Experiment 4: Radiation 1. Introduction 2. Basics

advertisement

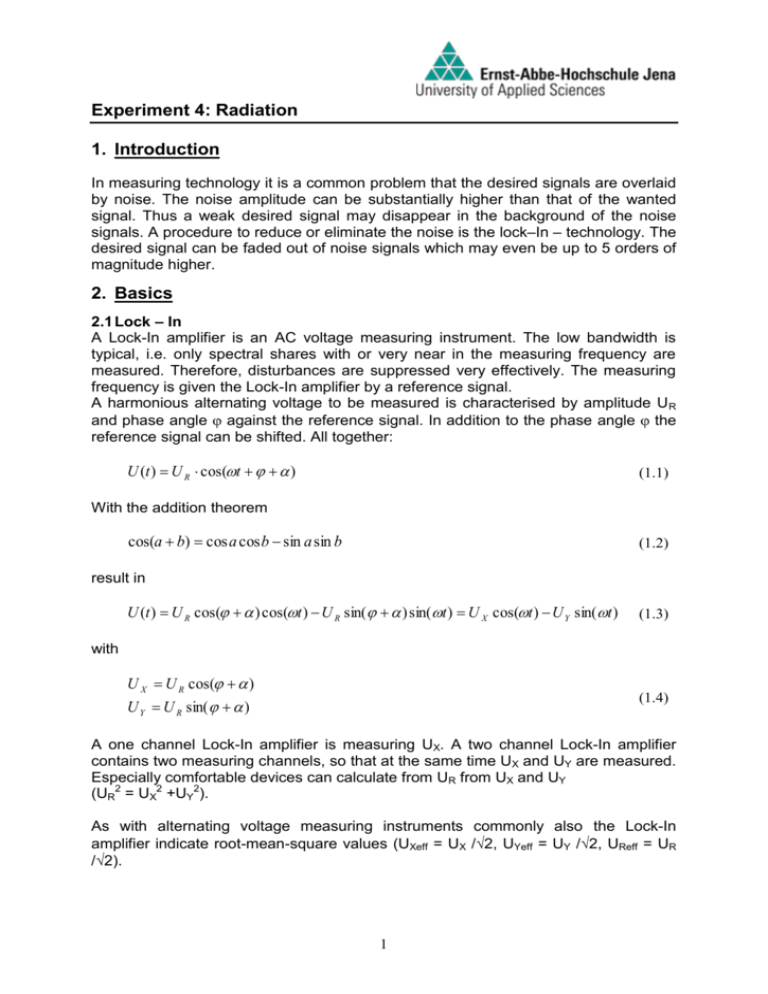

Experiment 4: Radiation 1. Introduction In measuring technology it is a common problem that the desired signals are overlaid by noise. The noise amplitude can be substantially higher than that of the wanted signal. Thus a weak desired signal may disappear in the background of the noise signals. A procedure to reduce or eliminate the noise is the lock–In – technology. The desired signal can be faded out of noise signals which may even be up to 5 orders of magnitude higher. 2. Basics 2.1 Lock – In A Lock-In amplifier is an AC voltage measuring instrument. The low bandwidth is typical, i.e. only spectral shares with or very near in the measuring frequency are measured. Therefore, disturbances are suppressed very effectively. The measuring frequency is given the Lock-In amplifier by a reference signal. A harmonious alternating voltage to be measured is characterised by amplitude U R and phase angle against the reference signal. In addition to the phase angle the reference signal can be shifted. All together: U (t ) U R cos(t ) (1.1) With the addition theorem cos(a b) cos a cos b sin a sin b (1.2) result in U (t ) U R cos( ) cos(t ) U R sin( ) sin(t ) U X cos(t ) U Y sin(t ) (1.3) with U X U R cos( ) (1.4) U Y U R sin( ) A one channel Lock-In amplifier is measuring UX. A two channel Lock-In amplifier contains two measuring channels, so that at the same time UX and UY are measured. Especially comfortable devices can calculate from UR from UX and UY (UR2 = UX2 +UY2). As with alternating voltage measuring instruments commonly also the Lock-In amplifier indicate root-mean-square values (UXeff = UX /2, UYeff = UY /2, UReff = UR /2). 1 The Lock-In amplifier works after one of the following procedures: - Rectification of the modulated measuring signal by means of a synchronous rectifier sensitive to phase (the changeover switch which is synchronised on frequency and phase of the measuring signal) and next smoothing with a lowpass filter - Multiplication of the modulated measuring signal with a sine alternating voltage of the same carrier frequency and next smoothing with a low-pass filter A Lock-In amplifier cannot measure DC voltages. Therefore, DC-signals must be modulated if necessary. In our experiment the Ir radiation is modulated by a cutting wheel (chopper). The reference signal comes from a light barrier which is interrupted by the same chopper. There must be paid attention to the fact that only the measuring signal itself is modulated, because all additional signals (e.g., scattered light) are amplified together with the measuring signal. 2.2 Bolometer Bolometers contain several thermocouples which are connected in row. Their advantage consists in the fact that they work as almost ideal black receivers, i.e. her sensitivity in the Infrared–area is nearly steady. Their disadvantage is the long set time (time constant), in the area between 10ms to 1s. 3. Procedure In the experiment the infrared radiation of a current-heated silicon carbide – hanger are measured with a Bolometer. Standard operating voltage for the IR emitter is 8 V. The current may not cross 2 A. Therefore, put the current limitation to 2 A (short circuit), before you connect the IR emitter. 