Safe Use of the Sheet Sander

advertisement

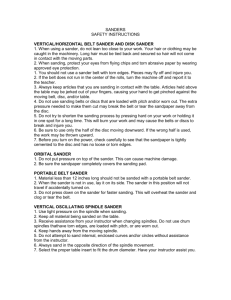

Safe Use of the Sheet Sander Description of the Sheet Sander A Sheet Sander is a portable electric sander that sands with a high speed orbital action, much like the human hand would use when polishing with a cloth. Abrasive paper is attached to a cushioned sanding pad and due to the orbital motion of this pad, using a Sheet Sander ensures a fine finish, especially on large surfaces. The removal rate, however, is much slower than that of a belt sander and the Sheet Sander is only useful for fine finishing of your work. The Sheet Sander has a palm grip handle and a trigger switch that can be locked in the “ON” position. This gives comfortable single handed use, and reduces operator fatigue during continuous sanding operations. Sheet Sanders have a quick action paper clamping system which makes changing or replacing sandpaper fast and easy. A built in dust collection bag collects dust through punched holes in the sandpaper or from around the sides of the base cushion. The Sheet Sander can be used with coarse, medium, and fine grit sandpaper and will produce an almost scratch free finish when used with fine grit sandpaper on wood surfaces. Sheet Sanders are described as Half Sheet, Third Sheet and Quarter Sheet models. This refers to the fitted paper size which is therefore half, one third or one quarter of a standard abrasive sheet size. The quarter sheet sander is sometimes referred to as a Palm Sander because it fits easily into one’s palm. Main parts of a Sheet Sander Trigger Switch Lock Button Trigger Switch Button Switch Dust Bag Paper Clamp Cushion Pad Quarter Sheet Palm Sander Half Sheet Sander Common dangers, risks and hazards 1. 2. 3. 4. 5. Impact Injury – It is unusual for the work piece to be thrown violently by the sander but this can happen under some circumstances, particularly when the work piece is quite light. A lightweight work piece should be secured with a clamp or vise. Eye Injury – The operator must always use eye protection. Particles or objects can be thrown into the operator’s eyes from the working of the sander. Hearing Damage – The Sheet Sander makes a high noise level during operation. Hearing protection must be used. Electrocution – Electrocution can occur if the operator comes into contact with exposed wiring on the Sheet Sander. Dust – Some dusts generated while using a Sheet Sander can be toxic. Avoid sanding lead based paints, chromium and arsenic treated timbers and Medium Density Fibreboard. High exposure to the dust from all timbers will damage your health. Copyright 2011 www.SafetyTestingOnline.com You may use this document for educational (non-commercial) use provided the copyright notice remains intact. Page 1 Safe Use of the Sheet Sander Operator checks made before use 1. 2. 3. 4. 5. Tidy work area – The work bench and the floor should be clear of off cuts, waste and other rubbish. Secure and steady footing must not be impeded and an operator must have a clear working space. Power Lead – The Sheet Sander power lead must be free of cuts or cracks and loose wiring. Any exposed wiring should be reported to the teacher. On/Off Switch – The On/Off switch should be in good operating order and should operate effectively. Dust Collection – If a dust collection hose is fitted, extraction should be running while the Sheet Sander is in use. If a dust bag is fitted, it must be cleaned before use. Paper – Abrasive paper should be fitted securely and fully cover the cushion pad. It should not be ripped. Safe operating procedure Training – An operator must have received training and have permission to use before operating the Sheet Sander. 2. PPE – Personal Protective Equipment must be worn when using the Sheet Sander. This includes eye protection and hearing protection. A protective apron is useful for keeping clothes clean. 3. Wood Dust – The dust generated by a sheet sander is harmful. You should either use a dust extraction system or a dust filtering face mask. 4. Switching on/off – The operator is always responsible for switching the machine on or off. There can be no exceptions to this rule. 5. Carrying the Sheet Sander – Never carry the Sheet Sander by the power lead. This may damage the lead to the electrical connections and may allow dangerous wires to become exposed. 6. Electrical Isolation – If abrasive paper is to be changed the sheet sander should be electrically isolated first. 7. Safety Zone – An operator is should have a clear working area around the Sheet Sander. 8. Small Work Pieces – Secure small or lightweight work pieces with a vise or clamp. 9. Awareness – Switch off and notify the teacher if you think that there may be something wrong with the Sheet Sander. 10. Damaged Abrasive Paper – Torn, worn out or incorrectly fitted abrasive paper should be replaced. It is ineffective in sanding and an operator is likely to apply excessive pressure, possibly damaging the base pad. Working with damaged paper usually creates excessive noise. 11. Drugs, Medication and Alcohol – Do not operate the Sheet Sander if under the influence of any of these. 1. Copyright 2011 www.SafetyTestingOnline.com You may use this document for educational (non-commercial) use provided the copyright notice remains intact. Page 2