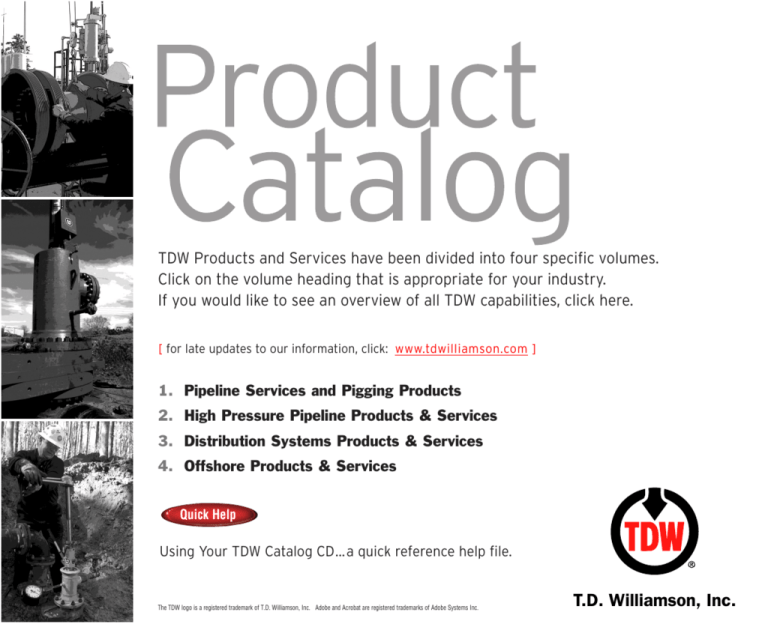

TDW Products and Services have been divided into four specific volumes.

Click on the volume heading that is appropriate for your industry.

If you would like to see an overview of all TDW capabilities, click here.

[ for late updates to our information, click: www.tdwilliamson.com ]

1. Pipeline Services and Pigging Products

2. High Pressure Pipeline Products & Services

3. Distribution Systems Products & Services

4. Offshore Products & Services

Quick Help

Using Your TDW Catalog CD... a quick reference help file.

The TDW logo is a registered trademark of T.D. Williamson, Inc. Adobe and Acrobat are registered trademarks of Adobe Systems Inc.

/°°Ê7>Ã]ÊV°

Using Your TDW Catalog CD

Welcome to the TDW Products and Services Catalog.

To assist in navigating through this detailed document, we’ve

included a few pointers and a little extra help. Acrobat ® Reader

allows you to view, navigate and print PDF document files. The

TDW Catalog is a PDF document.

Jagged Text Problem:

To improve the readability of your Catalog, go the the Preference

window under File, then General and select “Smooth Text and

Monochromatic Images.”

Previous

Bulletin

Navigating Through Your TDW Catalog:

1. Along the left side of your catalog you will find “book marks“

to key points. 2. The Table of Contents is linked to respective

items. 3. At the top of each product bulletin are three square

buttons. Click the top button to return to the previous bulletin,

click the middle button to go to the Table of Contents, and click

the bottom button to move to the next bulletin. (Refer to

illustration —left).

Table of

Contents

Next

Bulletin

Below is Acrobat Reader’s Tool Bar to assist you in

viewing, printing and navigating through PDF documents. You

may also use the keyboard to move through the document.

Acrobat ® Reader’s Tool Bar

View

Page

View with

Bookmarks

Grabber

Hand

Zoom

In/Out

Navigating Through Acrobat ® Reader:

Move around page/document—use the scroll bars or arrow keys

to move up, down, right, or left...or use the “grabber” hand.

Go to the first page—press the Home key.

Go to the last page—press the End key.

Jump to a specific page—drag the vertical scroll bar up and

down until the rectangle to the left of the scroll bar displays

the number of the page desired.

Re-size page view—Click the magnification box in the status bar

at the bottom of the window, type or select a magnification level.

Searching the TDW Catalog:

In the Acrobat tool bar, click the Binocular icon. Type the text for

which you are searching. Click the Find Again button. Click anywhere in the document to unhighlight the results of your search.

You can continue the search for the same information by simply

clicking the Binocular icon, and Find Again.

Printing Your TDW Catalog:

From the Acrobat Reader’s tool bar click the Print icon. Select

the range of pages you wish to print. To print the entire volume,

simply press Print—do not enter any page numbers.

There are many ways to navigate, print or view in Acrobat

Reader. We have provided one choice to assist users who may

be unfamiliar with this product. If you would like further information, please refer to Help on the main tool bar.

Privious Return

view

View

View Fit to

100% Window

Search

High Pressure Piping Systems

Date: April 2009

Supersedes: February 2009

Contents

Notice

Product Warranty

Terms and Conditions

Drilling and Tapping Machines

T-101 Drilling Machine

1/2” through 6”

2000.001

904 Drilling Machine

1/2” through 4”

2000.003

360 Tapping Machine

2” through 6”

1000.004

660 Tapping Machine

3” through 12”

1000.005

760 Tapping Machine

3” through 16”

1000.006

860 Tapping Machine

3” through 20”

1000.008

936 Tapping Machine

12” through 36”

1000.009

1200 Tapping Machine

12” through 36”

1000.001

2400 Tapping Machine

30” through 60”

1000.002

Air Motors

Fall Protection Equipment

1010.002

For TDW Tapping & Plugging Equipment

1010.003

STOPPLE ® Plugging Equipment

STOPPLE Applications

STPPL

STOPPLE Plugging Machines

1030.001

®

®

4” through 48”

SANDWICH ® Valves

SANDWICH Valves

1020.001

®

Rehabilitation Products

RES-Q™ Composite Wrap for Pipelines

2” through 60”

5300.003

RES-Q™ Composite Wrap for Process Piping

2” through 60”

5300.004

Steel Repair Sleeves

2” through 48”

7300.002

Leak Repair Clamp

2” through 36”

7300.003

Next

Back

Contents Continued High Pressure Piping Systems

Date: April 2009

Supersedes: February 2009

Fittings

Flange and Fitting Application Data Form

ff 3/99

STOPPLE Fittings

4” through 22”

1100.001

STOPPLE Plus Fittings

4” through 20”

1100.002

STOPPLE Fittings - ASME B31.3

4” through 8”

1100.004

STOPPLE Fittings - ASME B31.4

4” through 8”

1100.005

STOPPLE Fittings - ASME B31.8

4” through 8”

1100.006

LOCK-O-RING Flanges and Plugs

4” through 36”

1120.001

TDW Tapping Fittings

2” through 30”

1110.001

TDW Tapping Fittings -ASME B31.3

4” through 8”

1110.004

TDW Tapping Fittings -ASME B31.4

4” through 8”

1110.005

TDW Tapping Fittings -ASME B31.8

4” through 8”

1110.006

No. 3 Branch Connection Fittings

2” through 24”

1110.002

WEDGE-LOCK Pipe Plug

2” through 14”

5200.001

THREAD-O-RING™ Fitting

2” and 3”

2100.001

THREAD-O-RING™ Flanged Fitting

2”

2100.019

2” x 4” through 36” x 44”

5210.001

M-2 Plastic THINSULATOR 2” through 48”

5210.002

Insulator and 3-Way Cradles

2” x 6” through 36” x 42”

5210.003

®

®

®

®

®

®

®

Cathodic Protection Equipment

U-Seals™ and Z-Seals™

®

Next

Back

Contents Continued High Pressure Piping Systems

Date: April 2009

Supersedes: February 2009

TDW Services

Tapping and Plugging Solutions Brochure

Process Industry Piping System Maintenance and Repair

Brochure

Underwater Hot Tapping & Plugging Brochure

Tapping & Plugging Services for Water & Wastewater Systems

Brochure

Water Applications Tapping & Plugging Fittings

1160.001

Hot Tapping Service Application Data Form

tp 11/01

Hot Tapping & Plugging Service Application Data Form

tp-pg 11/01

Planning: HT&P Field Requirements/Clearances

ff 1/00

Freeze Service

1300.712

Freeze Plugging Application Data Form

fs 1/01

Cutter/Pilot Repair Service

LineMaster™ Operator Qualification Training

Flyer

Brochure

®

T. D. Williamson, Inc.

Date: March 1999

Supersedes: n/a

Notice

Any operation involving work on pipe containing liquids or gases under pressure is potentially hazardous.

It is necessary that correct procedures be followed in the use of this equipment to maintain a safe working environment.

No person should use this equipment who is not fully trained in the procedures stated in its manual and who is not fully aware

of the potential hazards connected with work on pipe containing liquids or gases under pressure.

The equipment purchaser is responsible for the manner in which the equipment is used and the training and competence

of the operators.

Should any difficulty arise at any time in the use of equipment, please contact TDW immediately. In the U.S., Toll Free:

1-888-TDWmSon (839-6766), Phone: (918) 447-5100, Fax: (918) 446-6327, Email: info@tdwilliamson.com

© Copyright 1999.

All rights reserved T.D. Williamson, Inc.

® Registered trademark of T.D. Williamson, Inc.

