July 2011 - National Association of Manufacturers

The National Association of Manufacturers

Leading Innovation. Creating Opportunity. Pursuing Progress.

July 2011 www.nam.org

NAM MANUFACTURING

SUMMIT 2011

Summary and Highlights from Capitol Hill (p.2)

NAM LEADERSHIP

Urges Action on Regulatory Burden (p.7)

INTERVIEW

BMW: A Leader in Sustainability

The National Association of Manufacturers

MEMBER FOCUS

Leading Innovation. Creating Opportunity. Pursuing Progress.

NAM’S 2011

MANUFACTURING

SUMMIT

Summary and Highlights

From Capitol Hill (p.2)

• • •

CONTENTS

4

CAPITAL CONNECTION

Help the NAM Stop the EPA’s Overregulation

5

PRESIDENT OBAMA ENDORSES

NAM-Supported Manufacturing Skills Certification Program

6

ECONOMIC ANALYSIS

Top States for Manufacturing Growth

8

FOR MANUFACTURERS

NAM Manufacturing Summit 2011 in Pictures

9

SENATE BILL ON CRITICAL MINERALS

Will Revitalize the Supply Chain

10

MEMBER FOCUS

BMW: A Leader in Sustainability

NAM LEADERSHIP

Urges Action on Regulatory

Burden (p.7)

• • •

MEMBER FOCUS

CHAIR OF THE BOARD

VICE CHAIR OF THE BOARD

CHAIR

,

SMALL AND MEDIUM MANUFACTURERS

PRESIDENT AND CEO

SENIOR VICE PRESIDENT

,

MEMBER AND BOARD RELATIONS

SENIOR VICE PRESIDENT , CHIEF FINANCIAL OFFICER AND TREASURER

SENIOR VICE PRESIDENT

,

EXTERNAL AFFAIRS

SENIOR VICE PRESIDENT

,

POLICY AND GOVERNMENT RELATIONS

SENIOR VICE PRESIDENT

,

STRATEGIC DEVELOPMENT

Mary Andringa

Douglas R. Oberhelman

Kellie Johnson

Jay Timmons

Ann E. Heins

Rick Klein

Ned Monroe

Aric Newhouse

Jeff Pierce

Erin Streeter SENIOR VICE PRESIDENT , COMMUNICATIONS

VICE PRESIDENT

,

MEMBERSHIP MARKETING

SENIOR DIRECTOR

,

PUBLICATIONS

,

AND MANAGING EDITOR

SENIOR DIRECTOR

,

BRANDING AND MULTIMEDIA

MANAGER , BRANDING AND MULTIMEDIA

J. Cliff Johnson, III

Clare James Johnson

James Skelly

Ronni Hutchason

Member Focus is published monthly by the National Association of Manufacturers.

© 2011 NAM. All rights reserved. Reproduction is prohibited except with the written permission of the NAM. Periodicals postage pending at Washington, D.C.

Postmaster: Send address changes to NAM Mem ber Focus, attn: Marcie Cox,

National Association of Manufacturers, 1331 Pennsylvania Ave., NW, Washington,

DC 20004-1790. Phone: (202) 637-3000. Fax: (202) 637-3182. Website: www.nam.org

Printed on Anthem ® , 80 lb. gloss cover and 70 lb. gloss text, from NewPage.

Manufactured in North America.

MANUFACTURING MATTERS

• •

Time for a Reality

Check

By Jay Timmons, president and CEO, National Association of Manufacturers

F or the past several months, Congress and the Administration have been engaged in a kabuki dance around the subject of raising the debt ceiling and dealing with the nation’s long-term debt.

If you are like me, you have heard the term “kabuki dance” but never quite known the meaning when applied to politics. The definition aptly fits the current discussions about the federal debt. It refers to “carefully scripted yet meaningless movements that do not reflect reality.”

Let’s establish this: It is critical that the

U.S. government not default in any way on its fiscal obligations. A default would result in a worldwide economic catastrophe like we’ve never seen or even contemplated.

So let’s have a reality check.

A default resulting from failure to extend the debt ceiling likely would precipitate a downgrading of our U.S. debt, resulting in higher interest rates, a depreciation of the dollar, greater inflation and a decline in equity prices.

Defaulting would reverberate throughout the global economy and our entire economic system. Americans trying to borrow for homes, cars and education would find access to loans more difficult, and available loans would be much more expensive. A weaker dollar would likely drive up oil prices, making the cost of gasoline and home energy bills much more expensive. Any stock market declines would destroy household wealth and further depress consumption.

Merely voting to increase the debt limit is not the answer for Congress. Our policymakers will need to make the difficult choices now to make sure we don’t get ourselves in this situation again.

What is the definition of a difficult choice? Is it tax increases? That is, frankly, the easy choice. Increase taxes on individuals and business in the middle of an economic downturn and watch how quickly that downturn gets worse. Congress needs to stay away from eliminating the Section 199 manufacturing tax deduction, avoid disturbing long-standing tax policy by repealing LIFO and resist the temptation to increase tax rates for higher incomes.

Such a change will impact 70 percent of manufacturers who file as S-corporations.

Higher taxes mean higher costs for manufacturers and fewer jobs for Americans — not exactly a laudatory goal for Congress or the Administration.

The difficult choices fall on the spending side of the ledger, where administration after administration and Congress after

Congress, Republicans and Democrats alike have been adding to long-term spending obligations without thinking about how the programs will be paid for in the future.

