CASE STUDY: LI & FUNG USA, Empire State Building

advertisement

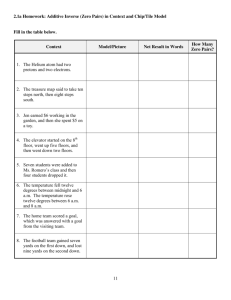

CASE STUDY: LI & FUNG USA, Empire State Building Principal Author: Lauren Zullo Contributing Authors: Wendy Fok and Greg Hale TABLE OF CONTENTS I. II. III. IV. V. Executive Summary Introduction Project Background Lease Cycle Energy Optimization Process a. Select an Office Space b. Select a Project Team c. Set Energy Performance Goals and Select Menu of Measures d. Model the Energy Performance of the Space e. Review Incremental Costing and Available Incentives f. Perform Value Analysis g. Review Budget and Select Measures h. Build the Space i. Develop Post-Occupancy Plan j. Communicate Results Appendix ACKNOWLEDGEMENTS The authors of this report wish to acknowledge and thank the following people for providing information, analysis, and assistance in executing this project: Belinda Fung with Li & Fung Limited; Rick Darling, Adrian Chiu, Merton Owens, Laura Rainier, and Nathaniel Hochman with LFUSA; Tamela Johnson, Sean McDonagh, John Fitzgerald, and Christopher Cummings with Gardiner & Theobald; Dana Schneider and Andrew Bush with Jones Lang LaSalle; Anthony E. Malkin with Malkin Holdings; John Weale with Integral Group; Adam Slakman with Greenprint Foundation; Kyung-Ah Park and Kevin Smith with Goldman Sachs; Megan Casey with Lighting Works; David Ford with AMA PC; Mitch Palais with Benchmark Builders, Inc; Rebecca Shore with CodeGreen; Radhika Khosla, Jay Orfield, and Yerina Mugica with NRDC’s Center for Market Innovation. The authors would also like to thank the following individuals for providing peer review of this case study: Arah Schuur with U.S. Department of Energy; Craig Graeber, Janice Barnes, and Joan Blumenfeld with Perkins + Will; Ariella Cohen and Scott Kessler with NYSERDA; Meg Waltner and Starla Yeh with NRDC. 1 CMI has engaged several industry leaders as technical advisors for the Project, including Goldman Sachs, Johnson Controls, Jones Lang LaSalle, Malkin Holdings, SKANSKA, and ULI/Greenprint. This work is made possible by the generous support of Goldman Sachs and the Rockefeller Foundation. EXECUTIVE SUMMARY Li & Fung USA (LFUSA), a global consumer goods company, has committed to design and construct a high performance tenant space in the Empire State Building to reduce energy demand, increase efficiency, and improve indoor environmental quality. The tenant project is the first in a series of case studies by the Natural Resources Defense Council’s Center for Market Innovation aimed at demonstrating the energy and cost savings impact of high performance tenant design. The first phase of LFUSA’s high performance build-out encompassed three floors and is projected to yield a 28 percent annual electricity savings compared to an ASHRAE 90.1-2007 code-compliant design (minimum energy performance required by law), resulting in nearly $38,000 in annual electricity cost savings for these three floors. Over the 15-year lease term, the performance measures are projected to return $566,495 in energy savings ($392,000 present value using a 5% discount rate).1 The incremental implementation cost of the EPM package is 134,000 ($0.98/ft2) over a code-compliant design budget, including energy modeling soft costs and net NYSERDA incentives, resulting in a simple payback period of 3.5 years. The net present value of the projected full lease term energy savings, after recouping tenant’s up-front incremental cost, is $258,000, constituting a 192% return on tenant’s initial investment in the energy performance package and a 27% annualized rate of return. If the suggested package of performance measures is implemented on the remaining six floors that LFUSA has yet to build-out, the company can capture 31% in energy savings on those floors, yielding a combined savings across all floors of $1.8 million over the 15-year lease term. The package of energy performance measures for the three floors of Phase 1 is projected to reduce electricity consumption by nearly 3.3 million kilowatt-hours (kWh) over the lease term, which will avoid approximately 1,660 metric tons of CO2 emissions,2 roughly equal to taking 346 cars off of the road for one year.3 1 Assuming zero escalation in electricity prices over the lease term, and a 5% administrative fee per the terms of tenant’s lease. 2 Calculation based on eGRID2012 Version 1.0 Year 2009 GHG Output Emission Rates for the NYCW Subregion (1,119.25 lb CO2e/MWh). Available at http://epa.gov/cleanenergy/documents/egridzips/eGRID2012V1_0_year09_GHGOutputrates.pdf 3 Calculation based on EPA Greenhouse Gas Equivalencies Calculator (May 2011). Available at http://www.epa.gov/cleanenergy/energyresources/calculator.html#results 2 Phase 1 Build-Out (Floors 7, 8, 9) Phase 1 Build-Out (Floors 7, 8, 9) Square Footage 137,400 sq. ft. Modeled Energy Reduction 28% Total Electricity Savings over Lease Term Incremental Implementation Cost (w/o incentives) State Incentives (net of review and filing costs) Energy Modeling Soft Cost 3,273,780 kWh $164,370 $36,940 $6,600 Adjusted Incremental Implementation Cost 2 $134,030 ($0.98/ft ) Total Electricity Cost Savings over Lease Term $566,495 Present Value of Electricity Cost Savings over Lease Term $392,002 Net Present Value of Project Investment $257,972 Return on Investment (ROI) over Lease Term Annual Rate of Return 192% 27% Payback Period 3.5 years Total Build-Out (9 Floors) Total Build-Out (9 Floors) Square Footage Modeled Energy Reduction Total Electricity Savings over Lease Term 412,200 sq. ft. 31% 10,519,320 kWh Incremental Implementation Cost (w/o incentives) $511,110 State Incentives (net of review and filing costs) $124,876 Energy Modeling Soft Cost Adjusted Incremental Implementation Cost $19,800 2 $406,034 ($0.99/ft ) Total Electricity Cost Savings over Lease Term $1,813,733 Present