TM Trademark of T. D. Williamson, Inc.

Data subject to change without notice.

Printed in USA.

ISO Certified 9001 and 9002

®

T. D. Williamson, Inc.

Date: June 2000

Supersedes: n/a

Product Warranty

1. Products manufactured by T. D. Williamson, Inc., are warranted free from defects in material and workmanship for a period of three

(3) years from the date of shipment from the factory. Elastomer products are warranted for one (1) year under proper storage to

be free from defects in material and workmanship. The foregoing warranty does not apply to any items not manufactured by

T. D. Williamson, including but not limited, to, electronic devices, switch components, pumps, o-rings, purchase cylinders,

etc. These third party parts will revert back to suppliers warranty. TDW assumes no liability under this or any other warranty

for components not manufactured by TDW. This Warranty applies only to products shipped after June 30, 2000.

2. If TDW accepts any claim made under this Warranty, TDW’s liability, if any, shall be limited to, at TDW’s sole option, repair or

replacement of the failed part or product, or a refund of the purchase price, less an allowance for services rendered for the product

prior to the Warranty claim. TDW disclaims any and all responsibility for special, consequential or incidental damages arising

out of or related to the sale, use, or inability to use any products covered by this Warranty.

3. Buyer agrees not to return goods for any reason except with the prior written consent of TDW, which consent, if given, shall specify

the terms, conditions and charges upon which any returns may be made. Materials returned to TDW for Warranty work must have a

Return Material Authorization (RMA) number, and such number must be noted on the package at the time of shipment. Claims

under this Warranty must be made in writing within ten (10) days of any failure and sent by registered mail to: P. O. Box 3409,

Tulsa, Oklahoma 74101. Any failed products or parts must be held for inspection by TDW or, at TDW’s option, returned to TDW’s

factory. Customer shall prepay shipping charges, and shall pay all duties and taxes, as applicable, for products or parts returned to

TDW for warranty service.

4. This Warranty shall not apply to any product or component which has been repaired or altered by anyone other than TDW, or

has become damaged due to misuse, negligence or casualty, or has been operated or maintained contrary to TDW’s printed

instructions and warnings.

5. The sole purpose of the exclusive remedy contained in the limited Warranty shall be to provide repair or replacement of failed

products, or to refund the purchase price of the failed product as explained above in paragraph 2. This exclusive remedy shall not

be deemed to have failed of its essential purpose so long as TDW agrees to repair or replace the failed product or to refund the

purchase price as explained above.

6. All rights, duties, and obligations arising under this limited Warranty shall be governed by the laws of the State of Oklahoma,

U.S.A., regardless of conflict of laws provisions. In the event Buyer initiates litigation under this Warranty, Buyer hereby agrees

that jurisdiction for such litigation shall be brought only in the District Court for the County of Tulsa, Oklahoma.

7. TDW reserves the right to make any changes in or improvements on its products without incurring any liability or obligation to

update or change previously sold product and/or the accessories thereto.

8. THIS WARRANTY IS IN LIEU OF ALL OTHER WARRANTIES EXPRESS OR IMPLIED, INCLUDING THE WARRANTIES OF

MERCHANTABILITY AND FITNESS FOR PARTICULAR PURPOSE, WHICH ARE EXPRESSLY DISCLAIMED. TDW NEITHER

ASSUMES NOR AUTHORIZES ANY OTHER PERSON TO MODIFY THESE TERMS AND CONDITIONS, WARRANT SPECIFIC

APPLICATIONS, OR ASSUME FOR TDW ANY OTHER LIABILITY IN CONNECTION WITH THE SALE OF ANY TDW PRODUCT

OTHER THAN AS PROVIDED IN THIS WARRANTY.

..

Terms and Conditions

T.D. Williamson, Inc.

September 1999

1. Minimum Order: $50.00 (U.S.). Any combination of products or services is allowed to satisfy minimum on a single shipment to a

single destination.

2. Orders: All orders are subject to acceptance by T. D. Williamson, Inc.

3. Return of Materials: Goods may be returned to T. D. Williamson, Inc., only after approval and receipt by customer of definite

shipping instructions and our written Return Materials Authorization. Returned goods are subject to restocking or reconditioning charges.

Customer fabricated items or those requiring special material or special size will not be accepted for return.

4. Prices: Prices are subject to change without notice.

5. Taxes: Any tax based on or measured by the charges made for, or the cash receipts from the sale of products or services shall be added to

the stated price.

6. Delivery: Our responsibility ceases upon delivery to any common carrier; and we do not, unless previously instructed, insure shipments

beyond the point of delivery to said carrier. We make every effort to ship all material within the time indicated by us, but do not guarantee

to do so, and all such indications are subject to delays occasioned by causes beyond our control. We assume no responsibility for delays

in delivery or defaults resulting from strikes, work stoppages, fire, floods, accidents, inability to obtain materials, fuels or transportations,

governmental decree, or any other causes which are unavoidable.

7. Claims: Claims for shortages or defective products must be made within 10 days after receipt of shipment. Loss or damage to materials

in transit is the responsibility of the carrier.

8. Cancellations and Changes: Orders once placed and accepted can be canceled or changed only with our consent and upon terms that will

save us from loss.

9. Cost of Collection and Attorney Fees: Buyer shall be responsible for all our costs and expenses, including attorney fees, incurred by us

in collecting the purchase price for goods or services sold beyond its due date inclusive of delinquency charge.

10. Terms of Payment and Delinquency Charge: Our terms of payment are as shown on our quotation or invoice. All accounts are payable

in United States funds, free of exchange rate variation or collection charges. A delinquency charge will be added on any amount not paid

within the stated terms of payment and thereafter on all accounts in arrears until paid.

11. Delays in Performance: T. D. Williamson, Inc., shall not be liable for any delay in performance hereunder due to unforeseen circumstances

or due to causes beyond its control including, but not limited to, acts of nature, acts of government, labor disputes, delays in transportation,

and delays in delivery or inability to deliver by T. D. Williamson, Inc.’s suppliers.

12. Order of Precedence: (a) These Terms and Conditions and any attachments take precedence over customer’s additional or different

terms and conditions, to which notice of objection is hereby given. Acceptance by customer is limited to these Terms and Conditions.

Neither T. D. Williamson, Inc.’s commence of performance nor delivery shall be deemed or construed as acceptance of customer’s additional

or different terms and conditions. (b) Customer’s purchase of T. D. Williamson, Inc., products hereunder represents acceptance of these

Terms and Conditions and any attachments, which together constitute the entire understanding between the parties and supersede any

previous communications, representations, or agreements by either party whether verbal or written. No change or modification of the Terms

and Conditions herein shall be valid or binding on either party unless in writing and signed by an authorized representative of each party.

13. Governing Law: Any dispute regarding the interpretation or validity hereof shall be governed by the laws of the State of Oklahoma.

The parties hereby agree that any dispute relating to the products or services sold hereunder shall be subject to the jurisdiction of the

courts within the State of Oklahoma.

14. Miscellaneous: (a) Except as may be prohibited by the U.S. Bankruptcy Laws, in the event of any insolvency or inability to pay debts as they

become due by a party hereto, or voluntary or involuntary bankruptcy proceeding by or against a party hereto, or appointment of a receiver

or assetnee for the benefit of creditors, the other party may elect to cancel any unfulfilled obligations hereunder. (b) Any required notices

shall be given in writing at the address of each party set forth herein, or to such other addresses either party may substitute by written notice

to the other. (c) Neither party may assign nor transfer any of the rights, duties, or obligations herein, without the prior written consent

of the other, and any purported attempt to do so shall be null and void. (d) TDW’s failure to exercise any of its rights hereunder shall

not constitute or be deemed a waiver or forfeiture of such rights. (e) Stenographic and clerical errors are subject to correction.

Drilling and Tapping

M A C H I N E S

T-101 Drilling Machine

Sizes: 1/2- to 4-inches

Bulletin No: 2000.001.07

Date: February 2009

Cross Indexing No: n/a

Supersedes: April 2008

Features

Typical Setup

The Model T-101B Drilling Machine is available

in two versions: the standard T-101B with 18” of

travel and the XL Model with 28” of travel.

The T-101 and T-101 XL Drilling Machines

meets NACE Standard MR0175-93, sulfide stress

cracking resistant metalic material for oilfield

equipment. The maximum working pressure is

1,480 psi (100 bar) at 100°F (38°C). Its operating

temperatures are -20°F (-29°C) to 700°F (371°C)

at 700 psi (48 bar) for intermittent service. The

maximum continuous rating is 350°F (177°C) at

1,025 psi (70 bar).

The 904 Drilling Machine is a higher pressure

(balanced) version of the T101XL machine. It is

rated at 2,220 psi (150 bar) at 180°F (82°C). For

special requirements, such as higher pressure or

temperature, consult the factory.

