WHMIS Training

advertisement

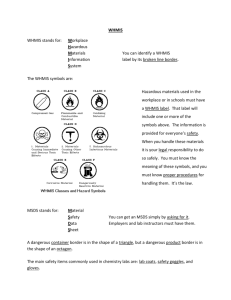

WHMIS Training Sarah Lamb Biological/Chemical/Radiation Safety Officer Environmental/Occupational Health & Safety Office WHMIS… W H M I S Workplace H Hazardous d Materials Information System Legislation • WHMIS became law on October 31, 1988 • WHMIS is a part of the Occupational Health & Safety Act • Suppliers Suppliers, employers and workers all have specified responsibilities for WHMIS Components of WHMIS Hazards are identified and products are g classified in WHMIS regulations Ed Education ti and dT Training i i Label Roles and Responsibilities Producers & Suppliers of Controlled Products Provide Labels and MSDSs Employers Provide Labels and MSDSs PLUS Education and Training Workers Roles and Responsibilities • Workers – Participate in WHMIS training program – Notify f supervisor off any potential hazards such as unlabelled containers – Apply A l workplace k l labels l b l when h transferring chemicals from one container to another – Wear W the th proper personall protective t ti equipment (PPE) when handling chemicals Worker Education and Training • WHMIS is your right to know • What you should take from thi session: this i – Where to get information about WHMIS-controlled WHMIS controlled products – How to find out the associated hazards – How to protect yourself from the hazards – What to do in an emergency Classes of WHMIS Controlled Products Controlled Products • Products, materials, and substances that are regulated by WHMIS legislation • All controlled products fall into one or more of six WHMIS classes Class A Class B Class C Class E Class D Class F Class A: Compressed Gas • Any material that is a gas at normal pressure, but packaged under pressure in a cylinder • Hazards due to high pressure; – the cylinder can turn into a 'rocket' or 'torpedo' at great speeds – heat may cause the gas to expand and the cylinder could explode – gas leaking l ki from f a cylinder li d is i very cold ld and could cause frostbite to exposed skin • Examples: propane, propane acetylene, acetylene oxygen, oxygen helium Class B: Flammable and Combustible Material • Flammable – the material will ignite below 37.8°C • Combustible – the material will ignite when heated above b 37.8°C 37 8°C • A spark, flame or friction may ignite these materials • Examples: propane, acetylene, varnish, i h acetone t Class C: Oxidizing Material • Materials that release oxygen which contributes to the combustion of other materials • Can be a solid, liquid or gas • Examples: oxygen, nitric acid, sodium chlorite Class D: Poisonous and Infectious Material Three divisions: • Materials causing Immediate and Serious Toxic Effects • Very poisonous and immediately dangerous to life and health • Examples: cyanide, cyanide styrene • Materials causing Other Toxic Effects • May y take time to cause damage g (i.e. ( cancer)) or causes immediate but temporary effects • Examples: asbestos, mercury, lead, benzene • Biohazardous Infectious Materials • Can produce disease or infection in humans • Examples: blood and body tissues Class E: Corrosive Material • Can cause severe burns to skin and other tissues such as eyes and lungs • Can attack clothes and other materials such as metals • Effects are permanent • Examples: sulfuric acid, caustic soda, d ammonia i gas Class F: Dangerously Reactive Material • Can Ca react eact violently o e t y under u de certain ce ta conditions: – contact with water – bumped or dropped – break down in a dangerous manner • Unstable • Examples: picric acid, ethylene oxide Are there any hazardous materials not included in WHMIS? Yes! – – – – – – – – – consumer restricted products explosives l i cosmetics, drugs, food or devices pest control products (pesticides, herbicides insecticides herbicides, insecticides, etc) radioactive materials wood and products made of wood a manufactured f t d article ti l tobacco or products made of tobacco hazardous wastes Material Safety Data Sheets MSDS • Material Safety Data Sheet • Contains information on the potential hazards (health, (health fire, fire reactivity and environmental) and how to work safely with the product • MSDSs must be readily available to the workers who are exposed to the controlled product MSDS • When a product is purchased, the supplier must include the most up t d to date t MSDS – updated d t d within ithi last 3 years • Your supervisor will give you the MSDS before you are expected to use the material • The MSDS will be readily available to you at any time during your work k with ith the th material t i l • Never hesitate to ask for an MSDS! MSDS Categories 1. Product Information: product identifier (name), manufacturer and suppliers names, addresses, and emergency phone numbers 2. Hazardous Ingredients 3. Physical Data 4. Fire or Explosion Hazard Data 5. Reactivity Data: information on the chemical instability of a product and the substances it may react with 6. Toxicological Properties: health effects 7. Preventive Measures 8. First Aid Measures 9. Preparation Information: who created MSDS and date of preparation WHMIS Labels WHMIS Labels • There are two main types of labels: – Supplier • Must be attached to container when h shipped hi d from f supplier li • Cross-hatched border – Workplace • If a material is transferred from its original container container, a workplace label must be attached • If a material is not leaving the laboratory a laboratory workplace laboratory, label can be used Supplier Label 1. Product Name 2. Supplier Name 3. Hazard Symbols 4. Risk Phrases 5. Precautionary Measures 6. First Aid Measures 7. MSDS Reference Workplace Label Three main components of a workplace label: Workplace Labels for Laboratories • For any sample that will never leave the laboratory, a simplified label may be used • The label must give the worker enough information to identify the chemical h i l and d obtain bt i the th MSDS – Full name of chemical – Concentration, if known – Any other information to ensure the safe f use, handling h dli and d storage t off the th chemical Chemical Name Concentration Emergency Response Emergency Response Emergency phone numbers: – 911 ffor any iin-progress emergencies • Remember to dial 9-911 9 911 if using a campus phone – then call Special Constable Service at extension 3333 Emergency Response at Laurier • This poster is l located t d in i every classroom and laboratory on campus and d instructs on fire alarm procedures • Be familiar with the emergency exits for rooms you are working in Emergency Response • Accidents – All accidents must be reported to the EOHS office – An Employee Accident Report must be completed by y the supervisor p and sent to the EOHS office – The Employee Accident R Report t is i available il bl on the th EOHS website www.wlu.ca/eohs under “Forms” Questions?