Congress needs to have two goals in mind: reduce spending and ensure that what is still being spent will positively impact economic growth and competitiveness.

Some would argue that we can simply cut discretionary spending – line items such as foreign aid. Once again, the facts don’t stand up to scrutiny.

Discretionary spending accounts for v Connect with us on the web @ www.nam.org/ConnectWithUs roughly 40 percent of our entire $3.4 trillion budget. One-half of that (about 20 percent of the entire budget) pays for national defense, arguably the most important function of any government.

Some 55 percent of the budget is dedicated to mandatory spending. That is spending

Congress doesn’t even vote on — it’s baked in the budget forever thanks to formulas and previous promises, and it is growing more each year. In addition, there is interest on the federal debt, which cannot be cut and now consumes about 6 percent of our nation’s budget.

Looked at another way, our budget deficit this year is projected to be $1.5 trillion.

That means we are borrowing about 44 percent of our spending (44 cents for every dollar we spend) from future generations.

Even if every single penny were eliminated from discretionary spending — including our entire national defense budget — we still would not get to a balanced budget.

We need immediate, fundamental reform on mandatory entitlement spending to fix our structural budgetary imbalance.

Manufacturing is poised for a renaissance.

To get there, our government must provide certainty on deficit reduction and send a clear message that it understands that costs faced by businesses need to be reduced through sound, pro-growth tax, energy and regulatory policy.

We have until August 2 to avoid an economic calamity. Let’s make sure our nation’s policymakers don’t let it happen now….or

ever.

•

July 2011 1

• • •

COVER STORY

Manufacturers Converge on Capitol

Hill for Jobs and Competitiveness

More than 400 manufacturers brought three key messages to

Capitol Hill during the National Association of Manufacturers’ (NAM)

Manufacturing Summit last month: stop the damaging overregulation, adopt pro-growth tax reform and pass pending free trade agreements. In hundreds of meetings with members of

the House and Senate June 15-16, manufacturing CEOs, plant managers and other industry leaders outlined the critical actions

Congress must take to help manufacturers create jobs, compete in the global marketplace, innovate and invest.

Manufacturers’ presence on Capitol Hill came at a critical time. Delays in passing free trade agreements could cost $13 billion in additional exports and about 100,000 new jobs. The United States also has the second highest corporate tax rate in the world. And new, costly regulations from the Environmental Protection Agency (EPA) and other agencies are putting jobs at risk and creating growth-stifling uncertainty. It is 18 percent more expensive to manufacture a product in the United States than in any other country.

The Manufacturing Summit’s message was simple: By passing free trade agreements with Panama, Korea and Colombia, lowering the corporate tax rate to 25 percent or less and reining in the EPA, lawmakers can help make manufacturing in the United

States vital and competitive.

In an op-ed published June 15 in Roll Call ,

NAM President and CEO Jay Timmons

2 MEMBER FOCUS framed the urgency of the task: “The United

States faces stiff competition. Governments all across the world envy our economic might, and they want to take it away from us. Today, companies can choose from a number of countries, many of which are adopting pro-growth reforms to lower taxes, implement trade pacts and reduce regulatory barriers. Inaction on our part is not an option.”

The Summit kicked off June 15 with a luncheon to brief manufacturers on key policy issues, give assignments and show a video highlighting the ins and outs of meetings with lawmakers on Capitol Hill.

Timmons also outlined the key goals of the

NAM’s “Manufacturing Strategy for Jobs and a Competitive America”: the United

States will be the best country in the world to headquarter a company; the United States will be the best country in the world for a company to innovate and perform the bulk

COVER STORY

• • • of its global research and development; and the United States will be a great place to manufacture, both to meet the needs of the

American market and to serve as an export platform for the world.

Before sending NAM members to meet with Congress, Timmons said, “The policies that you will be advocating on the Hill this week will go a long way toward promoting economic growth. You are offering a true jobs agenda. The policies you are advocating would make a meaningful difference — much more than the slew of so-called jobs bills that Congress has considered. When you are on the Hill, remember these three words: Manufacturing Means Jobs!”

Then, in 220 meetings with members of

Congress, manufacturers outlined specific measures policymakers can take to make the United States more competitive.

White House Chief of Staff William

Daley delivered the keynote address June

16, outlining the Obama Administration’s efforts to support manufacturing and create jobs. He highlighted the Administration’s work with the NAM on free trade agreements, export assistance and workforce skills, and he emphasized the President’s commitment to regulatory and tax reform.

“There are steps we can take to speed the recovery and put people back to work and ensure that America remains the best place in the world to do business. I am happy to say that you [manufacturers] have been a powerful advocate for taking those steps,”

Daley said.

During the question-and-answer period following Daley’s prepared remarks, several

NAM members voiced their concerns about the significant costs they face in implementing various new federal regulations. “I hear the message,” Daley said. “There is an enormous number of rules and regulations that are in the pipeline, and we’re trying to bring some rationality to that, especially at a time of economic crisis.”

Daley was also questioned about the status of the three key free trade agreements. Al

Bernard of The Manitowoc Company in

Manitowoc, Wis., asked, “In your opinion, will the finger pointing stop any time soon, and are we going to be able to move forward with these trade agreements?”

“Finger pointing will never stop in this town, but these trade agreements will get done,” Daley replied.

v Learn more @ www.nam.org/mfgsummit

Earlier in the day, Sen. John Thune (R-SD), chairman of the Senate Republican Policy

Committee, addressed Summit participants.

