Application Notes for Valve Sizing Sizing examples

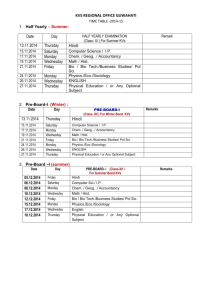

advertisement

Application Notes for Valve Sizing Sizing examples Inhalt Ventilberechnung bei Flüssigkeiten Ventilberechnung bei Wasserdampf Ventilberechnung bei Gas und Dampf Ventilberechnung bei Luft Durchfluss durch Rohrleitungen Seite 2 5 7 9 11 General information These application notes provide a simplified procedure for sizing control valves in standard service conditions. The data required to size a valve, such as the nominal size, nominal pressures and KVS coefficient, is contained in the SAMSON data sheets for self-operated regulators and control valves. Self-operated regulators and control valves can be sized accurately according to the IEC 60534 procedure. For most applications, however, the following sizing equations formulated in the VDI/VDE Guideline 2173 provide a sufficient degree of accuracy. In order to calculate the valve flow coefficient KV, the operating data specified in the diagram on the right are required. p1 p2 H100 H0 t1 . V W Typical sizing coefficients Explanatory notes Control valves and self-operated regulators Rated travel · The rated travel H100 is the amount of movement of the valve closure member from the closed position to the designated full open position published by the manufacturer for each control valve series. KV · The flow coefficient KV is defined as the number of cubic me. ters per hour (volume flow rate V) of water at 5 to 30 °C that will flow through a control valve at a specified travel H with a differential pressure (Dp = p1 – p2) of 1 bar. KVS · The KVS coefficient is the expected flow coefficient KV of the valve at rated travel H100 indicated and published by the manufacturer for each valve type (series). KV100 · This value is the effective (actual) flow coefficient KV of the valve at rated travel H100. It must not deviate by more than ±10 % from the specified KVS coefficient. p1 p2 Dp H Upstream pressure in bar Downstream pressure in bar Differential pressure (p1 – p2) across the valve in bar Travel in mm V W r r1 t1 Volume flow rate in m³/h Mass flow rate in kg/h Density (general) in kg/m³ Upstream density (for gases and steam) in kg/m³ Upstream temperature in ° C . Self-operated regulators KVS Safety factor S = KV KVS KV Indicated KVS Calculated KV For self-operated regulators: S » 1.3 to 5 To ensure the proper operation of a self-operated regulator, the kinematic viscosity n of the medium to be controlled must not exceed 1 · 10–4 m²/s = 100 cSt. All pressures stated are absolute pressures in bar, if not specified otherwise Fig. 1 · Operating data for determining the KV coefficient Edition August 2012 Application Notes AB 04 EN Liquids Calculation of the maximum volume flow rate of liquids with different densities . . æ rA ÷ VB = VA × çç ÷ è rB ø 1000 × Dp r × Dp0 . V = KV · Equation (1) generally applies to liquids: (1) . Diagram 1 shows the relationship