risk assessment of distal upper extremity disorders in smes v/s large

advertisement

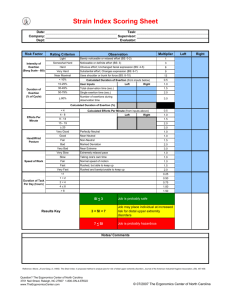

International Journal of Advanced Engineering Technology E-ISSN 0976-3945 Research Article RISK ASSESSMENT OF DISTAL UPPER EXTREMITY DISORDERS IN SMES V/S LARGE SCALE AUTOMOTIVE INDUSTRY USING STRAIN INDEX METHOD L P Singh Address for Correspondence Department of Industrial & Production Engineering, Dr B R Ambedkar National Institute of Technology Jalandhar (Punjab), 144011. India. E Mail lakhi_16@yahoo.com, singhl@nitj.ac.in ABSTRACT Musculoskeletal disorders (MSDs) of upper extremities are associated with highly repetitive occupational activities, especially those involving high force, extreme joint postures and exposure to vibration. Strain index (SI) is a semi-quantitative job analysis methodology based upon principles of physiology, biomechanics and epidemiology for exposure assessment of musculoskeletal stressors of distal upper extremity (DUE). Its purpose is the identification of jobs that place workers at increased risk of developing disorders in the DUE. The present study finds the DUE disorders in workers of small scale forging unit verses a small scale automated casting and large automotive industry of northern India. The average stain Index was found very high (avg=15.35, SD=7.74) in forging unit as compare to automated casting unit and automotive car assembly plant. The workers of small scale units are working > 8 hrs (average 10 hrs/ day). The study concluded that worker of small scale forging units are more prone DUE disorders as compare to an automated casting unit and large automotive industry. It also emphasized on introducing job rotations and low cost automation for material handling devices for higher SI. KEY WORDS: DUE disorders in SMEs, Upper extremities musculoskeletal disorders risk in SMEs. 1. INTRODUCTION upper extremities i.e. extreme joint force with The small scale industry (SSI) of the nation is odd posture. Distal upper extremity (DUE) is contributing a lot for the growth of national defined as the elbow, forearm, wrist, and hand. economy. Most of the small scale units are Distal upper extremity (DUE) disorders are involved either in exports or supplying to the significant occupational health problems like; large scale manufacturers. In the present medial and lateral epicondylitis (tennis elbow), scenario the multinational companies are tendon entrapment at the dorsal wrist and providing better work conditions, sanitation, digits, and and syndrome (hand). There is big lack of emphasizing on better work postures to reduce assessment of job risk factors of such disorders the musculoskeletal disorders (MSDs). At the in same time the workers of small scale biomechanical, or psychophysical models. The manufacturing industry are exposed to various objective of this paper is to briefly discuss and hazards like noise, temperature, dust and risk compare the levels of DUE disorders (using of MSD. The small scale forging units the Strain Index method) of workers deputed to involves various kinds of high repetitive various processes in small scale forging units processes like hot forging, blanking punching, and semi automated casting units. trimming, machining (like: broaching, grinding The Strain Index (SI) was developed by Moore etc.). The Occupation with such high repetitive and Garg [1] and It is primarily a method to activities involves musculoskeletal disorders of “analyze jobs for risk of distal upper extremity occupational health facilities IJAET/Vol.I/ Issue III/Oct.-Dec.,2010/347-357 SSI peritendinitis, using and practical carpal tunnel physiological, International Journal of Advanced Engineering Technology E-ISSN 0976-3945 Disorders”. There are six task variable used to 2. Duration of Exertion: is the proportion of determine the SI score. These variables are the exertion cycle. The average length of both qualitative and quantitative. Each of these the exertion divided by the cycle time variables attempts to quantify the amount of multiplied by 100 gives the duration the percent. physical and physiological strain experienced by the muscle-tendon units of the 3. Efforts per minute: is synonymous with distal upper extremity due to physical activity frequency of exertions per minute. or the stress associated with the task. Each of 4. Hand/wrist posture: relates the anatomical the six task variables is assigned a rating of 1 posture of the hand. to 5 (Table 1 to 7). Three out of the following 5. Speed of work: estimates “the perceived six task variables (Duration of exertion, pace of the task and accounts for the number of exertions/minute and duration of stresses associated with dynamics of work task per day) are quantitative. 