Document

Proceedings of the 2 nd International Conference on Operations and Supply Chain Management,

May 18-20, 2007, Novotel Bangkok on Siam Square, Bangkok, Thailand

IMPROVING EFFICIENCY OF MATERIAL REQUIREMENT

PLANNING AND SAFETY STOCK: A CASE STUDY OF

CREATIVE MACHATRONICS CO., LTD.

ABSTRACT

A main objective of this research study is to investigate characteristic and implication of stockout for reel stand that may impact to an exemplary company in Thailand.

By considering causes and effects of the problem, this research used Collaborative Planning, Forecasting, and

Replenishment to solve such problem by means of sharing information, supply chain management implementation, and well coordination. This concept leads to cost reduction, efficient and effective inventory management, along with low ordering cost, economics order quantity, and low product cost caused by over time cost in longer lead time of raw materials to meet customer requirement.

It may enhance work efficiency and develop good relationship with suppliers in a long term, thereby gaining business competitive advantage. By gaining the business competition would increase sale volume, regain customer loyalty, and lead to increasing customer satisfaction level.

Therefore, several entrepreneurs have concentrated on production by enhancing its efficiency that may be instrumental to increasing customer requirement.

KEYWORDS

Stock Out, Minimum Stock, Economics Order Quantity,

Collaborative Planning Forecasting and Replenishment

1. Introduction

Chantana Thongma

1

, Ungul Laptaned

2

1

MBA in Logistics Management, Graduate School,

University of the Thai Chamber of Commerce

Vibhavadee-Rangsit Road, Dindaeng, Bangkok, 10400, Thailand

Tel: 02-957-7816, Fax: 02-957-7816,

Email: chan_062@hotmail.com

2

Logistics Engineering Department, School of Engineering,

University of the Thai Chamber of Commerce

Vibhavadee-Rangsit Road, Dindaeng, Bangkok, 10400, Thailand

Tel: 02-697-6707, Fax: 02-275-4892,

Email: ungul_lap@utcc.ac.th

This research was aimed at planning the material requirements used for the “Reel Stand” and its safety stock in case of out of stock in unforeseeable future.

Causes of the identified problem that were analyzed by using the Pareto and Fish-Bone Diagram were insufficient materials and unplanned material requirement that had a direct impact on company’s production, high cost of production due to overtime, late delivery time, low customer satisfaction level, and low customer’s confidentiality to the company.

Owing to such reasons, several entrepreneurs have recently concentrated on an increase in customer responsiveness in production management to improve efficiency, reduce production cost, and control product’s quality level under determined standard. Overall objective is to gain business competitive advantage.

2. Review of Literature

Forecasting is a statement about the future value of a variable such as demand. Forecasts are predictions about the future that can be long range covering several years.

Forecasting is a component of yield management, which relates to the percentage of capacity being used.

Technique for forecasting can be categorized into several kinds such as naïve, moving average, weighted moving average, exponential smoothing, linear trend, trendadjusted, or linear regression forecast [14].

Aggregate planning is intermediate-range capacity planning that typically covers a time horizon of 2 to 18 months. It is useful for organizations that experience seasonal or other fluctuations in demand or capacity. The goal of aggregate planning is to achieve a production plan that will effectively utilize the organization’s resources to satisfy expected demand [14].

Master production schedule (MPS) determines the quantities needed to meet demand from all sources, and that governs key decisions and activities throughout the organizations. It interfaces with marketing, capacity planning, production planning, and distribution planning.

MPS enables marketing to make valid delivery

UTCC Engineering Research Papers 2007

243

Proceedings of the 2 nd International Conference on Operations and Supply Chain Management,

May 18-20, 2007, Novotel Bangkok on Siam Square, Bangkok, Thailand commitments to warehouses and final customers, as well as enables production to evaluate capacity requirements.

The master schedule drives the material requirement planning (MRP) system and is an input to MRP [14].

Material requirement planning (MRP) is a computerbased information system that translate the finished product requirements of the master schedule into timephased requirements for subassemblies, component parts, and raw materials, working backward from the due date using lead times and other information to determine when and how much to order. The MRP is designed to describe what is needed, how much is needed, and when is it needed [14].

