in different climatic conditions and

with high DFT’s. Less repair work needed.

Redefine

ed

defi

fine your expectati

expectations

ions off a

anti-corrosion coatings with AvantGuard® by Hempel.

For more information:

Email: avantguard@hempel.com

Visit: www.hempel.com/avantguard

For more information, enter 9 at pei.hotims.com

1411PEI_17 17

11/10/14 9:46 AM

Carbon abatement

As Ryan says: “They’re expensive projects

based at older coal-fred plants and coincide

steam temperatures. We expect that to be

and you have to build pilot and demonstration

with opportunities for EOR – the opportunities

done next year, and then another year or two

plants to get everyone comfortable that they

for carbon reduction are based on alternative

from there we will have the ability to test some

can add this technology to their plant.” He

approaches. As Krishnan explains: “Given the

of these components.”

adds: “We’ve been pleased with the DOE

early-stage development of the affordable

Michael Gradoia, Manager of Power

support.They are seeing this to be the future of

large-scale carbon capture technologies and

Generation Product Marketing for GE Power

coal-fred generation.”

associated high CAPEX of transportation and

and Water, also highlights the challenges

An alliance between commercial and

storage, I believe that the industry will focus on

of reducing carbon intensity with power

state parties is also behind Canada’s Canmet

increasing effciency by innovative equipment

generation products. He says: “Gas turbine

advanced

upgrades, best practices and switching to

effciency is primarily a function of fring

currently abundant natural gas.”

temperature

coal-fring

research

project.

Between 1993 and 1995, CanmetEnergy

and

compressor

pressure

invested over C$4 million in building the world’s

He continues: “The new EPA carbon

ratio. There is a need for materials that can

frst advanced oxy-fuel combustion pilot-scale

pollution emission guideline for stationary

withstand those higher temperatures, and

research facility. Since its commissioning in

sources will obviously result in new innovative

cooling technologies that allow you to reduce

1995, CanmetENERGY’s CO2 R&D Consortium

approaches outside of CCS to meet the

the amount of air used for cooling that is

is now in Phase 9, which is developing a CO2

proposed

therefore not used for power.”

capture and compression unit.

seriously look at increasing the effciency of

For example, GE’s latest products, the HA

fossil fuel power plants through upgrading

gas turbines, utilize single crystal alloys in the

Challenging economics

technologies. Switching to coals that will

turbine section. Illustrating the challenges,

But even with government support, the

improve the heat rate of the units and reduce

Gradoia adds: “When looking at a turbine

economics of CCS can be challenging. For

its utilization will also be employed.”

section, there are components that are

targets.

Power

producers

will

example, in late September Leucadia National

Krishnan concludes: “In recent years,

operating at about 400 degrees above

Corporation announced that it had decided

marginal or ineffcient coal-fred power plants

the melting point of the base metals, and

not to proceed with further development of

have been under tremendous pressure to

advanced coatings and cooling technologies

the greater Lake Charles project based on

lower their cost of generation to improve the

are what enable that part to do its job while

“fnal estimates of the likely ultimate cost”.

despatchability of their units.As a result, several

providing a reliable service life.”

The decision came despite a December

innovative

boiler

effciency

improvement

On improving the effciency of existing

2013 announcement from the DOE that it

technologies through retrofts, combustion

coal-fred assets, Gradoia says: “We can help

would support the project to the tune of

controls and fuel switching have been

enhance the effciency of existing units by

$261.4 million under its Industrial Carbon

incorporated. These strategies have resulted in

retroftting the steam turbines with the latest

Capture Sequestration (ICCS) programme.

some modest improvement in CO2 emissions.”

blading and sealing technology.”

The petcoke-fred gasifcation plant was to

Ryan highlights the focus on more effcient

Similarly, B&W is looking at developing

transport the CO2 to the West Hastings oil feld

combustion technologies: “About two years

technologies and techniques to enable units

for use in EOR. The estimated total cost of the

ago we were fortunate to get a contract with

to operate more effciently at reduced load.

Lake Charles CCS project was $435.6 million.

