anti vibration technology - VIB et TEC

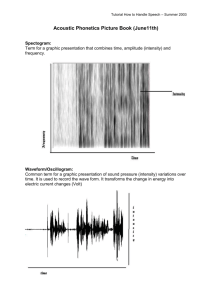

advertisement