ISE419: Advanced Mould and Die Design

advertisement

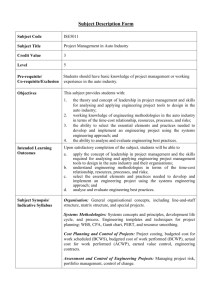

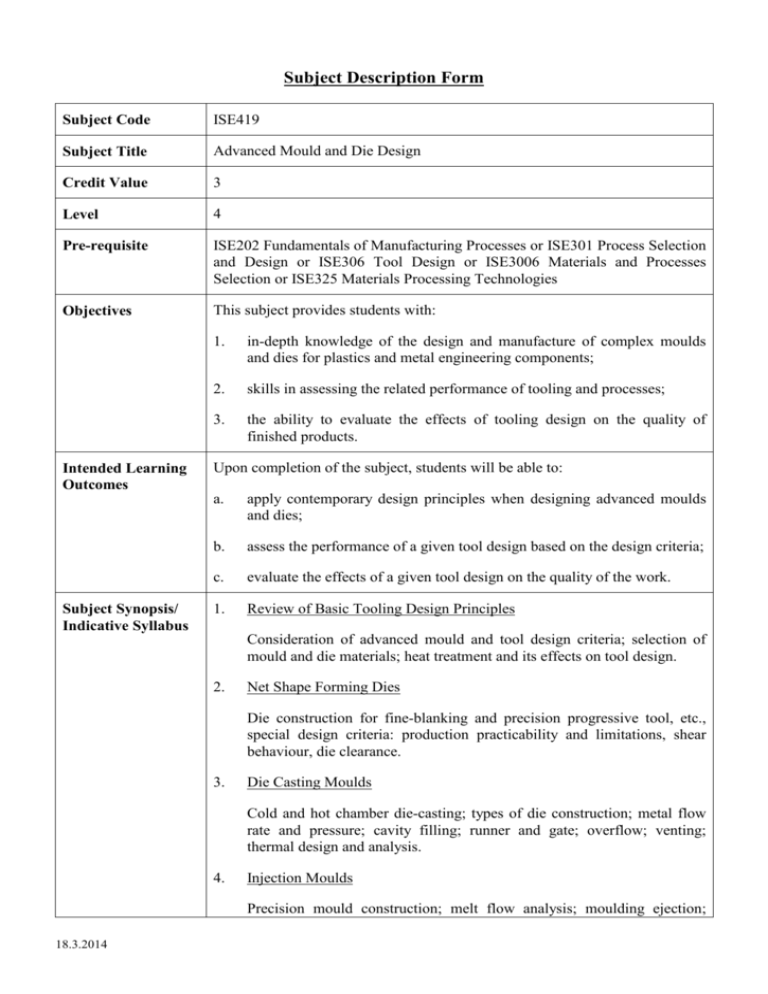

Subject Description Form Subject Code ISE419 Subject Title Advanced Mould and Die Design Credit Value 3 Level 4 Pre-requisite ISE202 Fundamentals of Manufacturing Processes or ISE301 Process Selection and Design or ISE306 Tool Design or ISE3006 Materials and Processes Selection or ISE325 Materials Processing Technologies Objectives This subject provides students with: Intended Learning Outcomes Subject Synopsis/ Indicative Syllabus 1. in-depth knowledge of the design and manufacture of complex moulds and dies for plastics and metal engineering components; 2. skills in assessing the related performance of tooling and processes; 3. the ability to evaluate the effects of tooling design on the quality of finished products. Upon completion of the subject, students will be able to: a. apply contemporary design principles when designing advanced moulds and dies; b. assess the performance of a given tool design based on the design criteria; c. evaluate the effects of a given tool design on the quality of the work. 1. Review of Basic Tooling Design Principles Consideration of advanced mould and tool design criteria; selection of mould and die materials; heat treatment and its effects on tool design. 2. Net Shape Forming Dies Die construction for fine-blanking and precision progressive tool, etc., special design criteria: production practicability and limitations, shear behaviour, die clearance. 3. Die Casting Moulds Cold and hot chamber die-casting; types of die construction; metal flow rate and pressure; cavity filling; runner and gate; overflow; venting; thermal design and analysis. 4. Injection Moulds Precision mould construction; melt flow analysis; moulding ejection; 18.3.2014 cooling and warpage; design for advanced plastics processing. Teaching/Learning Methodology The subject is taught through a combination of lectures and tutorials integrated with practical design mini-projects. The lectures provide students with in-depth knowledge of contemporary mould and die practices. Laboratory work and tutorial exercises provide students with opportunities to learn and apply the teaching materials. Typical mould and die designs are demonstrated and examined to help students to become familiar with real-life practices. Assessment Methods in Alignment with Intended Learning Outcomes Specific assessment methods/tasks % Intended subject learning outcomes to weighting be assessed a b 1. Assignments 20% 2. Tests 40% 3. Mini-group projects 40% Total 100% c The assignments, which are given throughout the course, are designed to facilitate students to reflect on and apply the in-depth knowledge learnt. The tests are designed to enable students to demonstrate their learning ability and comprehension. Continuous assessment comprises all laboratories, tutorials, assignments, progress tests, and mini-group projects with presentations and written reports. All assessment components require students to apply what they have learnt and show their ability to apply different technologies. Student Study Effort Expected Class contact: Lectures 27 Hrs. Tutorials, tests, laboratory work, and miniprojects 12 Hrs. Other student study effort: Assignments 20 Hrs. Test preparation, mini-group projects (including presentation and report writing) 58 Hrs. Total student study effort Reading List and References 18.3.2014 1. 117 Hrs. Donaldson, C, LeCain, GH & Goold, VC, Tool Design, latest edition, McGraw-Hill, New York 18.3.2014 2. Spitler, D, Lantrip, J, Nee, J & Smith, DA, Fundamentals of Tool Design, latest edition, Society of Manufacturing Engineers, Dearborn 3. Eary, DF & Reed, EA, Techniques of Pressworking Sheet Metal, latest edition, Prentice-Hal, Englewood Cliffs, New Jersey 4. Menning, G & Stoeckhert, K, Mold-making Handbook: for the Plastics Engineer, latest edition, Hanser Gardner Publications, Cincinnati 5. Pye, RGW, Injection Mould Design, latest edition, Affiliated East-west Press Pvt Ltd, New Delhi 6. Manzione, LT (ed.), Application of CAE in Injection Moulding, latest edition, Hanser Gardner Publications, Cincinnati 7. Gastrow, H, Injection Molds: 108 Proven Designs, latest edition, Hanser Gardner Publications, Cincinnati 8. Street, AC (ed.), The Diecasting Book, latest edition, Portcullis Press, Redhill, Surrey