6. Duration of task per day: is a measure of 1. Intensity of Exertion: is the force required how much of the workday is allocated to for a single performance of the task. Table. 1 Intensity rating for strain index. Rating criterion %Maximum Borg strength scale Light <10% <2 Somewhat hard 10-29% 4 Hard 30-49% 6 Very hard 50-79% 8 Near maximal >79% 10 performing that task. Perceived effort Rating Barely noticeable or relaxed effort. Noticeable or definite effort. Obvious effort; unchanged facial expression. Substantial effort; changes facial expression. Uses shoulder or trunk to generate force. 1 2 3 4 5 Table2: Percent duration of effort ratings for the strain index. % Duration of effort Rating % Duration of effort <10 1 50 to 65 10 to 19 1.5 65 to 79 20 to 29 2 80 to 90 30 to 39 2.5 >90 40 to 49 3 Table: 3 Efforts per minutes rating for the strain index. Efforts/minutes Ratings <4 1 4 to 6 1.5 6 to 8 2 9 to 11 2.5 12 to 14 3 Table: 4 Hand/wrist rating for the strain index. Rating criterion Very good Good Fair Bad Very bad Wrist extension (degrees) 0-10 11 to 25 26-40 41-55 >55 Wrist flexion (degrees) 0 to 5 6 to 15 16 to 30 31 to 50 >50 IJAET/Vol.I/ Issue III/Oct.-Dec.,2010/347-357 Rating 3.5 4 4.5 5 Efforts/minutes Ratings 15 to 17 18 to 19 20 to 24 >=24 3.5 4 4.5 5 Ulnar deviation (degrees) 0 to 10 11 to 15 16 to 20 21 to 25 >25 Perceived posture Perfectly neutral Near neutral Non-neutral Marked deviation Near extreme Ratings 1 2 3 4 5 International Journal of Advanced Engineering Technology E-ISSN 0976-3945 Table: 5 speed of work for strain index. Rating criterion Perceived speed Rating very slow slow Fair Fast Very fast Extremely relaxed pace Taking one's own time Normal speed of motion Rushed , but able to keep up Rushed and barely or unable to keep up 1 2 3 4 5 Table: 6 duration of task per day ratings for strain index Duration of Task per day (hours) Ratings <1 1 1 to 2 2 2 to 4 3 4 to 8 4 >=8 5 Table: 7 combined rating values for strain index. Rating Intensity of values exertion Duration of exertion 1 light <10 somewhat hard 10 to 29 2 3 hard 30 to 49 4 very hard 50 to 79 near maximal >=80 5 J. S. Moore, and A. Garg,1995 [6] proposed a Efforts per min Hand/ wrist posture Duration per day(hrs) <4 4 to 8 9 to 14 15 to 19 >=20 with the very good 0 to 1 good 1 to 2 fair 2 to 4 bad 4 to 8 very bad >8 same job titles), and some unique job method to analyze jobs for risk of distal upper titles to specific worksites such as (hook extremity disorders and to distinguish between fabricator and deck hand). Authors used jobs which are associated with distal upper different SI computation methods and resulted extremity disorders from those which are not. in significantly different SI scores along with Phillip Drinkaus, Donald S. Bloswick, Richard different risk level classifications calculated by F. Sesek, and Clay Mann, Thomas Bernard [8] the explored one method of modifying the existing Pourmahabadian M., Saraji J.N., Aghabeighi tool, “The Strain Index”, to assess the M. and Saddeghi-Naeen H, 2005 [7] observed ergonomic risk of multi-task jobs in a case more than 50% of investigated jobs are control setting. The author concluded that the categorized as "hazardous" with a significant Strain Index may be modified to estimate the difference between SI mean in hazardous and risk to distal upper extremity ergonomic risk safe jobs (P < 0.0001). Jones T. and Kumar S, injury. Stephen Bao, Peregrin Spielholz, 2007 [3] Observed 0.12 to 0.86 per person per Ninica Howard and Barbara Silverstein, 2009 year worked incidence of upper extremity [9] multi task jobs and evaluated the strain musculoskeletal index for various worksites with job titles occupation (saw-filer). Seth Vishal, Weston including assemblers, painters, and office Roberta Lee and Freivalds Andris, 1999 [10] workers (which performed very different tasks developed a cumulative trauma disorders between the different worksites even though (CTD) risk assessment model for predicting IJAET/Vol.I/ Issue III/Oct.