Bleeder

Valve

Other features include:

Lightweight 32 pounds (XL is 50 pounds)

Threaded Valve

Adapter

Versatile 1/2” through 4” taps

Operates to 1,480 psi (2,220 psi for 904

Model)

Hole Saw

(or drill)

T-101 Drilling Machine

Model T-101B

Options

Description

Drilling machines are used to make

connections to pipelines, tanks and plant piping

without shutdown and are used to make hot taps

in preparation for plugging machine applications.

The T-101 Drilling Machine is a manual or

power-driven machine which taps into pipe

while under pressure. It is used for making

1/2” through 4” (DN 15 - DN 100) taps without

shutdown. It can be used to install 2” and 3”

completion plugs in tapping nipples to permit

recovery of tapping valves and to install TDW

PIG-SIG® Scraper Passage Indicators.

T.D. Williamson, Inc.

P.O. Box 3409

Valve

T.D. Williamson, Inc., is committed

to providing you with the exact product

to assist you in planning, budgeting and

meeting the specifications for your individual

application needs. The following options are

available:

The T-101 Drilling Machine is

furnished with a ratchet crank for

manual operation. An optional hoseconnected, hand-held air motor can be

easily added.

ISO 9001 Certified

Toll Free

1-888-TDWmSon (839-6766)

Tulsa, Oklahoma 74101-3409

918-447-5100

Fax: 918-446-6327

www.tdwilliamson.com

Data subject to change without notice. / Dimensions not for construction unless certified. / ® Registered trademark of T.D. Williamson, Inc. in the United States and foreign countries / TM Trademark of T.D. Williamson, Inc. in the United States and foreign countries / © Copyright 2009. All rights reserved T.D. Williamson, Inc. / Printed in USA

Dimensions and Part Numbers

T-101 Drilling Machine

2000.001.07 - p2

Models T-101B and T-101B-XL

Drilling Machine

Item

Wt./ Lb.

Wt./Kg.

Part Number

T-IO1B Drilling Machine

32

15

05-1028-0000

T-101B-XL Drilling Machine

50

22

05-1029-0000

Includes: Ratchet Crank

00-1443-0009-03

Cap

05-1028-0046

Bleeder Valve

00-0774-0001

Nipple

00-0220-0001

Packing Wrench

05-0184-0020

Optional Equipment:

The cap locks the feed

and rotation of machine

to set and retrieve

completion plugs.

Air Motor (Pistol Grip)

6

3

Air Motor (Right Angle)

8

4

00-1508-0001

05-2160-0000

Drive Socket

00-1509-0004

Steel Carrying Case (Std.)

15

7

05-2100-0000

Steel Carrying Case (XL)

20

9

05-2101-0000

Plug Holder for 2” THREAD-O-RING™ Plug

05-0185-0001

®

Plug Holder for 2” and 3” SHORTSTOPP Completion Plug

08-2120-0000

Operating Specifications

Maximum Operating Pressure

1,480 psi (100 bar) @ 100°F (38°C )

Maximum Operating Temperature

700°F (371°C) @ 700 psi (48 bar)*

* For intermittent service only. Maximum continuous rating is 350°F (177°C) at 1,025 psi (70 bar).

Standard Model

Drilling Machine Specifications

Item

Inches

Boring Bar Travel

Inches

mm

18

457

28

711

46-5/16

1176

66 5/16

1684

Boring Bar Extension/Revolution

0.125

3.2

0.125

3.2

Feed Mechanism

Hand-Fed Machine

Overall Length

Accessories for PIG-SIG® IV and V Installation

XL Model

mm

Hand-Fed Machine

Item

Part Number

Drill for wall thickness more than 3/8” (9.5mm)

05-0193-0001

Valve Adapter for Cutter or Drill - for use on 2” (50 mm) threaded valve

®

2” (50 mm) THREAD-O-RING Plug Holder for use with PIG-SIG IV

™

®

PIG-SIG V Plug Holder

00-0706-0016

05-0185-0001

00-8138-0000

2” (50 mm) ASME CIass 600 conventional valve with 2-1/16” (53mm) through-bore is recommended for use in making taps for PIG-SIG® Scraper

Passage Indicator installation.

T.D. Williamson, Inc.

P.O. Box 3409

Tulsa, Oklahoma 74101-3409

918-447-5100

Fax: 918-446-6327

www.tdwilliamson.com

Data subject to change without notice. / Dimensions not for construction unless certified. / ® Registered trademark of T.D. Williamson, Inc. in the United States and foreign countries / TM Trademark of T.D. Williamson, Inc. in the United States and foreign countries / © Copyright 2009. All rights reserved T.D. Williamson, Inc. / Printed in USA

Dimensions and Part Numbers

T-101 Drilling Machine

2000.001.07 - p3

Models T-101B and T-101B-XL

Drill Diameter

Drills

Inches

Hole Saws/Cutters and Holder Pilots

Drill Length

DN

Inches

Valve Size

mm

Inches

1-1/4 - 2 32-50

1/2

12.7

6

150

1/2

12.7

22-1/4

565

3/4

19.0

6

150

3/4

19.0

22-1/4

565

1

mm

Part Number

05-0203-0005

25

05-0189-0001

1-1/4 - 2 32-50

1

05-0203-0009

25

05-0189-0002

1

25.0

6

150

1-1/4 - 2 32-50

05-0203-0012

1-1/4

32.0

6

150

1-1/2 - 2 40-50

05-0203-0013

1-7/16

36.5

7-3/8

187

1-1/2 - 2 40-50

05-0193-0001

Tap Size

Inch

DN

Cutter Diameter

Inch

mm

Size-on-Size

Hole Saw/Cutter

Holder Pilot

Part No.

Part No.

Not Size-on-Size

Holder Pilot

Part No.

1-1/4

32

1-5/16

33.3

00-1151-0005

05-0634-0000

05-0290-0000

1-1/2

38

1-9/16

39.7

00-1151-0009

05-0275-0000

05-0290-0000

2

50

1-7/8

47.6

05-0179-0002

05-0204-0000

05-0207-0000

3

80

2-7/8

73.0

05-0179-0003

05-0204-0000

05-0207-0000

4

100

3-7/8

98.4

05-0179-0004

05-0205-0000

05-0228-0000

Maximum Pressure

Threaded Valve Adapters

Flanged Valve Adapters - ASME Class

Inches

DN

Part Number

psi

Bar

1

1-1/4

25

06-1223-0001

1480

100

32

00-0757-0012

1480

100

1-1/2

38

00-0757-0011

1480

100

2

50

00-0706-0015

1480

100

3

80

06-1303-0001-02

1480

100

Inches

DN

Class 150 RF

Class 300 RF

Class 600 RF

2

50

06-1305-0015

06-1305-0030

06-1305-0060

3

80

06-1318-0015

06-1318-0030

06-1318-0060

4

100

06-1302-0015

06-1302-0030

06-1302-0060*

150

06-8872-0001

06-8872-0002

06-8872-0003

150

06-8684-0001

06-8685-0001

06-8872-0004

6” SANDWICH

®

6” Gate Valve

*For 4-inch taps with the T-101 this adapter must be used with TDW 4-inch SANDWICH® Valve to ensure sufficient boring bar

travel to complete the tap.

Nominal Size

Valve Dimensions for Making Taps

T.D. Williamson, Inc.

P.O. Box 3409

Minimum Bore

Inches

DN

Inches

mm

2

50

2-1/16

52.4

3

80

3-1/16

72.8

4

100

4-1/32

102.4

Tulsa, Oklahoma 74101-3409

918-447-5100

Fax: 918-446-6327

www.tdwilliamson.com

Data subject to change without notice. / Dimensions not for construction unless certified. / ® Registered trademark of T.D. Williamson, Inc. in the United States and foreign countries / TM Trademark of T.D. Williamson, Inc. in the United States and foreign countries / © Copyright 2009. All rights reserved T.D. Williamson, Inc. / Printed in USA

904 Drilling Machine

Sizes: 1/2- to 4-inches Model 904B

Bulletin No: 2000.003.01

Date: October 2004

Cross Indexing No: n/a

Supersedes: January 2004

Features

Typical Setup

The Model 904B Drilling Machine is available in

the XL Model with 28-inches of travel.

The 904B Drilling Machine meets NACE

Standard MR0175-2002, sulfide stress cracking

resistant metalic material for oilfield equipment.

The maximum working pressure is 2,220 psi (153

bar) at 100°F (38°C). Its operating temperatures

are -20°F (-29°C) to 180°F (82°C) for intermittent

service. The maximum continuous rating is 180°F

(82°C) at 1,025 psi (48 bar).

The 904B Drilling Machine is a high pressure

balanced machine. At this high pressure, it is

limited to a maximum of 4-inch (DN 100) taps. For

special requirements, such as higher pressure or

temperature, consult the factory.

Other features include:

Lightweight 85 pounds (39 kg)

2-inch 900#

RTJ Flanged

Valve Adapter

Bleeder

Valve

Versatile 1/2- through 4-inch taps

Operates to 2,220 psi

Threaded Valve

Adapter

Options

Hole Saw

(or drill)

904 Drilling Machine

Model 904B

T.D. Williamson, Inc. is committed to

providing you with the exact product to

assist you in planning, budgeting and

meeting the specifications for your individual

application needs. The following options are

available:

Description

The 904B Drilling Machine is Drilling machines are used to make

connections to pipelines, tanks and plant piping

without shutdown and are used to make hot taps

in preparation for plugging machine applications.

