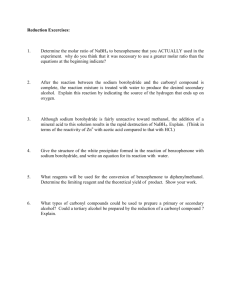

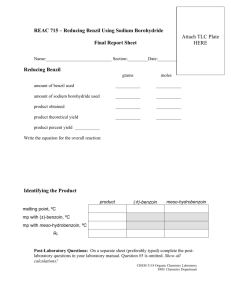

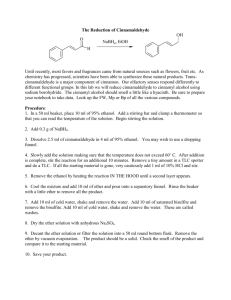

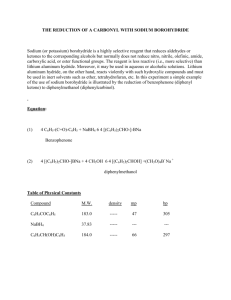

An investigation into the synthesis and characterisation of metal

advertisement