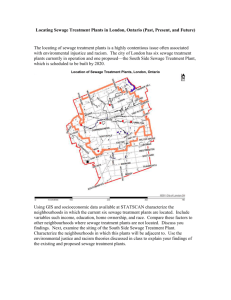

enviromental engg

advertisement