Collaborative Planning, Forecasting, and Replenishment

(CPFR) is a concept that aims to enhance supply chain integration by supporting and assisting joint practices.

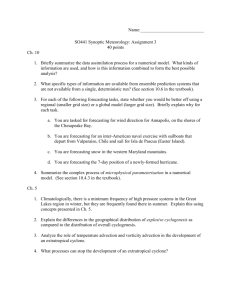

CPFR seeks cooperative management of inventory through joint visibility and replenishment of products throughout the supply chain. Information shared between suppliers and retailers aids in planning and satisfying customer demands through a supportive system of shared information [8]. This allows for continuous updating of inventory and upcoming requirements, making the end-toend supply chain process more efficient. Efficiency is created through the decrease expenditures for merchandizing, inventory, logistics, and transportation across all trading partners (see Figure 1).

Figure 1: CPFR Business Process Scenario workbook

(Source: CPFR.org web site, CPFR 1998, VICS)

In 2001, Aviv analyzed the effect of collaborative forecasting on supply-chain performance. Aviv (2002) extends the CPFR model to auto-correlated demand processes, whereas Aviv (2003) further provides a timeseries framework for supply-chain management.

Chen (2004) provides a review on the role of informationsharing in achieving supply-chain collaboration and the consequences of failing to share (or imperfectly transmitting) it.

Deshpande et, al. (200x) conducted a study in Secure

Collaborative Planning, Forecasting, and Replenishment

(SCPFR). This research developed and applied SMC protocols to the CPFR business process between a single supplier and a single retailer. The primary goal was to demonstrate that collaborative forecasting and inventory planning can be conducted without disclosing private information of any supply-chain partners.

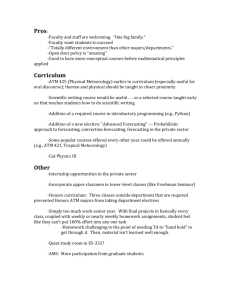

3. Research Methodology

This study analyzed the causes of the problem and proposed the solution to overcome the causes by using a method of “Collaborative Planning Forecasting and

Replenishment.” A number of companies have utilized the CPFR in supply chain management (SCM) by collaborating and sharing information with the partners, thereby reducing cost and leading to high efficiency and effectiveness of inventory management [5].

To analyze the data, this research identified sale volume from forecasting by using Economics Growth Rate in year

2007 with the forecasting sale of 4.7 percents

1

(see

Appendix A). Additionally, identifying the Aggregate

Planning, Master Production Schedule (MPS), and

Material Requirement Planning (MRP) of an exemplary case study will also be developed shown in more detail in

Appendix B, C, and D, respectively.

4. Results

Implementing the CPFR concept that leads to collaboration among supply chain partners of the exemplary company in planning and replenishment indicates the total forecasting sale volume (in year 2007)

1

Source: Office of Thailand Economics and Social Board and Forecasting in Year 2007 Made by Center for

Economy Forecast and Business, University of the Thai

Chamber of Commerce.

244

UTCC Engineering Research Papers 2007

Proceedings of the 2 nd International Conference on Operations and Supply Chain Management,

May 18-20, 2007, Novotel Bangkok on Siam Square, Bangkok, Thailand of Reel Stand products - RM150 and RM250 equals to 69 and 60, respectively (see Figure 1 and 2). Accordingly, the forecasting sale volume of both products was used for preparing the aggregate planning of production shown in

Table 3 (Appendix A), the aggregate planning indicates that a forecasting value equals to production capacity due to the product is a “make to order.” By calculating labor cost per machine, it may cost 9,000 Baht. Over time to produce the machine will cost 11,064 Baht including labor cost per year equals to 1,167,192.00 Baht.

An output of the Aggregate Planning was then used for planning the MPS shown in Appendix B. Table 4 shown in Appendix B identifies the MPS of RM150 and RM250 in year 2007 started from January to December. The MPS is a schedule detailing a volume and type of products to be produced, along with scheduled employee and used raw materials. In this case study, the MPS was made according to a customer order called “Make to Order.”