between V, KV and Dp for liquids that have a density of r = 1000 kg/m³ at a temperature of t = 20 °C. Example 1 Flow rate calculation for a valve Determine: Volume flow rate of acetone (m³/h) in a fully open valve Type 3241-1 Pneumatic Control Valve · DN 40 Pressure drop Dp = p1 – p2 · Density in kg/m³ for acetone Calculate according to equation (2): Known: Solution: Symbols and units p1 Absolute presssure p2 in bar Pressure drop (differential pressure) in Dp bar Reference differential pressure of 1 bar Dp0 according to the definition of K V. It is omitted in the other calculations to simplify them. Density in kg/m³ r . Flow rate in m³/h V KV coefficent in m³/h KV Minimum differential pressure across the Dpmin valve in bar Differential pressure in bar created DpWirk at the restriction in the flow path for flow measurement purposes KVS Valve flow coefficient in m³/h KVS = Dp = r = . 1000 × Dp V = KVS · r . 25 m³/h 1) p1 – p2 = 0.5 bar 800 kg/m³ 1000 × 0.5 = 19.76 m³/h 800 V = 25 · 1) The KVS coefficient has a permissible tolerance of ±10 % and, as result, the calculated volume (2) . flow rate V , too . Example 2 Pressure reducing valve (self-operated regulator) for water Determine: Type ... Pressure Reducing Valve, KVS and nominal size of the valve Volume flow rate of water · Pressure drop Dp Density r in kg/m³ for water Calculate KV coefficient according to equation (3) derived from equation (1): Known: Solution: . KV = V · r 1000 × Dp (3) After calculating the KV coefficient, select the KVS coefficient of the valve. As a general rule: KVS » 1.3 · KV Solution according to Diagram 1: KV » 8.2 m³/h can be read from Diagram 1 for . Dp = 2.1 bar and V = 12 m³/h. Flow velocity in the pipe: The following can be read from Diagram 4 (page 11) for . V = Dp = r = 12 m³/h p1 – p2 = 2.1 bar 1000 kg/m³ KV = 12 · 1000 = 8.2 m³/h 1000 × 2.1 KVS = 1.3 · KV = 1.3 · 8.2 = 10.7 m³/h Selected: Type 41-23, DN 40, KVS = 20 Determining the safety factor: KVS 20 = S = » 2.4 KV 8.2 . V = 12 m³/h and DN 40: wpipe » 2.8 m/s Note: The flow velocity wpipe must not exceed 2 m/s for HVAC and district heating applications! 2 AB 04 EN m3 h 1000 800 Kv 600 500 400 00 20 00 12 00 10 0 80 0 60 0 50 0 40 300 200 0 30 0 25 0 20 0 16 0 12 0 10 80 100 80 60 50 40 60 50 40 30 25 20 16 30 20 10 8 12 10 8 6 5 4 6 5 3 4 3.0 2.5 2.0 1.6 1.2 1.0 0.8 0.6 0.5 0.4 0 0.3 5 0.2 0 0.2 6 0.1 2 0.1 0 0.1 8 0.0 6 0.0 5 0.0 4 0.0 30 0.0 25 0.0 20 0.0 6 1 0.0 2 1 . 0 0 10 0.0 2 1 0.8 0.6 0.5 0.4 0.3 0.2 0.1 0.08 0.06 0.05 0.04 0.03 0.02 p 0.01 10 20 30 40 60 80 100 0.1 200 300 400 600 800 1000 mbar 0.2 2 0.3 0.4 0.6 0.8 1 3 4 6 8 10 20 30 40 bar . V in m³/h KV in m³/h Dp in bar . V = KV · 1000 × Dp r Diagram 1 · Volume flow rate diagram for water r = 1000 kg/m³, t = 20 °C AB 04 EN 3 Liquids Example 3 Self-operated flow regulator for water Determine: Required minimum differential pressure Dp for flow rate control Type 42-36 Flow Regulator Differential pressure at restriction of 0.2 bar DN 40 · KVS 20 · Flow rate of water Calculate according to equation (4) for flow regulators with incompressible media 1): Known: Solution: æ . 