AEP to build the frst [US] ultra-supercritical

The CCS project was to include two Lurgi

unit which is in the just-under-4000 psi steam

The US low-carbon future

Rectisol Acid Gas Removal (AGR) units and

pressure range, but the steam temperatures

More than 25 US states have already set energy

was designed to capture approximately

are up to the 1100–1150 range. That gave a

effciency targets, and more than 35 have set

89 per cent of the CO2 produced.

5 per cent to 6 per cent improvement in heat

renewable energy targets. Meanwhile, it is

Nonetheless, there are efforts to further

rate over the traditional supercritical cycles.”

evident that the DOE will pursue additional

commercialize CCS technology in the US. In

He adds: “We’re involved in a consortium

constraints on carbon.

April SaskPower and Vattenfall signed a fve-

of companies here in the US to develop

Ryan says: “In terms of where we think it’s

year agreement to explore opportunities

advanced supercritical technology. That is

going at some point down the road, it’s hard

for collaboration on CCS knowledge and

pushing the steam pressures up to 5000 psi at

for me to imagine that higher levels of carbon

technologies. More recently, Shell Cansolv,

the turbine inlet.”

capture, up to and including 100 per cent,

the subsidiary of Royal Dutch Shell behind the

He points out the challenges of materials

development

steam

He concludes: “I think it’s a matter of time,

a deal with Technology Centre Mongstad

conditions, saying: “The single biggest area

we just have to keep working on development

(TCM) in Norway for further testing of the CO2

we’re working on now is to make sure we

and getting it to a commercial state.”

capture process.The testing was scheduled to

understand the properties of the material, that

start in the third quarter of this year and will last

it’s going to withstand those pressures and

David Appleyard is a freelance journalist

for approximately fve months.

temperatures, have the life expectancy that

focused on the energy, technology and

developing

utilities like to see, and be able to fabricate

process sectors.

economically viable CCS technology – it is

and repair the material in the feld. We’re in

no coincidence that the projects that have

the process of designing a small test facility to

been developed in North America to date are

actually run some components at the same

Given

18

1411PEI_18 18

the

challenges

of

Power Engineering International November 2014

in

achieving

these

aren’t going to be required.”

technology used at Boundary Dam, agreed

i

Visit www.PowerEngineeringInt.com

for more information

www.PowerEngineeringInt.com

11/10/14 9:47 AM

YOU AIN’T SEEN

NOTHING YET

The new benchmark in electric valve actuators

All will be revealed

Valve World Expo D¸sseldorf

December 2nd ñ 4th, 2014

Hall 3 Booth D36

PROFITRON

STAY AHEAD. STAY SIPOS

info@sipos.de, www.siposseven.com

For more information, enter 10 at pei.hotims.com

1411PEI_19 19

11/10/14 9:47 AM

For use in potentially explosive environments, ATEX certifcation is an option

Credit: Deprag Schulz

Motors and drives

An engineer’s guide

to selecting a drive

Selecting a drive involves

careful consideration

when looking for the

optimal motor for a given

application.

Dagmar Dübbelde looks

at how to avoid design

errors and save money

R

ight from the initial selection of

then this will drastically reduce the torque of

a drive, a designer has to make

the motor.

careful

considerations

when

You can imagine that the developer does

looking for the optimal motor for

not necessarily have the length of hoses at

their application. Determining

the forefront of their mind when designing the

the torque and speed, selecting

machine; equally; the connectors between

a pneumatic motor from suppliers’ catalogues

the flter units and oiler are not considered to

and clarifying the size and connections

be particularly relevant. But it is exactly these

required for the machine – it sounds simple.

throttle points which ultimately determine

But unfortunately it is not that easy, and a rude

whether the machine works correctly and if

awakening may follow if, after installation, the

the motor provides the right torque.

selected pneumatic motor does not produce

the power required. Determining the problem

Steps to selecting the right motor

may take weeks; in the worst-case scenario the

So what are these steps for the selection of

entire drive may have to be redesigned and

the right motor? First of all, the drive system

purchased again. Therefore it is worthwhile to

best suited to the customer’s application must

talk to the specialists at the beginning of the

be chosen. Then the materials of which the

drive design phase.