Value of Electricity Cost Savings over Lease Term $1,255,062 Net Present Value of Project Investment Return on Investment (ROI) over Lease Term Annual Rate of Return Payback Period $849,028 209% 29% 3.4 years 3 Overview of Package of Energy Performance Measures. Energy performance measures (EPMs) are technologies and systems that aim to reduce energy use through efficiency and conservation Working closely with the building owner and the Natural Resources Defense Council’s (NRDC) Center for Market Innovation (CMI), LFUSA evaluated an integrated, multi-component package of energy performance measures, which were then incorporated into the space design to achieve substantial, cost-effective energy savings, and corresponding carbon emissions reductions (see table 1). The project team determined six target energy performance measures to include in the initial stage of analysis including lighting, mechanical, and plug load measures. Table 1: Overview of Proposed Energy Performance Measures Overview of Proposed Energy Performance Measures I. Daylight Harvesting Lighting Controls: Utilize luminaires with built-in photosensors and controls to dim lights when ambient daylighting lights the space. II. High Efficiency Lighting: Utilize high efficiency luminaires and install occupancy sensors. III. Optimized HVAC Units: Right-sized, high efficiency, variable air volume (VAV) units. IV. Demand Control Ventilation (CO2 Sensors): Use CO2 sensors to control outdoor air damper. V. Low Velocity Air Handlers: Reduce the fan power requirement through use of lower face velocity air handlers (larger footprint or additional unit). VI. Plug Load Management: Circuit plug loads to a single master shutoff switch that is turned off outside of business hours. The project team streamlined coordination among the architect, engineer, energy modeler, and general contractor to facilitate the design planning process. Early on, the team engaged an energy modeling consultant to build an iterative eQUEST energy model for the leased premises, which incorporated the proposed EPM package, and reviewed results for energy reduction potential against a baseline codecompliant design (based upon ASHRAE 90.1-2007 standards).1 Package Selection. Due to the long lead time of custom heating, ventilation and air conditioning (HVAC) units, the project team was not able to pursue one of the target measures—low velocity air handling units (AHUs)— for the first phase of the project because the tenant had purchased the standard units before a final decision could be made. The results described below are inclusive of the five implemented measures listed in table 1. However, the package recommendation for the build-out of future floors incorporates the low -velocity AHU measure, leading to higher projected savings on the future floors. 4 Energy Reduction. The implemented package of energy performance measures is projected to reduce electricity consumption by 28 percent (218,252 kWh) across the three floors (see figure 1). Figure 1: Projected annual energy consumption of code compliant space and high performance space. LFUSA's three highperformance floors are projected to consume 27.7 percent less electricity than a code compliant space due to the implementation of a package of EPMs. Value Analysis. The incremental cost to implement the package of measures is an additional $164,370 ($1.20/ft2) in construction costs over a code-compliant design budget and $6,600 ($0.05/ ft2) in energy modeling soft costs. This up-front cost was reduced by the capture of NYSERDA incentives totaling $36,940 ($0.27/ ft2), net of filing fees and consulting review costs, yielding an adjusted incremental cost of $134,030 ($0.98/ ft2). Using the energy modeling outputs and the incremental costing information, accounting for energy modeling soft cost and net incentives received, the CMI team performed a quantitative value analysis that determined the projected electricity cost savings annually and over the lease term, the resulting payback period, and the tenant’s return on investment. This value analysis process enabled the team to package the energy performance measures to meet the three- to five-year simple payback threshold desired by the tenant and prescribed by the lease. $432,465 net savings $500,000 $400,000 $300,000 3.5 Year Payback $200,000 Floor 9 Floor 8 Floor 7 $100,000 $0 ($100,000) ($200,000) 0 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 Lease Year Figure 2: Modeled Electricity Cost Savings for Floors 7, 8, and 9 over the 15-year Lease Term. The incremental first cost of implementation ($134,030) is paid back within 3.5 years, and the $566,495 of electricity cost savings over the lease term nets a projected savings of $432,465. 5 Future Opportunities. After the completion of construction on floors 7, 8, and 9, LFUSA will have six floors remaining to build-out.2 Assuming that the future floors have a floor plan similar to the Phase 1 design, LFUSA has the opportunity to reduce energy consumption by 31 percent (7.2 million kWh) and realize a projected $1.25 million in additional electricity cost savings over the 15-year lease term by implementing the full package of recommended EPMs. The projected energy savings for future floors is greater than the savings projected for the Phase 1 floors because the recommended package of EPMs for the future floors includes incorporation of low-velocity air handling units, which were not implemented in Phase 1. The estimated incremental implementation cost of the EPM package for the future floors is $272,000 ($0.99/ ft2), including construction and energy modeling costs and assumes the tenant will capture net NYSERDA incentives of $14,656 per floor. 1 The energy model was built using DOE-2 eQuest software, which is a free and open source platform. 2 Floors 3, 4, 5, 6, 10, and 11. 6