2 V ÷ Dpmin = Dprestriction + ç çç KVS ÷÷ è ø KVS Dprestriction = = 20 m³/h 0.2 bar V = 10 m³/h water 1) Dpmin = æ 10 2 0.2 + ç ÷ = 0.45 bar è 20 ø . (4) 1) Contact SAMSON for flow rate control of air, steam or gases Dprestriction = 0.2 or 0.5 bar; depending on regulator version Example 4 Determining the pressure loss with water Determine: Known: Pressure loss Dp = p1 – p2 in a fully open valve Type 4 Temperature Regulator (self-operated) · DN 50 . Volume flow rate V of water Density r in kg/m³ for water Calculate pressure loss according to equation (5) derived from equation (1): Solution: æ . 2 V ÷ r · Dp = ç çç KVS ÷÷ 1000 è ø KVS = . V r = = Dp = 32 m³/h 10 m³/h 1000 kg/m³ æ 10 2 1000 = 0.097 bar » 0.1 bar ç ÷ · 1000 è 32 ø (5) Solution according to Diagram 1: The pressure loss Dp » 0.1 bar can be read from Diagram . 1 for V = 10 m³/h and KVS 32 4 AB 04 EN Steam A modified version of equation (9) applies to steam: W = KV · m · Z Z m (6) The dimensionless compressibility factor Z is defined as follows: Z = 14.2 · p1 × r1. Determine Z from Table 2 using the upstream pressure p1 and differentiating between saturated steam and superheated steam. Determine the dimensionless head loss coefficient m from Table 1 or, interpolate values from Diagram 2 using c = 1.135. Symbols and units p1 Absolute pressure p2 in bar Pressure loss (differential pressure) in bar Dp W Mass flow rate in kg/h KV KV coefficient in m³/h m Pressure loss coefficient, dimensionless Z 14.2 · p1 × r1 , dimensionless Example 5 Determining the flow rate in a valve Determine: Known: Steam flow rate in kg/h in a fully open valve Type 3241-2 Electric Control Valve Steam temperature · Upstream and downstream pressures p2 Calculate p1 KVS = t = p1 = p2 = p1 40 m³/h 1) 200 °C 4 bar p2 = 3 bar 3 = 0.75 4 Determine m from Table 1 or Diagram 2 Determine Z from Table 2 using the upstream pressure and temperature m = Z = W = 0.92 38.5 40 · 0.92 · 38.5 = 1417 kg/h Solution: W = KVS · m · Z (6) Example 6 Steam pressure reducing valve (self-operated) Determine: Type ... Pressure Reducing Valve, KVS and nominal size of the valve Steam flow rate · Steam temperatures · Upstream and downstream pressures p2 Calculate p1 Determine m from Table 1 · Determine Z from Table 2 using the upstream pressure and temperature Calculate KV from equation (7): Known: Solution: KV = W Z ×m Example 7 Determining pressure loss with steam Determine: Known: Pressure loss Dp = p1 – p2 in a fully open valve Type 4 Temperature Regulator Steam flow rate · Steam temperature · Upstream pressure Select compressibility factor Z from Table 2 depending on pressure and temperature upstream of the valve m= W Z × KVS p2 from diagram 2 for m = 0.701 p1 p2 = 0.89 · p1 -> Pressure loss Dp = p1 – p2 Find the ratio