-Dec.,2010/347-357 different computation injury in the methods. sawmill International Journal of Advanced Engineering Technology E-ISSN 0976-3945 injury incidence rates. The model was found is capable of identifying jobs with no distal best suited for job tasks with cycle times upper extremity morbidity as “safe “ and jobs greater than 4 s. Stephens John-Paul, Gordon with distal upper morbidity as “hazardous.” A. Vos, Edward M. Stevens Jr., J. Steven Evidence was provided for the Strain Index’s Moore, 2006 [11] evaluated (by estimating generalizibility and predictive validity. 2002 average and peak hand forces, duration of [1] provided a normal value (<=7) of SI index exertion, cycle time, and exertions per job for reference. cycle, calculated percent duration of exertion 2.1 Material and method and efforts per minute, and assigned ratings for The study was done in small scale forging unit five of the six Strain Index task variables) the without automation, a semi automated casting test–retest repeatability of published data unit and a large scale automotive car assembly collection and rating methods of the Strain industry in northern India. A sample of at 50 Index by analyzing 61 jobs, twice over a 5- workers deputed at various repetitive tasks in month period and found that the Strain Index each small scale forging and casting units was has good test–retest reliability. Moore J. selected. In small scale casting and forging Steven and Garg Arun, 1998 [5] evaluated the units data was collected in two parts first effectiveness through of a corporate ergonomics personal interviews and second program that used a participatory approach to through video analysis whereas in large scale solving problems related to musculoskeletal automotive plant data was collected through hazards. The video analysis only. Corporation experienced a A comprehensive significant decrease in the percentage of questioner was developed for calculating the recordable disorders related to musculoskeletal self reported Strain Index (SI) (Appendix A). risk factors; a marked decrease in the lost-time Each question was asked in local language and incidence rate; and a marked decrease in total the worker was explained about the strain and per capita annual workers' compensation parameters. costs. Ling LEI and Youxin LIANG [4] 2.1.1 SI Calculation studied to clarify the prevalence and risk Each task was observed and six aspects of each factors musculoskeletal task were recorded and compared with disorders (WMSDs) among foundry workers quantitative and qualitative measures provided and found the dominance of lower back pain by the SI authors. Ratings correspond with with highest rank followed by shoulder, neck, each measure. These metrics and their wrist and hand pain regardless of the job title. corresponding ratings are presented in tables 1- The authors suggested that pain occurring in 6, summarized in Table 7 and the multipliers the lower back, neck and shoulder are the for each rating are shown in table 8. predominant ergonomic problems in the metal 2.1.1.1 Intensity of Exertion is an estimate of casting industry. Garg Arun, Moore J. Steven,. the strength required to perform the task one Kapellusch Jay M, 2007 [2] presented three time. There are five rating criterion used for different studies showing that strain Index (SI) this variable: “Light”, “Somewhat Hard”, of work-related IJAET/Vol.I/ Issue III/Oct.-Dec.,2010/347-357 International Journal of Advanced Engineering Technology E-ISSN 0976-3945 “Hard”, “Very Hard” and, “Near Maximal”. In the present study case jobs at various These criteria can be linked to percent sections in each industry were identified. maximal strength, the ten-point Borg Scale, Videos of each job were recorded and and Perceived Effort. Table 1 illustrates these observed. The focus for videography was the relationships. upper extremities of the worker. Repeated Duration of Exertion is calculated videography was done to ensure that the full by measuring the duration of all exertions cycle of the worker was covered so that the during an observation period, then dividing the focus area was clear. Each job was divided into measured total work elements or tasks, these tasks are defined observation time and multiplying by 100. For as sub-activities of a job that could be done the purpose of this study the total observation before transferring the job to next workstation. time is the cycle time. Usually these tasks involve the same motion 2.1.1.2 effort duration by the and intensity of efforts in the repetitive cycles. The next step was to calculate the cycle time 