The 904 Drilling Machine is a manual or

power-driven machine which taps into pipe

while under pressure. It is used for making 1/2through 4-inches (DN 15 - DN 100) taps without

shutdown. It can be used to install 2-inch and

3-inch completion plugs in tapping nipples to

permit recovery of tapping valves and to install

TDW PIG-SIG® Scraper Passage Indicators.

T.D. Williamson, Inc.

Valve

P.O. Box 3409

furnished with a ratchet crank for manual operation. An optional hose-

connected, hand-held air motor can be easily added or a hand held hydraulic drive option is available

ISO 9001 Certified

Toll Free

1-888-TDWmSon (839-6766)

Tulsa, Oklahoma 74101-3409

918-447-5100

Fax: 918-446-6327

www.tdwilliamson.com

Data subject to change without notice. / Dimensions not for construction unless certified. / ® Registered trademark of T.D. Williamson, Inc. in the United States and foreign countries / TM Trademark of T.D. Williamson, Inc. in the United States and foreign countries / © Copyright 2006. All rights reserved T.D. Williamson, Inc. / Printed in USA

Dimensions and Part Numbers

904 Drilling Machine

2000.003.00- p2

Model 904B

Drilling Machine

Item

Wt./ Lb.

Wt./Kg.

Part Number

85

39

05-1046-0000

904B XL Drilling Machine

Includes: Ratchet Crank

00-1443-0001

Cap

05-1028-0046

Bleeder Valve

00-0774-0001

Nipple

00-0220-0001

Packing Wrench

05-0184-0020

Optional Equipment:

The cap locks the feed and rotation of machine

to set and retrieve completion plugs.

Air Motor

8

4

00-1508-0004

Hydraulic Drive (w/ 60’ Hoses)

30

14

05-1026-0000

Drive Socket

Steel Carrying Case (XL)

9

05-2152-0000

Plug Holder for 2” THREAD-O-RING™ Plug

05-0185-0001

Plug Holder for 2” and 3” SHORTSTOPP® Completion Plug

08-2120-0000

20

00-1509-0004

Operating Specifications

Maximum Operating Pressure

2220 psi (153 bar) @ 100°F (38°C )

Maximum Operating Temperature

180°F (82°C) @ 700 psi (48 bar)

Drilling Machine Specifications

Accessories for PIG-SIG® IV Installation

Item Standard Model (XL)

Inches

mm

Boring Bar Travel

28

711

Overall Length

70 3/4

1797

Boring Bar Extension/Revolution

0.125

3.2

Feed Mechanism

Hand-Fed Machine

2-inch 900# Flange

Standard

2-inch NPT Adapter

Standard

Item

Part Number

Drill for wall thickness more than 3/8” (9.5mm)

05-0193-0001

Valve Adapter for Cutter or Drill - for use on 2” (50 mm) threaded valve

00-0706-0016

2” (50 mm) THREAD-O-RING™ Plug Holder

05-0185-0001

2” (50 mm) ASME CIass 600 conventional valve with 2-1/16” (53mm) through-bore is recommended for use in making

PIG-SIG® IV Taps.

T.D. Williamson, Inc.

P.O. Box 3409

Tulsa, Oklahoma 74101-3409

918-447-5100

Fax: 918-446-6327

www.tdwilliamson.com

Data subject to change without notice. / Dimensions not for construction unless certified. / ® Registered trademark of T.D. Williamson, Inc. in the United States and foreign countries / TM Trademark of T.D. Williamson, Inc. in the United States and foreign countries / © Copyright 2006. All rights reserved T.D. Williamson, Inc. / Printed in USA

Dimensions and Part Numbers

904 Drilling Machine

Models 904B

2000.003.00- p3

Drill Diameter

Drills

Drill Length

Inches

Valve Size

Inches

DN

mm

Inches

1/2

12.7

1/2

12.7

6

150

1-1/4 - 2 32-50

22-1/4

565

3/4

19.0

6

150

3/4

19.0

22-1/4

565

1

25.0

6

150

1-1/4 - 2 32-50

05-0203-0012

1-1/4

32.0

6

150

1-1/2 - 2 40-50

05-0203-0013

1-7/16

36.5

7-3/8

187

1-1/2 - 2 40-50

05-0193-0001

1

mm

Part Number

05-0203-0005

25

05-0189-0001

1-1/4 - 2 32-50

1

05-0203-0009

25

05-0189-0002

Tap Size

Inch

DN

C utter Diameter

Inch

mm

Size-on-Size

Hole Saw/Cutter

Holder Pilot

Part No.

Part No.

1-1/4

32

1-5/16

33.3

00-1151-0005

05-1094-0000

05-1064-0000

1-1/2

38

1-9/16

39.7

00-1151-0009

05-0275-0000

05-0290-0000

2

50

1-7/8

47.6

05-0179-0002

05-0204-0000

05-0207-0000

3

80

2-7/8

73.0

05-0179-0003

05-0204-0000

05-0207-0000

4

100

3-7/8

98.4

05-0179-0004

05-0205-0000

05-0228-0000

Hole Saws/Cutters and Holder Pilots

Not Size-on-Size

Holder Pilot

Part No.

Maximum Pressure

Threaded Valve Adapters

Flanged Valve Adapters - ASME Class

Inches

DN

Part Number

psi

Bar

1

25

06-1223-0001

1480

100

1-1/4

32

00-0757-0012

1480

100

1-1/2

38

00-0757-0011

1480

100

2

50

00-0706-0015

1480

100

3

80

06-1303-0001-02

1480

100

Inches

DN

Class 150 RF

Class 300 RF

Class 600 RF

Class 900 RJT

2

50

06-1305-0015

06-1305-0030

06-1305-0060

Standard

3

80

06-1318-0015

06-1318-0030

06-1318-0060

-*

4

100

06-1302-0015

06-1302-0030

06-1302-0060

-*

*Consult Factory

Nominal Size

Valve Dimensions for Making Taps

Minimum Bore

Inches

DN

Inches

mm

2

50

2-1/16

52.4

3

80

3-1/16

72.8

4

100

4-1/32

102.4

T.D. Williamson, Inc.

P.O. Box 3409

Tulsa, Oklahoma 74101-3409

918-447-5100

Fax: 918-446-6327

www.tdwilliamson.com

Data subject to change without notice. / Dimensions not for construction unless certified. / ® Registered trademark of T.D. Williamson, Inc. in the United States and foreign countries / TM Trademark of T.D. Williamson, Inc. in the United States and foreign countries / © Copyright 2006. All rights reserved T.D. Williamson, Inc. / Printed in USA

360 Tapping Machine

Sizes: 2-inch through 6-inch

Bulletin No: 1000.004.03

Date: November 2008

Cross Indexing No: n/a

Supersedes: October 2005

Typical Tapping Setup

Features

The basic machine includes:

Model 360b

Tapping Machine

Lower-in crank

Measuring rod

Ring gasket

Bleeder valve and nipple

Motor adapter

Set of bolts and nuts

LOCK-O-RING® bypass gauge

Options

Boring Bar

T. D. Williamson, Inc., is committed to providing

you with the exact product to assist you in

planning, budgeting and meeting the specifications

for your individual application needs. The following

options are available:

Cutter Holder

Cutter

The Model 360a Tapping Machine is manually operated.

360 Tapping Machine

Model 360a

Gasket

Pilot

The Model 360b Tapping Machine is air or hydraulic operated.

* For design code options not listed and additional sizes,

consult your sales representative.

Description

Adapter

SANDWICH

Valve

®

Tapping machines are used for making

connections to pipelines, tanks, and plant piping

without shutdown and are used to make hot taps

in preparation for plugging machine applications.

Model 360 Series Tapping Machines are

designed to make hot taps into pipelines, tanks and

plant piping. It can be a manual, air or hydraulic

driven machine used for making tank taps to

4-inch and pipe taps to 6-inch. Its maximum

working pressure is 1,480 psi (100 bar) at 100°F

(38°C). Its operating temperature is -20°F (29°C) to 700°F (371°C) at 700 psi (48 bar) for

intermittent service. Its maximum continuous

rating is 350°F (177°C) at 1,025 psi (70 bar).

T.D. Williamson, Inc.