AB 04 EN The KVS coefficient has a tolerance of ±10 %, and, as a result, the calculated steam flow rate W, too. W t p1 p2 p1 = = = m Z = = = 1 71.3 1000 = 14 m³/h 713 . ×1 KVS = 1.3 · KV = 1.3 · 14 = 18.2 m³/h Selected: Type 39-2, DN 40, KVS = 20 KVS = W = t = p1 = Z = m (8) 1000 kg/h corresponds to saturated steam 7 bar p2 = 2 bar 2 = 0.286 7 KV = (7) Determine the KVS value of the valve from the following equation using the calculated KV value. In general: KVS » 1.3 · KV Solution: 1) = p2 = p1 p2 = Dp = 20 m³/h 1000 kg/h Corresponding to saturated steam 7 bar 71.3 1000 = 0.701 713 . × 20 0.89 0.89 · 7 = 6.23 bar p1 – p2 = 7 – 6.23 = 0.77 bar 5 Table 1 · Pressure loss coefficient m as a function of p2/p1 Pressure ratio p2/p1 Pressure loss coefficient m 0 to 0.6 0.70 0.75 0.80 0.85 0.90 0.95 0.99 1.0 0.96 0.92 0.86 0.77 0.66 0.48 0.22 Table 2 · Compressibility factor Z for steam · All pressures stated as absolute pressures in bar Compressibility factor Z for ... p1 in bar Superheated steam at the following temperatures ... 60 °C 1.13 2.27 80 °C 1.1 2.21 100 °C 1.07 2.15 120 °C 1.04 2.09 140 °C 1.02 2.04 160 °C 0.99 1.99 180 °C 0.97 1.95 200 °C 0.95 1.90 250 °C 0.90 1.81 300 °C 0.86 1.73 350 °C 0.83 1.66 400 °C 0.80 1.59 3.31 4.42 3.22 4.29 3.14 4.18 3.06 4.08 2.99 3.98 2.92 3.89 2.86 3.81 2.71 3.62 2.59 3.46 2.49 3.32 2.39 3.19 0.1 0.2 1.16 2.27 0.3 0.4 3.37 4.45 0.5 0.6 5.53 6.58 5.37 6.45 5.23 6.28 5.10 6.12 4.98 5.97 4.86 5.84 4.76 5.72 4.52 5.43 4.33 5.19 4.15 4.98 3.99 4.78 0.7 0.8 7.65 8.71 7.53 8.62 7.33 8.39 7.15 8.17 6.97 7.97 6.82 7.79 6.67 7.63 6.34 7.25 6.06 6.91 5.80 6.64 5.59 6.37 0.9 1.0 9.76 10.8 9.70 10.8 9.44 10.5 9.19 10.2 8.98 9.98 8.77 9.76 8.58 9.53 8.16 9.07 7.90 8.66 7.37 8.30 7.18 7.98 1.1 1.2 11.9 12.9 11.5 12.6 11.3 12.3 11.0 12.0 10.8 11.8 10.5 11.4 10.0 10.9 9.50 10.4 9.10 10.0 8.70 9.60 1.3 1.4 13.9 15.0 13.7 14.7 13.3 14.3 13.0 14.0 12.7 13.7 12.3 13.4 11.8 12.7 11.2 12.1 10.8 11.6 10.4 11.2 1.5 1.6 16.0 17.0 15.8 16.9 15.4 16.4 15.0 16.0 14.7 15.6 14.3 15.3 13.6 14.5 13.0 13.9 12.4 13.3 12.0 12.8 1.7 1.8 18.0 19.1 17.9 19.0 17.5 18.5 17.0 18.0 16.6 17.6 16.3 17.2 15.4 16.4 14.7 15.6 14.1 14.9 13.6 14.4 1.9 2.0 20.1 21.1 20.1 21.1 19.5 20.6 19.0 20.0 18.6 19.6 18.1 19.1 17.3 18.2 16.5 17.3 15.8 16.6 15.2 16.1 2.2 2.4 23.2 25.2 22.6 24.7 22.1 24.1 21.5 23.5 21.0 23.1 20.0 21.8 19.1 20.8 18.3 20.0 17.6 19.2 2.6 2.8 27.2 29.3 26.8 28.9 26.0 28.1 25.5 27.5 24.9 26.8 23.6 25.5 22.6 24.3 21.5 23.2 20.8 22.4 3.0 3.2 31.0 33.4 31.0 33.1 30.2 32.2 29.4 31.4 28.8 30.7 27.3 29.1 26.0 27.8 24.9 26.6 24.0 25.6 3.4 3.6 35.4 37.4 35.2 37.3 34.3 36.3 33.4 35.4 32.6 34.6 31.0 32.8 29.6 31.3 28.2 29.9 27.2 28.9 3.8 4.0 39.4 41.4 38.3 40.4 37.4 39.4 36.5 38.5 34.7 36.5 33.0 35.1 31.6 33.3 30.4 32.0 4.5 5.0 46.4 51.4 45.6 50.8 44.4 49.4 42.8 48.2 41.1 45.7 39.1 43.6 37.3 41.8 36.1 40.0 5.5 6.0 56.4 61.4 56.0 61.2 54.4 59.5 53.0 57.9 50.2 54.9 47.8 52.3 46.7 50.2 44.2 48.2 6.5 7.0 66.3 