2.1.1.3 Efforts per Minute are determined by by taking three observation of full cycle at the counting the number of exertions that occur factory shop floor and taking the average. In during an observation period, then dividing the each cycle two time attributes were measured number of exertions per cycle by the duration with a stopwatch. The first timed attribute was of the observation period, measured in the total time of the cycle and second was minutes. effort duration. Effort duration is the time during which the operator is exerting a significant force for that task. This time of 2.1.1.4 Hand/Wrist Posture is an estimate of exertion is used to determine the ‘Duration of the hand or wrist position relative to neutral. Effort’ SI variable. The quantitative and qualitative markers are 2.3 presented in Table 4. After videography at the entire line of sections, 2.1.1.5 Speed of Work is an estimate of how the analysis on the videos was carried out by a fast the worker is working. The rating criterion team of 3 members, in order to diminish the guidelines are presented in Table 5. biasness. During the video analysis, the three 2.1.1.6 Duration of Task per Day is a parameters Cycle time, No of efforts/minute measure of the total time that a task is and Duration of exertion were calculated. performed per day. It is either measured or Afterwards the ratings for two parameters (No obtained from plant personnel. Duration of of efforts/minute & Duration of Exertion) was Task per Day is divided into five categories: done. The three parameters Intensity of <1hr, 1-2 hrs, 2-4 hrs, 4-8 hrs and, ≥8 hrs per Exertion, Hand Wrist movement and Speed of day and the ratings are presented in Table 6. work were judged for their ratings. Since as 2.2 per the survey shift for the worker is >10 hrs, Data collection Analysis of video hence the average duration of task per day was IJAET/Vol.I/ Issue III/Oct.-Dec.,2010/347-357 International Journal of Advanced Engineering Technology E-ISSN 0976-3945 taken as 10 hrs and a rating of 1.75 was given kind of unit are shown in Appendix-B. The for DDM. Rating for the wrong or difficult data reveals that the automation in casting has posture was inculcated in the Hand wrist rating reduced SI score significantly, and thus the itself. risk of DUE disorders has been reduced except 2.4 Determine the multipliers the tasks like molding and grinding of medium Each variable’s multiplier is determined by its components of automobile or valves. However rating. The relationship between the SI rating workers are having problems of back ache, scores and the SI multipliers are illustrated in neck stiffness but DUE disorders are found Table 8. less in the tasks under consideration. The job Calculations of SI Index of forger in hammer section was near the On the basis of the ratings obtained during the normal SI value (7.0) [1] in standard method as video analysis, six multipliers were obtained in well as in self reported subjective response. accordance to the same. The multipliers are The job of rope puller was found to be highly Intensity of exertion (IEM), Duration of strained in upper limbs with highest SI value exertion (DEM), Efforts per minute (EMM), both in video as well as in self reporting Hands/wrist posture (HPM), Speed of work response analysis. The workers performing (SWM) and Duration per day multiplier other tasks were also prone to high strain (DDM). On the basis of the multipliers, the SI except in broaching and grinding of small size Index was calculated as: components. The majority of the workers are Strain Index; found with high strain index. It is very clear from the overall SI score that workers of small 3.1 RESULTS AND DISCUSSIONS scale forging industry are highly exposed to The SI score obtained through video analysis distal upper extremities strain as compare to of tasks and self reported SI score at different semi automated small casting unit. It is sections is shown in Tables 9 to 11. In forging therefore observed that there is a dire need of unit SI score calculated from video analysis implementing the job rotation on highly ranges from 6.56 to 26.25 (avg=15.35, stained jobs to lower the possibility of SD=7.74) where as the SI score obtained musculoskeletal disorders of upper limbs with through subjective responses ranges from 5.25 provision of regular rest pauses. The study to 23. 