He praised manufacturers for their willingness to meet personally with their legislators on key business priorities. “Everybody in this room contributes mightily to pushing this economy forward, creating jobs and making this country the greatest place to do business in this world,” he said.

On the issue of taxes, Thune said, “We need to come up with a system of business taxation, a territorial system, so that we aren’t just completely at odds with every taxing system in the world and driving jobs overseas when they ought to be created right here in the United States. We need a tax reform agenda in this country, and I believe that can happen.”

Thune also echoed manufacturers’ sentiments on regulatory policy. “We have got to have some common sense and allow science to guide our decision-making rather than having people who have ideological agendas putting out regulations that make it more difficult for American businesses to compete.”

Summit attendees also enjoyed a congressional reception at the scenic Newseum, featuring members of the House of Representatives and the Senate as well as key staffers.

The lasting impacts of the Summit will become evident in the coming months, as work continues within Congress and the

Administration on policies to rein in the burdensome regulatory system, lower taxes and expand free trade.

“We know that our most effective advocates are the people who are out there on the front lines, doing business every day,” said

Timmons. “I think we changed some minds on Capitol Hill during the Manufacturing

Summit . At the very least, we have lawmakers and their staffs thinking about the issues that are critical to manufacturers, and that’s a significant accomplishment.” • n Sen. John Thune (R-SD) talks with NAM Board member Al Kurtenbach, chairman at

Daktronics, Inc., and NAM Board Chair Mary Andringa at the 2011 Manufacturing

Summit on June 16.

July 2011 3

• • •

CAPITAL CONNECTION

with

Ned Monroe, senior vice president, external affairs

Help the NAM Stop the

EPA’s Overregulation

L ast month, hundreds of manufacturers traveled to Washington, D.C., to spread the message that “Manufacturing

Means Jobs.” They talked with lawmakers about specific policies that will create jobs and help the country compete, and they expressed their concerns about burdensome regulations.

Manufacturers told their story, and members of Congress got the message.

We have to keep it up. As the National

Association of Manufacturers’ (NAM) new senior vice president for external affairs, my job is to make sure we maintain this momentum. Manufacturers cannot confine their advocacy efforts to a single event in Washington. Telling the manufacturing story is a year-round job. Manufacturers can make a difference in Washington 365 days a year.

Manufacturers need to communicate with policymakers and share their ideas and concerns. Members of Congress need to hear directly from the people who provide good jobs in their states and districts.

At the NAM, we hear from manufacturers about a number of issues, but one that comes up repeatedly is the Environmental Protection

Agency’s (EPA) aggressive regulatory agenda.

As the nation’s economy continues to inch forward, costly new regulations from the

EPA will have an impact on manufacturers of all sizes and will extend to nearly every sector of the economy. The EPA’s expensive proposals directly impact manufacturing and will kill jobs and create uncertainty for business leaders.

Manufacturers work hard — and they care about protecting and improving the

4 MEMBER FOCUS environment. Our member companies are on the cutting edge of developing new technologies that create energy efficiencies.

Manufacturers reduce waste and recycle materials and focus on sustainable production practices. Manufacturing in America is the leader in creating innovative solutions to advance renewable and alternative energy and greenhouse gas emissions (GHGs) reduction technology.

Unfortunately, the EPA continues to impose and propose regulatory hurdles that hamper this growth and innovation. Companies are closing plants, re-evaluating growth strategies and even laying off team members as a result.

We cannot afford the barriers to competitiveness the EPA is trying to erect.

Other manufacturers are holding their breath, waiting to see what the EPA will do with its new Boiler MACT standards. Already, manufacturers’ concerns have led the agency to delay and now reformulate the rules.

As long as these and other burdensome regulations are looming, manufacturers need to keep the pressure on Congress. The NAM’s

No New Regs campaign is a grassroots effort that shines a light on the EPA’s agenda that threatens economic growth and jobs. Manufacturers need solutions that protect the environment and help increase access to affordable domestic energy.

This No New Regs effort helps NAM members share their personal stories with members of Congress and urge lawmakers to enact common-sense solutions. In August, members of Congress will leave Washington and return home for about a month. During that time, they will meet with constituents, hold town hall meetings and connect with the people who sent them to Washington.

The August recess is the perfect opportunity to reach out to members of Congress and give them your input about how to grow the economy and create jobs.

Your engagement can make a difference.

Research shows that face-to-face meetings between elected officials and constituents back home can influence decision-makers.

Conversations with trusted sources, like NAM members, can change minds. Now is the time to tell manufacturing’s story—how the EPA’s regulations on ozone, greenhouse gases and offshore drilling, to name a few—impact businesses, hiring decisions and communities.

Contact your member of Congress and ask to schedule a meeting with him or her this

August. Inquire about upcoming town hall meetings—and attend them with your colleagues. Ask your senators or representatives to tour your shop floor. Strengthen manufacturing’s voice in Washington and around the country and promote and protect the future of manufacturing in America.

I look forward to working with you in the weeks and months ahead.

