Unit 2.2: Physical & Chemical Properties

advertisement

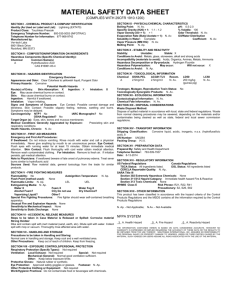

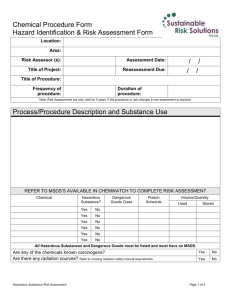

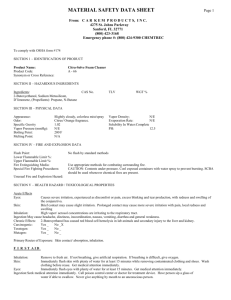

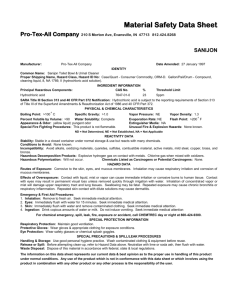

INSTRUCTOR GUIDE Unit 2.2 Physical & Chemical Properties INSTRUCTOR GUIDE TERMINAL OBJECTIVE The participant shall identify the physical and chemical properties which are key to determining the basic hazards and risks associated with a hazardous material or WMD product. FLORIDA OPERATIONS LEVEL HAZARDOUS MATERIALS TRAINING PROGRAM IG – 2.2 – 2 UNIT 2.2 — PHYSICAL AND CHEMICAL PROPERTIES EDUCATIONAL OBJECTIVES Identify two ways to obtain a MSDS in an emergency. (1.2.2) Using a MSDS for a specified material, identify the following hazard and response information: • Physical and chemical characteristics • Physical hazards of the material • Health hazards of the material • Signs and symptoms of exposure (1.2.3) Describe the important chemical and physical properties of hazardous materials. Match the following chemical and physical properties with their significance and impact on the behavior of the container and/or its contents: • Boiling point • Chemical reactivity • Corrosivity (pH) • Flammable (explosive) range (LEL & UEL) • Flash point • Ignition (auto ignition) temperature • Particle size • Persistence • Physical state (solid, liquid, gas) • Radiation (ionizing and non-ionizing) • Specific gravity • Toxic products of combustion • Vapor density • Vapor pressure • Water solubility (1.3.1.1) Describe the properties and characteristics of the following: • Alpha radiation • Beta radiation • Gamma radiation • Neutron radiation (1.2.9) Match the definitions associated with the UN/DOT hazard classes and divisions of hazardous materials/WMD, including refrigerated liquefied gases and cryogenic liquids, with the class or division. (1.2.1) UNIT TIMELINE IG – 2.2 – 3 FLORIDA OPERATIONS LEVEL HAZARDOUS MATERIALS TRAINING PROGRAM DURATION 5 min. 20 min. 10 min. 10 min. 10 min. 60 min. 10 min. 5 min. 20 min. 20 min. 10 min. 30 min. TYPE Lecture Lecture Video Discussion Video Discussion Video Discussion Discussion Discussion Review Activity 2.2 4 hrs TOTAL TITLE Gathering Product Information Sources of Product Information Introduction to CHEMTREC Contents of MSDS and Physical Properties Physical Properties Contents of MSDS and Chemical Properties Chemical Reactions Contents of MSDS (continued) Radioactive Hazards DOT Hazard Classes Summary Assessing Physical and Chemical Properties REQUIRED MATERIALS - Visuals for Unit 2.2 A Material Safety Data Sheet for each participant. The instructor should select a MSDS that is common in the community or of unique community concern A North American Emergency Response Guide Book (NAERG) for each participant A NIOSH Pocket Guide to Chemical Hazards for each participant Video “Introduction to CHEMTREC” Video “Physical Properties” Video “Chemical Properties” Sample set of DOT placards and labels for use in discussion on hazard classes ATTITUDES TO FOSTER In this unit the participants will be introduced to the various physical and chemical properties of hazardous materials. The participants must understand the impact of those properties upon the determination of response objectives. IG – 2.2 – 4 UNIT 2.2 — PHYSICAL AND CHEMICAL PROPERTIES IG – 2.2 – 5 FLORIDA OPERATIONS LEVEL HAZARDOUS MATERIALS TRAINING PROGRAM I) GATHERING PRODUCT INFORMATION (5 MINUTES) A) Hazard class using the NAERG is the minimum amount of information needed Explain that the NAERG gives us only limited information and that we may need more or better information to successfully handle the scene. The NAERG is designed for the first 15 to 20 minutes of the incident. B) Physical and chemical properties 1) Physical properties describe how a material will physically act within the environment. Physical properties include: (a) Physical state (solid, liquid or gas) (b) Phase changes (melting point, boiling point and sublimation) (c) Vapor pressure (d) Specific gravity (e) Vapor density (f) Solubility 2) Chemical properties describe how a material will chemically act. Examples of chemical properties include: (a) Flammability (flammable range, ignition temperature) (b) Reactivity (corrosivity, chemical incompatibilities, polymerization) (c) Toxicity (exposure limits, routes of exposure and physiological effects) (d) Radioactivity IG – 2.2 – 6 UNIT 2.2 — PHYSICAL AND CHEMICAL PROPERTIES These properties will be discussed later in more detail. This is only intended to be an introduction to the topic matter that will be presented. II) SOURCES OF PRODUCT INFORMATION (20 MINUTES) A) Electronic sources 1) CAMEO 2) Chemknowlege 3) Internet search Explain to the participant that there are numerous electronic resources available. In this class we will discuss how to use the NAERG, NIOSH Pocket Guide, and Material Safety Data Sheets. Most of these can be found in an electronic version or online. B) Those commonly available to the operations level responder 1) The North American Emergency Response Guidebook (NAERG) 2) NIOSH Pocket Guide to Chemical Hazards 3) EPlan 4) Material Safety Data sheets (MSDS) C) North American Emergency Response Guide Book (NAERG) 1) Participants were trained to use this guidebook during awareness level training. 2) Operations level responders must insure that these minimum actions have been implemented. IG – 2.2 – 7 FLORIDA OPERATIONS LEVEL HAZARDOUS MATERIALS TRAINING PROGRAM The participants should already be very familiar with this document. Depending upon the participants, the instructor may wish to take a few minutes to insure an understanding of how to properly use this reference. 3) Guide for the first 15 – 20 minutes of the incident 4) Has limited information on chemicals 5) Does not list all chemicals 6) In order to use it, you need working knowledge of the guide Make sure the participants have a working knowledge of how to use the guide and discuss the limitations of the system. Also, discuss the limitations of the placarding system we use today for vehicles, e.g. 1000 lb. rule, 5000 lb. rule and difficulty in enforcement. Discussion of each hazard class will come later. D) NIOSH Pocket Guide o Chemical Hazards 1) Put out by the National Institute of Safety and Health 2) Need to have a basic understanding of the book 3) Limited number of chemicals listed 4) Short, abbreviated, concise information 5) Good tool to use on scene Give the participants a basic overview of how to use the pocket guide. Also, discuss the abbreviations used and their meanings. E) CHEMTREC Show Video (10 Minutes) IG – 2.2 – 8 UNIT 2.2 — PHYSICAL AND CHEMICAL PROPERTIES Introduction to CHEMTREC 1) CHEMTREC (1–800–424–9300). You need the following information: (a) Caller's name and call back number (b) NAERG guide page number being used (c) Name of shipper or manufacturer (d) Rail car or truck number (e) Carrier's name (f) The consignee (g) Local conditions (h) Shipper 2) Retailer 3) Manufacturer 4) Other users 5) Worker or Community Right-to-Know files on file at the fire department Under OSHA 29 CFR 1910.1200 the OSHA “Hazard Communication Standard” the employer must maintain MSD sheets on chemicals that they use, sell or manufacture. In some areas these businesses must also notify the local department of the chemicals stored on site and provide the department with a copy of the MSDS on request. This information can be of significant help when pre-planning a facility or just looking into the chemicals stored in your area. If there is a shipping accident you can obtain MSD sheets from known retailers in your area or possibly another business that uses the same chemical. The people from such a business may be a good resource for handling guidelines. IG – 2.2 – 9 FLORIDA OPERATIONS LEVEL HAZARDOUS MATERIALS TRAINING PROGRAM III) CONTENTS OF THE MSDS AND PHYSICAL/CHEMICAL PROPERTIES (45 MINUTES) A) Basic design 1) Nine sections 2) Various designs 3) Some are of poor quality B) Nine basic sections Have the participant follow along with a sample MSDS sheet. The instructor should select an MSDS for a material that is commonly found or of unique community concern. Participants should use the MSDS as the organizational scheme to help keep them focused with the program flow. 1) Product and manufacturer information (a) Emergency contact number 2) Hazardous ingredients (compounds, etc.) (a) Must match MSDS to specific chemical (b) May be listed as a mix for trade secrecy and just gives hazards if the ingredients (c) C.A.S. Number • Chemical Abstract Service • A unique number assigned to each registered chemical compound • Average 50,000 new chemicals monthly (d) Any hazardous substance found in a concentration of >1% will be listed IG – 2.2 – 10 UNIT 2.2 — PHYSICAL AND CHEMICAL PROPERTIES (e) Exposure limits — Also found in NIOSH Pocket Guide • Need basic understanding to help with decision making process • Time Weighted Average (TWA) — Average for 8 hour day, 40 hour week • Short Term Exposure Limit (S.T.E.L.) — Can reach this level for 15 minutes with a 60 minute break in between for no more than 4 times daily • Ceiling Limit (C) — Must never be exceeded without personal protective equipment Discuss the relationship between TWA, S.T.E.L. and Ceiling Limit. Insure that the participants understand the relationship between these values. The instructor may wish to direct the participants to the definitions of these values in the front of the NIOSH pocket guide • Immediately Dangerous to Life and Health (IDLH) — Effects may be acute or chronic • Acute Exposure Guidelines Levels (AEGL) — Guidelines for acute exposures to chemicals – AEGL1 — Airborne concentration above which will cause notable discomfort IG – 2.2 – 11 FLORIDA OPERATIONS LEVEL HAZARDOUS MATERIALS TRAINING PROGRAM – AEGL2 — Airborne concentration above which will cause irreversible or long lasting health effects – AEGL3 — Airborne concentration above which will cause life-threatening health effects or death 3) Physical data Show Video (10 minutes) Physical Properties (a) Physical properties describe how a material will physically act (b) Describes a condition, not reactivity (c) Helps predict the PHYSICAL behavior of the material (d) Aides in the selection of PPE and control methods (e) Physical state — Solid, liquid or gas • Most can exist in more than one state (f) Phase change — Going from one state to another IG – 2.2 – 12 • Melting point (M. P.) and freezing point (F.P.) • Vapor pressure (V.P.) UNIT 2.2 — PHYSICAL AND CHEMICAL PROPERTIES Vapor pressure is the pressure exerted by a substance against atmospheric pressure. Insure that the participants understand that all liquids (and some solids) give off vapors. The vapor pressure determines the rate at which those vapors will be released. The higher the vapor pressure, the greater the release of vapors or the faster the evaporation from the liquid state to the vapor state. The higher the vapor pressure, the more volatile the product and the greater the chance for air borne exposure. • Boiling point (B.P.) The boiling point is the temperature at which the vapor pressure of a material equals atmospheric pressure (760 mm/hg). At this point the material will release vapors at the fastest possible rate. Discuss the relationship between B.P. and V.P. • Sublimation Sublimation refers to the ability of a solid to change to a vapor without becoming a liquid. Discuss the relationship of each and discuss how each may effect how the product behaves and evolves vapors. (g) Specific gravity Specific gravity is the weight of a substance in comparison to water. Water is assigned the value of 1. Materials with a specific gravity greater than 1 are heavier than water and those with a SG less than 1 are lighter than water and will float. Discuss different types of dams that