71.3 64.6 69.7 62.9 67.8 59.4 64.2 56.6 61.1 54.2 58.3 52.2 56.2 8.0 9.0 81.2 91.0 79.9 90.2 77.6 87.7 73.4 82.6 69.8 78.7 67.0 75.0 64.3 72.4 10.0 11.0 101 101 97.9 92.2 87.4 83.2 80.4 111 108 102 96.5 92.1 88.5 12.0 121 130 118 128 111 121 105 114 99.7 109 96.7 105 140 150 139 150 130 139 123 132 118 125 113 121 13.0 14.0 15.0 16.0 17.0 160 149 141 134 129 170 159 150 143 137 18.0 19.0 180 189 169 178 159 168 151 161 146 154 20.0 21.0 199 209 188 198 177 187 168 178 162 170 23.0 229 248 218 238 205 224 195 213 187 203 27.0 29.0 268 258 242 230 216 288 279 261 248 236 31.0 33.0 308 328 300 322 280 299 264 282 253 270 35.0 37.0 348 368 343 365 318 338 301 319 286 304 39.0 41.0 388 408 387 356 376 337 354 320 338 25.0 6 Saturated steam AB 04 EN Gases and vapors Symbols and units p1 Absolute pressure p2 in bar Pressure loss (differential pressure) in bar Dp W Mass flow rate in kg/h KV KV coefficient in m³/h Density in kg/m³ r1 p2 p1 1 c = 1.135 0.9 c = 1.3 c = 1.4 The calculation procedure provides approximate values meeting practical needs c = 1.66 0.8 c = 1.66 For monatomic gases such as helium, argon, krypton c = 1.4 For diatomic gases such as hydrogen, nitrogen, air, chlorine gas, city gas c = 1.3 For triatomic and multiatomic gases such as carbon dioxide, propane, butane, methane, acetylene, ammonia c = 1.135 For steam 0.7 W = 14.2 · KV · m · p1 × r1 The values for m and r1can be found in Diagrams 2 and 3 respectively. Diagram 2 · Pressure loss coefficient m in p2 as a function of p1 0.6 0.2 For 0.3 p2 < 0.6 ---> m = 1 p1 0.4 0.5 0.6 0.7 0.8 0.9 1 m Example 8 Mass flow rate with gas Determine: Known: Propane gas mass flow rate W in kg/h in a fully open valve Type 3241-1 Pneumatic Control Valve, DN 50 · Upstream and downstream pressures Determine the upstream density r1 from Diagram 3 p2 p2 Calculate · Find m from Diagram 2 for the given p1 p1 c = and 1.3 Solution: W = 14.2 · KVS · m · p1 × r1 Reducing pressure valve (self-operated) for nitrogen Determine: Type ... Reducing Pressure Valve, KVS and nominal size of valve Nitrogen network · Flow rate· Upstream and downstream pressures p2 Calculate · Find m from diagram 2 (c = 1.4) · Find r1 p1 from diagram 3 for p1 = 5 bar Solution: KV = W 14.2 × m × p1 × r1 (10) Example 10 Determining the pressure loss with nitrogen Determine: Known: Pressure loss Dp = p1 – p2 in a fully open valve Type 3241-2 Electric Control Valve, DN 20 · Nitrogen network · Nitrogen flow rate · Upstream pressure Find r1 from Diagram 3 for p1 = 5 bar m= W 14.2 × KVS × p1 × r1 p Find the ratio 2 from Diagram 2 with m = 0.791 p1 p2 = 0.815 · p1 -> Pressure loss Dp = p1 – p2 AB 04 EN 40 m³/h 1) 2.7 bar p2 = 2.2 bar 5 kg/m³ 2.2 = 0.815 2.7 m = 0.805 W = 14.2 · 40 · 0.805 · 2.7 × 5 = 1680 kg/h The KVS coefficient has a tolerance of ±10 %, and, as a result, the calculated mass flow rate W, too. p1 = W = p2 = p1 5 bar 230 kg/h 3 = 0.6 5 m = r1 = 0.97 6.2 kg/m³ 230 = 3.00 m³/h 14.2 × 