Foundation Types: Advantages & Disadvantages - Case Study

advertisement

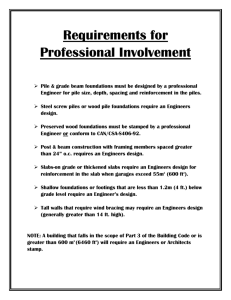

A case study identifying the advantages and disadvantages of certain foundation types J. & W. LOWRY LIMITED This report has been prepared for J & W Lowry Limited Produced By Thomas Elliott Foster A case study identifying the advantages and disadvantages of certain foundation types ID:07004101 12/3/2012 Table of Contents 1.0. Brief ..................................................................................................................................... 2 2.0. Introduction .......................................................................................................................... 3 2.1. Foundation types Covered in this Report............................................................................. 3 2.2. Considered factors affecting the foundations ...................................................................... 3 2.3. Foundation ........................................................................................................................... 3 2.4. Elements requiring foundations ........................................................................................... 4 2.5. Information required before designing foundations ............................................................ 4 3.0. Assumptions/Belief of ground type/condition ..................................................................... 5 3.2. After the nature of the ground has been ascertained a risk register should be completed to identify; ........................................................................................................................................... 5 3.3. A remedial strategy should then be formed subject to;........................................................ 6 4.0. Report 1 – Shallow foundation ............................................................................................ 7 4.1. Strip Foundation (see appendix 1 for detail) (trench foundations are very similar to strip foundations, differing mainly in thickness of foundation).............................................................. 7 4.2. Pad foundations .................................................................................................................. 10 4.3. Raft foundations ................................................................................................................. 13 5.1. Friction/Driven piles/Displacement piles .......................................................................... 15 5.2. End-bearing piles/Bored piles/Replacement piles ............................................................. 18 6.0. Decision matrix (showing the value you each foundation through a rating system of 1-5 in which 1 – poor and 5 – ideal)........................................................................................................ 20 7.0 Conclusion ......................................................................................................................... 21 Reference ...................................................................................................................................... 22 07004101 Page 1 1.0. Brief A client has identified a city centre, brownfield site (with possible obstructions within the ground) that is surrounded by buildings and has bedrock 8m below ground level. The site is to accommodate a five storey office building that is to house 250 staff. The client requires a technical report that will enable them to understand the suitability of various substructures. Where appropriate the report shall identify relevant guidance, legislation and sustainability considerations relating to the proposed building. The report must: 1) Illustrate various foundation types (excluding piles) that may be used to support a building. Investigate and analyse the advantages and disadvantages of these various systems including the way in which they transmit the loads to the ground. Suggest when it may be appropriate to use each of the foundation types. 2) Illustrate various types of pile foundation that may be used to support a building. Investigate and analyse the advantages and disadvantages of these various systems including the way in which they transmit the loads to the ground. Suggest when it may be appropriate to use each of the pile types. 07004101 Page 2 2.0. Introduction Foundations are primarily required to support building construction but on brownfield sites they can also act as a barrier to contaminants. The performance of foundation materials can be adversely affected by contaminants Charles, J (2004). 2.1. Foundation types Covered in this Report a. Shallow foundations i. Strip foundations ii. Pad foundations iii. Raft foundation b. Deep foundations i. Pile foundations 1. Friction/Driven piles/Displacement piles 2. End-bearing piles/Bored piles/Replacement piles 2.2. Considered factors affecting the foundations a. Live Loads b. Dead Load (5 storey building) c. Wind Load d. Earthquake e. Uplift f. Structural Member Forces g. Horizontal Pressures below Grade i. Sum of the loads is considered the combined load 2.3. Foundation a. Must transfer the combined load to the required load bearing stratum, while coping with i. The grounds settlement characteristics ii. Possible ground heave 07004101 Page 3 iii. The impact of creep on the foundation b. Should be technically and economically feasible 2.4. Elements requiring foundations a. External walls b. Separating walls c. Chimney breasts d. Piers e. Internal loadbearing or masonry walls f. Sleeper walls 2.5. Information required before designing foundations a. site and ground appraisals b. dwelling design c. site layout d. site levels e. sulphate and acids in ground or groundwater f. trees g. frost susceptible soils 07004101 Page 4 3.0. Assumptions/Belief of ground type/condition 3.1. A Brownfield site can have many hazards, these need to be identified so remedies can be taken to eliminate/limit their impact on the building and its’ users. Most sites have a Land Condition Record (LCR) which should provide a record of the nature of any contamination and the previous used of the land. Along with the LCR it is recommended to consult a specialist in land contamination (SILC). The chart below illustrates the recommended steps to take from initial assessment to complete construction. Charles, J (2004). 07004101 Page 5 3.2. After the nature of the ground has been ascertained a risk register should be completed to identify; a. Hazards b. The nature and degree of risk resulting from the hazards c. A planned response d. An estimated effect of response e. The nature and degree of residual risk and with whom it lies 3.3. A remedial strategy should then be formed subject to; a. Technical adequacy b. Cost c. Environmental effects d. Perception NHBC (2011) Note: Advice and guidance on foundations have been given solely based on the clients’ information given in the brief (1.0). Should any information change the advised foundation type should be re-analysed as it may not be suitable. 07004101 Page 6 4.0. Report 1 – Shallow foundation Illustrate various foundation types (excluding piles) that may be used to support a building. Investigate and analyse the advantages and disadvantages of these various systems including the way in which they transmit the loads to the ground. Suggest when it may be appropriate to use each of the foundation types. 4.1. Strip Foundation (see appendix 1 & 2 for detail) (trench foundations are very similar to strip foundations, differing mainly in thickness of foundation) a. Required for: i. External walls ii. Separating walls iii. Chimney breasts iv. Piers v. Internal loadbearing walls b. Dimensions are 150mm -500mm thick depending of bearing stratum (refer to appendix 2 for more information) c. Material i. Cast in-situ concrete (OPC or SRPC) ii. pre-cast concrete (OPC or SRPC) d. Concrete shall be of a mix design which is suitable for the intended use, items to be taken into account include: i. strength to safely transmit loads ii. durability against chemical or frost action e. Normal depth of 1m f. Not recommended for soils with low bearing capacity and should be laid at a depth where the foundation can transfer the required load to good bearing stratum g. Except where strip footing sit on bedrock, foundations should be taken to a minimum of 450mm below ground h. Reinforcement can be added 07004101 Page 7 i. When taking the foundations to the required depth the water table may have to be taken into consideration j. Brownfield site ground maybe hazardous therefore the foundation should be designed by an engineer i. Designed in accordance with 1. BS EN 1991-1-1 2. BS EN 1991-1-3 3. BS EN 1991-1-4 4. BS 648. 5. BS 8500-1 6. BRE Special Digest 1 RIBA (2010), NHBC (2011), Hodgkinson, A (1986) Strip Foundations Advantages Disadvantages When Required Shallow foundations, Limited load carrying ability In ground of medium to good therefore little excavation due to foundation depths and bearing stratum, on domestic needed. design, therefore only suited scale developments, to small/medium underneath loadbearing walls, developments. separating walls, chimneys, Economically cheap due to the narrow, shallow design. Little to no impact on Not ideal for framed construction. neighbouring properties. Sulphate Resisting Portland Cement (SRPC) can be used in place of Ordinary Portland Cement (OPC) to cope with 07004101 Weak against uplift forces, piers and internal loadbearing walls. To carry light loads wind forces and earthquake forces. Weak in stratum of loose sand Page 8 sulphur attack from soils. or gravel. Riley et al.(2009) The continuous narrow trenches excavated for the Strip foundations are suited to continuous load bearing walls as opposed to point loads. Not intended to support building higher than 3/4 storeys. The narrow trenches would need to be taken to a depth where the foundation could transfer the load to suitable stratum, at depth the excavated trenches would require supports to prevent caving in. Working space needed of 600mm (under building regulations) for health and safety would need to be provided for workers to carry out work, the sided of the excavated working space trenches requiring support. Once all required work has been carried out the working space trenches would have to be backfilled. 07004101 Page 9 4.2. Pad foundations (see Appendix 3) a. An alternative to strip foundations for framed structures b. Required for: i. External walls ii. Separating (party) walls iii. Chimney breasts iv. Piers v. Internal loadbearing or masonry walls vi. Sleeper walls c. Material i. Cast in-situ concrete (OPC or SRPC) ii. Reinforcement d. Thickness designed to transmit the load at a 45° angle through the Pad to minimise tensile stresses on the soffit of the foundation e. Transmit the load to the bearing strata through individual foundations f. Concrete shall be of a mix design which is suitable for the intended use, items to be taken into account include: i. strength to safely transmit loads ii. durability against chemical or frost action g. Reinforcement can be added to carry the tensile stresses and required loads h. Shear reinforcement can be added to avoid punching failure i. Not recommended for soils with low bearing capacity and should be laid at a depth where the foundation can transfer the required load to good bearing strata j. Brownfield site ground maybe hazardous therefore the foundation should be designed by an engineer i. Designed in accordance with; 1. BS 648 2. BS EN 1991 3. BS EN 1997-1 07004101 Page 10 4. BS EN 1992 5. BS 10175 NHBC(2011), RIBA (2010), Hodgkinson, A (1986) Pad Foundations Advantages Disadvantages When Required Shallow foundation Foundation size can be a very Ideal foundation for point Requires little excavation. large to cope with high point loads from framed loads. buildings when bearing Can be designed to accommodate tight sites. capacity of ground is Limited foundation suitability to suitable a shallow depths. point loads of framed buildings. Economic due to control of foundation size. Separate foundations make this design weak against differential Reinforcement for tension and settlement that may affect the shear can be added. building. Concrete mix can use SRPC in Deep excavations for place of OPC foundations would require support to prevent caving in. Weak against uplift forces, wind forces and earthquake forces. Riley et al.(2009) Pad foundations are suited to a framed construction however the ground type described in the brief and the heavy load of the 5 story building would require this usually shallow foundation to be taken deeper to better bearing stratum, thus eliminating the economic advantage of this 07004101 Page 11 foundation. The foundation size would have to be enlarged to cope with the high point loads. Additional costs occur for supporting the excavations to prevent cave-ins. As the site is a brownfield site SRPC my need to be introduced thus increasing the material cost. Hodgkinson, A (1986) 07004101 Page 12 4.3. Raft foundations (see appendix 4) a. Used in ground with very low bearing capacity or where excessive variations in ground conditions would cause unacceptable differential settlements b. Recommended for; i. External walls ii. Separating walls iii. Chimney breasts iv. Piers v. Internal loadbearing walls vi. Sleeper walls c. Recommended when Strip or Pad foundations occupy more than 50% of the floor area d. Requires reinforcement to carry the tensile, load Steel reinforcing fabric should comply with BS 4483 e. Suitable for projects where there is a shallow water table f. Material i. Cast in-situ concrete (OPC or SRPC) g. Approved Document C4 requires the minimum quality of the concrete to be at least mix ST2 of BS 5328-1 h. Concrete shall be of a mix design which is suitable for the intended use, items to be taken into account include: i. strength to safely transmit loads ii. durability against chemical or frost action i. Brownfield site ground maybe hazardous therefore the foundation should be designed by and engineer i. Designed in accordance with; 1. BS 648 2. BS EN 1991 3. BS EN 1997-1 07004101 Page 13 4. BS EN 1992 5. BS 10175 NHBC(2011), RIBA (2010). Raft Foundations Advantages Disadvantages When Required Financially cheap due to the Weak when supporting point Lightweight structures on combined use of the loads, specific treatment poor ground with low foundation as the floor. required. bearing capacity. Shallow depth of foundation Susceptible to edge erosion. Used in areas with mixed means little excavation. bearing capacity usually filled ground. Can cope with poor/mixed ground conditions. Riley et al.(2009), Hodgkinson, A (1986) Raft foundations are ideal foundation choice to support light weight buildings (3/4 stories high). The design provides an economical advantage that is the dual use of the raft as the ground floor concrete slab. The foundation is suited to traditional buildings in grounds of poor/mixed bearing stratum. The raft provides very good protection against differential ground settlement, earthquakes and heave due to the design. The raft would traditionally not suit a famed building. The raft can be designed to accommodate framed structures however they were not intended to cope with high point loads. The concrete mix can have SRPC added to help resist chemical attack. 07004101 Page 14 5.0. Report 2 – Deep Foundations Illustrate various types of pile foundation that may be used to support a building. Investigate and analyse the advantages and disadvantages of these various systems including the way in which they transmit the loads to the ground. Suggest when it may be appropriate to use each of the pile types 5.1. Friction/Driven piles/Displacement piles (see appendix 5) a. Are piles driven into the ground, they derive their bearing capacity from skin friction and/or adhesion b. Required for; i. External walls ii. Separating walls iii. Chimney breasts iv. Piers v. Internal loadbearing or masonry walls vi. Sleeper walls c. Suited to loose and moisture bearing granular soils d. Material i. Reinforced concrete ii. Prestressed concrete iii. Steel e. Unsuited to ground containing boulders or obstacles f. Brownfield site ground maybe hazardous therefore the foundation should be designed by and engineer i. designed in accordance with; 1. BS 648 2. BS EN 1991 3. BS EN 1997-1 4. BS EN 1992 07004101 Page 15 5. BS 10175 g. May be accompanied by a reinforced ring beam or pile caps to provide stability against forces and help transfer loads NHBC(2011), RIBA (2010), Biddle et al.(2002) Friction/Driven piles/Displacement piles Advantages Disadvantages When Required Can transfer load in variable Problematic when dimensional Sites with poor ground ground conditions. stability of the ground is an conditions. issue. Can transfer loads to deep bearing stratum Suitable to tight sites. Soils that have low Problematic when there is bearing capacity but offer demolition debris or boulders in good friction forces. the ground. Bearing stratum is deep Made off site and quality Noisy installation method can maintained due to factory cause environmental impact below the surface. production. Vibration can affect neighboring There is no evidence that properties Steel piles are susceptible to corrosion by the action of Can cause ground heave sulphur reducing bacteria (<0.03mm corrosion per annum). No excavation required. 07004101 Page 16 No need to support excavated holes. Suited to framed construction. Harrison et al.(2012), Riley et al.(2009), Biddle et al.(2002), Technical Committee B/517 (2009) Friction Pile foundations are uniformly distributed columns driven into the ground via the repeated dropping of a weight onto the head of the pile, to reach the required depth and transmit the required building loads to good bearing stratum. Pile foundations would normally be used when ground conditions are not suitable to economically support reason for traditional foundations. Friction piles cope well with live loads, dead loads, wind loads, earthquakes and uplift. They can cause problems such as heave. The piles are compatible with framed buildings and designed to carry loads of light to heavy weight structures. Steel piles have a very high resistance to sulphur attack or SRPC can be added to concrete mixes. Piles are ideal for brownfield sites that may have had previous buildings on the site. Reinforcement can be added to cope with the horizontal forces. There is an economic advantage not excavating material. Chudley, R., et al. (2010), Hodgkinson, A (1986) 07004101 Page 17 5.2. End-bearing piles/Bored piles/Replacement piles (see appendix 6) a. Holes bored into the ground and filled with concrete b. Required for; i. External walls ii. Separating walls iii. Chimney breasts iv. Piers v. Internal loadbearing or masonry walls vi. Sleeper walls c. The pile transmits the load through the pile to the bearing strata which the pile is in contact with d. Suited to poor/mixed ground e. Material i. In-situ concrete (OPC or SRPC) ii. Reinforced f. Brownfield site ground maybe hazardous therefore the foundation should be designed by and engineer i. Designed in accordance with; 1. BS 648 2. BS EN 1991 3. BS EN 1997-1 4. BS EN 1992 5. BS 10175 g. May be accompanied by a reinforced ring beam or pile caps to provide stability against forces and help transfer loads from the building to good bearing stratum NHBC(2011), RIBA (2010), Biddle et al.(2002), Hodgkinson, A (1986) 07004101 Page 18 Large diameter bored piles Advantages Disadvantages When Required Can transmit heavy loads. Require reasonably good soil Heavy buildings with large content to avoid bore hole loads. Larger diameter of piles mean collapsing. less piles needed. No need to support bore hole When there is a risk of Large plant needed to damage to surrounding excavate earth. buildings through vibration. as concrete replaces the void created. Bearing stratum is deep below the surface. Almost vibration free. Almost noise free. Not susceptible to boulders or debris below ground. Can transfer loads to deep bearing stratum on tight sites. Riley et al.(2009), Biddle et al.(2002), Technical Committee B/517 (2009) End-bearing piles are suited to sites where there is a requirement to transfer large loads to a bearing stratum that is too deep for other foundations. The boring process eliminates the noise and vibration factor. Bored pile diameters range from 450mm to 1200mm so fewer piles would be needed if larger piles were used. Piles can be combined with pile caps or a ring beam to increase stability to the structure. Suited to framed structures and ideal for dealing with point loads and they are very strong in compression. Reinforcement can be added to cope with the 07004101 Page 19 horizontal forces. SRPC can be added to the concrete mix to combat the sulphate chemicals in soils. Piles are ideal for brownfield sites. NHBC(2011), Hodgkinson, A (1986) 6.0. Decision matrix (showing the value you each foundation through a rating system of 1-5 in which 1 – poor and 5 – ideal) Information/requirements Strip known Pad Raft Driven Pile Bored Pile Foundation Foundation Foundation Foundation Foundation (weighting) (weighting) (weighting) (weighting) (weighting) 1 1 5 5 5 five storey office building 2 2 3 5 5 brownfield site 3 3 2 5 3 city centre 4 4 4 2 4 possible obstructions 5 5 5 3 5 15 15 19 20 22 Bed rock 8m below ground within the ground Total 07004101 Page 20 7.0. Conclusion After analysing the various foundations and processing them into the decision matrix, Bored pile foundations appear to be the most suitable, however there is very little information known at this stage and it would be possible to use raft, driven piles or bored piles on such a project. Strip and pad foundation would not be suitable sue to land, size of building and loads the foundations would have to cope with. Raft foundation although used mainly for light weight structures could be designed to cope with greater loads. The building design is not known and it would be suggested if this building would be a framed building then it would be best not to use raft foundation as its design is traditionally weak in supporting point loads, the raft would cope with the land and deep bearing stratum issue. Driven piles appear to be a better option according to the decision matrix as they are designed to cope with heavier loads. Driven piles are ideal for tight sites as they require no excavation, there would be an economical benefit to this too. The driven pile foundations are not perfect, they are unsuitable for use in ground with boulders or debris below ground, which the pile may hit and be pushed off course, in this case it would be a cost to, have the pile removed and relocated, or excavate the boulder/debris, and drive the pile again. The decision matrix shows bored piles have come out as the favourite choice, the reason for this is its ability to cope with the loads specified for the building. They can reach the depths of the bedrock, the reduced vibration and noise in comparison to the driven pile are to the advantage of the bored piles, this is a city centre site and therefore likely to have neighbouring buildings, which with driven piles may be subject to heave or settlement displacement. With bored piles the client would have less chance of falling foul to disturbing the neighbouring properties. More information at this stage is required in order to properly select the right foundation such as the LCR. Based on the information provided either of the pile foundation types would be suitable. 07004101 Page 21 Reference Biddle,A.,Yandzio,E (2002). Specifiers’ Guide to Steel Piling. Berkshire: The Steel Construction Institute. 1-46. Charles, J (2004). Building on brownfield sites: reducing the risks. Watford: BRE Bookshop. 1-8. Chudley, R., Greeno, R (2010). Building Construction Handbook, Incorperating Current building & Construction Regulations. 8th ed. Oxford: BSIElsevier Ltd. p206-319. European committee for standardisation (2007). Precast concrete products — Foundation piles. Brussels: BSI. 1-44. Harrison,H.,Trotman,P (2012). Foundations,basements and external work. London: BRE Building elements. 1-249. Hodgkinson, A (1986). Foundation Design. London: Architectural Press Ltd. p15-81. NHBC (2011). NHBC Standards: Land Quality - Managing Ground Conditions Chapter 4. 1. 4th ed. England: National house building council. 1-16. RIBA (2010). Structures Approved Document A. London: NBS. p1-45. RIBA (2010). Fire Safety Approved Document B, Volume 2: Buildings Other Than Dwelling Houses. London: NBS. p1-150. RIBA (2010). Site Preparation and Resistance to Contaminants and Moisture Approved Document C. London: NBS. p1-40. RIBA (2010). Toxic Substances Approved Document D. London: NBS. p1-5. Riley,M.,Cotgrave,A (2009). Construction technology 2:Industrial and commercial building. 2nd ed. England: Palgrave. 109. Technical Committee B/517 (2003). Concrete — Complementary British Standard to BS EN 2061 — Part 1: Method of specifying and guidance for the specifier. London: BSI. p1-40. Technical Committee B/517 (2009). Code of practice for noise and vibration control on construction and open sites – Part 2: Vibration. 3rd ed. London: BSI. p1-90. Technical Committee B/517 (2011). Structural design of low-rise buildings Part 1: Code of practice for stability, site investigation, foundations, precast concrete floors and ground floor slabs for housing. 3rd ed. London: BSI. p1-58. 07004101 Page 22 Appendix 1 Image taken from: NHBC(2011) 07004101 Page 23 Appendix 2 Image taken from: http://www.google.co.uk/imgres?imgurl=http://www.thebeamlockcompany.co.uk/images/Bea mlockFoundations.jpg&imgrefurl=http://www.thebeamlockcompany.co.uk/technical.html&h=602&w =566&sz=94&tbnid=1QOdwPHCDx63HM:&tbnh=90&tbnw=85&prev=/search%3Fq%3Dpad%2Bf oundations%2Bdetails%26tbm%3Disch%26tbo%3Du&zoom=1&q=pad+foundations+details&us g=__-kM0aIizEOTaO-c3ub9h3ytAV8g=&docid=WTfGBMNXwOLKM&hl=en&sa=X&ei=J_C7UJGEDsWg0QXxlIGoDA&ved=0CC4Q9QEwAA&dur=0 07004101 Page 24 Appendix 3 Image taken from: http://www.google.co.uk/imgres?imgurl=http://www.thebeamlockcompany.co.uk/images/Bea mlockFoundations.jpg&imgrefurl=http://www.thebeamlockcompany.co.uk/technical.html&h=602&w =566&sz=94&tbnid=1QOdwPHCDx63HM:&tbnh=90&tbnw=85&prev=/search%3Fq%3Dpad%2Bf oundations%2Bdetails%26tbm%3Disch%26tbo%3Du&zoom=1&q=pad+foundations+details&us g=__-kM0aIizEOTaO-c3ub9h3ytAV8g=&docid=WTfGBMNXwOLKM&hl=en&sa=X&ei=J_C7UJGEDsWg0QXxlIGoDA&ved=0CC4Q9QEwAA&dur=0 07004101 Page 25 Appendix 4 Image taken from: http://www.google.co.uk/imgres?imgurl=http://www.thebeamlockcompany.co.uk/images/Bea mlockFoundations.jpg&imgrefurl=http://www.thebeamlockcompany.co.uk/technical.html&h=602&w =566&sz=94&tbnid=1QOdwPHCDx63HM:&tbnh=90&tbnw=85&prev=/search%3Fq%3Dpad%2Bf oundations%2Bdetails%26tbm%3Disch%26tbo%3Du&zoom=1&q=pad+foundations+details&us g=__-kM0aIizEOTaO-c3ub9h3ytAV8g=&docid=WTfGBMNXwOLKM&hl=en&sa=X&ei=J_C7UJGEDsWg0QXxlIGoDA&ved=0CC4Q9QEwAA&dur=0 07004101 Page 26 Appendix 5 Image taken from: http://www.google.co.uk/imgres?q=friction+driven+piles&um=1&hl=en&sa=N&tbo=d&biw=13 66&bih=648&tbm=isch&tbnid=lk5DNHOkKOqPNM:&imgrefurl=http://www.substruck.ie/ourservices/foundationrepair/piling&docid=qzfj53dH8b7PKM&imgurl=http://www.substruck.ie/wpcontent/themes/substruck/pictures/frictionpile.jpg&w=604&h=367&ei=duq7UKjLBu7M0AWar 4HQCw&zoom=1&iact=hc&vpx=1035&vpy=375&dur=1369&hovh=175&hovw=288&tx=109&ty =121&sig=104003884147091334153&page=1&tbnh=131&tbnw=216&start=0&ndsp=25&ved=1 t:429,r:24,s:0,i:160 07004101 Page 27 Appendix 6 Image taken from: http://www.google.co.uk/imgres?q=friction+driven+piles&um=1&hl=en&sa=N&tbo=d&biw=13 66&bih=648&tbm=isch&tbnid=lk5DNHOkKOqPNM:&imgrefurl=http://www.substruck.ie/ourservices/foundationrepair/piling&docid=qzfj53dH8b7PKM&imgurl=http://www.substruck.ie/wpcontent/themes/substruck/pictures/frictionpile.jpg&w=604&h=367&ei=duq7UKjLBu7M0AWar 4HQCw&zoom=1&iact=hc&vpx=1035&vpy=375&dur=1369&hovh=175&hovw=288&tx=109&ty =121&sig=104003884147091334153&page=1&tbnh=131&tbnw=216&start=0&ndsp=25&ved=1 t:429,r:24,s:0,i:160 07004101 Page 28 Appendix 7 Image taken from: NHBC(2011) 07004101 Page 29 Appendix 8 Image taken from: NHBC(2011) 07004101 Page 30 Appendix 9 Image taken from: http://www.buildingscience.com/index_html 07004101 Page 31