•

POLICY FOCUS

• • •

President Obama

Endorses Manufacturing

Skills Certification

Program

T he Obama Administration last month announced key steps toward building the educated and skilled workforce U.S. manufacturers need to successfully compete in the 21st-century economy. Responding to the President’s call for employers and community colleges to work together to connect students with jobs, The Manufacturing Institute and the

National Association of Manufacturers (NAM) announced the goal of credentialing 500,000 community college students with skills certifications aligned to manufacturers’ hiring needs, citing The Manufacturing Institute’s

NAM-Endorsed Skills Certification System as a national solution and highlighting The

Manufacturing Institute’s new partnership with the Skills for America’s Future initiative.

The cutting-edge Manufacturing Skills

Certification System provides high school, community college and four-year-college students across the country with nationally portable, industry-recognized credentials needed to be productive and successful in today’s manufacturing workplaces. The program gives individuals, whether right out of high school or transitioning to new careers, a clearly defined set of skills and courses v Learn more on the web @ institute.nam.org

needed to get a job in manufacturing.

At a June 8 event at Northern Virginia

Community College, President Obama said,

“The irony is even though a lot of folks are looking for work, there are a lot of companies that are actually also looking for skilled workers. There’s a mismatch that we can close.

And this partnership is a great way to do it.”

The Manufacturing Skills Certification

System directly addresses the deficits in manufacturing education and training limiting the pool of qualified candidates for high-quality manufacturing jobs. The result is a professional technical manufacturing workforce with valuable industry credentials, making companies more innovative, more competitive and more marketable.

“These certified training programs build the skills valued by potential employers, and those who complete the certification have access to higher paying jobs,” said NAM

President and CEO Jay Timmons.

The Manufacturing Skills Certification

System can also be used by workers who need to improve their skills to advance to higher-level positions or those whose current jobs may be at risk. Individuals who have lost their job, are coming out of the military or are moving out of welfare and into work also will have an array of long-term career opportunities once they begin earning the industry-endorsed credentials.

The credentials range from foundational personal effectiveness, academic and workplace skills to industry-wide technical and applied science, technology, engineering and math (STEM) skills. The NAM-Endorsed

Manufacturing Skills Certification System comprises nationally portable, industry-wide career-readiness and technical certifications from ACT, the American Welding Society

(AWS), the Manufacturing Skill Standards

Council (MSSC), the National Institute of

Metalworking Skills (NIMS) and the Society of Manufacturing Engineers (SME).

“Manufacturers have been telling us for quite some time now that they cannot find individuals with the skills required for today’s high-tech, high-productivity manufacturing environment,” said Manufacturing Institute

President Emily DeRocco. “We have responded by developing a nationwide system that provides competency-based, customized education and training for the manufacturing workforce of today and tomorrow.”

President Obama also announced other key new business-education partnerships. The board of directors of Jobs for America’s

Graduates ( JAG) is establishing a five-year goal to help 30,000 high-risk young people obtain professional credentials in high-demand occupations, including advanced manufacturing. Archer Daniels Midland Company will serve as JAG’s National Business Partner.

Air Products, a global manufacturer, is building partnerships with SkillsUSA’s 3,500 member high schools and more than 200 colleges to include industry-recognized credentials in their career and technical education pathways. The SME and the SME

Education Foundation is partnering with the National Action Council for Minorities in Engineering, the National Academy

Foundation and General Dynamics —

Ordnance and Tactical Systems to provide over 1,000 mentorships every year for the next five years.

Futures Inc. is partnering withThe Manufacturing Institute to leverage Pipeline , an online talent connection platform that links qualified employees to employers with indemand jobs in advanced manufacturing.

For more information, contact Jacey Wilkins at (202) 637-3493 or jwilkins@nam.org. •

July 2011 5

• • •

ECONOMIC ANALYSIS

with

Chad Moutray, chief economist

Top States for

Manufacturing Growth

T he manufacturing sector was hit hard in the Great Recession, with more than

2 million nonfarm payroll jobs lost in

2008 and 2009. The United States lost nearly

8.7 million workers in the same time frame, meaning just over one out of every four lost jobs was in manufacturing. (Including lost construction jobs would account for nearly half of all jobs lost in those two years.)

Since December 2009, though, manufacturing has bounced back. According to the

May employment numbers, the United States has gained 238,000 manufacturing workers, or roughly 10 percent of what was lost during the recession. Manufacturers have contributed 14 percent of the net job growth during that time, despite that fact that manufacturing employment is just 9 percent of total nonfarm payrolls.

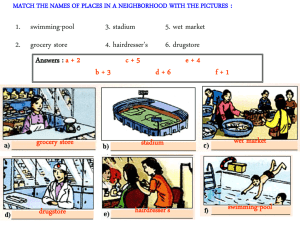

Increased durable goods sales are helping to drive employment up. The table on this page shows the top 10 manufacturing sectors for employment growth between December 2009 and May 2011. It is clear that the fastestgrowing sectors now were the hardest hit in the recession. Fabricated metal products have seen the most gains, adding 96,400 new workers in the past 18 months—nearly one-third of the total lost in the recession years. Other fast-growing sectors include

Top 10 States for Manufacturing

Employment Growth

(December 2009 to May 2011, in Thousands of Workers)

Michigan

Wisconsin

Illinois

Ohio

Texas

Indiana

Pennsylvania

Oklahoma

California

Missouri

35.8

19.9

23.8

15.7

19.1

11.6

15.3

15.2

8.8

10.8

Source: Bureau of Labor Statistics durables such as machinery, motor vehicles, computers, plastics and electrical equipment.