3.1 Use of the Lock – In – amplifier Heat the IR emitter by putting on a voltage of 8 V (current limitation on 2 A). Put the Bolometer with minimum distance before the IR emitter. Use sensor no.2. Put the height of the used sensor above the table possibly on the height of the IR emitter, so that the ray way is in parallel with the table surface. - Measure the output voltage with the oscilloscope and multimeter Turn the ray on/off by hand. Switch on the chopper, and increase the chopper frequency, change afterwards also the distance of the Bolometer in front of the IR – source. - Check the measuring signals, and write down the observations - Draw in each case the temporal change of the sensor signal for chopper frequency of 0.1 Hz and 10 Hz. - Measure now with the Lock–In – amplifier: Lock–In settings: Measuring area 1mV, time constant 1s, signal input: A, Coupling: DC, Slope: 12db/oct - Choose a frequency of round 8Hz. Adjust the phase in such a way that the x component of the output signal becomes zero (simulation of 1-channel Lock–In – amplifier). 2 - Shift the phase around 90° and read them then the x component. The y component of the output signal must become zero. - Measure now the components with any phase situation and calculate the amplitude. 3.2 Dependence of the output signal versus the chopper frequency Measure the output voltage with chopper frequency between 0.1Hz and 60Hz. Vary the frequency in steps of possibly factor 2. 3.3 Dependence of the output signal versus distance of the Bolometer Set a suitable chopper frequency. - Measure the output voltage with distances of 10... 100cm between emitter and Bolometer. Take up at least 10 value pairs with expressive distances. 3.4 Dependence of the output signal versus the electric power Set the Bolometer again with minimum distance in front of the IR emitter. Regulate the voltage at the IR emitter to 0V and wait so long, until the measuring signal disappears. Increase then the voltage in steps of 0.5V up to 8V. Wait in each case, until the output signal of the sensor becomes stationary. Measure then the sensor signal as well as the current which flows by the IR emitter. 3.5 Dependence of the time constants versus the filling gas Repeat the measurement from 3.2. - Use sensor 3 (filling gas neon) - Use sensor 4 (filling gas nitrogen) Pay attention to the fact that sensor and source are aimed precisely on each other. 3.6 „Unknown sensors“ No.1 and No.5 Repeat the measurement from 3.2. - Use sensor 1 (filling gas helium) - Use sensor 5 (filling gas nitrogen) Pay attention to the fact that sensor and source are aimed precisely on each other. The orientation marks are right on the rider's foot. 4. Evaluation 4.1 Handling with the Lock-In – amplifier - Which conclusions do you get from the observations of the measurements with the oscilloscopes or the multimeter? - How high are the absolute values of the x- and y-components with adjusted phase, minimum distance and 8Hz of chopper frequency? - Estimate the radiation power on the Bolometer by two different considerations. 1. Assume that the electric power is radiated isotropic. 2. Use the sensitivity which is given in the data sheet of the Bolometer (sensitivity of the Bolometer see /25/, TS-100, filling gas is a krypton) - To which temperature difference between measuring element and comparative element does this correspond? (Thermo tension of the used materials see table 3) - The IR - signal is modulated by the chopper roughly rectangle-shaped. Which influence does this have on the measuring result in comparison to for example sine-shaped modulation? 3 4.2 Dependence of the output signal versus the chopper frequency Draw the sensor voltage as a function versus the chopper frequency (transference identity line). (Logarithmic x-y-axis). - Which transference behaviour shows the Bolometer? (Analogy to filters in the electrical engineering) - How high is -3dB – cutoff frequency? - How big is the time constant? (Comparison with/25/) - Which statements can be derived from the time constant for the application of a Bolometer? 