0.99 × 5 × 6.2 KV = KVS = p2 = 3 bar 1.3 · KV = 1.3 · 3.00 = 3.90 m³/h Selected: Type 44-1, G ¾, KVS = 4 Determine KVS coefficient from the calculated KV. As a rule: KVS » 1.3 · KV Solution: KVS = p1 = r1 = p2 = p1 1) (9) Example 9 Known: (9) (11) KVS = p1 = W = r1 = m = p2 = p1 p2 = Dp = 4 m³/h 5 bar 250 kg/h 6.2 kg/m³ 250 = 0.791 14.2 × 4 × 5 × 6.2 0.815 0.815 · 5 = 4.08 bar 5 – 4.08 = 0.92 bar 7 100 80 kg m3 4 60 50 40 7 30 20 1 10 8 6 5 4 9 10 3 11 8 3 5 6 2 2 1 0.8 0.6 0.5 0.4 0.3 0.2 0.1 0.08 0.06 0.05 0.04 0.03 0.02 0.01 0.008 0.006 0.005 0.004 0.003 0.002 p 0.001 0,01 1 0.02 0.03 0.06 0.1 0.04 0.08 0.2 0.3 0.4 0.6 0.8 1 If the operating temperature t deviates considerably from 0 °C, correct r1 using the equation rt = r1 × 273 273 + t 1 2 3 4 2 3 Chlorine gas Butane Propane Carbon dioxide 4 6 5 6 7 8 8 10 Air Nitrogen Acetylene Ammonia 20 30 40 bar 9 Methane 10 City gas 11 Hydrogen Diagram 3 · Density of gases r or r1 as a function of pressure at 0 °C 8 AB 04 EN Air The calculation procedure provides approximate values meeting practical needs. The equation derived for dry air is as follows: W = 15.3 · m · KV · p1 × r1 (12) Equation (6) can be written as follows: W = KV · m · Z (13) The value for Z can be obtained from Table 4 using p1. The value for m can be found in Table 3 (interpolated values can be determined from Diagram 2 for c = 1.4). Example 11 Air flow rate Determine: Given: Mass flow rate W in kg/h in a fully open valve Type 41-23 Self-operated Pressure Regulator, DN 50 Upstream and downstream pressures · Temperature p2 Determine p1 Determine the value for m from Table 3 or Diagram 2 Determine the value for Z from Table 4 using the upstream pressure and temperature Solution: W = KVS · m · Z (13) Example 12 Pressure reducing valve (self-operated) for air Determine: Type ... Pressure Reducing Valve, KVS and nominal size of valve Upstream and downstream pressures · Temperature Compressed air as medium p2 Determine p1 Determine the value for m from Table 3 or Diagram 2 Determine the value for Z from Table 4 using the upstream pressure and temperature Given: Solution: KV = W Z ×m (14) Determine KVS coefficient from the calculated KV. As a rule: KVS » 1.3 · KV Example 13 Determining the pressure loss with air Determine: Given: Pressure loss Dp = p1 – p2 in a fully open valve Type 42-24 Differential Pressure Regulator, DN 50 Flow rate of compressed air · Upstream pressure Temperature Determine the value for Z from Table 4 using the upstream pressure and temperature Solution: m= W Z × KVS Determine the ratio (15) p2 for m = 0.884 from Diagram 2 or p1 Table 3 p2 = 0.75 · p1 -> Pressure loss Dp = p1 – p2 AB 04 EN Symbols and units p1 Absolute pressure p2 in bar Pressure drop (differential pressure) in bar Dp W Mass flow rate in kg/h KV KV coefficient in m³/h Density in kg/m³ r m Pressure loss coefficient, dimensionless Z Compressibility factor, dimensionless Note: Please contact SAMSON AG to