In an economy where the latest technologies from Silicon Valley get much of the press, it is perhaps surprising to see such older industries leading the pack. Yet durables have been leading the way thanks to pent-up demand, rising incomes and increased exports. The most recent trade numbers suggest that manufactured goods exports grew by 15 percent over the last year, helped along by strong demand overseas for machinery, metals, transportation equipment, computers and other durables.

As a result, many states that have seen the most manufacturing employment growth recently are located in the Rust Belt. Leading the list is Michigan — a state that suffered mightily over the past few years. Now a revitalized auto industry is helping to bring work back, with 35,800 new workers hired in manufacturing since December 2009.

Similar stories can be told in Wisconsin,

Illinois, Ohio and Indiana, with durable goods accounting for much of the growth.

Illinois has revved up exports over the past few years, which has helped boost employment. Manufactured goods exports rose from

$30.4 billion in 2000 to $46.3 billion in 2010, with Canada serving as its largest trading partner at nearly $14 billion. Machinery, transportation equipment, chemicals and computer and electronic products were the largest export sectors from Illinois to Canada in 2010, and each experienced substantial growth over the past decade. Each of those four sectors has at least 30 percent or more of its total employment related to exports, according to the International Trade Administration. Other Midwestern states mirror this finding.

While this recovery is still in its nascent stages, an interesting trend has emerged, with old-line industries helping to lead the bounce-back in manufacturing. Strong export growth is a central factor in this storyline, with durable goods sectors growing faster than others both in terms of sales and employment. As a result, many of the states that were hardest hit in the recession have been bouncing back over the past year and a half.

Looking ahead, a strong economy will depend on continued growth in manufacturing, including healthy advances in both durable and nondurable goods. Companies that look to expand both their domestic and international market shares should flourish.

•

Top 10 Manufacturing Sectors for Recent Employment Growth

(in Thousands of Workers)

Fabricated Metal Products

Machinery

Motor Vehicles and Parts

Transportation Equipment

Primary Metals

Computer and Electronic Products

Semiconductors and Electronic Components

Plastics and Rubber Products

Electrical Equipment and Appliances

Computer and Peripheral Equipment

December 2007 to

December 2009

-301.7

-208.5

-306.0

-377.9

-104.3

-162.2

-77.8

-140.0

-74.0

-24.2

Source: Bureau of Labor Statistics

December 2009 to

May 2011

96.4

66.5

46.2

45.0

38.0

27.7

21.6

18.0

14.3

10.3

6 MEMBER FOCUS

POLICY FOCUS

• • •

NAM Leadership Urges Action on

Regulatory Burden

In testimony June 15 before President Obama’s Council on Jobs and Competitiveness, leaders from the National Association of

Manufacturers (NAM) highlighted the damaging effects of overreaching regulations and offered the NAM’s recommendations for improving the regulatory system.

NAM President and CEO Jay Timmons,

Chair Mary Andringa and Small and

Medium Manufacturers Group Chair Kellie

Johnson joined a number of business and government luminaries at the working group’s meeting, which followed the

Council’s meeting with President Obama in North Carolina June 13.

While commending the Council for its efforts to improve the regulatory process and the Administration for the executive order requiring a review of all regulations enacted in the past two years, Timmons also sounded a cautionary note.

“Added unnecessary regulatory costs can harm manufacturers’ efforts to create jobs in this difficult business climate,” he said. “We can’t assume that manufacturers are going to grow. Instead, we must ensure that we put in place policies that make manufacturers competitive in the global marketplace.”

Specifically, Timmons noted that the

Environmental Protection Agency’s (EPA) decision to make the National Ambient

Air Quality Standard (NAAQS) for ozone more stringent could cost as many as 7.3

million jobs and add up to $1 trillion in new regulatory costs annually between

2020 and 2030, according to the Manufacturers Alliance/MAPI.

“We believe this Council should recommend that the EPA defer reconsideration of the ozone standard altogether and focus instead on consideration of a 2013 standard.

Any savings that agencies may realize in their retrospective reviews of existing regulations could be eaten up instantly by this unnecessary mid-course reconsideration on ozone,” Timmons said.

Andringa’s comments to the Council focused on the labyrinthine and delayladen regulatory process imposed at the v Learn more on the web @ www.nam.org/regulatory federal, state and local levels on permitting for infrastructure projects.

“Our current system is a product of unintentional design with a myriad of overlapping and duplicative processes that leads to extensive delays and higher costs for both privately funded and government-funded projects,” she said. “As we seek to invest scarce resources in our nation’s infrastructure to support our economy, it is a waste of those resources that it still takes 13 years or more to advance a highway project. That is too long,” Andringa noted.

Streamlining the permitting process was one of the key proposals the Council included in its first progress report and set of five

“fast action steps,” presented to the President on June 13 in Durham, N.C.

In a Wall Street Journal op-ed outlining the Council’s five recommendations, GE

CEO and Council Chair Jeffrey Immelt and Council member Ken Chenault, CEO of American Express, wrote, “The administration can take a few simple steps to streamline the process of obtaining permits, without undercutting the protections that our regulatory system provides.”

The Council also proposed improving worker training by forming partnerships with community colleges and vocational schools, an effort the NAM is spearheading in conjunction with the Administration, educational leaders and the business community.

Other Council recommendations included facilitating more small business loans, boosting jobs in travel and tourism and putting construction workers back to work.

The NAM shared its suggestions for the

Council with the White House and will continue to work closely with the Council as it works to foster job creation and a sustained economic recovery. “We welcome the

Council’s input and leadership because a strong manufacturing sector is key to overall

U.S. economic health,” Timmons said. •

July 2011 7

• • •

FOR MANUFACTURERS

NAM Manufacturing Summit 2011

n Sen. Ron Johnson (R-WI) talked with

NAM members.

n White House Chief of Staff Bill Daley addressed Summit attendees on June 16.

n Sen. John Thune (R-SD) addressed the Manufacturing Summit on June 16.

n Rep. Jim Himes (D-CT) met with NAM members on the Hill.

n NAM President and CEO Jay Timmons, NAM Board Chair Mary Andringa and

NAM members met with Senate Minority Leader Mitch McConnell (R-KY) .

n Sen. Chuck Grassley (R-IA) discussed manufacturers’ top issues.

8 MEMBER FOCUS

POLICY FOCUS

• • •

Administration Announces

New Cybersecurity Proposal

The Obama Administration recently unveiled a legislative proposal on cybersecurity that includes many reforms sought by manufacturers, such as better collaboration between private industry and the government and an emphasis on industrywide best practices.

The Administration’s plan sets up a framework for the federal government to provide assistance to industry, states and local governments in the event of a cyberattack and provides for partnerships between industry and government in developing comprehensive cybersecurity plans and reporting potential threats. The proposal also sets national guidelines on data breach reporting and defines and clarifies penalties for computer crimes.

Protecting our nation’s critical cyberinfrastructure is of the utmost importance to manufacturers because cyber-attacks can lead to lost or stolen data, decreased productivity, compliance issues, lost sales and even loss of reputation for businesses of all sizes.

The National Association of Manufacturers (NAM) supports encouraging manufacturers to adopt industry-standard best practices through incentives as a way to ensure innovation while addressing the evolving threats to our nation’s security.

Mandates on the use of specific technologies or standards would inhibit flexibility and innovation and limit their effectiveness.

Technology-neutral open standards and best practices will allow manufacturers who act as network operators the speed and flexibility to keep cyber-criminals in check.

“Manufacturers have a critical interest in cybersecurity and should have a seat at the table as potential legislation is discussed,” said Brian Raymond, the NAM’s director of technology and domestic economic policy.

“We look forward to working with both the Administration and Congress as these proposals are developed into legislation and the process moves forward.” • v Learn more on the web @ www.nam.org/technology

Senate Introduces NAM-

Supported, Bipartisan Bill on Critical Minerals

A bill to revitalize the supply chain for U.S.

rare earth and other critical minerals and to reduce the nation’s growing dependence on foreign suppliers was introduced in the Senate on May 27. It is the latest in a number of bills introduced to address rare earths and other critical minerals.

The bipartisan legislation, sponsored by

Sen. Lisa Murkowski (R-AK), would establish an official process to assess and designate minerals as critical in regard to potential supply restrictions and their importance to various manufacturing applications. It would create an interagency working group on critical materials to facilitate greater exploration and development of these minerals domestically and would establish a critical minerals research and development program on recycling technology and possible alternative minerals.

Rare earth minerals are used in numerous manufacturing applications, including renewable energy products, hybrid car batteries, consumer electronics and defense. Over the past year, demand for some of these minerals has continued to increase while the export of several of these minerals has dropped dramatically. This has created a shortage in these minerals but also significantly increased their price. Many manufacturers depend on these minerals to develop products and to make their processes more efficient.

The National Association of Manufacturers (NAM) supports efforts to tackle this complex issue and believes legislation should address the minerals problem in an expedited and flexible manner that takes into account the unique aspects of different industry sectors. Other key components of a comprehensive solution should include the development of domestic processing capabilities; workforce improvements; research and development for affordable alternative minerals; and support for recycling and reuse of minerals.

The NAM spearheaded a letter to Sen.

Murkowski thanking her for her efforts and outlining shared principles for legislation.

Twenty other trade associations also signed the letter. The groups pledged to work closely with lawmakers in the coming months to craft an effective and workable solution to this critical shortage. •

July 2011 9

• • •

MEMBER FOCUS

Manufacturing Means

Jobs!

BMW:

A Leader in Sustainability

Max Metcalf is communications manager at BMW Manufacturing

Co. and sits on the National Association of Manufacturers’ (NAM)

National Public Affairs Steering Committee. BMW Manufacturing is the global producer of the BMW X5 and X3 Sports Activity Vehicles and X6 Sports Activity Coupe. Mr. Metcalf spoke with Member

Focus about BMW’s commitment to protecting the environment.

Member Focus (MF): Tell us about what

BMW is doing to promote sustainability and the use of renewable energy.

Max Metcalf (MM): BMW is committed to protecting the environment. It is something our company takes very seriously. Use of green energy is a key aspect of that commitment.

At our Greer, S.C., manufacturing facility, we generate power on-site using gas that is produced when waste decomposes at a landfill. For the past eight years, we have collected methane gas from a local landfill and turned it into a power source that fuels our plant’s operations. Last year, we generated almost

62 million kilowatt-hours of power with our landfill gas system. That’s more than one-third of the electrical energy we used at our facility.

This renewable energy program has had a measurable impact on our carbon footprint.

Because of this initiative, we have reduced carbon dioxide emissions by 92,000 tons annually in upstate South Carolina.

MF: And you are using methane gas that might otherwise be wasted.