Such order determined MRP that acquire how much and when to order the product of Reel Stand (RM150 and

RM250) in parallel to constant lead time and on time replenishment. Table 5 in Appendix C illustrates an economic order quantity and reorder point that are used for MRP

Table 1: Sale Forecasting in Year 2007 of

Product: RM150

Month

Actual

Sale

Percentage of Increasing

Economy with 4.7%

1 5.00

2 4.00

6.00

5.00

3 6.00

4 5.00

5 6.00

6 5.00

7.00

6.00

7.00

6.00

7 4.00

8 2.00

9 5.00

10 4.00

11 7.00

12 5.00

Total 58.00

5.00

2.00

6.00

5.00

8.00

6.00

69.00

Table 2: Sale Forecasting in Year 2007 of

Product: RM250

Month

Actual

Sale

Percentage of Increasing

Economy with 4.7%

1 4.00 5.00

2 4.00

3 4.00

5.00

5.00

4 5.00

5 4.00

6 6.00

7 3.00

8 5.00

9 4.00

10 2.00

11 5.00

6.00

5.00

7.00

4.00

6.00

5.00

2.00

6.00

12 3.00 4.00

Total 49.00 60.00

After finding the aggregate planning, MPS, and MRP, this research study investigated how to improve customer response for product delivery and cost reduction of production due to over time in waiting raw materials order receipts. To cope with this problem, it is therefore to implement a concept of CPFR in order to improving a degree of collaboration in business plan between a buyer and a seller that can be of competitiveness for sale volume increase. A benefit of CPFR applicable for supply management is an accuracy of forecasting for product ordering that reduces inventory and a number of processes. Therefore, CPFR enables an integration of business processes and all supply chain participants together can develop a synchronized forecast. Any participant along supply chain such as supplier, manufacturer, or distributor can view and amend forecast data to optimize the process from end to end [9].

Phase I — Planning

The first phase relates to people, processes, and developing of trust. Partners must break down cultural barriers and company-centric perceptions, and must share a unified vision to make the process work. They must define their relationships and identify what processes need to be changed to allow stronger collaboration. On the other hand, suppliers may have to change compensation plans so that shared forecasts can pull information through the processes. Therefore, particular benchmarks and key performance indicators (KPIs) have to be established in order to determine the efficacy of the shared plan [13] . The two major steps in this plan are developing a front-end agreement and creating a joint business plan described as follows:

Step 1: Developing a Front-End Agreement.

Step 2: Crafting a Joint Business Plan.

Phase II — Forecasting

Forecasting begins with a collaborative forecast of enduser demand and continues through all aspects of supply chain planning. It provides support for both long-term and day-to-day decisions. In the second phase, an organization creates the sales forecast, which then feeds into the order

UTCC Engineering Research Papers 2007

245

Proceedings of the 2 nd International Conference on Operations and Supply Chain Management,

May 18-20, 2007, Novotel Bangkok on Siam Square, Bangkok, Thailand forecast. A large quantity of information rapidly permeates the entire process. A single, collaborative forecast is created with dynamic capability to address the complexities in the business environment [13]. The 5 major steps in this plan are described as follows:

Step 3: Forecasting Sales.

Steps 4 and 5: Collaborating to Develop a Shared

Forecast.

Step 6: Forecasting Orders.

Steps 7 and 8: Identifying and Resolving Exceptions.

Phase III — Executing

The final phase of CPFR covers front-end planning and forecasting come, in concert with supply chain execution.

The order needs to be generated and committed to delivery during this phase, enabling successful order delivery execution [13] .

The last 2 major steps in this plan are described as follows:

Step 9: Generating Orders.

Step 10: Executing to the CPFR Plan.

From the above CPFR phases, this research study implemented each steps into a case study of Creative

Machatronics Co., Ltd., Bangkok, Thailand and found that the company could:

• Reduced forecast error.

• Increased in-stock at shelf.

• Decreased account receivables.

• Reduced lead time/cycle time.

• Reduced average network inventory.