P.O. Box 3409

®

STOPPLE Fitting or

Tapping Fitting

Pipeline

ISO 9001 Certified

Toll Free

1-888-TDWmSon (839-6766)

Tulsa, Oklahoma 74101-3409

918-447-5100

Fax: 918-446-6327

www.tdwilliamson.com

Data subject to change without notice. / Dimensions not for construction unless certified. / ® Registered trademark of T. D. Williamson, Inc. in the United States and foreign countries / TM Trademark of T. D. Williamson, Inc. in the United States and foreign countries / © Copyright 2008. All rights reserved T. D. Williamson, Inc. / Printed in USA

Dimensions and Part Numbers

1000.004.03 - p2

360 Tapping Machine

Operating Specifications

Boring Bar Travel

Tank Taps*

Pipe Taps*

Max. Operating Pressure

Max. Operating Temperature

Power

Feed Rate

Lower-In Crank

Length (without measuring rod)

Length (with measuring rod)

Meets NACE specification

24" (610 mm)

to 4" (100 DN)

to 6" (150 DN)

1,480 psi (100 bar) at 100°F (38°C)

700°F (371°C) at 700 psi (48 bar)**

Manual, Air Motor or Hydraulic

0.005" (0.127 mm) per revolution

12 turns per inch (2 mm per turn)

42-3/4" (1,086 mm)

70" (1,778 mm)

MR0175-93

* See note 4 in "Recommended Options" Chart.

** For intermittent service only. Its maximum continuous rating is 350°F (177°C) at 1,025 psi (70 bar).

Manual Operation (Model 360a) Air or Hydraulic Operation (Model 360b)

Operating Options

Lbs.

Kg.

Part Number

Lbs.

Kg.

Part Number

Tapping Machine

127

58

05-2064-0000

135

61

05-2068-0000

Steel Carrying Case

98

44

05-0026-0000

101

46

05-0029-0000

Air Motor Drive Assembly

-

-

-

40

18

05-2327-0000

Hydraulic Motor Drive Assembly

-

-

45

20

05-1258-0000

TOTAL WEIGHT

225

102

321

145

The basic machine includes: Measuring rod and stop collar; Bleeder valve; Packing wrenches; Lower-in crank; Power crank.

Hydraulic Power Unit

Hydraulic Power Unit and 50' Hose w/Oil

Manual Start/Diesel

Electric Start/Diesel

Manual Start/Gas

Electric Start/Gas

Lbs.

585

600

533

550

Kg.

266

272

242

250

Part Number

05-2017-0000

05-2330-0000

05-2351-0000

05-2354-0000

* If skid is not purchased with the tapping machine, there will be a special crating charge; consult factory

Gasoline Power Unit

T.D. Williamson, Inc.

Vitalizer for Air Motor

Diesel Power Unit

P.O. Box 3409

Tulsa, Oklahoma 74101-3409

918-447-5100

Minimum Compressor Requirement: 105 cfm at 90 psi (6 bar). Compressor and connecting hose furnished by customer.

Fax: 918-446-6327

www.tdwilliamson.com

Data subject to change without notice. / Dimensions not for construction unless certified. / ® Registered trademark of T. D. Williamson, Inc. in the United States and foreign countries / TM Trademark of T. D. Williamson, Inc. in the United States and foreign countries / © Copyright 2008. All rights reserved T. D. Williamson, Inc. / Printed in USA

Dimensions and Part Numbers

360 Tapping Machine

1000.004.03 - p3

Adapters

Nominal Tap Size

ASME Class 150 RF Flange

ASME Class 300 RF Flange

ASME Class 600 RF Flange

600# SANDWICH & Ball Valves

®

Inches

DN

Part Number

Lbs.

Kg.

Part Number

Lbs.

Kg.

Part Number

Lbs.

Kg.

1

25

06-0027-0001

18

8

06-0028-0001

17

8

06-0030-0001

20

9

-

-

-

1-1/4

32

06-0027-0002

19

9

06-0028-0002

20

9

06-0030-0002

22

10

-

-

-

1-1/2

40

06-0027-0003

19

9

06-0028-0003

22

10

06-0030-0003

23

10

-

-

-

2

50

06-0027-0004

16

7

06-0028-0004

18

8

06-0030-0004

20

9

-

-

-

3

80

06-0027-0005

21

10

06-0028-0005

24

11

06-0030-0005

27

12

-

-

-

4

100

06-6098-0004*

32

15

06-6099-0004

42

19

06-6101-0004**

35

16

06-6097-0004 53

24

6

150

06-6098-0006*

45

20

06-6099-0006

62

28

06-6101-0006** 100

45

06-6097-0006 110

50

Part Number Lbs. Kg.

* Will also work on SHORTCUTT® Valves;

** See special adapters for SANDWICH® & Ball valves.

Cutter Holders, LOCK-O-RING Holders, THREAD-O-RING™ Holders & LOCK-O-RING Bypass Gauge

®

Size

Inches DN

®

LOCK-O-RING Holders

Lbs. Kg. Part Number

Cutter Holder

Lbs. Kg. Part Number

®

THREAD-O-RING™ Holders

Lbs. Kg. Part Number

LOCK-O-RING Bypass Gauge

Lbs. Kg Part Number

®

2

50

-

-

-

-

-

-

1/2

0.2 05-0061-0001

1/2

0.2

07-0963-0000

3

80

2

9

05-0053-0003

-

-

-

1-1/4

0.6 05-0073-0001

-

-

-

9

05-0053-0003

3-1/2

2 05-0074-0000

-

-

-

-

-

-

3 05-0053-0002*

3-1/2

2 05-0074-0000

-

-

-

-

-

-

4

100

2

6

150

6-1/2

* Cutter holder extension (P/N 05-0071-0000) required for 6" (150 DN) ASME Class 600 taps

Twist Drills

Nominal Tap Size

Inches

DN

2

Actual Size

50

Weight

Inches

mm

Lbs.

Kg.

Part Number

1-7/16

37

6

3

05-0046-0004

Insert Drills

Nominal Tap Size

Actual Size

Inches

DN

Inches

mm

Wt./Lbs.

Wt./Kg.

Part Number

1

25

3/4

19

2-1/2

1

05-0047-0001

1-1/4

32

1

25

4

2

05-0047-0002

1-1/2

40

1-1/4

32

5-1/2

3

05-0047-0003

Standard Accessories

Nominal Tap Size

Actual Size

Cutters

Pilot Drills

Wt./Lbs. Wt./Kg.

Spare U-Rods

Inches

DN

Inches

mm

Wt./Lbs.

Wt./Kg.

Part Number

Part Number

Part Number

3

80

2-7/16

61.9

1

0.4

05-0001-0001

1/22

0.2

05-0293-0001

00-1424-0012

4

100

3-7/16

87.3

2

0.9

05-0328-0004

1/2

0.2

05-0293-0008

00-1424-0012

6

150

5-15/32

138.9

5-3/4

3

05-0328-0006

2

0.9

05-0293-0002

00-1424-0003

SHORTSTOPP Accessories

®

Nominal Tap Size

Actual Size

Inches

DN

Inches

4

100

3-7/8

98.4

3-1/4

1

05-0330-0004

1/2

6

150

5-7/8

149.2

8-3/4

3

05-0330-0006

2

P.O. Box 3409

Wt./Lbs. Wt./Kg.

Pilot Drills

T.D. Williamson, Inc.

mm

Cutters

Part Number

Tulsa, Oklahoma 74101-3409

Wt./Lbs. Wt./Kg.

918-447-5100

Spare U-Rods

Part Number

Part Number

0.2

05-0293-0008

00-1424-0012

0.9

05-0293-0002

00-1424-0003

Fax: 918-446-6327

www.tdwilliamson.com

Data subject to change without notice. / Dimensions not for construction unless certified. / ® Registered trademark of T. D. Williamson, Inc. in the United States and foreign countries / TM Trademark of T. D. Williamson, Inc. in the United States and foreign countries / © Copyright 2008. All rights reserved T. D. Williamson, Inc. / Printed in USA

Dimensions and Part Numbers

360 Tapping Machine

1000.004.03 - p4

STOPPLE Accessories

®

Nominal Tap Size

Actual Size

Cutters

Pilot Drills

Inches

DN

Inches

mm

Wt./Lbs.

Wt./Kg.

Part Number

Wt./Lbs. Wt./Kg.

4

100

3-15/16

100

3-1/2

2

05-0329-0004

1/2

6

150

5-15/16

150.8

9

4

05-0329-0006

2

Spare U-Rods

Part Number

Part Number

0.2

05-0293-0008

00-1424-0012

0.9

05-0293-0002

00-1424-0003

Recommended Options for Tapping Size-On-Size

2"

Cutter Size

3"

4" 6"

A

A

A

A

B

B

B

B

C

C

C

D

D

D

E

E

E

F

F

F

E

Notes

1. The following letters represent:

A = Carbon steel pipe SMYS 30,000 to 50,000 psi maximum tensile strength of 70,000 psi.

B = Carbon steel pipe SMYS 50,000 to 70,000 psi maximum tensile strength of 90,000 psi.

C = Cast iron pipe. Cutting characteristics vary widely; hard to predict.

D = Chrome-moly, high temperature, steel pipe.

E = 300 series stainless steel pipe.

F = Flat plate cuts using special cutters on the materials listed above (refer to Notes 3 and 4). Pilot drill must be through before cutter tooth engages material.

2. The table for selecting power options (above) is based on the latest TDW designs and past experience. The data should be used as a guideline. There have been, and will be, conditions which will not strictly follow the guidelines.