62 (avg=14.72, SD=7.42). In casting therefore recommends that time standards for unit the SI ranges from 3.52 to 17.35 workers performance levels should be prepared (avg=7.52, SD=4.62) where as the self by incorporating the job rotation as well as the reported SI ranges from 4.25 to 19.25 regular rest pauses. It is also recommended (avg=8.78, SD=5.03). The average SI score of that low cost automation and gravity chutes automated car assembly unit is 8.5 (SD = must be introduced for material handling at 4.72). The comparison of average SI score of small distances. the three plants is shown in figure1. The As far as the self reporting SI values are calculations of SI for each work station in each concerned, these were found at lower side IJAET/Vol.I/ Issue III/Oct.-Dec.,2010/347-357 International Journal of Advanced Engineering Technology E-ISSN 0976-3945 (except hot material handling task) as compare Although the SI values of forging unit found to the SI values found by the video analysis, by both methods differed by (-0.44 to 7.00), which can be attributed to the following even there was significant correlation (0.5547 reasons: at 99 % confidence level) for forging section 1. The workers subject to the study have and (0.5305 at 99 % confidence level) for been working at the same job for at least machining section between the SI score 5 years and thus they have become obtained by both the methods. There was a habitual of working at the observed level highest difference between average video of intensity and speed of work. Therefore analysis SI score and self reported SI score for they perceive the job as less strenuous. hot material handling (from furnace to forger) The majority of the workers were at forging section (Table 9). The reason for habitual smokers and tobacco consumers, high self reported SI score for hot material which could be one of the reasons that handling task could be that the workers may the workers do not feel much strain. feel high strained due to high ambient The majority of the workers are illiterate temperature and insufficient ventilation. 2. 3. or less educated; therefore they are not aware of musculoskeletal disorders caused by strenuous repetitive jobs. Table:8 Multipliers for strain index Rating values 1 1.5 2 2.5 3 3.5 4 4.5 5 Intensity of exertion multiplier (IEM) 1 2 3 4.5 6 7.5 9 11 13 Duration of exertion multiplier (DEM) 0.5 0.75 1 1.25 1.5 1.75 2 2.5 3 Efforts per minute multiplier (EMM) 0.5 0.75 1 1.25 1.5 1.75 2 2.5 3 Hands/wrist posture multiplier (HPM) 1 1 1 1.25 1.5 1.75 2 2.5 3 Figure 1 Overall Average SI of casting, forging and car assembly line. IJAET/Vol.I/ Issue III/Oct.-Dec.,2010/347-357 Speed of work multiplier (SWM) 1 1 1 1 1 1.25 1.5 1.75 2 Duration per day multiplier (DDM) 0.25 0.375 0.5 0.625 0.75 0.875 1 1.25 1.5 International Journal of Advanced Engineering Technology E-ISSN 0976-3945 Table.9 Strain Index score associated with various processes in forging unit. Sr. No. Forging Section 1) 2) 3) Machining Section 1) Section Job Description Rope puller Small Forger Components Hot material handler Rope puller Medium Forger Components Hot material handler Rope puller Large Forger Components Hot material handler Punching section 2) Broaching section 3) Grinding section Large component1 Very small Components 2 Medium Components 3 Small Components 4 Small Components1 Medium Components 2 Large Components 3 Belt grinding small components1 Duplex grinding Medium Components 2 Duplex grinding Large components 3 Wheel grinding 4 Average (SI) Std. Deviation (SI) Strain Index (SI) Video Analysis 26.25 9.84 14.76 26.25 8.20 14.76 21.00 6.56 19.68 Strain Index (SI) Self reported 15.75 5.25 23.63 18.38 7.88 23.63 18.38 9.18 23.63 27.56 8.20 13.13 9.84 6.56 9.18 10.5 6.56 15.75 9.84 15.75 9.84 7.87 9.18 10.5 7.87 26.25 31.5 26.25 7.00 15.75 15.35 7.74 23.62 14.72 7.42 Table.10 SI Strain Index score associated with various processes in automated casting unit. IJAET/Vol.I/ Issue III/Oct.