external parts of the motor are composed are

Deprag Schulz has developed a simple

determined. After these initial decisions, the

guide with six steps to follow so that nothing

theoretically required motor power can be

is forgotten.

calculated and all performance-infuencing

The selection of a pneumatic motor is

20

1411PEI_20 20

factors can be taken into consideration.

not diffcult. But, particularly with pneumatic

The fourth step is the integration of the

systems, there are many factors which can

motor into the complete system of the

decisively infuence the power of an air motor.

machine. You have to decide how the motor

If, for example, when installing a motor it is

will be connected to the machine and

found that too short a hose has been chosen,

which gears are required. Perhaps a brake

Power Engineering International November 2014

www.PowerEngineeringInt.com

11/10/14 9:47 AM

Through the Alternative Energy Source Incentives

Program (Programa de Incentivo ‡s Fontes

Alternativas ñ PROINFA), a total of

wind power projects have been put into

action, spurring the still nascent industryís

development throughout Brazil.

41

Because of the program, another,

19 biomass thermal stations, powered

by rice husks and sugarcane bagasse, are in

operation with the support of ELETROBRAS.

Cutting-edge projects such as Megawatt

Solar, implemented in Brazilís South Region,

and Xapuri, in the state of Acre, employ solar

photovoltaic panel technology.

ELETROBRAS is committed to generating clean

and renewable energy. The majority of the energy

produced by the company derives from these sources.

ELETROBRAS is one of the leading producers of electric energy in Brazil. In this light, it is encouraging

to know that a substantial portion of this energy stems from clean and renewable sources. In

addition to tapping hydroelectric power, one of the cleanest known sources of energy, ELETROBRAS

Brazilís energy sources and leveraging the related industries. These initiatives have helped transform

the Brazilian energy grid into one of the industrialized worldís most renewable systems.

It is for these reasons that ELETROBRASís work stretches as far and wide as Brazil itself.

B R A Z I L I A N

G O V E R N M E N T

Ministry of

Mines and Energy

eletrobras.com

For more information, enter 11 at pei.hotims.com

1411PEI_21 21

11/10/14 9:47 AM

Motors and drives

will be necessary in order to ensure safety

of the system. Then the durability of the

machine must be guaranteed, and fnally the

purchasing and running costs of the motor

must be calculated and optimized.

Pneumatic

motors

are

available

in

diverse design options. Their application and

the intended operating time are of great

importance when selecting the right basic

principles. An air vane motor is suitable for

regular running cycles. If you wish to run it nonstop then you must consider the wear on the

vanes and the shorter maintenance intervals

this requires. In comparison, gear motors and

turbines are maintenance-free and therefore

better suited to continuous operation. In this

case the required speed must be considered.

Turbines and gear motors rotate in upper

speed ranges at approximately 140,000 rpm.

Vane motors are available which rotate at

very low speeds, e.g., 1 rpm. Oil-free operation

is also an option for all three drive principles. A

slight loss of power must be taken into account

with oil-free operation of a vane motor.

Different materials

The second step examines the motor’s

Calculation of theoretical motor power

Credit: Deprag Schulz

construction material. If operating in a dry

surrounding atmosphere and in normal

stationary production, an inexpensive air

to the air motor manufacturers in advance

torque times working speed (nominal speed)

motor made from cast iron will be suffcient.

about your application and to describe it in

divided by 9550 you can fnd the theoretically

Deprag offers a wide spectrum of low-priced

as much detail as possible.

required power in kW.

and machines there are a variety of grinding

Motor power

data is based on varied operating pressures.

motors, drilling motors and milling motors

The next step is the calculation of the

At Deprag this is 6 bar. If the application only

available which are distinguished by their low

theoretical motor power. Motors which are

has 5 bar directly at the motor then the motor

weight and compact size.

designed for use in only one rotational

loses 23 per cent of its power. If there is only 4

For use in the food industry, pneumatic

direction are more effcient than reversible

bar available then motor power is reduced by

motors must be able to withstand cleaning

motors. When determining the rotational

45 per cent. A differing operating pressure is

agents and steam.The Deprag Advanced Line

direction, the pneumatic expert looks towards

so decisive that it must be taken into account

motors with external parts made from stainless

the motor shaft from the air inlet. This is the

at the start of the design phase using the

steel are additionally sealed and lubricated

other way around for electric motors, where

adjustment table, in order to avoid nasty

with food industry standard USDA-H1 grease.

the rotational direction is specifed by looking

surprises.