3. Special cutters are available for flat plates, stainless steel pipe, cast iron pipe and other special conditions.

4. When tapping a larger pipe or tank, the cutter will sometimes go through the flat-plate condition. For example, all teeth are cutting at the same time. This is the most power-

consuming condition possible and special cutters may be required.

Considering cutter size, diameter of cylinder, wall thickness, feed rates, different materials of construction, etc., the possibilities are infinite. The following table gives some examples of flat-plate conditions. Any pipe or tank with wall thicknesses greater than those shown will also be considered flat plate.

Cutter Size

Nom. Pipe x Wall

Nom. Pipe x Wall

Nom. Pipe x Wall

3"

4" x .359" 6" x .232"

8" x .176"

4" 6" x .481" 8" x .357"

10" x .282"

6"

10" x .748" 12" x .616"

14" x .556"

T.D. Williamson, Inc.

P.O. Box 3409

Tulsa, Oklahoma 74101-3409

918-447-5100

Fax: 918-446-6327

www.tdwilliamson.com

Data subject to change without notice. / Dimensions not for construction unless certified. / ® Registered trademark of T. D. Williamson, Inc. in the United States and foreign countries / TM Trademark of T. D. Williamson, Inc. in the United States and foreign countries / © Copyright 2008. All rights reserved T. D. Williamson, Inc. / Printed in USA

660 Tapping Machine

Sizes: 3- through 12-inch

Bulletin No: 1000.005.01

Date: December 2004

Cross Indexing No: n/a

Supersedes: February 1999

Model 660b

Model 660B Tapping Machines can be either

air or hydraulically operated and are used for

making pipe and tank taps from 3" to 12" (DN 80

to DN 300). Its maximum working pressure is

1,480 psi (100 bar) at 100°F (38°C). Its operating

temperature is -20°F (-29°C) to 700°F (371°C)

at 700 psi (48 bar) for intermittent service. Its

maximum continuous rating is 350°F (177°C) at

1,025 psi (48 bar).

Typical Tapping Setup

This model features a split frame for lower

maintenance costs and ease of packing

replacement.

Features

The basic machine includes:

Lower-in crank

Measuring rod

Split Frame

Retainer rod pusher

Boring Bar

Ring gasket

Bleeder valve and nipple

Cutter Holder

Adapter

Motor adapter

Cutter

Set of bolts and nuts

®

LOCK-O-RING bypass gauge

Gasket

Options*

660 Tapping Machine

T. D. Williamson, Inc., is committed to providing

you with the exact product to assist you in

planning, budgeting and meeting the specifications

for your individual application needs. The

following options are available:

Description

Tapping machines are used for making

connections to pipelines, tanks, and plant

piping without shutdown and are used to

make hot taps in preparation for plugging

machine application.

Pilot

Model 660B Tapping Machine can be either air or hydraulically operated with optional dual drive.

SANDWICH® Valve

Gasket

®

STOPPLE Fitting

or Tapping Fitting

* For design code options not listed and additional sizes,

consult your sales representative.

Pipeline

Patented in the United States and in foreign countries.

ISO 9001 Certified

Toll Free

1-888-TDWmSon (839-6766)

T.D. Williamson, Inc.

P.O. Box 3409

Tulsa, Oklahoma 74101-3409

918-447-5100

Fax: 918-446-6327

www.tdwilliamson.com

Data subject to change without notice. / Dimensions not for construction unless certified. / ® Registered trademark of T.D. Williamson, Inc. in the United States and foreign countries / TM Trademark of T.D. Williamson, Inc. in the United States and foreign countries / © Copyright 2006. All rights reserved T.D. Williamson, Inc. / Printed in USA

Dimensions and Part Numbers

660 Tapping Machine

1000.005.01 - p2

Model 660b

Operating Specifications

Boring Bar Travel

Tank Taps*

Pipe Taps*

Max. Operating Pressure

Max. Operating Temperature

Power

Feed Rate

Lower-In Crank

Length without measuring rod

Length with measuring rod

Meets NACE specification

42" (1,067 mm)

3" through 12" (80-300 mm)

3" through 12" (80-300 mm)

1,480 psi (100 bar) at 100°F (38°C)

700°F (371°C) at 700 psi (48 bar)**

Hydraulic or Air Motor

Standard .005" (.127 mm) per revolution/optional .003" (.076 mm) per revolution

4-1/2 turns per inch (5.6 mm per turn)

64-1/2" (1,638 mm)

110-1/2" (2,087 mm)

MR0175-93

* See note 5 in "Recommended Power Options" Chart.

** For intermittent service only. Maximum continuous rating is 350°F (177°C) at 1,025 psi (70 bar).

Air

Operation Model

Tapping Machine

Air Motor Drive Assembly

Skid*

TOTAL WEIGHT

Lbs.

405

40

179

624

Kg.

184

18

81

283

Standard Feed (.005"/Revolution)

Part Number

05-2179-0000

05-2326-0000

05-0019-0000

* If skid is not purchased with the tapping machine, there will be a special crating charge; consult factory.

Hydraulic Operation Model

Lbs.

Kg.

Tapping Machine

405

184

Single Drive Unit & Control Valve

45

20

Dual Drive Unit & Control Valve

100

45

Skid*

179

81

Power Unit

Hydraulic Power Unit and 50' Hose w/Oil

Manual Start/Diesel

585

266

Electric Start/Diesel

600

272

Manual Start/Gas

533

242

Electric Start/Gas

550

250

Slow Feed (.003"/Revolution)

Part Number

05-2177-0000

05-2326-0000

05-0019-0000

Standard Feed (.005"/Revolution)

Part Number

05-2179-0000

05-0006-0000

05-0930-0000

05-0019-0000

Slow Feed (.003"/Revolution)

Part Number

05-2177-0000

05-0006-0000

05-0930-0000

05-0019-0000

05-2017-0000

05-2330-0000

05-2351-0000

05-2354-0000

05-2017-0000

05-2330-0000

05-2351-0000

05-2354-0000

* If skid is not purchased with the tapping machine, there will be a special crating charge; consult factory

Gasoline Power Unit

T.D. Williamson, Inc.

P.O. Box 3409

Diesel Power Unit

Tulsa, Oklahoma 74101-3409

918-447-5100

Fax: 918-446-6327

www.tdwilliamson.com

Data subject to change without notice. / Dimensions not for construction unless certified. / ® Registered trademark of T.D. Williamson, Inc. in the United States and foreign countries / TM Trademark of T.D. Williamson, Inc. in the United States and foreign countries / © Copyright 2006. All rights reserved T.D. Williamson, Inc. / Printed in USA

Dimensions and Part Numbers

660 Tapping Machine

1000.005.01 - p3

Model 660b

Standard Adapters for Gate Valves

ASME Class 150 RF Flange

Inches mm

Lbs.

Kg.

Part Number

ASME Class 300 RF Flange

Lbs.

Kg.

ASME Class 600 RF Flange

Part Number

Lbs.

Kg.

Part Number

57

26 06-6105-0003

3

80

54

24

06-6102-0003

55

25

06-6103-0003

4

100

57

26

06-6102-0004*

65

29

06-6103-0004

80

36 06-5091-0004

6

150

70

32

06-5088-0006*

95

43

06-6103-0006

146

66 06-5091-0006

8

200

85

39

06-6102-0008*

100

45

06-6103-0008

150

68 06-6105-0008

10

250

115

42

06-6102-0010*

155

70

06-6103-0010

200

91 06-6105-0010

12

300

170

77

06-6102-0012*

215

98

06-6103-0012

315

143 06-6105-0012

* Will work on SHORTCUTT® Valves, Bulletin 2010.000.00

Adapters for SANDWICH® Valves and Ball Valves

ASME Class 300 RF Flange

ASME Class 600 RF Flange

Inches

mm

Lbs.

Kg.

Part Number

Lbs.

Kg.

Part Number

4

100

65

29

06-6103-0004

76

34

06-5091-0004

6

150

95

43

06-6103-0006

130

59

06-5091-0006

8

200

100

45

06-5089-0008

265

91

06-5091-0008

10

250

155

70

06-5089-0010

265

120

06-5091-0010

12

250

215

97

06-5089-0012

384

174

06-5091-0012

Split Frame Feature

The frame assembly is split at the lower end,

so that the lower section can be unbolted and

removed over the drive tube and boring bar

and the packing replaced.

T.D. Williamson, Inc.

P.O. Box 3409

Tulsa, Oklahoma 74101-3409

918-447-5100

Fax: 918-446-6327

www.tdwilliamson.com

Data subject to change without notice. / Dimensions not for construction unless certified. / ® Registered trademark of T.D. Williamson, Inc. in the United States and foreign countries / TM Trademark of T.D. Williamson, Inc. in the United States and foreign countries / © Copyright 2006. All rights reserved T.D. Williamson, Inc. / Printed in USA

Dimensions and Part Numbers

660 Tapping Machine

1000.005.01 - p4

Model 660b

Cutter Holders & LOCK-O-RING® Plug Holders

Tap Size

Cutter Holders

Kg.