can be built for product control. (h) Vapor density (V.D.) Vapor density (also seen as vapor specific gravity) is the comparison of the weight of the vapors in comparison to IG – 2.2 – 13 FLORIDA OPERATIONS LEVEL HAZARDOUS MATERIALS TRAINING PROGRAM the weight of air. Air is established the standard value of 1. Those materials with a VD greater than 1 will be heavier than air and will sink. Those with a VD less than 1 will be lighter than air and will tend to naturally dissipate upwards. Explain how this affects the way technicians will monitor for a gas or vapor and how it affects our tactics on scene. (i) Solubility/miscibility Solubility and miscibility refers to the ability of one substance to blend uniformly with another. The term solubility is usually applied to a solid solute being dissolved with a liquid solvent (e.g., water, alcohol). The term miscibility is generally applied to a liquid or gas solute being mixed in another liquid or gas solvent. 4) Spill type — Tactics and exposures Spill types obviously are not included on the MSDS. However, now that physical properties have been discussed, it is a logical time to discuss spill types and relate that information to what the participants have learned. (a) Once the physical properties of the material are understood, the spill type that is being dealt with can be assessed. (b) Understanding the spill type provides a greater appreciation for the hazards that might be presented to the responder. Spill Type Matrix Physical State/ Environment Gas Liquid Solid IG – 2.2 – 14 Air Release Water Release Surface Release Gas/Air Liquid/Air Solid/Air Liquid/Water Solid/Water Liquid/Surface Solid/Surface UNIT 2.2 — PHYSICAL AND CHEMICAL PROPERTIES Draw the participants’ attention to the spill type matrix in the Student Manual. Discuss the various common types of spills and how spill types can mimic or transform to other types of spills. Examples include: A liquid/surface spill will always have a gas/air component due to vapor pressure. If a spilled solid is in a fine enough form, the solid/surface spill can mimic a gas/air release. 5) Fire and explosion hazards (a) The fourth section of the MSDS deals with fire and explosion hazards. (b) Fire and explosion hazards are one of the chemical properties exhibited by materials. Have the participants return to the MSDS that they were following along with and insure they are tracking with the flow of the program. The MSDS should be used as an organizational scheme to keep the participants focused on the direction of the lecture. (c) Fire triangle Review the basics concerning the fire triangle as necessary for the target audience. Insure that everyone in the class has an understanding of the concept. These concepts are very important to this section, as well as our later discussion on explosives. (d) Flash point • “The temperature at which a liquid or volatile solid gives off vapors sufficient to form an ignitable mixture near the surface…” National Fire Protection Association (NFPA) IG – 2.2 – 15 FLORIDA OPERATIONS LEVEL HAZARDOUS MATERIALS TRAINING PROGRAM • If an ignition source were provided, a flash fire would occur. Discuss with the participants the relationship between vapor pressure and the flash point of a combustible or flammable material. Using the following examples, allow the participants to recognize that as vapor pressure increases, flash point decreases. This is because the higher the vapor pressure at a given temperature, the less heating is required to evolve sufficient vapors. Product Kerosene Octane Gasoline Propane Vapor Pressure Combustible liquid 2.12 mm/hg Flammable liquid 11.7 mm/hg Up to 300 Flammable liquid mm/hg 1313 mm/hg Flammable gas @ -20 °F Type Liquid Flash Point (°F) 100 – 162 °F 56 °F -36 °F -76 to – 156 °F (e) Flammable range • This is the percentage of the gas in air necessary to form a flammable mixture. • Measured in % by volume in air • Lean and rich mixtures • 1% = 