ninja book - Another71.com

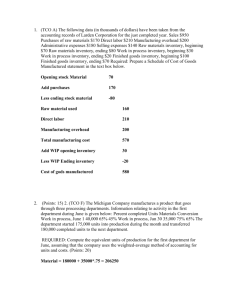

advertisement