Production Planning and Control with SAP ERP - beck

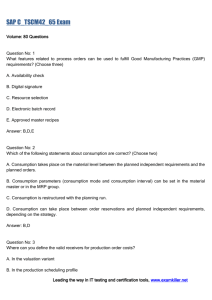

advertisement