4.3 Dependence of the output signal versus the distance of the thermo column Draw the output voltages as a function of the distance in a twice logarithmic graph. - Which dependence do you recognise from the graph which physical principle can you see? 4.4 Dependence of the output signal versus the heating achievement Draw the output signal as a function of the heating power. Describe the dependence qualitatively. 4.5 Dependence of the time constants versus the filling gas Calculate the time constant of the sensors, compare this together, and explain occurrent differences. 4.6 „Unknown sensors“ No.1 and No.5 Compare the measured thermo voltages to those of the sensors 2 – 4 with same measuring conditions. Explain available differences? Use for your argumentation the data sheets in the appendix. 5. References /20/ /21/ /22/ /23/ /24/ /25/ /26/ Niebuhr, J., Lindner, G.: Physikalische Meßtechnik mit Sensoren. Oldenbourg Verlag München, Leipzig, 1996 Ehrhard, D.: Verstärkertechnik. Vieweg Verlag Braunschweig, 1992 Friedrich, W. [Begr.], Rohlfing, H. [Hrsg.]: Tabellenbuch Elektrotechnik, Elektronik, Dümmler, Bonn, 1993 Manual Chopper (Firma Scientific Instruments) Manual Lock-In Verstärker (Firma Stanford Research) Datenblätter Thermosäulen (Firma IPHT Jena) Tabelle Thermospannungen (Quelle: Friedrich, W.: Tabellenbuch Elektrotechnik, Fachbuchverlag Leipzig, 1976, S. 149) 6. Appendix 6.1 Manual SR 830 You find prospectus and manual on the experiment place. 6.2 Manual Oszilloskop HM 1507-2 4 You find the manual on the experiment place. 5 6.3 Data sheet and description TS-72 FEATURES 1. High Sensitivity 2. Rugged Construction 3. Low Cost 4. Broad Spectral Response 5. Self-Generating Voltage 6. No Bias Required 7. No 1/fNoise 8. Ambient Temperature Operation 9. High Reliability 10. Hermetically Sealed 11. Excellent long-term Stability TECHNICAL DESCRIPTION The model TS-72 sensor is a miniaturised multijunction thermopile made by modern thin-film technology on Si wafers. It consists of 72 radially arranged junction pairs formed from evaporated antimony and bismuth thin films. The centrally located active (hot) junctions comprising the active area of 0.24mm 2 are blackened by metallic smoke or an interference absorption multilayer System. The element is hermetically sealed in a small modified TO-5 package under an inert gas atmosphere. In the case of the metallic smoke absorbing layer the thermopile sensor’s broad and flat spectral response from UV to far lR is limited only by the transmission characteristics of the window material selected. Standard window materials are KRS-5 (0.6 ... 40µm) or band pass filter (8 ... 14µm), other materials on request. The output e.m.f. of the sensor is proportional to the temperature difference between the active and the reference junctions. The thermopile requires no cooling and no bias voltage or current for Operation. It generates no 1/f noise but only the thermal resistance (Nyquist) noise. The sensor can be used for DC and low frequency AC measurements. The model TS-72K is a compensated variant of the model TS-72 with all the same Parameters. It contains additionally a contact temperature sensor (e.g. a spreading resistance, IC, or thin-film resistor) near the thermopile reference (cold) junctions for compensation ambient temperature changes (- 20 ... 70°C) by including this additional sensor in a special external circuit. 6 TYPICAL SPECIFICATIONS TS-72 0.24 (0.5mm ) 72 10 ...25 -0.2 ...-0.4 20nV 12 N2 Krypton 130...150 280 -0.35...-0.55 -0.40...-0.65 15...20 30... 40 8 4x10 7.5 x108 2) with Standard window KRS-5 Flat from UV to FIR (dependent on Window Material) Standard: KRS-5; 8-14µm Filter Other Materials on Request 83 ° (KRS-5 Window 4mm) TO-5 Package (modified) - 20 ... + 70°C 2grms Active Area mm2 Number of Junctions Resistance kΩ Resistance TC %/K Noise Voltage nV/Hz1/2 Max. Irradiance mW/mm2 1) Filling Gas DC Responsivity 2) V/W Responsivity TC %/K Time Constant ms 2) D* (500 K, DC) cm Hz1/2/W 1) other filling gases : He, Ne, Xe Spectral Response Window Materials Field of View Case Operating Temperature Weight Window Material useful Spectral Range (µm) Transmission (%) KRS-5 CaF2 Quartz Glass Silicon BP Filter LWP Filter 70 90 90 90 55 75 75 0.6 ... 