Basic Line motors. For installation in robots

Pneumatic drives can even be operated

In manufacturers’catalogues,performance

at the motor spindle.

Next, the air supply volume – which is

underwater. In this case it is essential to

First the required working point of the motor

specifed by the air consumption in the

determine the water depth required. If the

is determined: which nominal torque and

manufacturers’ details – must be ensured. Every

motors must be started underwater they

speed under load do you want to reach? The

reduction in the width of the opening, whether

can be used up to a depth of 5 metres. If

most economic use of the motor (least wear

on the feed hose itself or due to connection

the motors are started on the surface and

and least air consumption) is attained by

parts, flters, oilers or the exhaust hose and

then submerged, they can be used in a

running close to the nominal speed. If you look

silencer all have an effect on the air volume.

depth of up to 20 metres without damaging

at the characteristic curve of an air motor, it

Therefore Deprag recommends an exhaust air

the motor. If the motor must be sterilizable,

shows that it reaches its maximum torque just

throttle to its customers to regulate their speed.

as requirements demand in some medical

before standstill (around twice the specifed

Using a throttle on the supply air reduces the

technology applications, then it can be

nominal torque).

speed of the motor but, at the same time, the

equipped with special vanes. There are many

At the nominal speed the air motor reaches

torque is reduced as well. Exhaust air throttles

examples here of why it is important to speak

maximum power. With the formula nominal

can reduce the speed without great loss

22

1411PEI_22 22

Power Engineering International November 2014

www.PowerEngineeringInt.com

11/10/14 9:47 AM

Motors and drives

of torque. The exhaust throttle means that

permissible axial and radial load on the drive

are particularly maintenance-friendly. The

customers can better utilize the wider working

spindle of the air motor.

patented vane exchange system enables

range which air motors provide.

Air motors are powerful, durable and

an air motor’s vanes to be quickly replaced

framework

in situ using a key and tweezers. Operating

an air motor is reached with lubricated running

conditions determined during the design

costs are determined by the air consumption.

(1–2 drops of oil per 1 m³ air consumption).

phase and compliance with the instruction

The right choice of motor sets the course for

Unlubricated operation can lead to a loss of

manual will ensure the longest possible life of

low running costs. The closer the motor runs to

power of around 10–20 per cent.

the drive. These conditions include adhering

nominal speed (50 per cent of the idle speed),

to the recommended air quality, lubricated

the more effciently the air is used.

The optimal lifespan and performance of

robust.

Adherence

to

the

Design integration

operation, maintenance intervals, a maximum

Deprag Schulz has been using compressed

If the right motor with the required power has

length of the feed hose of three metres and

air as a working medium for many decades.

been found, then the next step is to integrate

suffcient opening widths of the feed hose and

Deprag’s standard programme offers a wide

it into the design. Deprag provides various

connection parts.

range of options and, from this modular

spindle designs and individual fxing methods.

system, individual drive solutions for the

Considering costs

required application can be developed and

than seeking a gear solution separately.

Finally, the purchase price is the predominant

produced at an attractive price-performance

Within the Deprag range there are numerous

consideration in the acquisition of a new

ratio. Around 85 per cent of the frm’s projects

air motors with integrated planetary gears,

drive system. But the designer should also

in the feld of air motors are special solutions

spur gears and worms gears. If you require

remember running expenses and consider the

which have been quickly and simply realized

additional safety then a holding brake can

operating costs and price for maintenance

from its standard programme.

be recommended. In the manufacturer’s

and servicing. When planning and selecting

programme you can also fnd brake motors.

a new system, the question must be asked:

