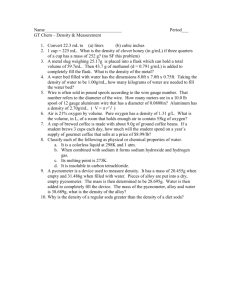

Specific Gravity, Absorption and Dry Rodded Density

advertisement

Revised 2007, WKS Datasheet No. 31 MOHAWK COLLEGE OF APPLIED ARTS AND TECHNOLOGY BUILDING AND CONSTRUCTION SCIENCES DEPARTMENT Specific Gravity, Absorption and Unit Weight of Aggregates INTRODUCTION The specific gravity of coarse and fine aggregates and the dry rodded density of the coarse aggregate are needed for the ACI (American Concrete Institute) mix design method. The absorption capacity and moisture conditions are needed for corrections in all mixes. In this laboratory procedure you will make these determinations and then use them in the later laboratory work. EQUIPMENT The following equipment will be required: – balances sensitive to 1 g and 0.1 g – 500 ml pycnometer – conical mold and tamper for SSD determination – electric forced air heater – volume measure for coarse aggregate and tamping rod – wire basket for submerging coarse aggregate – miscellaneous pans, trowels, etc. PROCEDURE A: Specific Gravity and Absorption of Fine Aggregate 1. Fill the pycnometer with water at 23 ± 1.7° C to the 500 ml mark and weigh to the nearest 0.1 g ensuring the outer surface of the pycnometer is dry. 2. Spread approximately 1000 g of the saturated sand on a glass plate and direct the air current from the electric heater on to it. Stir the sample frequently to ensure uniform drying. 1 3. When the sand approaches a free flowing condition place the sand loosely in the conical mold and lightly tamp the surface 25 times with the 25 mm diameter tamper. Lift the mold vertically off the sand. If the sand retains its shape, free moisture is present and drying must be continued. 4. When the sand slumps on removal of the cone, it indicates that a saturated surface dry condition has been reached. Immediately place 500.0 g of the SSD sand into the empty pycnometer and fill with water to approximately 90% of its capacity (about 2 cm below the neck). Connect the pycnometer to a vacuum for five minutes. Then fill to the calibration line and, if necessary, adjust the temperature to 23 ± 1.7° C by placing the pycnometer under a running tap. Weigh to the nearest 0.1 g ensuring the outer surface of the pycnometer is dry. 5. Wash all of the fine aggregate from the pycnometer into a tared container (a container which has been previously weighed and the weight recorded) and place in the oven to dry with an oven tag clipped to the outer wall. Overnight (18 hours) is usually sufficient. When dry weigh again to the nearest 0.1 g. B: Free Moisture in Fine Aggregate 1. Obtain about 1 kg of damp sand from the bin and split or quarter it into two halves. Place one of the halves into a tared container and weigh to the nearest 0.1 g. 2. Put enough water, at 23 ± 1.7o C into your pycnometer to cover the sample and then put the sample into the pycnometer. 3. Connect to a vacuum for 5 minutes. 4. Fill the pycnometer to the calibration mark with water at 23 ± 1.7o C and weigh to the nearest 0.1 g ensuring the outer surface of the pycnometer is dry. C: Specific Gravity and Absorption of Coarse Aggregate 1. Select about 3 kg of saturated coarse aggregate and dry the sample to an SSD condition by rolling it on a cloth until all visible films of moisture are removed. Weigh the sample in the SSD condition. 2. Immediately place the sample in a wire basket and obtain its weight in water in kilograms to the nearest gram. Shake the basket while immersed to dislodge all entrapped air. 2 3. Place the sample in a tared container, dry in the oven and obtain its weight in kilograms to the nearest gram. D: Moisture Content of Coarse Aggregate 1. From below the surface of the bin take a sample of about 6 kg and split or quarter to about 1.5 kg. 2. Weigh the sample in kg to the nearest gram, dry in the oven and weigh again in kg to the nearest gram. E: Dry Rodded Density of Coarse Aggregate 1. Using the ⅓ ft3 (0.00944 m3) container, fill one third full with air dry coarse aggregate, level with your fingers and rod 25 times with the 16 mm diameter tamping rod. 2. Repeat the above with the container ⅔ full and then overflowing. 3. Strike off level and weigh the aggregate in kg to the nearest gram. The contents only are weighed since the mass of the container and aggregate will exceed the capacity of the balance. CALCULATIONS Note: All specific gravity calculations must be carried to 3 decimal places (4 significant digits). A: Specific Gravity and Absorption of Fine Aggregate 1. Calculate the SSD Bulk Specific Gravity as follows: GSSD = 500 B + 500 - C where B = Mass of the pycnometer + water (g) 3 C = Mass of pycnometer + sample + water (g) 2. Calculate the Bulk Specific Gravity (ASTM) as follows: GASTM = where A B + 500 - C A = Oven dry mass of the sample (g) 3. Calculate the Apparent Specific Gravity as follows: GAPPARENT = A B +A-C 4. Calculate the Absorption Capacity as follows: Abs = 500 - A × 100% A B: Free Moisture in Fine Aggregate 1. Calculate the amount of water displaced and using it calculate the free moisture as a percent by weight of the SSD mass as follows: Vs = Mc + Ms − M Vd = P= where Ms GSSD Vs - Vd × 100% Ms - Vs Vs = mass of water displaced by the sample (g) Vd = mass of water that would be displaced by the SSD sample (g) Mc = mass of pycnometer + water (g) Ms = mass of sample (g) M = mass of pycnometer + sample + water (g) P = free moisture as a percent of SSD mass 4 C : Specific Gravity and Absorption of Coarse Aggregate 1. Calculate the SSD Bulk Specific Gravity as follows: GSSD = where B B-C B = mass of SSD sample in air (kg) C = mass of SSD sample in water (kg) 2. Calculate the Bulk Specific Gravity (ASTM) as follows: GASTM = where A B-C A = mass of oven dried sample (kg) 3. Calculate the Apparent Specific Gravity as follows: GAPPARENT = A A-C 4. Calculate the Absorption Capacity as follows: Abs = where B−A × 100% A A = Mass of Oven dried sample (kg) B = Mass of SSD sample in air (kg) C = Mass of SSD sample in water (kg) D: Moisture Content of Coarse Aggregate 1. Calculate the internal moisture in the sample as follows: w= where M - Ms × 100% Ms M = SSD mass (g) 5 Ms = oven dried mass (g) w = percent moisture content (%) 2. Calculate the effective absorption, Ed as a percent of oven dry mass as follows: Ed = Abs − w where Abs = percent absorption obtained in test C, step 4 E: Dry Rodded Density of Coarse Aggregate: 1. Calculate the dry rodded density as follows: ρd = where M V ρd = the dry rodded density in kg/m3 M = the mass of aggregate to fill container kg V = volume of container in m3 REPORT 1. The report should include a title page, the completed Report Form, the completed data sheet No. 31 and a detailed documentation of the calculations. 6