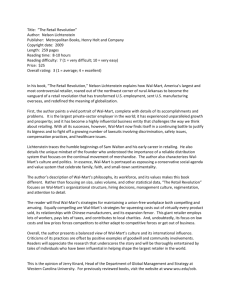

Sourcing ethically through a socially responsible program

advertisement