Dagmar Dübbelde is Product Manager, Air

For use in potentially explosive environments,

how readily available are replacement parts

Motors at Deprag Schulz

there are also options with the required ATEX

and what are their prices? Maintenance and

certifcation. Integration is concluded with

repair service quotations ensure that this is

the technical verifcation of the maximum

calculable. Deprag’s Basic Line air motors

A complete solution is often better value

i

Visit www.PowerEngineeringInt.com

for more information

ONLY ONE

BOLTING SYSTEM

IMPROVES

SAFETY, QUALITY,

& SCHEDULE

FOR GAS TURBINE

MAINTENANCE

www.PowerEngineeringInt.com

1411PEI_23 23

Power Engineering International November 2014

23

11/10/14 9:47 AM

Hoosier Energy’s Merom Generating Station in Indiana, US

Credit: Ametek Land

Coal plant safety

Strengthening safety

in mills and silos

Equipment selection and operating criteria are vital for reducing the risk of fre in

coal storage silos and mills, writes Derek Stuart of Ametek

R

isks of unwanted combustion

Good operating procedures are designed

danger that any residual coal left within the

injury,

to ensure that coal is used before it has time to

mill will oxidize, and may explode as the mill

downtime

self-ignite, and many operators use a nitrogen

is restarted. To prevent a coal fre, the mills can

– occur everywhere coal is

blanket to minimize the scope for oxidation.

be made inert with a steam deluge when an

handled, processed or stored.

Even with appropriate precautions, silo fres

unexpected shutdown occurs, or when there

Safe coal handling practices

can still occur and appropriate monitoring is

is a high risk of a coal fre.

are designed to ensure that the fuel remains

needed to prevent oxidation from developing

intact throughout its journey from the mine

into a silo fre.

–

potentially

damage

causing

and/or

until the point at which it is ignited in the boiler.

The greatest risk of fre occurs when the

It takes as little as 1.4 kg of pulverized

mill is shut down under load, as this leaves a

3

Several methods are available to detect

the presence of oxidization within the mill or

silo:

l

Thermocouples are widely used to detect

coal in 28.3 m of air to form an explosive

large amount of pulverized fuel inside a hot

the heat buildup from oxidation or an early-

mixture. Since a large boiler burns 45.4 kg or

mill. The large surface area of the pulverized

stage mill fre, but they have limited sensitivity

more of coal per second, the safe burning of

coal and the high temperature inside the mill

and

pulverized coal necessitates strict adherence

lead to rapid oxidation of the coal. This results

monitoring the whole volume of the mill. It

to planned operating sequences.

discrete

sensors

have

diffculty

in further heat buildup and the potential for a

also takes time for suffcient heat to build up

All coals oxidize during storage, but sub-

fre. If the mill is restarted without frst removing

within the mill to give a detectable increase

bituminous coals are especially prone to self-

the hot coal, an explosion can occur when

in temperature. Experience shows that

ignition. The increasing use of sub-bituminous

particles are suspended and exposed to

thermocouples do not provide a reliable

coals throughout Asia has increased the risks

the air.

indication that a hazardous condition is

of silo fres.

24

1411PEI_24 24

Power Engineering International November 2014

Even in routine mill shutdowns, there is a

developing.

www.PowerEngineeringInt.com

11/10/14 9:47 AM

IC1000-E320-F236-X-7600

Totally Integrated Power

HB3-80 generator switchgear

Trend-setting with vacuum technology

The single-phase enclosed HB3-80 generator

switchgear provides for sustainable and reliable power

supply in power plant technology.

The HB3-80 is the first generator switchgear worldwide

with vacuum generator circuit-breakers for ratings up to

10,000 A with natural cooling, and a switching capacity of

80 kA type-tested according to the IEEEC37.013 standard.

Thanks to its single-phase enclosure if offers maximum

operational and personal safety, as short circuits between

phases are excluded.

