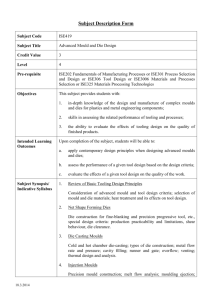

Compression Moulding of SMC, Visualisation and Inverse Modelling

advertisement