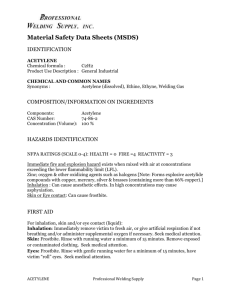

Acetylene: Properties, Production, and Uses

advertisement