Applications:

Power plant generating units up to 160 MW or 250 MW,

depending on the on the type of power plant and

operating voltage

Indoor and outdoor installation

Advantages:

Optimum operational and personal safety

Sustainable and environmentally friendly

vacuum technology

Minimum installation and maintenance costs

High cost-efficiency and service continuity

www.siemens.com/generatorswitchgear

For more information, enter 12 at pei.hotims.com

1411PEI_25 25

11/10/14 9:47 AM

Coal plant safety

l

Carbon monoxide (CO) gas detection offers

a fast and sensitive means to detect the

presence of oxidizing coal, as the oxidation

inevitably produces large amounts of CO.

The most important reasons to choose CO

measurement for this application are the

availability of sensitive CO sensors able

to detect a few parts per million (ppm)

of CO, and the ability to sample a large

portion of the mill using a probe mounted

at the classifer outlet. CO monitoring is fast,

sensitive, specifc and can be calibrated to

determine alarm levels that reliably identify

a potentially hazardous condition while

minimizing the occurrence of false alarms.

•Once a fre has started, optical detectors

respond to sparks and fames within the mill.

By the time fames are visible, it is too late to

take preventative actions because the mill is

already in a very hazardous condition.

One

of

confguring

the

a

biggest

Millwatch

challenges

system

is

in

the

determination of suitable alarm levels. A

carbon monoxide concentration greater than

250 ppm can be seen during mill startup, but

in normal operation the CO concentration is

in the region of 10 ppm.

Millwatch analyzers offer two independent

Inside view of Millwatch analyzer

Credit: Ametek Land

alarm points, so alarm levels were set at

300 ppm during startup and 50 ppm in

normal operation. Although the startup alarm

l

seemed robust, there were occasional spikes

above 50 ppm CO in normal operation, so the

Rugged sample probes with automatic

power to electric distribution co-operatives

blowback to maintain a good sample fow;

in the midwestern US. At full load it uses

l

Automatic

calibration

verifes

correct

alarm level was increased several times with a

operation of the analyzers, confrming that

fnal fgure of 125 ppm. This avoided nuisance

they respond correctly to CO;

alarms, while providing good sensitivity and

l

10,000 tonnes of coal per day, with the supply

coming from mines by road and rail.

Hoosier Energy has a strong commitment

Continuous measurement of each sample

to safety and maintains a robust safety

response to abnormal operating condition

point, with no multiplexing and response

programme, endeavouring to operate with

when the mill may need to be inerted.

time less than 60 seconds.

the utmost regard for the health and safety of

This last feature is especially important as a

its employees and the public.

Monitoring in China and the US

hazardous condition can develop within a few

Each generating unit at Merom Station

HouShiPower

electricity

minutes, and a multiplexed system sampling

has three Riley Power double-ended ball tube

generating plant in China’s Fujian province,

six measurement points will typically sample

mills. The mills can each provide 65 tonnes per

operated by the Huayang Group. It supplies

each point only once every 10–15 minutes.

hour of pulverized coal to the boiler, a total of

is

a

4200

MW

electricity to the city of ZhangZhou and the

surrounding area.

The system proved its value in 2013 when

195 tonnes per hour per boiler. The boilers at

the Millwatch system showed rapidly rising CO

Merom station burn 54 kg of coal per second.

There are seven electricity generating

levels in the outlet of one of the coal mills. It

Because the ball-tube mills have outlets

units at the site, each of which is rated for

would have taken at least 15 minutes for the

at each end with a classifer on each outlet,

600 MW. In 2011, the plant operators decided

temperature and fre detection systems to

two sample points were needed on each

to add CO monitors to the fve coal mills in Unit

respond and show an indication of a problem,

mill. For enhanced reliability, a redundant

1, supplementing their existing temperature

so the Millwatch analyzers allowed corrective

confguration was chosen with two sample

and

action to be taken signifcantly earlier than

points on each classifer, giving four samples

would otherwise have been possible.

per mill. With three mills per generating unit,

fre

sensors. They

determined

that

Ametek Land’s Millwatch analyzers were best

suited to the task. The analyzers have a long

Hoosier Energy’s Merom Generating Station

a total of 12 sample points were needed

track record, with hundreds of installations

in Indiana, US, is a coal-fred baseload plant

for each unit or six twin-stream analyzers.

worldwide, and include a number of desirable

with two 535 MW generating units. It went into

Redundant

features: