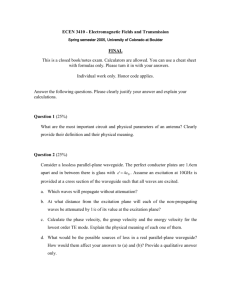

Lamb Wave Interaction with Adhesively Bonded Stiffeners and

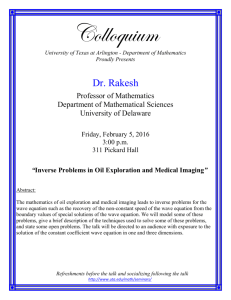

advertisement