Program 60-100—AGMA Gear Classification and Inspection

advertisement

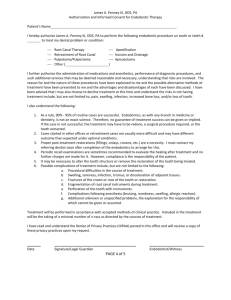

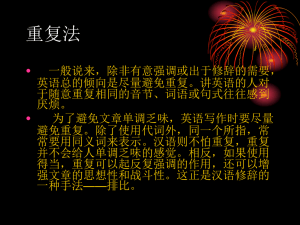

Program 60-100—AGMA Gear Classification and Inspection Handbook Model Introduction This model calculates the dimensional tolerances for unassembled spur, helical, double helical, and herringbone gears in accordance with ANSI/AGMA Standard 2000-A88, Gear Classification and Inspection Handbook. For pitches between .5 and 20 (inclusive), the standard supplies tolerances for runout, pitch, profile, lead, tooth to tooth composite, and total composite depending `upon the quality class. (Composite tolerance is used when checking with a master gear.) For pitches above 20 the standard supplies only the tooth to tooth and total composite tolerances. However, the model furnishes the remaining tolerances for reference. In this case the tolerances are labeled “NOT STD”. If the tooth thickness code is entered the model will furnish the tooth thickness tolerance for the gear if the data is within the scope of the standard for tooth thickness. To use the model in the conventional manner, enter the Quality number and obtain the tolerances. (See Figure 1 and Report 1.) If desired, the actual readings from the gear may be entered and the corresponding Quality number for each element obtained. The Quality number, in this case, will be broken down to the closest tenth to indicate how close the gear is to the closest integer quality number. (See Figure 2 and Report 2.) Examples Figure 1 and Report 1 show the solved model of a 23 tooth spur gear with a 9 AGMA quality class and a tooth thickness tolerance to Code B. Since the tooth thickness code is valid for this gear we obtain the AGMA Quality Number “Q9B”. 1 UTS Integrated Gear Software Fig. 1 Report 1 Model Title : Program 60-100 Unit System: US Description Value AGMA Quality Unit 9 Message-Quality Number OK Tooth Thickness Tolerance Code B Message-Tooth Thickness Tol Code OK AGMA Quality Number Q9B Number of teeth 23 Normal pitch 10.000000 1/in ` Helix angle 0.000000 deg Face width 1.7500 in Transverse pitch 10.000 1/in ` 2 Comment 60-100–AGMA Gear Classification and Inspection Handbook Model Title : Program 60-100 Unit System: US Description Value Reference pitch diameter 2.3000 in Normal module Unit Comment 2.540000 mm ` Transverse module 2.540 mm ` Radial Runout (TIR) 0.00170 in Runout Quality Q# 9.000 m1 OK Pitch Variation +/- 0.00051 in Pitch Quality Q# 9.0000 m2 OK Profile Variation 0.00064 in Profile Quality Q# 9 m3 OK Tooth Alignment 0.00060 in Alignment Quality Q# 9.0000 m4 OK Tooth to Tooth Composite 0.00110 in Tooth Composite Quality Q# 9.0000 m5 OK Total Composite 0.00270 in Total Composite Quality Q# 9.0000 m6 OK Tooth Thickness Tolerance 0.00209 in In this example we entered the AGMA quality number and the AGMA tooth thickness code and obtained the tolerances for the various elements of the gear. 3 UTS Integrated Gear Software Figure 1M and Report 1M show the same data after changing to metric units. Fig. 1M Report 1M Model Title : Program 60-100 Unit System: Metric Description Value AGMA Quality Unit 9 Message-Quality Number OK Tooth Thickness Tolerance Code B Message-Tooth Thickness Tol Code OK AGMA Quality Number Q9B Number of teeth 23 Normal pitch 10.000000 1/in ` Helix angle 0.000000 deg Face width 44.4500 mm 4 Comment 60-100–AGMA Gear Classification and Inspection Handbook Model Title : Program 60-100 Unit System: Metric Description Value Transverse pitch 10.000 1/in ` Reference pitch diameter Unit Comment 58.4200 mm Normal module 2.540000 mm ` Transverse module 2.540 mm ` Radial Runout (TIR) 0.04318 mm Runout Quality Q# 9.000 m1 OK Pitch Variation +/- 0.01295 mm Pitch Quality Q# 9.0000 m2 OK Profile Variation 0.01626 mm Profile Quality Q# 9.0000 m3 OK Tooth Alignment 0.01524 mm Alignment Quality Q# 9.0000 m4 OK Tooth to Tooth Composite 0.02794 mm Tooth Composite Quality Q# 9.0000 m5 OK Total Composite 0.06858 mm Total Composite Quality Q# 9.0000 m6 OK Tooth Thickness Tolerance 0.05302 mm Now we will enter the actual measurements for a gear to find the AGMA Quality Number of the various elements of the gear. Figure 2 is the completed data entry form and Report 2 the solved model for a 23-tooth helical gear. 5 UTS Integrated Gear Software Fig. 2 Report 2 Model Title : Program 60-100 Unit System: US Description Value Unit AGMA Quality Message-Quality Number NA Tooth Thickness Tolerance Code Message-Tooth Thickness Tol Code NA AGMA Quality Number NA Number of teeth 23 Normal pitch 10.000000 1/in ` Helix angle 15.000000 deg Face width 1.0000 in 6 Comment 60-100–AGMA Gear Classification and Inspection Handbook Model Title : Program 60-100 Unit System: US Description Value Transverse pitch Unit Comment 9.659 1/in ` Reference pitch diameter 2.3811 in Normal module 2.540000 mm ` Transverse module 2.630 mm ` Radial Runout (TIR) 0.00280 in Runout Quality Q# 7.500 m1 OK Pitch Variation +/- 0.00075 in Pitch Quality Q# 7.9000 m2 OK Profile Variation 0.00090 in Profile Quality Q# 8 m3 OK Tooth Alignment 0.00040 in Alignment Quality Q# 9.0000 m4 OK Tooth to Tooth Composite 0.00140 in Tooth Composite Quality Q# 8.2000 m5 OK Total Composite 0.00390 in Total Composite Quality Q# 7.9000 m6 OK Tooth Thickness Tolerance NA in Reference Data Extracted from ANSI/AGMA 2000-A88, Gear Classification and Inspection Handbook, with the permission of the publisher, American Gear Manufacturers Association, 1500 King Street, Suite 201, Alexandria, VA 22314. 7