• Reduced cost of goods.

• Increased sales.

• Reduced operating expense.

• Share collaborative information and materials.

5. Conclusion and Recommendation

From the results analysis, the stock-out problem was resulted from several causes that might be directly to personnel, warehouse, or inventory management.

Considering the pros and cons of the problem, it was suggested that the exemplary company in the case study need to fully implement the CPFR concept by collaborating and sharing information in order to maximize profit, reduce cost, and improve efficiency and effectiveness of the Reel Stand production in the exemplary company.

In conclusion, CPFR concepts evolved to address critical business inefficiencies and deficiencies between manufacturers and retailers. It has progressed to becoming an accepted solution for enhancing the relationships and operations among these trading partners. The fundamental objective of CPFR is to shift the exemplary company focus from an inward focus to a multi-enterprise view of sharing knowledge and information.

References

[1] Aviv, Y. (2001). The Effect of Collaborative

Forecasting on Supply Chain Performance. Management

Science , 47 1326–1343.

[2] Aviv, Y. (2002). Gaining Benefits from Joint

Forecasting and Replenishment Processes: The Case of

Auto Correlated Demand. Manufacturing & Service

Operations Management , 4 55–74.

[3] Aviv, Y. (2003). A Time-Series Framework for

Supply-Chain Inventory Management. Operations

Research , 51 210–227.

[4] Chantajiraporn, K. (2004). Logistics Management .

Bangkok, Thailand: Office of Industry Promotion.

[5] Chantajiraporn, K. (2003). Collaborative Planning

Forecasting and Replenishment (CPFR). Logistics

Thailand , August 2003, pp 33-43.

[6] Chantanaroj, S. (200x). Production Management . (3 rd

Eds.) School of Business, University of the Thai Chamber of Commerce.

[7] Chen, F. 2004. Information sharing and supply chain coordination. Handbook of Operations Research and

Management Science: Supply Chain Management . North-

Holland, Amsterdam.

[8] CPFR Business Process Scenario workbook (1998).

[Online Available]: www.CPFR.org.

[9] Deshpande, V., Schwarz, L. B., Atallah, Blanton, M.,

Frikken, K. B., and Li, J. (200X). Secure Collaborative

Planning, Forecasting, and Replenishment (SCPFR).

Journal of Management Science , Manuscript.

[10] Haag, S., Maeve, C., Donald, M., Alain, M., and

Richard, D. (2006). Management Information Systems - for the Information Age . Toronto, Canada. McGraw-Hill

Ryerson Publishing.

[11] Lalitaporn, P. (2000). Management of Material

Requirement Planning and Reorder Point . Bangkok,

Thaland: Thai-Japan Technology Institute.

[12] Lalitaporn, P. (2002). Production Planning and

Control . (8 th

Eds.) Bangkok, Thailand: Prachachon.

[13] Peoplesoft (200x). CPFR–Collaborative Planning,

Forecasting, and Replenishment: Delivering Results for

Manufacturers Serving the Retail Sector

[14] Stevenson, W. J. (2007). Operations Management .

(9 th

Eds.), New York, NY: McGraw-Hill Companies.

246

UTCC Engineering Research Papers 2007

UTCC Engineering Research Papers 2007

247

248

UTCC Engineering Research Papers 2007

Proceedings of the 2 nd International Conference on Operations and Supply Chain Management,

May 18-20, 2007, Novotel Bangkok on Siam Square, Bangkok, Thailand

Appendix C

Material Requirement Planning

Table 5: Material Requirement Planning of RM150 for 3 Months Period

Proceedings of the 2 nd International Conference on Operations and Supply Chain Management,

May 18-20, 2007, Novotel Bangkok on Siam Square, Bangkok, Thailand

Appendix C

Material Requirement Planning

Table 5: Material Requirement Planning of RM150 for 3 Months Period

UTCC Engineering Research Papers 2007

249

Proceedings of the 2 nd International Conference on Operations and Supply Chain Management,

May 18-20, 2007, Novotel Bangkok on Siam Square, Bangkok, Thailand

250

UTCC Engineering Research Papers 2007