Defects and nonstoichiometry Defects in crystals

advertisement

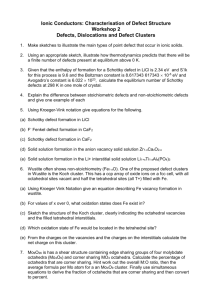

Defects and nonstoichiometry Simple intrinsic point defects The thermodynamics of defect formation Extrinsic defects Defects in nonstoichiometric materials Defect clustering Solid solutions Extended defects – CS planes and shear structures Defects in crystals It is not possible to make crystals that are prefect in every respect – some are more perfect than others It takes energy to create defects in crystals The presence of defects increases the entropy of the crystal – above absolute zero always expect some intrinsic defects Stoichiometry Many solid materials are non-stoichiometric – all that really matters is charge balance Non-stoichiometry is common amongst transition metal compounds – FexO where 0.957 >x > 0.833 – YBa2Cu3O7-x, 1 > x > 0 Non-stoichiometry can control properties Non-stoichiometric compounds TiO x “TiO ” 0.65 < x < 1.25 “TiO 2 ” 1.998 < x < 2.000 VO x “VO ” 0.79 < x < 1.29 Mn xO “MnO ” 0.848 < x< 1.000 NixO “NiO ” 0.999 < x < 1.000 LixV2 O 5 0.2 < x < 0.33 The thermodynamics of defect formation All macroscopic samples of materials contain some defects as defect formation is entropically favored – when defect formation is enthalpically very unfavorable there may be very small numbers of defects Types of defect Defects may occur in isolation due to the increase in entropy of the crystal – intrinsic point defects May occur in isolation to balance the presence of an impurity – extrinsic point defect Defect may occur throughout the crystal – extended defect Intrinsic point defects Two common types of intrinsic point defect – Schottky and Frenkel A Schottky defect consists of charge balancing cation and anion vacancies – Found in NaCl A Frenkel defect is a charge balancing interstitial and vacancy – can have cation or anion Frenkel defects Schottky and Frenkel defects Shottky defect in NaCl - both cation and anion are missing from their regular lattice sites -at room temp on 1 in 1015 sites are vacant in NaCl -200 kJmol-1 creation energy Cation Frenkel defect in AgCl -cation is displaced from regular lattice site onto interstitial site - 130 kJ mol-1 creation energy Frenkel defects Frenkel defects may occur on either the anion or cation sublattice Cation Frenkel defects are more common than anion defects – cations are smaller than anions and hence easier to accommodate in interstitial positions Fluorite structures (CaF2, SrF2, ZrO2, UO2) are good at accommodating anion Frenkel defects Kroger-Vink notation for defects Defect is denoted by symbol of atom involved or by V if it is a vacancy Superscript • indicates a net charge of +1, superscript ‘ indicates a net charge of –1. Superscript x indicates no net charge Subscript indicates nature of site in crystal lattice, s for surface, I for interstitial, element symbol for normal lattice site Examples: – – – – – – V’Na sodium ion vacancy net charge –1 V•Cl chloride ion vacancy net charge +1 x Na Na, ClxCl Na and Cl on their normal lattice sites Cd•Na cadmium on Na site net charge +1 Ag•i silver on interstitial site net charge +1 F’i fluoride on interstitial site net charge -1 Estimation of defect concentration It is possible to calculate the equilibrium concentration of defects in a solid using statistical mechanics ns ~ N exp(-∆HS / 2RT) nF ~ (NNi)1/2 exp(-∆HF/2RT) Defect concentration depends upon the energy needed to form a defect and the temperature Typical values of the defect concentration Most simple ionic solids have low defect concentrations However, small changes in the energetics for defect formation can lead to high defect concentrations Values of ns/N T/K ∆HS = 5 x 10-19 J ∆HS = 1 x 10-19 J 300 6.12 x 10-27 5.72 x 10-6 1000 1.37 x 10-8 2.67 x 10-2 Defects in AgCl Ag+ + Vi Agi+ + VAg K = [Agi+][VAg] / [Ag+][Vi] Let N be the number of lattice sites and Ni the number of interstitial sites – Ni = [VAg] = [Agi+] – [Ag+] = N - Ni [Vi] = αN – number of interstitials is simply related to number of lattice sites for most materials Defects in AgCl continued K ~ Ni2 / α N2 – Substitute into equilibrium constant ∆G = -RT lnK, so [VAg] = Ni = N α1/2 exp(-∆G/2RT) ∆Hf for defects Color centers Electrons trapped in vacant sites give rise to colored materials – color centers – color arises due to transitions between electron in a box levels Trapped electrons can be produced by – irradiation of the sample – treatment with an electron donor like sodium or potassium vapor F, H and V centers Irradiation can lead to defects where an electron has bee lost or added Treatment with alkali metal vapor can lead to excess electrons in material F Center – electron trapped in anion vacancy Example of color center as trapped electron leads to absorption in visible H Center – interstitial Cl atom bonds to lattice ClV Center – electron removed from lattice anion site, resulting Cl atom pairs with neighboring Cl- Imaging plates Color centers are useful in medical X-rays using BaFBr:Eu2+ phosphors BaFBr:Eu2+ phosphors Extrinsic point defects If cationic impurities are introduced into a solid and the dopant does not have the same valence as the cation it is replacing extrinsic defects will be introduced – Fe1-xO has cation vacancies – Ca2+ in ZrO2 - anion vacancies – Y3+ in ZrO2 - anion vacancies – Ca2+ or Cd2+ in NaCl - cation vacancies Real crystals contain both intrinsic and extrinsic defects – the dominant defect type depends upon temperature and doping/nonstoichiometry level Defect clusters and aggregates Point them defects interact and effect the structure around – This may lead to clustering Even in something as simple as NaCl, cation and anion vacancies tend to pair up as they are electrostatically attracted to one another Nonstoichiometric 3d oxides FeO Wustite is a very well studied example of a nonstoichiometric compound The compound “FeO” is not stable The stoichiometry is always Fe1-xO The iron oxygen phase diagram The nature of the defects in “FeO” Density measurements confirm that the nonstoichiometry is incorporated by having vacant iron sites There is Fe(III) present to charge compensate the system The defect structure of “FeO” The defect structure is more complicated than random iron vacancies and Fe(III) Koch clusters in Fe1-xO The Fluorite structure Defect clusters in UO2+x Excess oxygen is incorporated in interstitial sites – This leads to displacement of oxygens from normal sites – Arrangement of defects is similar to structure of U4O9 » Can view defects as forming clusters of U4O9 in UO2 matrix The defect structure of TiO “TiO” spans the composition range TiO0.65 TiO1.25 The stoichiometric phase TiO has many vacancies – At high temperatures the vacancies are disordered – At low temperatures the Ti and O vacancies exist in an ordered array Defects in TiO Based on NaCl structure – 1 in every six atoms is missing – vacancies order at low temp The structure of TiO1.25 Based on NaCl with all anions present, but has ordered Ti vacancies Order disorder Many materials show temperature dependent ordering phenomena Spinels frequently show temperature dependent ordering – Mgtet[Al2]octO4 (normal) and Mgtet[MgTi]octO4 (inverted) but other compositions may be partially inverted and the degree of inversion may depend on synthesis temperature Substitutional solid solutions In many compounds it is possible to replace a metal atom or ion with another element that has similar size and bonding requirements – In metal alloy can replace metal atom with another element that is within 15% size – Can get complete solid solution formation between Al2O3 and Cr2O3 – Al2-xCrxO3 – Exstensive solid solution formation is favored by high temperatures due to the disorder associated with the solid solution Criteria for solid solution formation Typically, for an ionic solid the ion size difference should be less than 15-20% to get complete solid solution formation – > 30% size difference usually precludes solid solution formation End member of solid solution should hve same structure if complete solid solutions is to form – Zn2SiO4 and Mg2SiO4 have different metal coordination » So Zn2-xMgxSiO4 and Mg2-xZnxSiO4 have different structures Interstitial solid solutions Some solid solutions involve inserting atoms into interstitial sites in a parent structure – PdHx 0 < x < 0.7 - hydrogen occupies interstitial sites in fcc Pd – Carbon in interstitial