value chain analysis: juices

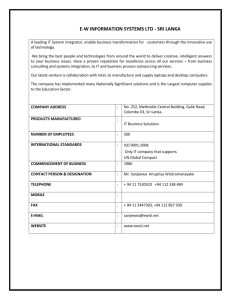

advertisement