10,000 ppm Product Propane Gasoline Acetylene Hydrogen LEL 2.2 % 1.4 % 2.5 % 4.0 % UEL 9.5 % 7.4 % 100 % 75 % (f) Ignition temperature • IG – 2.2 – 16 The minimum temperature required to initiate or UNIT 2.2 — PHYSICAL AND CHEMICAL PROPERTIES cause self-sustained combustion independently of the heating or heating element (g) BLEVE (Boiling Liquid Expanding Vapor Explosion) • Common hazard that may occur when direct flammable impingement upon a closed container occurs • Flammable contact with the steel container weakens the steel • Increased internal pressure • Runaway tearing of the container occurs Discuss the topic of BLEVE with the participants. Insure an understanding of the concept. Reinforce that the flame impingement upon the steel above the level of the liquid creates the greatest hazard. Control strategies must include the application of water to the surface of the container for a defensive posture. General rule of thumb is 500 gallons per minute (gpm) per point of flame impingement with close monitoring of relief valve activation and status. Failure of the relief valve to reset or changes in sound intensity or pitch can indicate a worsening situation. (h) Boil-over • A potential hazard found while fighting fires involving heavy, viscous fuels in containers (primary floating roof) • Water settles to the bottom of the container IG – 2.2 – 17 FLORIDA OPERATIONS LEVEL HAZARDOUS MATERIALS TRAINING PROGRAM • A thermocline (layer of highly heated fuel) develops under the surface of the fire • As the fuel level in the tank drops, the thermocline moves closer to the water in the bottom of the container • When the thermocline (greater than 212 degrees F) comes in contact with the water, the water converts to steam and ejects the remaining fuel from the tank (i) Other definitions • Pyrophoric — Ignites spontaneously on contact with air • Hydrophoric — Ignites spontaneously on contact with water • Flammable solids — Materials that are wetted explosives, self reactive, spontaneously combustible, pyrophoric or water reactive • Hygroscopic — Moisture absorbing. Readily mixes with water and in many cases creates a corrosive liquid. Example: anhydrous ammonia 6) Health hazards — Routes and effects of exposure IG – 2.2 – 18 UNIT 2.2 — PHYSICAL AND CHEMICAL PROPERTIES (a) Toxin — “There is nothing which is not a toxin, only the dose differentiates a poison from a remedy” — Paracelsus 1500s Discuss this statement with the participants. Use examples such as water (too much water can result in electrolyte imbalances) and salt to illustrate the concept that anything in a sufficient quantity can be toxic to humans. (b) Routes of exposure • Inhalation • Ingestion • Injection • Skin absorption (c) Local vs. systemic response (d) Dose vs. response • The greater the dose taken into the body, the greater the adverse health effects • With many materials there is a “threshold” of exposure prior to adverse health effects • Others have extremely low thresholds • Adverse health effects (e) Influences of toxicity • • Type of exposure – Acute – Chronic Route of exposure IG – 2.2 – 19 FLORIDA OPERATIONS LEVEL HAZARDOUS MATERIALS TRAINING PROGRAM • • Age of subject – Younger — Less developed immune system – Elderly — Degraded immune system Gender – • Some materials are gender specific (e.g., teratogens) State of health – Pre-existing conditions (e.g., pulmonary conditions, liver dysfunction) Discuss with the class these variables. 7) Reactivity hazards (a) Corrosives • pH Scale 0 – 14 with 7 +/being neutral • pH < 2 strong acid • pH > 12 strong base (alkaline) • pH is a logarithmic scale Insure participant understanding of the logarithmic function. A pH of 6 is 10 times more acidic than a 7. A pH of 5 is 100 times more acidic than a 7. A pH of 4 is 1,000 times more acidic than a 7, etc. IG – 2.2 – 20 UNIT 2.2 — PHYSICAL AND CHEMICAL PROPERTIES • Skin effects • Steel effects Even though a drum or container was made to carry an acid, if the product is coming into contact with the bare metal, there is a possibility for container failure from the reaction between the corrosive and its container. This is why many containers are “lined”. (b) Reactions • • • Rate of reactions are dependent upon – Quantity of materials involved – Concentration of materials – Temperature – Pressure Explosives – Fuel – Oxidizer – Energy – Pressure Incompatibility groups Refer the participants to the table of incompatibility groups in their Student Manual and discuss these groups and potential reactions. Show video (10 minutes) Chemical Reactions IG – 2.2 – 21 FLORIDA OPERATIONS LEVEL HAZARDOUS MATERIALS TRAINING PROGRAM 8) Spill and leak control (a) Spill/leak control information describes the actions to be taken for incidental spills and leaks • Incidental spills are those which can be handled easily by employees in the immediate area or maintenance personnel. • Persons conducting incidental spill still must be trained (Hazard Communication 29 CFR 1900.1200). • Proper protection must be provided in accordance with MSDS recommendations. (b) Spill leak control information can be used to help emergency responders determine goals and tactics. 9) Personal protective equipment (PPE) (a) PPE requirements during normal anticipated use, not during emergencies (b) Minimum level of protection for persons who work with the product or during incidental spills (c) Many times, PPE recommended on the MSDS is not applicable for emergency conditions 10) Special information (a) The last section of the MSDS discusses any special handling, packaging or disposal requirements IG – 2.2 – 22 UNIT 2.2 — PHYSICAL AND CHEMICAL PROPERTIES (b) Special information concerning environmental protection may be provided IV) RADIOACTIVE HAZARDS (20 MINUTES) A) Ionizing radiation 1) Natural or “background” radiation always present (from terrestrial, cosmic, food sources, etc…) 2) Man made or “refined” sources of radiation can be found in numerous areas of science and industry (a) Industrial radioactive isotopes (b) Medical radioactive isotopes (c) Agricultural and food irradiation (d) Special nuclear materials (plutonium, uranium or uranium enriched) 3) Unstable isotopes “decay” to reach a state of stability. This decaying process generally involves the release of ionizing radiation. B) Types of ionizing 1) Alpha particle (a) Emitted from the nucleus (b) Has significant mass (c) Travels only inches in air (d) No penetration (e) Most significant hazard is the inhalation or ingestion of the source material 2) Beta particle IG – 2.2 – 23 FLORIDA OPERATIONS LEVEL HAZARDOUS MATERIALS TRAINING PROGRAM (a) Very little mass (b) Can hold significant energy (c) Travels several feet in air (d) Limited penetration (e) Can cause “beta burns” to skin 3) Gamma emission (a) Not a particle (b) An electro-magnetic energy wave called a “photon” (c) Highly penetrating (d) Will ionize internal tissues 4) X-rays (a) Generated electronically by firing high energy electrons at a heavy metal (b) No radioactive source in an X-ray machine 5) Neutron particle (a) Found in fission or spontaneously fissionable materials (b) Unique characteristic of “special nuclear materials” • U-235, U-233 and plutonium C) Exposure limits 1) Standard unit of measure in U.S. is REM (a) 1 REM = 1,000 mREM (milli) (b) 1 mREM = 1,000 µREM (mirco) IG – 2.2 – 24 UNIT 2.2 — PHYSICAL AND CHEMICAL PROPERTIES 2) International community uses Sievert (Sv) (a) 1 Sv = 100 REM 3) Total dose = dose rate X duration 4) Action levels (a) Normal background 8 – 16 µREM/Hr (b) Hot zone 2 mREM/Hr (c) All actions to 5 REM dose (5,000 mREM) (d) Protect valuable property 10 REM dose (10,000 mREM) (e) Life saving rescue 25 REM (25,000 mREM) (f) LD (low) 100 REM (g) LD (50) 500 REM D) Florida’s Preventative Radiological Nuclear Detection Program (PRND) 1) Commercial vehicle inspection 2) Maritime interdiction 3) Special events 4) Intelligence driven operations The Florida PRND program goal is to protect the people, economy, and natural resources of Florida against threats posed by the unauthorized use of radiological and nuclear materials. 5) Types of devices (a) Thermonuclear device (b) Improvised Nuclear Device (IND) IG – 2.2 – 25 FLORIDA OPERATIONS LEVEL HAZARDOUS MATERIALS TRAINING PROGRAM (c) Radiological Dispersal Device (RDD) (d) Radiological Exposure Device (RED) V) DOT HAZARD CLASSES (NAERG) (20 MINUTES) A) Hazard Classes 1) Class 1: Explosives (a) Division 1.1 — Class A: Mass Detonation Hazard (b) Division 1.2 — Class A/B: Projectile (c) Division 1.3 — Class B: Fire Hazard (d) Division 1.4 — Class C: No Blast (e) Division 1.5 — Blasting Agent (f) Division 1.6 — Very Insensitive Optional Video The instructor may wish to secure a copy of the free training video provided by the Institute of Manufacturers of explosives dealing with “Emergency Response to Explosives”. (18 minutes) 2) Class 2: Gases (a) Division 2.1 — Flammable (b) Division 2.2 — Non-flammable (c) Division 2.3 — Poisonous 3) Class 3: Flammable Liquid (a) Any liquid with a flash point not more than 140 °F IG – 2.2 – 26 UNIT 2.2 — PHYSICAL AND CHEMICAL PROPERTIES (b) Combustible liquids with a flash point above 140 °F and below 200 °F 4) Class 4: Flammable Solids (a) Division 4.1 — Flammable Solid (b) Division 4.2 — Spontaneous/ Pyrophoric (c) Division 4.3 — Dangerous When Wet 5) Class 5: Oxidizers (a) Division 5.1 — Oxidizers (b) Division 5.2 — Organic Peroxides 6) Class 6: Poisons (a) Division 6.1 — Poisons (b) Division 6.2 — Infectious Substances 7) Class 7: Radioactive Materials 8) Class 8: Corrosives 9) Class 9: Miscellaneous It is important to remember that placarding requirements allow for some qualities to be carried without external placards or that multiple hazard classes can be placarded under the “Dangerous” placard. Review with the students the 1000 and 5000 pound rules. B) Other regulated materials: Consumer quantities C) Refrigerated gases 1) Hazard class of product 2) Temperature of product D) Cryogenic liquids IG – 2.2 – 27 FLORIDA OPERATIONS LEVEL HAZARDOUS MATERIALS TRAINING PROGRAM 1) Gases liquefied through the use of temperature rather than pressure 2) Hazards of cryogenics (a) High expansion ratios from liquid to gas (800 to 1000:1) (b) Extremely cold temperatures (less than -150 °F) (c) Chemical hazards of the material itself (e.g., oxygen = oxidizer, hydrogen = flammable, nitrogen = asphyxiation) Again, emphasize that the hazard class obtained from the NAERG is the least amount of information that is needed. Without it, a plan of action cannot be developed. This discussion of hazard classes is a review for the participants. VI) SUMMARY (10 MINUTES) A) Properties can be physical or chemical in nature B) Physical properties 1) Physical state 2) Vapor pressure 3) Vapor density 4) Specific gravity 5) Solubility C) Chemical properties 1) Flammability (a) Flash point (b) Flammable range (c) Ignition temperature IG – 2.2 – 28 UNIT 2.2 — PHYSICAL AND CHEMICAL PROPERTIES (d) Special flammability hazards • Pyrophoric • Hydrophoric 2) Reactivity (a) Corrosives (b) Hazardous reactions • Influences of reactions (amount, concentration, temperature and pressure) 3) Toxicity (a) Routes of exposure (b) Exposure limits • TWA • STEL • Ceiling (C) • IDLH D) Sources of product information 1) NAERG 2) NIOSH Pocket Guide 3) CHEMTREC 4) MSDS (a) Nine basic sections (b) Provides limited information • Some better than others E) Radioactive hazards F) MSDS (Material Safety Data Sheet) IG – 2.2 – 29 FLORIDA OPERATIONS LEVEL HAZARDOUS MATERIALS TRAINING PROGRAM 1) 9 Basic Sections 2) Provides limited information (a) Some better than others 3) NAERG 4) CHEMTREC 5) NIOSH Pocket Guide G) DOT hazard classes 1) Nine classes Activity 2.2 (30 Minutes) Assessing Physical and Chemical Properties IG – 2.2 – 30 UNIT 2.2 — PHYSICAL AND CHEMICAL PROPERTIES IG – 2.2 – 31