LOCK-O-RING® Plug Holders

Lbs.

Kg.

Part Number

Inches

mm

Lbs.

Part Number

3 & 4

80 & 100

2.5

1

05-0054-0001

--

--

--

6-12

150-300

8

4

05-0054-0002

--

--

--

4-16

100-400

--

--

--

3.5

2

05-0075-0000

Standard Cutters & Pilot Drills

Inches

mm

Inches

mm

Wt./Lbs.

Wt./Kg.

Part Number

Wt./Lbs. Wt./Kg.

Part Number

Part Number

3

80

2-7/16

67

1

0.5

05-0001-0001

1/2

0.2

05-0293-0001

00-1424-0012

4

100

3-7/16

87.3

2

0.9

05-0328-0004

1/2

0.2

05-0293-0008

00-1424-0012

6

150

5-15/32

138.9

5-3/4

3

05-0328-0006

2

0.9

05-0293-0002

00-1424-0003

8

200

7-5/16

185.8

14-1/2

7

05-0328-0008

2

0.9

05-0293-0003

00-1424-0003

10

250

9-1/2

241.3

22-1/2

10

05-0328-0010

2

0.9

05-0293-0004

00-1424-0003

12

300

11-1/2

292.1

36

16

05-0389-0012

2-1/2

1.0

05-0293-0005

00-1424-0008

SHORTSTOPP® Cutters & Pilot Drills

4

100

3-7/8

98.4

3-1/4

1

05-0330-0004

1/2

0.2

05-0293-0008

00-1424-0012

6

150

5-7/8

149.2

8-3/4

3

05-0330-0006

2

0.9

05-0293-0002

00-1424-0003

8

200

7-3/4

196.9

20

9

05-0330-0008

2

0.9

05-0293-0003

00-1424-0003

10

250

9-3/4

247.7

23

10

05-0330-0010

2

0.9

05-0293-0004

00-1424-0003

12

300

11-3/4

298.5

40

18

05-0330-0012

2-1/2

1.0

05-0293-0005

00-1424-0003

STOPPLE® Cutters & Pilot Drills

4

100

3-15/16

100

3-1/2

2

05-0329-0004

1/2

0.2

05-0293-0008

00-1424-0012

6

150

5-15/16

150.8

9

4

05-0329-0006

2

0.9

05-0293-0002

00-1424-0003

8

200

7-7/8

200

16

7

05-0329-0008

2

0.9

05-0293-0003

00-1424-0003

10

250

9-7/8

200.8

27

12

05-0329-0010

2

0.9

05-0293-0004

00-1424-0003

12

300

11-13/16

300.1

40-1/2

18

05-0388-0012

2-1/2

1

05-0293-0005

00-1424-0008

T.D. Williamson, Inc.

P.O. Box 3409

Tulsa, Oklahoma 74101-3409

918-447-5100

Fax: 918-446-6327

www.tdwilliamson.com

Data subject to change without notice. / Dimensions not for construction unless certified. / ® Registered trademark of T.D. Williamson, Inc. in the United States and foreign countries / TM Trademark of T.D. Williamson, Inc. in the United States and foreign countries / © Copyright 2006. All rights reserved T.D. Williamson, Inc. / Printed in USA

Dimensions and Part Numbers

660 Tapping Machine

1000.005.01 - p5

Model 660b

Recommended Power Options for Tapping Size On Size

Feed Rate

3"

4"

6"

8"

Cutter Size

10"

12"

(0.005"/REV) AIR/HYD

A

A

A

A

A

A

B

B

B

B

B

C

C

C

C

D

D

D

D

E

E

E

E

F

F

F

F

A

A

A

A

A

A

B

B

B

B

B

B

C

C

C

C

C

C

D

D

D

D

D

D

E

E

E

E

E

E

F

F

F

F

F

F

A

A

A

A

A

A

B

B

B

B

B

B

C

C

C

C

C

D

D

D

D

D

E

E

E

E

E

F

F

F

F

(0.005"/REV) DUAL HYD

(0.003"/REV) AIR/HYD

A

A

A

A

A

A

(0.003"/REV) DUAL HYD

B

B

B

B

B

B

C

C

C

C

C

C

D

D

D

D

D

D

E

E

E

E

E

E

F

F

F

F

F

F

Notes

1. The following letters represent:

A = Carbon steel pipe SMYS (Specified Minimum Yield Strength) 30,000 to 50,000 psi maximum, tensile strength of 70,000 psi.

B = Carbon steel pipe SMYS 50,000 to 70,000 psi maximum, tensile strength of 90,000 psi.

C = Cast iron pipe. Cutting characteristics vary widely; hard to predict.

D = Chrome-moly, high temperature, steel pipe.

E = 300 series stainless steel pipe.

F = Flat plate cuts using special cutters on the materials listed above (refer to Notes 3 and 4). Pilot drill must be through before cutter tooth engages material.

2. The dual hydraulic drive features an ability to shift from high speed/low torque to low speed/high torque when tapping the larger diameter pipes and/or the more difficult cutting steels.

3. The table for selecting power options (above) is based on the latest TDW designs and past experience. The data should be used as a guideline. There have been, and will be, conditions

which will not strictly follow the guidelines.

4. Special cutters are available for flat plates, stainless steel pipe, cast iron pipe and other special conditions.

5. When tapping a larger pipe or tank, the cutter will sometimes go through the flat-plate condition. For example, all teeth are cutting at the same time. This is the most power-consuming condition possible and special cutters may be required. Considering cutter size, diameter of cylinder, wall thickness, feed rates, different materials of construction, etc., the possibilities

are infinite. The following table gives some examples of flat-plate conditions. Any pipe or tank with wall thicknesses greater than those shown will also be considered flat plate.

Cutter Size

3"

4"

6"

8"

10"

12"

14"

16"

Nom. Pipe x Wall

4" x .359"

6" x .481

10" x .748"

18" x .776"

24" x .980"

36" x .943"

48" x .862"

56" x .980"

T.D. Williamson, Inc.

P.O. Box 3409

Nom. Pipe x Wall

6" x .232"

8" x .357

12" x .616"

20" x .692"

30" x .772"

48" x .699"

60" x .685"

60" x .913

Nom. Pipe x Wall

8" x .176

10" x .282

14" x .556

24" x .571

48" x .475"

60" x .556

72" x .569"

72" x .757"

Tulsa, Oklahoma 74101-3409

918-447-5100

Fax: 918-446-6327

www.tdwilliamson.com

Data subject to change without notice. / Dimensions not for construction unless certified. / ® Registered trademark of T.D. Williamson, Inc. in the United States and foreign countries / TM Trademark of T.D. Williamson, Inc. in the United States and foreign countries / © Copyright 2006. All rights reserved T.D. Williamson, Inc. / Printed in USA

760 Tapping Machine

Sizes: 3- through 16-inches

Bulletin No: 1000.006.03

Date: May 2005

Cross Indexing No: n/a

Supersedes: 1000.006.02 (12/04)

Model 760B

Model 760B Tapping Machines can be either air

or hydraulically operated and are used for making

pipe and tank taps from 3- to 16-inches (DN 80

to DN 400). Its maximum working pressure is

1,480 psi (102 bar) at 100°F (38°C). Its operating

temperature is -20°F (-29°C) to 700°F (371°C)

at 700 psi (48 bar) for intermittent service. Its

maximum continuous rating is 350°F (177°C) at

1,025 psi (70 bar).

Typical Tapping Setup

This model features a split frame for lower

maintenance costs and ease of packing

replacement.

Features

The basic machine includes:

Lower-in crank

Measuring rod

Retainer rod pusher

Split Frame

Ring gasket

Boring Bar

Bleeder valve and nipple

Motor adapter

Cutter Holder

Adapter

Set of bolts and nuts

Cutter

LOCK-O-RING® bypass gauge

Gasket

Options*

760 Tapping Machine

T. D. Williamson, Inc. is committed to providing

you with the exact product to assist you in

planning, budgeting and meeting the specifications

for your individual application needs. The

following options are available:

Description

Tapping machines are used for making

connections to pipelines, tanks, and plant

piping without shutdown and are used to

make hot taps in preparation for plugging

machine application.

Pilot

Model 760B Tapping Machine can be either air or hydraulically operated.

* For design code options not listed and additional sizes,

consult your sales representative.

SANDWICH®

Valve

Gasket

STOPPLE® Fitting

or Tapping Fitting

Pipeline

Patented in the United States and in foreign countries.

ISO 9001 Certified

Toll Free

1-888-TDWmSon (839-6766)

T.D. Williamson, Inc.