MM: That’s another way we are having a positive impact on the environment. Methane gas is a greenhouse gas. Landfills will often burn these gases off to prevent them from

10 MEMBER FOCUS escaping into the atmosphere. We’re using the methane gas—a previously wasted energy source — to power our facility.

MF: People are taking notice of BMW’s efforts.

MM: That’s right. The Environmental Protection Agency (EPA) recently ranked BMW fourth on its list of on-site green power generators. The Dow Jones Sustainability

Indexes rank BMW as the world’s most sustainable automobile manufacturer. We’ve been named an industry leader by this index for six years in a row.

MF: High energy costs are a challenge for manufacturers across the country. Is the renewable energy BMW is generating cost-competitive with traditional sources of energy?

MM : It is. In fact, we are saving money. I’d say we are saving around $5 million in energy costs each year. Our investment in clean energy was well worth the initial cost, and we plan to continue these investments.

MF: It sounds like you expect BMW to continue to lead the way in alternative energy initiatives.

MM : Absolutely. We have had great success so far and are going to continue to invest in clean energy alternatives. In fact, in 2009, we dedicated $12 million to improving the efficiency of our landfill gas system. We’re going to continue to invest. We recently added a hydrogen storage and distribution center for our hydrogen-fuel cell material handling fleet — that’s equipment like forklifts — at our new assembly facility for the X3 Sports Activity Vehicle. Hydrogen fuel cells power 91 pieces of material handling equipment, giving BMW Manufacturing one of the largest hydrogen fuel cell fleets in the nation.

These sustainable, alternative energy initiatives are good for the environment and good for our bottom-line. It’s a win-win situation.

•

Photos: BMW Manufacturing Co.

MEMBER FOCUS

• • •

NAM Member Tells Senate

Committee Panama Trade

Agreement Is Crucial

On May 25, NAM member Jason Speer, vice president and general manager of Quality Float Works, Inc., testified before the Senate

Finance Committee on the potential benefits of a free trade agreement

(FTA) with Panama. Speer had just returned from a sales trip in

Panama where he saw many opportunities for his company and other manufacturers to expand and export. As Speer testified, “The benefits of free trade have been fundamental to the growth of our company and our ability to provide quality jobs to American workers.

However, tariff and market access barriers in overseas markets continue to present challenges to us and other American exporters.” •

COOL STUFF BEING MADE

Refractories are ceramic materials designed to withstand the extremely high temperatures encountered in modern manufacturing and industrial processes. They line hot surfaces and endure physical wear and chemical corrosion.

Refractories include thousands of everyday items of all shapes and sizes, such as fireplaces, bathtubs and flower pots, but they also encompass sophisticated applications, such as the manufacture of petrochemical products and the refining of gasoline.

In this month’s “Cool Stuff Being Made” video, The Refractories Institute takes us through the exacting process by which natural and synthetic raw materials and minerals such as alumina, bauxite and zirconia are processed to enhance their ability to withstand temperatures above 1,000 degrees.

Whether processed into pre-formed shapes or poured, pumped, or sprayed into custom applications, the common denominator is that these materials are essential to 21stcentury manufacturing. To view the video, please visit www.nam.org/CoolStuffBeingMade.

Upcoming Events — Register Now!

National Public Affairs Steering Committee Meeting

Wednesday, September 14, 2011 –

Thursday, September 15, 2011

Hyatt Regency Capitol Hill

400 New Jersey Avenue, NW

Washington, D.C.

Contact: Candice Daniels

(202) 637-3122 • cdaniels@nam.org

Welcome Back to Congress Reception

Wednesday, September 14, 2011

5:30 p.m. – 7:30 p.m.

101 Constitution Avenue, NW

Washington, D.C.

Contact: Tiffany Adams

(202) 637-3118 • tadams@nam.org

“Cool Stuff Being Made” takes you inside the plants, factories and facilities of manufacturers producing high-quality goods right here in America. Want your manufacturing facility featured on the NAM’s YouTube page? Send us your “Cool Stuff Being Made” video.

It should include a tour of your manufacturing process, run less than 10 minutes and include voice narration.

For more information, please e-mail mpreiss@nam.org.

v Connect with us on the web @ www.nam.org/Events July 2011 11

• • •

MEMBER FOCUS

•

•

•

NAM News and Events

n On April 26, Sen. Rob Portman (R-OH) met with employees at Lincoln Electric Holdings, Inc. in Cleveland, Ohio, and toured the Lincoln Electric Automation Center.

NAM’s Aric Newhouse

Named One of DC’s

Most Influential

The June 2011 issue of The Washingtonian magazine features National Association of Manufacturers

(NAM) Senior Vice President for Policy and Government Relations Aric Newhouse among its top 40 lobbyists under 40. According to the magazine,

“Newhouse is leading the group’s charge to push for job growth in the industrial sector.” Read more at www.washingtonian.com.

Tell Us What You Think

Send us your feedback, ideas and insights on manufacturing or the new Member Focus .

Please e-mail Clare James Johnson, managing editor, at cjohnson@nam.org.

n NAM President and CEO Jay Timmons moderated a panel, “Manufacturing in the South,” in Roanoke, Va., on June 13.

Panelists included Virginia Governor Bob McDonnell,

Mississippi Governor Haley Barbour and Tennessee

Governor Bill Haslam.