42 0.2 ... 9 0.2 ... 3 0.4 ... 2 1.1 ... 15 8 ... 14 7.2 cut on APPLICATIONS 12. Non-Contact Temperature Measurements 13. Radiometry 14. Imaging System Requiring Small Spot Size 7 6.4 Data sheet and description TS-100 FEATURES 1. High Sensitivity 2. Rugged Construction 3. Low Cost 4. Broad Spectral Response 5. Self-Generating Voltage 6. No Bias Required 7. No 1/fNoise 8. Ambient Temperature Operation 9. High Reliability 10. Hermetically Sealed 11. Excellent long-term Stability TECHNICAL DESCRIPTION The model TS-100 sensor is a miniaturised multijunction thermopile made by modern thin-film technology. It consists of 100 radially arranged junction pairs formed from evaporated antimony and bismuth thin films. The centrally located active (hot) junctions comprising the active area of 1mm2 are blackened by metallic smoke. The element is hermetically sealed in a small modified TO-5 package under an inert gas atmosphere. The thermopile sensor's broad and flat spectral response from UV to far IR is limited only by the transmission characteristics of the window material selected. Standard window materials are KRS-5 (0.6 ... 40µm) or band pass filter (8 ... 14µm), other materials on request. The output e.m.f. of the sensor is proportional to the temperature difference between the active and the reference junctions. The thermopile requires no cooling and no bias voltage or current for operation. It generates no 1/f noise but only the thermal resistance noise. The sensor can be used for DC and low frequency AC measurements. The model TS-100K is a compensated variant of the model TS-100 with all the same parameters. It contains additionally a contact temperature sensor (e.g. a spreading resistance, IC, or thin-film resistor) near the thermopile reference (cold) junctions for compensation ambient temperature changes (- 20 ... 70°C) by including this additional sensor in a special external circuit. 8 TYPICAL SPECIFICATIONS TS-100 1 (1.13mm ) 100 18 ...43 -0.2 ...-0.4 30nV 12 N2 Krypton 60 ...70 100 … 125 -0.35...-0.55 -0.40...-0.65 40...50 70... 100 8 1x10 2 x108 2) with Standard window KRS-5 Flat from UV to FIR (dependent on Window Material) Standard: KRS-5; 8-14 um Filter Other Materials on Request 83 ° (KRS-5 Window 4mm) TO-5 Package (modified) - 20 ... + 70°C 2grms Active Area mm2 Number of Junctions Resistance kΩ Resistance TC %/K Noise Voltage nV/Hz1/2 Max. Irradiance mW/mm2 Filling Gas 1) DC Responsivity 2) V/W Responsivity TC %/K Time Constant ms D* (500 K, DC)2) cm Hz1/2/W 1) other filling gases : He, Ne, Xe Spectral Response Window Materials Field of View Case Operating Temperature Weight Window Material useful Spectral Range (µm) Transmission (%) KRS-5 CaF2 Quartz Glass Silicon BP Filter LWP Filter 70 90 90 90 55 75 75 0.6 ... 42 0.2 ... 9 0.2 ... 3 0.4 ... 2 1.1 ... 15 8 ... 14 7.2 cut on APPLICATIONS 12. Non-Contact Temperature Measurements 13. Radiometry 14. Imaging System Requiring Small Spot Size 9 6.5 data sheet and description TS-116 FEATURES 1. High Responsivity 2. Rugged Construction 3. Low Cost 4. Broad Spectral Response in the IR 5. Self-Generating Voltage 6. No Bias Required 7. No 1/fNoise 8. Ambient Temperature Operation 9. High Reliability 10. Hermetically Sealed 11. Excellent long-term Stability TECHNICAL DESCRIPTION The model TS-116 sensor is a miniaturised multijunction thermopile made by modern thin-film technology on Si wafers. It consists of 116 rectangularity arranged junction pairs formed from evaporated antimony and bismuth thin films. The centrally located active (hot) junctions comprise an area of 0.25mm2. The whole membrane (1.2 x 1.2mm2) supporting the active layers is coated with an interference absorption multilayer system. The element is hermetically sealed in a small TO-46 package under an inert gas atmosphere. Standard window material is a band pass filter (8 ... 14µm, other materials on request. The output e.m.f. of the sensor is proportional to the temperature difference between the active and the reference junctions. The thermopile requires no cooling and no bias voltage or current for operation. It generates no 1/f noise but only the thermal resistance (Nyquist) noise. The sensor can be used for DC and low frequency AC measurements. The model TS-116K is a compensated variant of the model TS-116 with all the same parameters. It contains additionally a contact temperature sensor (e.g. a spreading resistance, 1C, or thin-film Thermistors) near the thermopile reference (cold) junctions for compensation ambient temperature changes (- 20 ... 70°C) by including this additional sensor in a special external circuit. 10 TYPICAL SPECIFICATIONS TS-116 Active Area mm2 Number of Junctions Resistance kΩ Resistance TC %/K Noise Voltage nV/Hz1/2 Max. Irradiance mW/mm2 Filling Gas 1) DC Responsivity 4) V/W Responsivity TC %/K 2 DC Output (38µW/mm ) mV Time Constant ms 2) D* (500 K, DC) cm Hz1/2/W 1) other filling gases : He, Ne, Xe 1.44 (1.2mm x 1.2mm) 116 60 ...65 -0.2 ...-0.4 33nV 12 N2 Krypton 28 ...32 55 … 60 -0.35...-0.55 -0.40...-0.65 2) 3) 0.8 35...40 65... 75 8 1.1x10 2.1 x108 2) with Standard window 8 … 14µm 3) 500K, 4) KRS-5 Window Flat from 5.5 ... 10µm > 90 % from 5 ... 15um Standard: 8... 14µm Filter Other Materials on Request 80 ° (KRS-5 Window 2.4mm) TO-46 Package - 20 ... + 70°C <1grm Spectral Response Window Materials Field of View Case Operating Temperature Weight Spectral Absorbency of the Multilayer System APPLICATIONS 12. Non-Contact Temperature Measurements 13. Radiometry 14. Imaging System Requiring Small Spot Size 11 6.6 Design In the experiments application, a single Beam is chopped by the outer row of slots, and the reference output from the right BNC is used to lock the Lock-In amplifier to a chop frequency. Note, that inner row of slots could be used, in which case the reference from the left BNC would be used. In either case, the REFERENCE MODE switch is in the “up” position. Detector TS-Sensors IR Source Chopper Controller SR 830 Lock-In f Reference Input Chopper Wheel Abbildung 13: Single Beam Experiment /23/ 6.7 Lock–In – amplifier SR510 /24/ The Lock-In Technique The Lock-In technique is used to detect and measure very small ac signals. A LockIn amplifier can make accurate measurements of small signals even when the signals are obscured by noise sources which may be a thousand times larger. Essentially, a Lock-In is a filter with an arbitrarily narrow bandwidth which is tuned to the frequency of the signal. Such a filter will reject most unwanted noise to allow the signal to be measured. A typical Lock-In application may require a centre frequency of 10kHz and a bandwidth of 0.01 Hz This filter has a 0 of 106 - well beyond the capabilities of passive electronic filters In addition to filtering, a Lock-In also provides gain. For example, a 10 nanovolt signal can be amplified to produce a 10V output - a gain of one billion. All Lock-In measurements share a few basic principles. The technique requires that the experiment be excited at a fixed frequency in a relatively quiet part of the noise spectrum. The Lock-In then detects the response from the experiment in a very narrow bandwidth at the excitation frequency. Applications Include km level light detection, Hall probe and strain gauge measurement, micro-ohm meters, C-V testing in semiconductor research, electron spin and nuclear magnetic resonance studies, as well as a host of other situations which require the detection of small ac signals. A Measurement Example Suppose we wish to measure the resistance of a material, and we have the restriction that we must not dissipate very much power In the sample. If the resistance is about 0.1 Q and the current is restricted to 1 µA then we would expect a 100nV signal from the resistor. There are many noise signals, which would obscure this small signal. 60Hz noise could easily be 1000 times larger, and dc potentials from dissimilar metal junctions could be larger still. 12 In the block diagram shown below we use a Vrms sine wave generator at a frequency r as our reference source. This source is current limited by the 1 MΩ resistor to provide a 1 µA ac excitation to our 0.1 Ω sample. Two signals are provided to the Lock-In. The Vac reference is used to tell the Lock-In the exact frequency of the signal of interest. The Lock-In's Phase-Lock Loop (PLL) circuits will track this input signal frequency without any adjustment by the user. The PLL output may be phase shifted to provide an output of cos(rt +Φ). A high gain ac coupled differential amplifier amplifies the signal from the sample under test. The output of this amplifier is multiplied by the PLL output in the PhaseSensitive Detector (PM). This multiplication shifts each frequency component of the Input signal, s, by the reference frequency, r, so that the output of the PSI) is given by: Vpsd = cos(r t + Φ) cos(s t) = ½ cos[(r + s ) t + Φ] + ½ cos[(r + s ) t + Φ] The sum frequency component is attenuated by the low pass filter, and only those difference frequency components within the low pass filter's narrow bandwidth will pass through to the dc amplifier. Since the low pass filter can have time constants up to 100 seconds, the Lock-In can reject noise, which is more than .0025 Hz away from the reference frequency input. For signals, which are in phase with the reference, the phase control is usually adjusted for zero phase difference between the signal and the reference. Maximising the output signal can do this. A more sensitive technique would be to adjust the phase to null the signal. This places the reference oscillator at 90 degrees with respect to the signal. The phase control can now be shifted by 90 degrees to maximise the signal. Alternatively, since the phase control is well calibrated, the phase of the signal can be measured by adding 90 degrees to the phase setting, which nulls the signal. Understanding the Specifications The table below lists some specifications for the SR510 Lock-In amplifier. Also listed are the error contributions due to each of these items. The specifications will allow a measurement with a 2% accuracy to be made in one minute. We have chosen a reference frequency of 5kHz so as to be in a relatively quiet part of the noise spectrum. This frequency is high enough to avoid low frequency “1/f” noise as well as line noise. The frequency is low enough to avoid phase shifts and amplitude errors due to the RC time constant of the source impedance and the cable capacitance. The full-scale sensitivity of 100nV matches the expected signal from our sample. The sensitivity is calibrated to 1 %. The instruments output stability also affects the measurement accuracy. For the required dynamic reserve, the output stability is 0.1%/°C. For a 10°C temperature change we can expect a 1% error. A front-end noise of 7nV/√Hz will manifest itself as a 1.2nVrms noise after a 10 second low-pass filter since the equivalent noise bandwidth of a single pole filter is 1/4RC. The output will converge exponentially to the final value with a 10 second time constant. If we waft 50 seconds, the output will have come to within 0.70% of its final value. The dynamic reserve of 60dB is required by our expectation that the noise will be a thousand times larger than the signal. Additional dynamic reserve is available by using the band pass and notch filters. 13 A phase-shift error of the PLL tracking circuits will cause a measurement error equal to the cosine of the phase shift error. The SR510 phase accuracy will not make a significant contribution to the measurement error. Specifications for the Example Measurement Specification Full Scale Sensitivity Dynamic Reserve Reference Frequency Gain Accuracy Output Stability Front-End Noise Output Time Constant Total RMS Error Value 100nV 60dB 5kHz 1% 0.1%/°C < 7nV/√Hz > 10s Error 1% 1% 1.2% 0.7% 2% Shielding and Ground Loops In order to achieve the 2% accuracy given in this measurement example, we will have to be careful to minimise the various noise sources, which can be found in the laboratory. (See Appendix A for a brief discussion on noise sources and shielding) While intrinsic noise (Johnson noise, 1/f noise and alike) is not a problem in this measurement. Other noise sources could be a problem. Proper shielding can reduce these noise sources. There are two methods for connecting the Lock-In to the experiment: the first method is more convenient, but the second eliminates spurious pick-up more effectively. In the first method, the Lock-In uses the 'A' input in a 'quasi-differential' mode. Here, the Lock-In detects the signal as the voltage between the centre and outer conductors of the A input. The Lock-In does not force A´s shield to ground, rather it is connected to the Lock-In’s ground via a 10Ω resistor. Because the Lock-In must sense the shield voltage (in order to avoid the large ground loop noise between the experiment and the Lock-In) any noise pickup on the shield will appear as noise to the Lock-In. For a low impedance source (as is the case here) the noise picked up by the shield will also appear on the centre conductor. This is good, because the Lock-In’s 100dB CMRR will reject most of this common mode noise. However, not all of the noise can be rejected, especially the high frequency noise, and so the Lock-In may overload on the high sensitivity ranges. Quasi-Differential Connection The second method of connecting the experiment to the Lock-In is called the “true differential” mode. Here, the Lock-In uses the difference between the centre conductors of the A & B inputs as the input signal. Both of the signal sources are shielded from spurious pick-up. With either method, R is important to minimise both the common mode noise and the common mode signal. Notice that the signal source is held near ground potential in both cases. A signal, which appears on both the A & B inputs, will not be perfectly cancelled: the common mode rejection ratio (CMRR) specifies the degree of cancellation. For low frequencies the CMRR of 100dB indicates that the common mode signal is cancelled to 1 part in 105, but the CMRR decreases by about 6dB/octave (20dB/Decade) starting at 1kHz. Even with a CMRR of 105, a 10mV common mode signal behaves like 100nV differential signal. True-Differential Connection There are some additional considerations in deciding how to operate the Lock-In amplifier: Dynamic Reserve (DR) is the ratio of the largest noise signal that the Lock14 In can tolerate before overload to the full-scale input. Dynamic reserve is usually expressed in dB. Thus a DR of 60dB means that a noise source 1000 times larger than a full scale input can be present at the input without affecting the measurement of the signal. A higher DR results in degraded output stability since most of the gain is DC gain after the phase sensitive detector. In general, the lowest DR, which does not cause an overload, should be used. The Current Input has a 1kΩ input impedance and a current