-Dec.,2010/347-357 International Journal of Advanced Engineering Technology Sr No. 1 2 3 4 5 6 7 8 9 10 11 12 Job Description Cleaning and Matching of Moulding Boxes Clamp Fitting at Moulding boxes (1) Strain Index (SI) Video Analysis 3.52 4.69 Clamp Fitting at Moulding boxes(2) Large M/C Moulding man(1) Large M/C Moulding man(2) M/C molder (Medium box) machine control M/C molder (Medium box) with shoveling M/C molder (small box) machine control M/C molder (small box) with shoveling Manual Moulding Grinding (small components) Grinding (medium Components) Average (SI) Std. Deviation (SI) 4.10 3.94 4.50 7.20 13.12 4.50 6.56 7.03 13.75 17.35 7.52 4.62 E-ISSN 0976-3945 Strain Index (SI) Self reported 4.25 5.60 5.20 3.65 4.56 8.10 15.90 6.89 10.25 8.15 13.67 19.25 8.78 5.03 Table.11 Average SI Strain Index score associated with various processes in automated car assembly unit. Assembly line Trim-1 Trim-2 Trim-3 Chassis 1 Chassis 2 Final Assembly Grand Average Average SI Score 7.87 8.44 6.71 10.99 8.4 8.59 SD of SI Score 2.21 4.44 4.07 6.97 5.3 5.34 8.5 4.72 4.1 CONCLUSIONS: The following conclusions were drawn from the study: 1. The highly strained jobs should be rotated after every 2-4 hours with the low SI score jobs. 2. For the non rotatable jobs regular rest pauses must be provided for job at various sections of forging units. 3. The automation in small scale casting unit has resulted with lower SI score. 4. The low cost automation should be implemented for material handling and lifting. 5. Performance standards should be calculated by incorporating rest pauses to minimize the rate of DUE disorders. 5.1 ACKNOWLEDGEMENT The authors acknowledge the co-operation and help extended by the management and the workers of small scale (casting &forging units) and large scale manufacturing plant, for conducting personal interviews, making observations and videography at each section very thoroughly. Appendix-A IJAET/Vol.I/ Issue III/Oct.-Dec.,2010/347-357 International Journal of Advanced Engineering Technology E-ISSN 0976-3945 Questionnaire for Interview. Q.1 How much effort do you exert during work? a) Light, b) Somewhat hard, c) Hard, d) Very hard, e) Extreme Q.2 Do you get adequate rest pauses during work cycles? a) Maximum, b) More than adequate, c) Adequate, d) Least, e)Not at all Q.3 What is the frequency of efforts exerted (per minutes) by your upper limbs? a) Least, b) Moderate, c)Tolerable, d) More than tolerable, d) Maximum Q.4 What is the posture of your upper limbs during work? a) Very good, b) Good, c) Fair, d) Bad, e) Very bad Q.5 At what pace you are required to perform your task? a) Very slow, b) Slow, c) Fair, d)Fast, e) Very fast Q.6.What is working time /day? a) Up to 8 hours, b) to 10 hours, c) >10 hours Q.7 Do you tobacco / smoke at work place? a) Yes b) No (Signature of Worker) REFERENCES 1. 2. 3. 4. Ergonomics Today @ ergoweb August 20, 2002. Garg Arun, Moore J. Steven, and Kapellusch Jay M, “The Strain Index to Analyze Jobs for Risk of Distal Upper Extremity Disorders: Model Validation”; Proceedings of the 2007 IEEE IEEM. Jones T. and Kumar S, 2007, Comparison of ergonomic risk assessments in a repetitive high-risk sawmill occupation: Saw-filer, International Journal of Industrial Ergonomics, 37, 744–753. Ling LEI and Youxin LIANG, “Prevalence and risk factors of musculoskeletal disorders of foundry workers”; Department of Occupational Health, FUDAN University School of Public Health 138 Yixueyuan Rd., Shanghai, China. IJAET/Vol.I/ Issue III/Oct.-Dec.,2010/347-357 5. 6. 7. 8. Moore J. Steven and Garg Arun, 1998, The effectiveness of participatory ergonomics in the red meat packing industry, Evaluation of a corporation, International Journal of Industrial Ergonomics, 21, 47-58. Moore J. S., and Garg A, 1995, The Strain Index: A Proposed Method to Analyze Jobs For Risk Of Distal Upper Extremity Disorders, American Industrial Hygiene Association Journal, 56. Pourmahabadian M., Saraji J.N., Aghabeighi M. and Saddeghi-Naeen H. 2005, Risk assessment of developing distal upper extremity disorders by strain index method in an assembling electronic industry, Acta Medica Iranica, 43(5), 347-354, 14 Feb. Phillip Drinkaus, Donald S. Bloswick, Richard F. and Sesek, Clay Mann, Thomas Bernard, “The strain index: Using task level outputs to evaluate job risk”, University of Utah. International Journal of Advanced Engineering Technology 9. 10. Stephen Bao, Peregrin Spielholz, Ninica Howard and Barbara Silverstein, 2009, Application of the Strain Index in multiple task jobs, accepted 26 January 2008, Applied Ergonomics 40, 56–68. Seth Vishal, Weston Roberta Lee and Freivalds Andris, 1999, Development of a cumulative trauma disorder risk assessment IJAET/Vol.I/ Issue III/Oct.-Dec.,2010/347-357 11. E-ISSN 0976-3945 model for the upper extremities, International Journal of Industrial Ergonomics, 23, 281291. Stephens John-Paul, Gordon A. Vos and Edward M. Stevens Jr., J. Steven Moore, 2006 “Test–retest repeatability of the Strain Index”; Applied Ergonomics 37, 275–281.