WHMIS to GHS, or is it WHMIS 2015?

advertisement

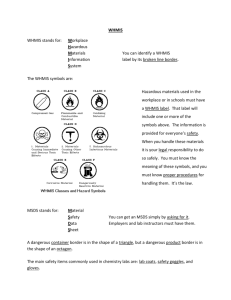

05/05/2015 Objectives for this talk WHMIS to GHS, or is it WHMIS 2015? WHMIS • • • • • • • • Focus on employers but Are you sure you are not a supplier WHMIS to GHS classification & symbols Timing Label content MSDSs to SDSs Education vs. Training Hazard assessments INTRODUCTION • WHMIS implemented in 1989 • Few changes since • Suppliers – Classify “Controlled Products” – Label products – Actively distribute MSDSs • Employers measured more than suppliers Why Change? After many years of discussion Canada has aligned WHMIS with GHS. Health Canada's goal is to have the updated federal WHMIS laws in force no later than June 2018. GHS Harmonization not Standardization With an increase in international trade harmonize chemical hazard classification and communication worldwide. GHS implementation will: • Reduce confusion • Ensure compliance • Maintain the health and safety of workers both here and abroad • Global Harmonized System for Classification and Labelling of Chemical Compounds • Harmonization not Standardization • Many years many governments and industries • Nobody can relax a rule How many have foreign SDSs? 1 05/05/2015 What Happens to WHMIS Keep training on ‘old’ WHMIS style labels and MSDSs until transition is complete. Before GHS Classification Issue • • • • • • • Acute toxicity classification by LD50 LD50 of 257 mg/kg body weight designation Non-toxic in India Hazardous in New Zealand Moderately toxic in China Harmful in EU, Australia, Thailand & Malaysia Toxic in Canada, US, Japan, Korea • CCOHS reference GHS Classification Alignment GHS Classification • Evolution of rules lead to differences • Combustible liquid in WHMIS has a different flammable range than in TDG • Classification temperature cut offs will be harmonized between TDG, WHMIS, Consumer Products • • • • Classification is more than Symbols GHS Symbols Physical Building Block Approach Physical Hazards Health Hazards Environmental Hazards • 16 Physical Hazard Classes – Explosives, Flammables, Oxidizers, etc. • 10 Health Hazard Classes – Acute, Chronic, Irritation, Repro, etc. • 2 Environmental Hazard Classes – Aquatic and Ozone • Hazard Categories 1 through 5 – 1 being most severe 2 05/05/2015 GHS Symbols Physical GHS Symbols Health Hazards Suppliers WHMIS now and in Future Are you a Supplier? • Suppliers for WHMIS are to: – Classify “Controlled Products” – Label products – Actively distribute MSDSs • Suppliers for GHS are to: – Classify “Hazardous Products” – Label products – Actively distribute SDSs • • • • WHMIS Implementation • Suppliers send SDSs & labels with products • Employers use this information to ensure workers know how to use, handle, store and dispose of chemicals. Do you sell products? Do you import products? Do you resell products? Do you mix products? GHS is here GHS has already been implemented in the USA. Worker training was to be completed by Dec 2013 and all MSDSs needed to be converted to SDSs by June 2015. With cross border trade your workers are likely seeing Labels and SDSs already in the workplace. 3 05/05/2015 SAFETY DATA SHEETS (SDS) How to Prepare What is new? • Standard 16 Sections • Very structured order • Hazard Statements • Hazard Symbols • Signal Words • 3 year rule gone What is not new? • Bilingual • Trade Secrets HMIRC Continue with WHMIS compliance. Start education and training about WHMIS to GHS changes – WHMIS 2015. Workplaces may already be receiving new GHS-compliant labels and safety data sheets (SDSs). Review chemical inventories and minimize unnecessary chemicals in the workplace. LABELS Product Identifier Signal Word Hazard Statements Hazard Symbols Precautionary Statements • Acute hazards • Supplier • • • • • • Hatched border gone • Bilingual kept EDUCATION vs. TRAINING Education General information Training Work specific information Examples of Topics How WHMIS works. How to find SDSs. How to store products. Hazards of the products. Procedures required for safe use, handling and disposal of a hazardous product. What precautions are required. PPE? Training in emergency procedures in the Understanding the new symbols. event of an accident or spill. The information you can find on SDSs and Procedure to follow if the hazardous product what that information means. is present in the air and a worker may be exposed. The information on both the supplier label and workplace label, and what that information means. Any other procedures required when the product is in a pipe, piping system, vessel, tank car, etc. 4 05/05/2015 Who Needs Training Examples of job roles who require education and training include workers who: • • • • May be exposed to a hazardous product due to their work activities (including normal use, maintenance activities, or emergencies). Use, store, handle or dispose of a hazardous product. Supervise or manage workers who may be exposed, or use, store, handle or dispose of a hazardous product. Are involved in emergency response. Responsibility of the Employer After GHS (typically provincial responsibility): • Develop, Implement and Maintain a WHMIS 2015 education and training program. • Review program annually or when conditions, chemicals, or hazard information changes. • Ensure workers know for products they use: • Hazards of the products • How to work safely with the products • What to do in case of emergency • Where to find more information. Chemical Hazard Assessments When should you train? Employer must ensure hazard assessments done Chemicals often overlooked in hazard assessments Assessments must include how a product is used Suppliers cannot predict your workplace conditions or all the methods of use. • Statements that protect the suppliers are on SDS • Supervision must determine controls PPE or other. • Goggles • Gloves • Respirator • Eye wash • • • • • Frequency of Education & Training Responsibility of the Worker • • • • • Employers are required to provide refresher education and training: • As needed to protect the workers. • If conditions of the workplace have changed. • If new products are introduced or changed. • If new hazard information becomes available. • With new information about safe use, handing, storage or disposal. MSDSs are being replaced with SDSs SDSs will be the main information source US SDSs are already arriving. Have you been receiving SDSs? At what point should you train on the new system? – – – – <10% <25% <50% Wait to 100% Participate in education and training. Follow employer’s safe work procedures. 5 05/05/2015 Successful Training & Education Workers should be able to answer these questions for every hazardous product they work with: 1. What is this product? 2. What are the hazards? 3. How to work with the product safely? 4. What to do in an emergency? 5. Where is more information found? Safety in Transition: Moving from WHMIS to GHS Who can provide training? Training can be provided by the employer or qualified person or agency. Employers remain legally responsible to ensure the protection of workers. 5 Fundamental Questions 1. What is this product? 2. What are the hazards? 3. How to work with the product safely? 4. What to do in an emergency? 5. Where is more information found? What is the product? What are the hazards? How to work with the product safely? 6 05/05/2015 What to do in an emergency? Where is more information found? Training + Education Use Training Aids Chemscape Can Help Summary GHS or WHMIS 2015 is in implementation phase Suppliers need to apply new classification to products Suppliers need to rewrite MSDSs into SDSs GHS SDSs are arriving now and to dominate by end of 2015 New hazard information is arriving which should induce training on the new system. • 5 Fundamental questions as training steps are conducive to structure of new hazard information. • • • • • Safety in Transition: Moving from WHMIS to GHS is authored by Chemscape under the guidance of an Industrial Hygienist who is certified with the American Board of Industrial Hygiene. 7 05/05/2015 Questions • • • • • • Mike Phibbs CIH ROH Chemscape Safety Technologies Inc. Suite 207, 5920 1A Street SW Calgary, AB T2H0G3 www.Chemscape.com 403-720-6737 • mphibbs@Chemscape.com 8