12 MEMBER FOCUS nam.org/Facebook nam.org/Twitter nam.org/ShopFloor nam.org/YouTube nam.org/Flickr nam.org/LinkedIn

Correction: The May 2011 issue of Member Focus incorrectly stated on page 5 that Japan recently reduced its corporate tax rate, making the United States’ corporate tax rate the highest in the world. Japan’s lower tax rate was not enacted as expected.

The United States continues to have the second-highest statutory corporate tax rate among developed nations— 35 percent.

MEMBER SERVICES

• • •

GET UP TO 25%

SAVINGS

PLUS $25 OFF

Enroll in the NAM Avis Car Rental

Program and receive up to 25% off rentals when you reserve with Avis.

You’ll also receive $25 off a weekly rental with coupon # MUGA258 .

Enjoy premium service with Avis.

Enroll at nam.org/carrental .

Visit avis.com/nam for reservations and full coupon

Terms and Conditions.

NAM members save up to

20% and get a FREE Sunday!

Enroll in the NAM Budget Car Rental Program and get up to 20% off rentals when you use Budget. And that’s just the beginning—you’ll also receive a FREE Sunday rental with coupon # TUFZ007 .

Enroll at nam.org/carrental . Visit budget.com/nam for reservations and full coupon Terms and Conditions.

Avis features GM vehicles. ©2010 Avis Rent A Car System, LLC

19195-02

Budget features Ford and Lincoln Mercury vehicles.

19195-02

©2010 Budget Rent A Car System, Inc. A global system of corporate and licenq`wsee-owned locations.

.

F N C F S T P G

/

F

" .

E & Y

T B

'

¥

W F

U I F

V T J O H

6 Q U P

6 Q U P

6 Q U P

6 Q U P

T

B

8

B S P

I

O

J

E

UJ

V

I

Q Q

U

O

J

U

E

O

I F

H

U

I F S F

T

D P

I F

F

B

S

N C

X

W

S F

J

P

D

MS E

F T

O P

J O F E

P

5

S

P

N J

W

E

F S

B Z

T B

O J

F

N

O S

V N

E

P

U

F

MJ m

UJ

O

Z

MM

T I

D

J

B

Q

UJ

M

P

F

Q

G ' F

D P

M

J O H

E

T

S F R V

& Y

U F

&

GG

Y

F

Q

D

S F

JU

T T

SJ F N

W

F

F

P

¥

T

O U T

S

F

B

H

S

P

W

O E

J D

'

F

U P

F E

U P

G SS

& Y

U I

O

( S P V O E ¥

F 6

D M

4

Q N

B

KK

O

@

E

Z P

$

C U

V

B

@ M

I B W F

O B E B

S @ F D

U

"

I

T

F

E D

B

C D

P Q

N

W

JU

F

B

P O

N C

P

F

G

S

N L

JU

P

N

G U

F

I F

E F m O UJ F

" .

V

/

T J O H O

T F

Z P

@ R

S W J D

V

R

H

B N

F

F

C

U

U E

P

D

J T D

ä /

P V

,

D

O

P

U T

V

2 1

O U

P G

JS

V

F

&

Q

T

O S

U

P

B

P

O E U F

MM N F O U

SS

P O

J T

UJ P

T

JS

F M

SG

F T

F D

F F

U

8 N T äQ , ä , D L A D äQ # H R B N T M S R ä

P

P G

P G

P

G

G

G

G

G

G

' F E & Y & Y Q S F T T

' F E & Y * O U F S O B

' F E & Y ( S P V O E ¥

' F E & Y ' S F J H I U ¥

¥ T F S W J D F T

JU P O B M ¥ T F S W J D F T

T F S W J D F T

T F S W J D F T

P

N

S

H

'

J

V

F E & Y

Z

O

B

J

S

P

B

V

O U

S

T

N V N T

SG

F

I

F

F

J Q

J H

Q

Q J O H

B

S

I U

D D

P H

T

S

F T T P

B W

B

E J T D P V O U

J O

N T

JS B

H T

ª

M

Q S

D I

T

B

P H

S

B S

H

S B

F

F

N

T

P G

' F

Q

E

P

S

& Y

G T

S T

U

Q

P W J E

B O E

F D

B

J B

S E

"

F S

M M JS

4

M I

H

F

I

JM T

B

F

O

U T

U

U

E

S

I

S

F

JM

B U F T

O H

F T

B

F

Q

S W

G F

Q

B

F

O

F

JM D

T

E D

&

E

B C M

B O O P

C M F

U

F

JM H

'

J

F E & Y

T

C F

F S

4

D P N C

F

W

S

J D

W J

F T

D

J O

F

B

F E

(

O E

V

X

J E

E

F

J T

UJ

D

I

P

P S

P U I F

'

V O

9 '

U T

S P

T V

GG F S T

C K F D U

4 F JS

P

F

U

T

S

P

E

D

3

J T D P

I

V M

B O

V O U T

F T

H F

%

5 B

' P

JS GG

J T D

S F

G P S

JM

P V O U

H

U

J

F

C M F

T

S N T

B S

' F

B

F

E &

O

F

Y

E

Y D

¥

D

M V

T

P O

F

T J W F

E J

S W

JU

J

P

D

P

F

O T

T

G B

P

B

G

O Z

O E

T F

S

'

S

B U

W J

F E & Y

F T

D F P

D

T V S

GG

O U P

F

D I B S

JS

B D

O H T

U

H

Z

F T

B

P V

Q

O E

S B

S F N

N

T T P

J V N T

D J

P O F Z

B

C

JU P O

B D L