P.O. Box 3409

Tulsa, Oklahoma 74101-3409

918-447-5100

Fax: 918-446-6327

www.tdwilliamson.com

Data subject to change without notice. / Dimensions not for construction unless certified. / ® Registered trademark of T.D. Williamson, Inc. in the United States and foreign countries / TM Trademark of T.D. Williamson, Inc. in the United States and foreign countries / © Copyright 2006. All rights reserved T.D. Williamson, Inc. / Printed in USA

Dimensions and Part Numbers

760 Tapping Machine

1000.006.03 - p2

Model 760B

Operating Specifications

Boring Bar Travel

Tank Taps*

Pipe Taps*

Max. Operating Pressure

Max. Operating Temperature

Power

Feed Rate

Lower-In Crank

Length without measuring rod

Length with measuring rod Meets NACE specification

66” (1,676 mm)

3” through 14” (80-350 mm)

3” through 16” (80-400 mm)

1,480 psi (102 bar) at 100°F (38°C)

700°F (371°C) at 700 psi (48 bar)**

Hydraulic or Air Motor

Standard .005” (.127 mm) per revolution/optional .003” (.076 mm) per revolution

4-1/2 turns per inch (5.6 mm per turn)

88-1/2” (2,248 mm)

158-1/2” (4,026 mm)

MR0175-93

* See note 5 in “Recommended Power Options” Chart.

** For intermittent service only. Its maximum continuous rating is 350°F (177°C) at 1,025 psi (70 bar).

Air Operation Model

Tapping Machine

Air Motor Drive Assembly

Skid*

TOTAL WEIGHT

Lbs.

500

40

212

752

Kg.

227

18

96

341

Slow Feed (.003”/Revolution)

Part Number

05-2178-0000

05-2327-0000

05-0040-0000

* If skid is not purchased with the tapping machine, there will be a special crating charge; consult factory.

Hydraulic Operation Model

Tapping Machine

Single Drive Unit & Control Valve

Dual Drive Unit & Control Valve

Skid*

Power Unit

Hydraulic Power Unit and 50’ Hose w/Oil

Manual Start/Diesel

Electric Start/Diesel

Manual Start/Gas

Electric Start/Gas

Standard Feed (.005”/Revolution)

Part Number

05-2180-0000

05-2327-0000

05-0040-0000

Lbs.

500

45

100

212

Kg.

227

20

45

96

585

600

533

550

266

272

242

250

Standard Feed (.005”/Revolution)

Part Number

05-2180-0000

05-0006-0000

05-0930-0000

05-0040-0000

05-2017-0000

05-2330-0000

05-2351-0000

05-2354-0000

Slow Feed (.003”/Revolution)

Part Number

05-2178-0000

05-0006-0000

05-0930-0000

05-0040-0000

05-2017-0000

05-2330-0000

05-2351-0000

05-2354-0000

* If skid is not purchased with the tapping machine, there will be a special crating charge; consult factory

Diesel Power Unit

Gasoline Power Unit

T.D. Williamson, Inc.

P.O. Box 3409

Tulsa, Oklahoma 74101-3409

918-447-5100

Fax: 918-446-6327

www.tdwilliamson.com

Data subject to change without notice. / Dimensions not for construction unless certified. / ® Registered trademark of T.D. Williamson, Inc. in the United States and foreign countries / TM Trademark of T.D. Williamson, Inc. in the United States and foreign countries / © Copyright 2006. All rights reserved T.D. Williamson, Inc. / Printed in USA

Dimensions and Part Numbers

760 Tapping Machine

1000.006.03 - p3

Model 760B

Standard Adapters for Gate Valves

ASME Class 150 RF Flange

Inches mm

ASME Class 300 RF Flange

ASME Class 600 RF Flange

Lbs.

Kg.

Part Number

Lbs.

Kg.

Part Number

Lbs.

Kg.

Part Number

3

80

54

24

06-6102-0003

55

25

06-6103-0003

57

26 06-6105-0003

4

100

57

26

06-6102-0004*

65

29

06-6103-0004

80

36 06-5091-0004

6

150

70

32

06-5088-0006*

95

43

06-6103-0006

146

66 06-5091-0006

8

200

85

39

06-6102-0008*

100

45

06-6103-0008

150

68 06-6105-0008

10

250

115

42

06-6102-0010*

155

70

06-6103-0010

200

91 06-6105-0010

12

300

170

77

06-6102-0012*

215

98

06-6103-0012

315

143 06-6105-0012

14

350

191

87

06-6102-0014

227

103 06-6103-0014

359

163 06-6105-0014

16** 400

300

136

06-6102-0016

350

160 06-6103-0016

460

210 06-6105-0016

* Will work on SHORTCUTT® Valves, Bulletin 2010.001.00 ** For dual hydraulic model only.

Adapters for SANDWICH® Valves and Ball Valves

ASME Class 300 RF Flange

ASME Class 600 RF Flange

Inches

mm

Lbs.

Kg.

Part Number

Lbs.

Kg.

Part Number

4

100

65

29

06-6103-0004

76

34

06-5091-0004

6

150

95

43

06-6103-0006

130

59

06-5091-0006

8

200

100

45

06-5089-0008

265

91

06-5091-0008

10

250

155

70

06-5089-0010

265

120

06-5091-0010

12

250

215

97

06-5089-0012

384

174

06-5091-0012

14

300

315

143

06-5089-0014

510

231

06-5091-0014

16*

350

415

188

06-5089-0016

580

262

06-5091-0016

* For dual hydraulic model only.

Split Frame Feature

The frame assembly is split at the lower end,

so that the lower section can be unbolted and

removed over the drive tube and boring bar

and the packing replaced.

T.D. Williamson, Inc.

P.O. Box 3409

Tulsa, Oklahoma 74101-3409

918-447-5100

Fax: 918-446-6327

www.tdwilliamson.com

Data subject to change without notice. / Dimensions not for construction unless certified. / ® Registered trademark of T.D. Williamson, Inc. in the United States and foreign countries / TM Trademark of T.D. Williamson, Inc. in the United States and foreign countries / © Copyright 2006. All rights reserved T.D. Williamson, Inc. / Printed in USA

Dimensions and Part Numbers

760 Tapping Machine

1000.006.03 - p4

Model 760B

Cutter Holders & LOCK-O-RING® Plug Holders

Cutter Holders

LOCK-O-RING Plug Holders

®

Inches

mm

Lbs.

Kg.

Part Number

Lbs.

Kg.

Part Number

3 & 4

80 & 100

2.5

1

05-0054-0001

--

--

--

6-12

150-300

8

4

05-0054-0002

--

--

--

14-16

350-400

7

3

05-0054-0003

--

--

--

4-16

100-400

--

--

--

3.5

2

05-0075-0000

Standard Cutters & Pilot Drills

Nominal Tap Size

Actual Size

Cutters

Pilot Drills

Inches

mm

Inches

mm

Wt./Lbs.

Wt./Kg.

Part Number

Wt./Lbs. Wt./Kg.

3

80

2-7/16

61.9

1

0.4

05-0001-0001

1/22

4

100

3-7/16

87.3

2

0.9

05-0328-0004

6

150

5-15/32

138.9

5-3/4

3

05-0328-0006

8

200

7-5/16

185.8

14-1/2

7

10

250

9-1/2

241.3

22-1/2

12

300

11-1/2

292.1

14

350

12-3/4

323.9

16

400

14-11/16 373.1

Spare U-rods

Part Number

Part Number

0.2

05-0293-0001

00-1424-0012

1/2

0.2

05-0293-0008

00-1424-0012

2

0.9

05-0293-0002

00-1424-0003

05-0328-0008

2

0.9

05-0293-0003

00-1424-0003

10

05-0328-0010

2

0.9

05-0293-0004

00-1424-0003

36

16

05-0389-0012

2-1/2

1.0

05-0293-0005

00-1424-0008

42

19

05-0389-0014

5-1/2

2.5

05-0293-0006

00-1424-0008

61

28

05-0389-0016

6

2.7

05-0293-0007

00-1424-0008

SHORTSTOPP® Cutters & Pilot Drills

Nominal Tap Size

Actual Size

Cutters

Pilot Drills

Inches

mm

Inches

mm

Wt./Lbs.

Wt./Kg.

Part Number

Wt./Lbs. Wt./Kg.

4

100

3-7/8

98.4

3-1/4

1

05-0330-0004

1/2

6

150

5-7/8

149.2

8-3/4

3

05-0330-0006

8

200

7-3/4

196.9

20

9

10

250

9-3/4

247.7

23

10

12

300

11-3/4

298.5

40

18

Spare U-rods

Part Number

Part Number

0.2

05-0293-0008

00-1424-0012

2

0.9

05-0293-0002

00-1424-0003

05-0330-0008

2

0.9

05-0293-0003

00-1424-0003

05-0330-0010

2

0.9

05-0293-0004

00-1424-0003

05-0330-0012

2-1/2

1.0

05-0293-0005

00-1424-0003

STOPPLE® Cutters & Pilot Drills

Nominal Tap Size

Actual Size

Inches

mm

Inches

4

100

6

150

8

200

10

250

12

300

11-13/16 300.1

14

350

13-1/16

16

400

15-1/16

Cutters

Pilot Drills

mm

Wt./Lbs.

Wt./Kg.

Part Number

3-15/16

100

3-1/2

2

05-0329-0004

1/2

5-15/16

150.8

9

4

05-0329-0006

2

7-7/8

200

16

7

05-0329-0008

9-7/8