obtain more detailed information on sizing flow regulators for air. KVS = t = p1 = p2 = p1 32 m³/h 1) 20 °C 4 bar p2 = 3 bar 3 = 0.75 4 m = Z = W = 0.884 66 32 · 0.884 · 66 = 1867 kg/h 1) The KVS coefficient has a tolerance of ±10 %, and, as a result, the calculated mass flow rate W, too. p1 t W p2 p1 = = = m Z = = = 5 bar 20 °C 190 kg/h 3 = 0.6 5 p2 = 3 bar 0.982 82.60 KV = 190 = 2.34 m³/h 0.982 × 82.60 KVS = 1.3 · KV = 1.3 · 2.34 = 3.04 m³/h Selected: Type 44-1, G ½, KVS = 3.2 KVS = W = t = p1 = Z = m = p2 = p1 32 m³/h 3270 kg/h 20 °C 7 bar 115.6 3270 = 0.884 115.6 × 32 0.75 p2 = 0.75 · 7 = 5.25 bar Dp = p1 – p2 = 7 – 5.25 = 1.75 bar 9 Table 3 · Pressure loss coefficient m as a function of p2/p1 Pressure ratio p2/p1 Pressure loss coefficient m 0.527 0.60 0.65 0.70 0.75 0.80 0.85 0.90 0.95 0.99 1 0.982 0.978 0.935 0.884 0.818 0.730 0.623 0.448 0.207 Table 4 · Compressibility factor Z for air · All pressures stated as absolute pressures in bar Compressibility factor Z for … Dry air for following temperatures … 100° C 150° C p1 in bar 0° C 20° C 50° C 200° C 250° C 300° C 0.1 0.2 1.71 3.42 1.65 3.30 1.57 3.15 1.47 2.93 1.38 2.77 1.30 2.60 1.24 2.47 1.18 2.31 0.3 0.4 5.13 6.84 4.96 6.61 4.74 6.29 4.39 5.85 4.13 5.50 3.89 5.20 3.71 4.95 3.55 4.72 0.5 0.6 8.55 10.26 8.26 9.90 7.87 9.42 7.32 8.79 6.88 8.24 6.50 7.79 6.18 7.42 5.92 7.09 0.7 0.8 11.97 13.68 11.56 13.22 11.00 12.58 10.22 11.72 9.61 11.00 9.09 10.40 8.64 9.79 8.27 9.45 0.9 1.0 15.40 17.10 14.86 16.50 14.15 15.72 13.18 14.65 12.36 13.75 11.69 13.00 11.12 12.35 10.62 11.81 1.1 1.2 18.83 20.50 18.15 19.80 17.30 18.20 16.07 17.52 15.10 16.50 14.32 15.60 13.60 14.70 13.00 14.12 1.3 1.4 22.10 24.00 21.42 23.10 20.45 22.00 18.25 10.70 17.85 19.25 16.90 18.19 16.09 17.30 15.35 16.55 1.5 1.6 25.65 27.30 24.75 26.40 23.60 25.15 21.68 23.35 20.06 21.95 19.46 20.80 18.55 19.78 17.70 18.88 1.7 1.8 29.10 30.80 28.10 29.70 26.70 28.30 24.80 26.35 23.40 24.75 22.05 23.35 20.90 22.25 20.10 21.20 1.9 2.0 32.25 34.20 30.25 33.00 29.60 31.45 27.55 29.27 26.15 27.70 24.65 25.95 23.50 24.70 22.50 23.10 2.2 2.4 37.65 41.10 36.40 39.60 34.70 37.75 32.20 35.15 30.20 33.30 28.50 31.20 27.20 29.70 25.90 28.35 2.5 42.70 41.40 39.30 36.60 34.40 32.45 30.90 29.50 2.6 44.50 42.60 40.90 38.05 35.75 33.80 32.15 30.70 2.8 47.80 46.20 44.00 41.70 38.45 36.35 34.55 33.10 3.0 51.30 49.55 47.40 43.95 41.25 38.90 37.10 35.45 3.2 54.30 52.40 49.90 46.60 43.90 41.60 39.80 37.70 3.4 58.25 56.20 53.50 49.80 46.70 44.20 42.00 40.10 3.6 62.20 59.60 56.60 52.70 49.40 46.80 44.50 42.60 3.8 4.0 65.00 68.20 62.70 66.00 59.75 62.90 55.60 58.55 51.50 55.00 49.40 52.00 46.90 49.40 44.80 47.20 4.5 77.00 74.40 70.70 65.80 61.80 58.50 55.60 48.50 5.0 86.90 82.60 78.75 73.20 68.75 65.00 61.75 59.20 5.5 94.00 90.90 87.40 80.60 75.60 71.60 68.00 64.90 6.0 102.06 98.90 94.30 87.90 82.40 77.90 74.15 70.90 6.5 111.0 107.2 101.10 95.20 88.40 84.50 80.40 76.80 7.0 119.6 115.6 110.0 102.2 96.90 90.90 