sites of fcc Fe Aliovalent substitution If you replace an ion by one with a different oxidation state (aliovalent substitution) there has to be a charge compensation mechanism Cation vacancies – Dope calcium into NaCl – Na1-2xCaxVxCl – Replacement of Mg2+ by Al3+ in spinel » [Mg1-3xVxAl2x]tet[Al2]octO4 – Oxidation of NiO » Ni2+1-3xVxNi3+2xO Aliovalent substitution Interstitial anions – Not common due to limited size of interstitial sites but occurs for fluorite structure » Ca1-xYxF2+x » U4+1-xU6+xO2+x Anion vacancies – Important in ionic conductors » Zr1-xCaxO2-x Interstitial 0.1 < x < 0.2 cations – Lix(Si1-xAlx)O2 stuffed quartz structure (0 < x < 0.5) Characterizing solid solutions Can determine if solid solution forms by measuring lattice constants of material using x-ray diffraction – Lattice constants typically vary linearly with solid solution composition » Vegard’s law Can work our mechanism of solid solution formation with the aid of density determination Magneli phases The oxides of metals such as W, Mo and Ti display a wide range of compositions – WO3-x, MO3-x, TiO2-x Magneli realized that these compounds were best represented as homologous series of phases rather than solid solutions – TinO2n-1, MonO3n-1 etc Crystallographic shear structures The homologous series can be formed by incorporating crystallographic shear planes into the structures – these are extended defects The shear planes change the stoichiometry of the material – at the CS plane may have face sharing rather than edge sharing or edge sharing rather than corner sharing Can get shear planes in 2 or 3-D leading to – slab structures and block structures Molybdenum and tungsten oxides A wide variety of tungsten and molybdenum oxides are known Many of them belong to homologous series – MnO3n-1 or MnO3n-2 – for example, Mo4O11, Mo5O14 and Mo6O17 Defects in molybdenum and tungsten oxides Why are there so many different oxides? The parent oxide WO3 has a ReO3 structure at high temperature All of these different stoichiometry oxides can be derived from WO3 by incorporating an ordered array of planar defects – crystallographic shear planes The ReO3 structure The incorporation of a shear plane Homologous series Each member of the homologous series has a different repeat distance between shear planes Consider W11O32 Block structures Crystallographic shear planes running in two directions can lead to double shear or block structures – W4N26O77 consists of 4 x 4 and 3 x4 blocks Tungsten bronzes MxWO3 – M is an alkali metal or alkaline earth or H They can be prepared by – electrocrystallization of melts – treatment of WO3 with alkali metal sources – hydrogen spillover There are a variety of possible crystal structures Are used as bronze pigments The structures of tungsten bronzes NaxWO3 - often ReO3 based KxWO3 - 0.19 < x < 0.33 from reaction of K with WO3 is hexagonal – potassium is bigger than sodium and needs a larger site KxWO3 - x < 0.19 regular intergrowth structure Tetragonal bronzes are known for Na and K Tungsten bronze structure types Tetragonal tungsten bronze Hexagonal tungsten bronze Intergrowths It is possible to combine slabs of simple structures together to build up a solid If the slabs grow together in an order array you have an ordered intergrowth – new structure type if order is long range If slabs are randomly stacked together you have a random intergrowth Intergrowth tungsten bronzes Double rows hexagonal structure intergrown with ReO3 structure Single rows hexagonal structure intergrown with ReO3 structure Hexagonal KxWO3 stable for 0.19 < x 0.33, lower values of x can be accommodated by intergrowing with ReO3 type WO3 Intergrowth bronze BaxWO3 Single rows of hexagons can be seen. Some of sites are not filled by Ba2+ Stacking faults Many structures can be thought of as consisting of an ordered stack of layers Sometimes this ordering of the layers breaks down – ABCABCABC..... normal – ABCBCABCABC...... with stacking fault Antiphase domain boundaries At an antiphase boundary the ordering pattern within a crystal structure abruptly changes – This could be a change in metal atom or cation ordering, for example in CuAu where there is ordering of Cu and Au