gain of 106 Volts/Amp. Currents from 500nA down to 100fA full scale can be measured. The impedance of the signal source is the most important factor to consider in deciding between voltage and current measurements. For high source impedances, (>1 MΩ or small currents, use the current Input. Its relatively low impedance greatly reduces the amplitude and phase errors caused by the cable capacitance source impedance time constant. The cable capacitance should still be kept small to minimise the high frequency noise gain of the current preamplifier. For moderate source impedances or larger currents, the voltage input is preferred. A small value resistor may be used to shunt the source. The Lock-In then measures the voltage across this resistor. Select the resistor value to keep the source bias voltage small while providing enough signal for the Lock-In to measure. The Auto-Tracking Band pass Filter has a 0 of 5 and follows the reference frequency. The pass band is therefore 115 of the reference frequency. The band pass filter can provide an additional 20dB of dynamic reserve for noise signals at frequencies outside the pass band. The filter also improves the harmonic rejection of the Lock-In. The second harmonic Is attenuated an additional 13dB and higher harmonics are attenuated by 6dB/octave more. You may wish to use the band pass filter and select a low dynamic reserve setting in order to achieve a better output stability. Since the processor can only set the band pass filter's centre frequency to within 1% of the reference frequency, this filter can contribute up to 50 of phase shift error and up to 5% of amplitude error when R is used. In addition, the band pass filter adds a few nanovolts of noise to the front end of the instrument when it is in use. Line Notch Filters should be used in most measurement situations. The filters will reject about 50dB of line frequency noise (about a factor of 300). If your reference frequency is one octave away, then these filters will introduce a 100 phase shift error, and a few percent amplitude error. Their effect on your signal is negligible if your reference frequency is more than two octaves away. The frequency range of the SR510 Lock-In amplifier extends from 0.5Hz to 100KHz. No additional cards are required for the instrument to cover its full frequency range. The SR510 can be used to detect a signal at the reference frequency or at twice the reference frequency to allow for convenient measurement of the harmonic of the signal. Noise measurement is a feature, which allows direct measurement of the noise density of the signal at the reference frequency. This is a useful feature to assess at what frequency you should run your experiment. Output Filters can have one pole (6dB per octave) or two poles (12dB/octave). A two-pole filter provides a signal to noise improvement over a single-pole filter due to its steeper roll off and reduced noise bandwidth. Single-pole filters are preferred when the Lock-In is used in a servo system to avoid oscillation. In many servo applications, no output filtering is needed. In this case, the SR51 0 may be modified to reduce the output time constant to about 20 µS. Contact the factory for details. Ratio Capability allows the Lock-In’s output to be divided by an external voltage input. This feature is important in servo applications to maintain a constant loop gain, and in experiments to normalise a signal to the excitation level. 15 Computer Interface allows a computer to control and to record data from the instrument. This is the single most important feature for extending the Lock-In’s capabilities and it's useful lifetime. Measurements, which are impractical without a computer become simple when a computer is, used to co-ordinate various parts of the experiment. 16