86.40 82.70 8.0 136.8 132.2 125.7 117.1 110.0 104.0 97.9 94.5 9.0 162.2 148.6 141.6 131.8 123.6 116.9 111.2 106.2 10.0 171.0 165.0 157.2 146.5 137.5 130.0 123.5 118.1 11.0 188.3 181.5 173.0 160.7 151.0 143.2 136.0 130.0 12.0 205.0 198.0 182.0 175.2 165.0 156.0 147.0 141.0 13.0 221.0 214.2 204.5 182.5 178.5 169.0 160.9 153.5 14.0 240.0 231.0 220.0 197.0 192.5 181.9 173.0 165.5 15.0 256.5 247.5 236.0 216.8 200.6 194.6 185.5 177.0 16.0 273.0 264.0 251.0 253.5 219.5 208.0 197.8 188.8 17.0 291.0 281.0 267.0 248.0 234.0 220.5 209.0 201.0 18.0 308.0 297.0 283.0 263.5 247.5 233.5 222.5 212.0 19.0 20.0 322.5 342.0 302.5 330.0 296.0 314.5 275.6 292.7 261.6 277.0 246.5 259.6 235.0 247.0 225.0 231.0 22.0 376.5 364.0 347.0 322.0 302.0 285.0 272.0 259.0 24.0 411.0 395.0 377.5 351.5 333.0 312.0 297.0 283.5 26.0 445.0 428.0 409.0 380.5 357.5 338.5 321.5 307.0 28.0 478.0 462.0 440.0 417.0 384.5 363.5 345.5 331.0 30.0 513.0 495.5 474.0 439.5 412.5 389.0 371.0 354.5 10 AB 04 EN Flow rate through pipelines wmax of self-operated regulators 1) wmax of district heating 1) Nominal size DN in mm/inch 40 0 3 25 00 20 0 0 m3 h 10000 8000 6000 5000 4000 3000 2000 50 65 80 10 1 12 50 5 0 1000 800 600 500 400 300 20 4 3 0 25 2 200 ¼ " " 15 100 80 60 50 40 30 20 10 8 6 5 4 3 2 1 0.8 0.6 0.5 0.4 0.3 1) 0.2 Only for water . Diagram 4 · V -w diagram for gases, vapors and liquids Diagram 4 shows the following relationship: . Vpipe = Apipe · wpipe . (16) DN æ DN 2 Determining velocity and nominal size with Apipe = ç ÷ è 18.8 ø Velocity w of the medium æ 18.8 2 wpipe = Vpipe · ç ÷ è DN ø . (17) Nominal size DN . AB 04 EN V wpipe Volume flow rate in m³/h Flow velocity in m/s Cross-section of nominal size, registered as straight Nominal size The flow rate of gases in m³/h determined for standard temperature and pressure using Diagram 4 can be converted into kg/h (operating conditions). See Example 14. VG . DN = 18.8 · V pipe wpipe Apipe Gas flow rate, based on standard temperature and pressure (18) 11 Example 14 Compressed air flow rate Determine: Flow rate of compressed air for operating conditions and standard pressure and temperature Pipe nominal size · Pressure p in the pipe Flow velocity Read volume flow rate in m³/h based on the operating conditions from Diagram 4 How high ist the mass flow rate of the compressed air in kg/h? Given: Solution: . W=V ·r Nominal size = DN 32 p = 5 bar wpipe = 7 m/s . = 20 m³/h V Diagram 3 shows: r = 6.3 kg/m³ In the operating state: W = 20 · 6.3 = 126 kg/h (19) . VG is the volume flow rate of gas in m³/h at a standard temperature of 0 °C and at a standard pressure of 1013 mbar. At standard temperature and pressure: 1 m³ air -> 1.293 kg . VG = W 126 = = 97.5 m³/h 1.293 1293 . SAMSON AG · MESS- UND REGELTECHNIK Weismüllerstraße 3 · 60314 Frankfurt am Main · Germany Phone: +49 69 4009-0 · Fax: +49 69 4009-1507 Internet: http://www.samson.de AB 04 EN 2012-12 Specifications subject to change without notice